E EXPERIENCE 28 - GF AgieCharmilles US

E EXPERIENCE 28 - GF AgieCharmilles US

E EXPERIENCE 28 - GF AgieCharmilles US

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

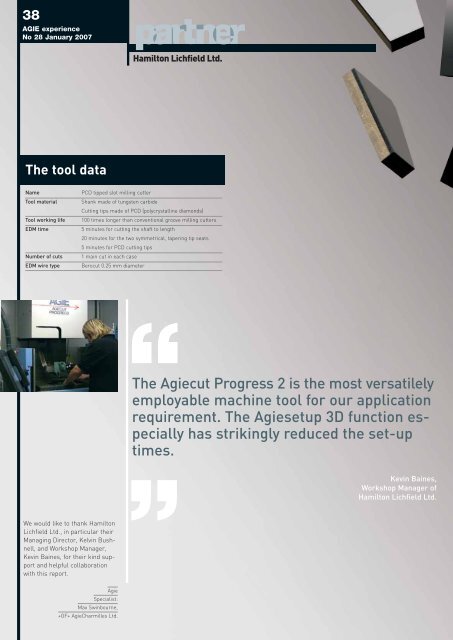

38<br />

AGIE experience<br />

No <strong>28</strong> January 2007<br />

Hamilton Lichfield Ltd.<br />

The tool data<br />

Name<br />

Tool material<br />

Tool working life<br />

EDM time<br />

Number of cuts<br />

EDM wire type<br />

PCD tipped slot milling cutter<br />

Shank made of tungsten carbide<br />

Cutting tips made of PCD (polycrystalline diamonds)<br />

100 times longer than conventional groove milling cutters<br />

5 minutes for cutting the shaft to length<br />

20 minutes for the two symmetrical, tapering tip seats<br />

5 minutes for PCD cutting tips<br />

1 main cut in each case<br />

Berocut 0.25 mm diameter<br />

“<br />

The Agiecut Progress 2 is the most versatilely<br />

employable machine tool for our application<br />

requirement. The Agiesetup 3D function especially<br />

has strikingly reduced the set-up<br />

times.<br />

We would like to thank Hamilton<br />

Lichfield Ltd., in particular their<br />

Managing Director, Kelvin Bushnell,<br />

and Workshop Manager,<br />

Kevin Baines, for their kind support<br />

and helpful collaboration<br />

with this report.<br />

”<br />

Kevin Baines,<br />

Workshop Manager of<br />

Hamilton Lichfield Ltd.<br />

Agie<br />

Specialist:<br />

Max Swinbourne,<br />

+<strong>GF</strong>+ <strong>AgieCharmilles</strong> Ltd.