pdf download

pdf download

pdf download

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Integrated Agri-Aquaculture<br />

Demonstration Facility<br />

Using irrigation storages for intensive native fish culture<br />

RIRDC Publication No. 09/060<br />

RIRDCInnovation for rural Australia

Integrated Agri-Aquaculture<br />

Demonstration Facility<br />

Using irrigation storages for intensive native fish culture<br />

By Dr Adrian Collins<br />

Mr Andrew Walls<br />

Mr Benjamin Russell<br />

April 2009<br />

RIRDC Publication No 09/060<br />

RIRDC Project No DAQ-290A

© 2009 Rural Industries Research and Development Corporation.<br />

All rights reserved.<br />

ISBN 1 74151 862 8<br />

ISSN 1440-6845<br />

Integrated Agri-Aquaculture Demonstration Facility - Using irrigation storages for intensive native fish culture<br />

Publication No. 09/060<br />

Project No. DAQ-290A<br />

The information contained in this publication is intended for general use to assist public knowledge and discussion<br />

and to help improve the development of sustainable regions. You must not rely on any information contained in<br />

this publication without taking specialist advice relevant to your particular circumstances.<br />

While reasonable care has been taken in preparing this publication to ensure that information is true and correct,<br />

the Commonwealth of Australia gives no assurance as to the accuracy of any information in this publication.<br />

The Commonwealth of Australia, the Rural Industries Research and Development Corporation (RIRDC), the<br />

authors or contributors expressly disclaim, to the maximum extent permitted by law, all responsibility and liability to<br />

any person, arising directly or indirectly from any act or omission, or for any consequences of any such act or<br />

omission, made in reliance on the contents of this publication, whether or not caused by any negligence on the<br />

part of the Commonwealth of Australia, RIRDC, the authors or contributors.<br />

The Commonwealth of Australia does not necessarily endorse the views in this publication.<br />

This publication is copyright. Apart from any use as permitted under the Copyright Act 1968, all other rights are<br />

reserved. However, wide dissemination is encouraged. Requests and inquiries concerning reproduction and rights<br />

should be addressed to the RIRDC Publications Manager on phone 02 6271 4165.<br />

Researcher Contact Details<br />

Dan Willett<br />

Project Leader Integrated Aquaculture<br />

c/- Bribie Island Aquaculture Research Centre<br />

PO Box 2066<br />

Bribie Island QLD 4507<br />

Phone: 07 3400 2000<br />

Fax: 07 3408 3535<br />

Email: bribie@dpi.qld.gov.au<br />

Website: www.dpi.qld.gov.au<br />

In submitting this report, the researcher has agreed to RIRDC publishing this material in its edited form.<br />

RIRDC Contact Details<br />

Rural Industries Research and Development Corporation<br />

Level 2, 15 National Circuit<br />

BARTON ACT 2600<br />

PO Box 4776<br />

KINGSTON ACT 2604<br />

Phone: 02 6271 4100<br />

Fax: 02 6271 4199<br />

Email: rirdc@rirdc.gov.au.<br />

Web: http://www.rirdc.gov.au<br />

Electronically published by RIRDC in April 2009<br />

Print-on-demand by Union Offset Printing, Canberra at www.rirdc.gov.au<br />

or phone 1300 634 313<br />

ii

Foreword<br />

The integration of aquaculture with traditional agriculture can provide a practical means for farmers to<br />

maximise their use of valuable water resources and infrastructure. This multiple use of water is<br />

practiced in many of the driest regions of the world where water is used, but not directly consumed, by<br />

the aquaculture operation and can then be used to irrigate the farm’s terrestrial crops.<br />

The Darling Downs region in southern Queensland is a hub for agriculture and contains large numbers<br />

of constructed water storages or ‘ring tanks’ to provide water for irrigation. The major irrigated crop in<br />

this region is cotton. The cotton industry’s access to this water infrastructure, and its location to<br />

markets and within the natural distribution of suitable native fish for culture, makes it a particularly<br />

suitable candidate to demonstrate the feasibility of integrating aquaculture into established farming<br />

operations. This project was an on-farm demonstration to highlight the needs, operational challenges<br />

and potential of integrated farming systems across rural Australia.<br />

The project screened a number of native fish species for their suitability to culture conditions in the<br />

farm’s primary water storage, within production systems that included floating cages and raceways.<br />

The floating raceways developed in this project were the first of their kind in Australia and proved to<br />

be an ideal fish culture system for permanent and non-specific water bodies (that is, water bodies not<br />

specifically designed as harvestable aquaculture ponds). This was due to their cost effectiveness and<br />

the improved management they offer in terms of stock inventory, feeding, growth and disease<br />

monitoring, predator control and harvesting.<br />

This study also highlighted the problems for integrating aquaculture with cotton production. In<br />

particular, integration requires changes to established water management practices to ensure adequate<br />

water quality is maintained for the aquaculture operation. Co-ordinating pumping events, maintaining<br />

appropriate volume in storages and managing overland flows from floods and tailwaters are vital for<br />

maintaining sound conditions for fish culture. Especially important is preventing pollutants such as<br />

pesticides from entering waters used for aquaculture due to the risk that pesticide residues can<br />

accumulate in fish tissues to unacceptable levels.<br />

Technically, aquaculture is a specialised discipline, and integrated operations with shared farm labour<br />

will require additional investment in aquaculture training to recognise and manage the needs of fish<br />

culture. However, the irrigation industry is well placed to make such investment because of its existing<br />

water infrastructure and because of its commitment to environmental management and sustainability.<br />

Successful integration would provide significant socio-economic benefits for growers as well as a<br />

number of other rural industries and their communities.<br />

The report, an addition to RIRDC’s diverse range of over 1800 research publications, forms part of our<br />

Environment and Farm Management R&D program which aims to support innovation in agriculture<br />

and the use of frontier technology to meet market demands for accredited sustainable production.<br />

Most of RIRDC’s publications are available for viewing, <strong>download</strong>ing or purchasing online at<br />

www.rirdc.gov.au. Purchases can also be made by phoning 1300 634 313.<br />

Peter O’Brien<br />

Managing Director<br />

Rural Industries Research and Development Corporation<br />

iii

Acknowledgments<br />

The authors would like to thank Mr Paul McVeigh and family for access to their farm, use of their<br />

facilities for demonstration and research activities, for the information provided concerning their<br />

whole of farm operations and general support for the project. Thanks also to Mark Taylor for his<br />

contribution to the conduct of onfarm trials.<br />

The authors would like to acknowledge the contributions and support of other DPI&F staff past and<br />

present, namely Peter Peterson, John Robertson, Paul Grieve, James Butler, Kelvin Spann, John<br />

Standley and Trent Lindsay.<br />

Abbreviations<br />

Abbreviation<br />

ABS<br />

ACG<br />

AGAL<br />

AGBOM<br />

AlSO 4<br />

APHA<br />

APVMA<br />

AQIS<br />

BCF<br />

BMP<br />

BOD<br />

CBWC<br />

cm<br />

CRDC<br />

DAFF<br />

DDD<br />

DDE<br />

DDT<br />

DO<br />

DPI&F<br />

EAR<br />

EPA<br />

ERL<br />

EXTOXNET<br />

FCR<br />

FL<br />

FSANZ<br />

FSDkg/m 3<br />

FW<br />

g<br />

G%/day<br />

GL<br />

ha<br />

HDPE<br />

hrs<br />

IAAS<br />

IPCS<br />

IPM<br />

IRR<br />

ISDkg/m 3<br />

IW<br />

Meaning<br />

Australian Bureau of Statistics<br />

The Australian Cotton Grower<br />

Australian Government Analytical Laboratories<br />

Australian Government Bureau of Meteorology<br />

Aluminium sulphate<br />

American Public Health Association<br />

Australian Pesticides and Veterinary Medicines Authority<br />

Australian Quarantine and Inspection Service<br />

Bio-concentration factors<br />

Best Management Practices<br />

Biological oxygen demand<br />

Condamine-Balonne Water Committee<br />

Centimetre<br />

Cotton Research and Development Corporation<br />

Department of Agriculture Fisheries & Forestry<br />

Dichlorodiphenyldichloroethane<br />

Dichlanodiphenyldichloroethylene<br />

Dichlorodiphenyltrichloroethane<br />

Dissolved oxygen<br />

Department of Primary Industries and Fisheries<br />

Equivalent Annual Return<br />

Environmental Protection Agency<br />

Extraneous residue limit<br />

Extension Toxicology Network<br />

food conversion rate<br />

Floor<br />

Food Standards Australia New Zealand<br />

Final stocking density<br />

Final weight<br />

Grams<br />

Daily percentage growth<br />

Giga litre<br />

Hectares<br />

High density polyethylene<br />

Hours<br />

Integrated Agri-Aquaculture Systems<br />

International Programme on Chemical Safety<br />

Integrated Pest Management<br />

Internal Rate of Return<br />

Initial stocking density<br />

Initial weight<br />

iv

Abbreviation Meaning<br />

kg<br />

Kilograms<br />

km<br />

Kilometres<br />

L<br />

Litre<br />

LC<br />

Lethal concentration<br />

LOQ<br />

Limit of Quantitation<br />

m<br />

Metre<br />

m 3<br />

Cubic metres<br />

mg<br />

Milligram<br />

mg/L<br />

Milligrams per litre<br />

min<br />

Minutes<br />

ML<br />

Mega litre<br />

ml<br />

Millilitres<br />

mm<br />

Millimetres<br />

MPR<br />

Modular plastic raceways<br />

MRL<br />

Maximum residue limit<br />

N<br />

Nitrogen<br />

N/m 3<br />

Number per cubic meter<br />

NPTN<br />

National Pesticide Telecommunications Network<br />

NPV<br />

Net present value<br />

NRA<br />

National Registration Authority<br />

NRS<br />

National Residue Survey<br />

OC<br />

Organochlorine<br />

ºC Degrees Celsius<br />

OP<br />

Organophosphate<br />

P<br />

Phosphorus<br />

P/L<br />

Proprietary Limited<br />

PAC<br />

Powdered activated carbon<br />

PAN<br />

Pesticide Action Network<br />

PIRSA<br />

Primary Industries and Resources South Australia<br />

PMEP<br />

Pesticide Management Education Program<br />

ppt<br />

Parts per thousand<br />

PV<br />

Present value<br />

RIRDC Rural Industries Research and Development Corporation<br />

SF<br />

Surface water<br />

SP<br />

Synthetic pyrethroids<br />

sp.<br />

Species<br />

t<br />

Tonne<br />

TAMCO Total Aquaculture Management Company<br />

TKN<br />

Total Kjeldahl Nitrogen<br />

TKP<br />

Total Kjeldahl Phosphorous<br />

USA<br />

United States of America<br />

USEPA United States Environmental Protection Agency<br />

V<br />

Volt<br />

VDPI<br />

Victorian Department of Primary Industries<br />

WHO<br />

World Health Organization<br />

βHCH<br />

Beta hexachlorocyclohexane<br />

μg/l<br />

Micrograms per litre<br />

v

Contents<br />

Foreword ............................................................................................................................................... iii<br />

Acknowledgments................................................................................................................................. iv<br />

Abbreviations........................................................................................................................................ iv<br />

List of Figures .................................................................................................................................... ix<br />

Executive Summary ............................................................................................................................. ix<br />

What the report is about ...................................................................................................................... x<br />

Who the report is targeted at ............................................................................................................... x<br />

Background ......................................................................................................................................... x<br />

Aims .................................................................................................................................................... x<br />

Methods used...................................................................................................................................... xi<br />

Results ................................................................................................................................................ xi<br />

Implications and Recommendations.................................................................................................. xii<br />

1. Introduction ....................................................................................................................................... 1<br />

2. Demonstration Farm......................................................................................................................... 4<br />

2.1 Background ................................................................................................................................... 4<br />

2.2 Aquaculture Systems..................................................................................................................... 5<br />

2.3 Fish Species................................................................................................................................... 7<br />

3. Water Use and Quality...................................................................................................................... 8<br />

3.1 Background ................................................................................................................................... 8<br />

3.2 Materials and Methods .................................................................................................................. 8<br />

3.3 Results ........................................................................................................................................... 9<br />

3.4 Discussion ................................................................................................................................... 15<br />

4. Production Systems and Growth ................................................................................................... 18<br />

4.1 Background ................................................................................................................................. 18<br />

4.2 Materials and Methods ................................................................................................................ 18<br />

4.3 Results ......................................................................................................................................... 27<br />

4.4 Discussion ................................................................................................................................... 37<br />

5. Pesticide Monitoring and Residues................................................................................................ 42<br />

5.1 Background ................................................................................................................................. 42<br />

5.2 Materials and Methods ................................................................................................................ 43<br />

5.3 Pesticide Bio-concentration and Depuration............................................................................... 45<br />

5.4 Results ......................................................................................................................................... 47<br />

5.5 Discussion ................................................................................................................................... 50<br />

6. Integrated Production Decision Tool............................................................................................. 55<br />

6.1 Description .................................................................................................................................. 55<br />

7. General Discussion .......................................................................................................................... 56<br />

Appendix 1 ........................................................................................................................................... 58<br />

References ............................................................................................................................................ 72<br />

vi

Tables<br />

Table 3.3.1<br />

Table 3.3.2<br />

Table 3.3.3<br />

Table 3.3.4<br />

Table 3.3.5<br />

Table 4.3.1<br />

Table 4.3.2<br />

Table 4.3.3<br />

Table 4.3.4<br />

Table 4.3.5<br />

Table 4.3.6<br />

Table 4.3.7<br />

Table 4.3.8<br />

Table 4.3.9<br />

Table 4.3.10<br />

Source, timing and duration of water harvesting activities at Loch Eaton from October<br />

2000 to February 2004 ............................................................................................................... 9<br />

Average monthly morning surface (SF) and floor (FL) dissolved oxygen levels (mg/L) in the<br />

aquaculture ring tank from November 2000 to March 2004 (mean ± standard deviation) ...... 11<br />

Average monthly afternoon ring tank surface (SF) and floor (FL) dissolved oxygen levels<br />

(mg/L) from November 2000 to March 2004 (mean ± standard deviation)............................. 12<br />

Average monthly morning ring tank surface (SF) and floor (FL) water temperatures from<br />

November 2000 to March 2004 (mean ± standard deviation).................................................. 12<br />

Average monthly afternoon ring tank surface (SF) and floor (FL) water temperatures from<br />

November 2000 to March 2004 (mean ± standard deviation).................................................. 13<br />

Number and volume of net cages and floating raceways in operation at Loch Eaton from<br />

September 2000 through to March 2004.................................................................................. 28<br />

List of known stock escape events at Loch Eaton, estimated numbers of fish lost and the<br />

observed cause of each escape event........................................................................................ 28<br />

The length of culture period (Days), number per cubic meter (N/m 3 ), initial weight (IW), final<br />

weight (FW), initial stocking density (ISDkg/m 3 ), final stocking density (FSDkg/m 3 ) and daily<br />

percentage growth (G%/day) for silver perch (Bidyanus bidyanus) held in 8 and 100m 3 net<br />

cages from the 07/12/00 up to the 31/01/01 ............................................................................. 30<br />

The length of culture period (Days), number per cubic meter (N/m 3 , initial weight (IW), final<br />

weight (FW), initial stocking density (ISDkg/m 3 ), final stocking density (FSDkg/m 3 ), percent<br />

stock retention (%SR) and daily percentage growth (G%/day) for silver perch (Bidyanus<br />

bidyanus) held in 8 and 100m 3 net cages from the 30/01/01 up to 26/04/01 in 8 and 100m 3 net<br />

cages......................................................................................................................................... 30<br />

.The length of culture period (Days), number per cubic meter (N/m 3 ), initial weight (IW), final<br />

weight (FW), initial stocking density (ISDkg/m 3 ), final stocking density (FSDkg/m 3 ), percent<br />

stock retention (%SR) and daily percentage growth (G%/day) for silver perch (Bidyanus<br />

bidyanus) held in 8 and 100m 3 net cages from the 02/03/01 up to 27/09/01 in 8 and 100m 3 net<br />

cages......................................................................................................................................... 30<br />

The length of culture period (Days), number per cubic meter (N/m 3 ), initial weight (IW), final<br />

weight (FW), initial stocking density (ISDkg/m 3 ), final stocking density (FSDkg/m 3 ), stock<br />

retention (%SR) and daily percentage growth (G%/day) for silver perch (Bidyanus bidyanus)<br />

from the 02/03/01 up to 27/09/01 in 7 and 14m 3 raceways...................................................... 31<br />

The length of culture period (Days), number per cubic meter (N/m 3 ), initial weight (IW), final<br />

weight (FW), initial stocking density (ISDkg/m 3 ), final stocking density (FSDkg/m 3 ), percent<br />

stock retention (%SR) daily percentage growth (G%/day) and food conversion ratio (FCR)for<br />

silver perch (Bidyanus bidyanus) from the 02/03/01 up to 27/09/01 in 7 and 14m 3 raceways 33<br />

The length of culture period (Days), number per cubic meter (N/m 3 ), initial weight (IW), final<br />

weight (FW), initial stocking density (ISDkg/m 3 ), final stocking density (FSDkg/m 3 ), percent<br />

stock retention (%SR), daily percentage growth (G%/day) and food conversion ratio (FCR) for<br />

silver perch (Bidyanus bidyanus) from the 02/03/01 up to 27/09/01 in 7 and 14m 3 raceways. 33<br />

The length of culture period (Days), number per cubic meter (N/m 3 ), initial weight (IW), final<br />

weight (FW), initial stocking density (ISDkg/m 3 ), final stocking density (FSDkg/m 3 ), percent<br />

stock retention (%SR), daily percentage growth (G%/day) and food conversion ratio (FCR) for<br />

silver perch (Bidyanus bidyanus) from the 05/02/02 up to 07/05/02 in 7 and 14m 3 raceways as<br />

well as a single 12m 3 raceway.................................................................................................. 33<br />

The length of culture period (Days), number per cubic meter (N/m 3 ), initial weight (IW), final<br />

weight (FW), initial stocking density (ISDkg/m 3 ), final stocking density (FSDkg/m3), percent<br />

stock retention (%SR), daily percentage growth (G%/day) and food conversion ratio (FCR) for<br />

silver perch (Bidyanus bidyanus) from the 19/07/02 up to 21/10/02 in 7 and 14m 3 raceways. 34<br />

vii

Table 4.3.11<br />

Table 4.3.12<br />

Table 4.3.13<br />

Figure 4.4.1<br />

Table 5.1.1<br />

The length of culture period (Days), number per cubic meter (N/m 3 ), initial weight (IW), final<br />

weight (FW), initial stocking density (ISDkg/m 3 ), final stocking density (FSDkg/m 3 ), percent<br />

stock retention (%SR), daily percentage growth (G%/day) and food conversion ratio (FCR) for<br />

silver perch (Bidyanus bidyanus) from the 06/11/02 up to 18/02/03 in 12 and 17.5m 3 raceways<br />

as well as a single 14m 3 raceway.............................................................................................. 36<br />

The length of culture period (Days), number per cubic meter (N/m 3 ), initial weight (IW), final<br />

weight (FW), initial stocking density (ISDkg/m 3 ), final stocking density (FSDkg/m 3 ), percent<br />

stock retention (%SR), daily percentage growth (G%/day) and food conversion ratio (FCR) for<br />

silver perch (Bidyanus bidyanus) from the 20/02/02 up to 25/03/03 in 12 and 17.5m 3<br />

raceways. .................................................................................................................................. 37<br />

The length of culture period (Days), number per cubic meter (N/m 3 ), initial weight (IW), final<br />

weight (FW), initial stocking density (ISDkg/m 3 ), final stocking density (FSDkg/m 3 ), percent<br />

stock retention (%SR), daily percentage growth (G%/day) and food conversion ratio (FCR) for<br />

silver perch (Bidyanus bidyanus) from the 08/04/03 up to 08/04/04 in 12, 17.5 and 23m 3<br />

raceways. 37<br />

Existing (E) and recommended (R) locations of aquaculture facilities and pumping<br />

infrastructure at Loch Eaton. Relocation of the floating raceway facility from the primary ring<br />

tank to the adjacent storage would serve to buffer the aquaculture facility from acute falls in<br />

dissolved oxygen as the result of harvesting large volumes of oxygen deficient, highly turbid<br />

flood waters.............................................................................................................................. 40<br />

Extraneous Residue Limits (ERL) for agricultural chemicals in whole fish (minus gut)<br />

according to Food Standards Australia New Zealand, Australia New Zealand Food Standards<br />

Code (FSANZ, 2006) ............................................................................................................... 42<br />

Table 5.2.1 List of agri-chemicals used at Loch Eaton from February 2001 to May 2003......................... 44<br />

Table 5.2.2<br />

Table 5.2.3<br />

List of organochlorine, organophosphate and pyrethroid compounds included in analytical<br />

testing of riverine and ring tank water samples........................................................................ 44<br />

List of organochlorine, organophosphate and synthetic pyrethroid compounds included in<br />

analytical testing of fish samples.............................................................................................. 45<br />

Table 5.4.1 Ranges of agents detected in Ring tank water.......................................................................... 47<br />

Table 5.4.2 Ranges of agents detected in River water................................................................................. 47<br />

viii

Figures<br />

Figure 2.1.1<br />

Area map of McVeigh Brothers properties Loch Eaton and Timberline located near Dalby,<br />

Queensland...................................................................................................................................... 4<br />

Figure 2.1.2 Layout of the McVeigh Brothers properties showing farm infrastructure...................................... 5<br />

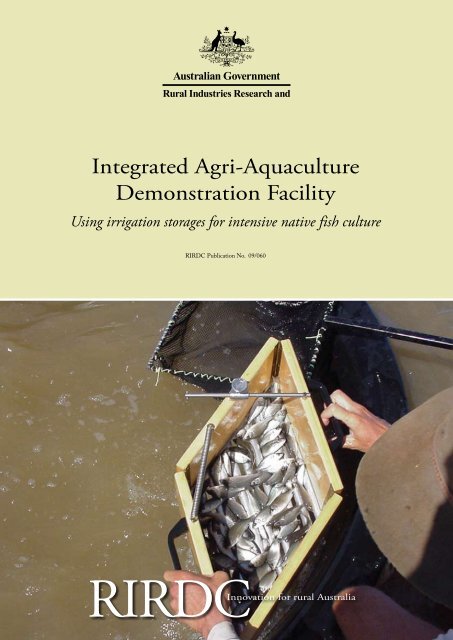

Figure 2.2.3 Net cages used for silver perch and Murray cod production in the ring tank at Loch Eaton .......... 6<br />

Figure 2.2.4 Floating raceway system developed for intensive fish production deployed in the ring tank at<br />

Loch Eaton ........................................................................................................................................ 6<br />

Figure 3.3.1 Daily turbidity readings for the aquaculture ring tank from January 2001 to March 2004 reported<br />

weekly. The red dashed line indicates a major riverine pumping event ....................................................... 14<br />

Figure 3.3.2 Total Kjeldahl Nitrogen (TKN) and Total Kjeldahl Phosphorous (TKP) in the Condamine River<br />

and Loch Eaton ring tank waters. ................................................................................................... 15<br />

Figure 4.2.1 Net cages 8m 3 used for silver perch and Murray cod fingerlings and juveniles.............................. 19<br />

Figure 4.2.2 Net cages 100m 3 used for silver perch grow out ............................................................................. 19<br />

Figure 4.2.3 The first 7m 3 floating plastic raceway being stocked with silver perch fingerlings at Loch Eaton. 20<br />

Figure 4.2.4 The first 14m 3 floating plastic raceways were constructed from HPDE sheets welded to rectangular<br />

pontoons that provided buoyancy.................................................................................................... 20<br />

Figure 4.2.5 The first 12m 3 TAMCO roto-moulded raceways in use at Loch Eaton .......................................... 21<br />

Figure 4.2.6 A bank of uplifts (100mm) drives the water exchange through each of the raceway units............. 21<br />

Figure 4.2.7 Uplift, baffle board and end screen of raceways ............................................................................. 22<br />

Figure 4.2.8 Water flow characteristics of raceways without an eddy board ...................................................... 23<br />

Figure 4.2.9 Water flow characteristics of raceways with an eddy board placed 120cm from the water entrance<br />

and extended 20cm from the surface............................................................................................... 23<br />

Figure 4.2.10 Purging tanks (10m 3 ) supplied with degassed bore water were used to clear silver perch of ‘off<br />

flavour’ taints .................................................................................................................................. 24<br />

Figure 4.2.11 Drum nets used to assess the potential for re-capturing ‘live’ silver perch and Murray cod stocked<br />

into the ring tank.............................................................................................................................. 25<br />

Figure 4.2.12 Box grader used for grading fingerling and juvenile silver perch and Murray cod ...................... 25<br />

Figure 4.2.13 Raceway push gate grader used to passively grade fish within the raceway and also to crowd fish<br />

for harvest and transfer activities..................................................................................................... 26<br />

Figure 4.2.14 Fish transfer hopper used to move fish during stocking, grading, stock transfer or harvesting<br />

activity ............................................................................................................................................. 26<br />

Figure 4.4.1 Existing (E) and recommended (R) locations of aquaculture facilities and pumping infrastructure at<br />

Loch Eaton. ..................................................................................................................................... 40<br />

Figure 5.4.1 Pesticide levels in ring tank water from November 2001 until March 2003................................... 48<br />

Figure 5.4.2 Pesticide levels in river water from November 2001 until March 2003.......................................... 49<br />

Figure 5.4.3 Concentration of pesticides in muscle tissue of silver perch (Bidyanus bidyanus) maintained at<br />

15ºC and exposed to 1 μg/L heptachlor, dieldrin, endosulfan sulphate, chlorpyrifos, p,p-DDE, o,p-<br />

DDE, metolachlor, lindane and β-BHC for 96hrs then transferred to clean water for a period of up<br />

to 28 days......................................................................................................................................... 49<br />

Figure 5.4.4 Concentration of pesticides in muscle tissue of silver perch (Bidyanus bidyanus) maintained at<br />

25ºC and exposed to 1 μg/L heptachlor, dieldrin, endosulfan sulphate, chlorpyrifos, p,p-DDE, o,p-<br />

DDE, metolachlor, lindane and β-BHC for 96hrs then transferred to clean water for a period of up<br />

to 28 days......................................................................................................................................... 50<br />

Figure 6.1.1 Example of spreadsheet based decision tool ................................................................................... 55<br />

ix

Executive Summary<br />

What the report is about<br />

This report shows how the water infrastructure developed by the cotton industry for such large scale<br />

irrigation may also have potential for development of aquaculture. The introduction of an additional<br />

cropping opportunity may have significant economic, environmental and social benefits. It does<br />

however, also face several operational challenges that stem from the need to manage these water<br />

bodies and the farm’s other activities in a more intensive and considered fashion.<br />

Who the report is targeted at<br />

This report is targeted at irrigators who may be interested in diversifying their business by integrating<br />

commercial aquaculture with irrigated agriculture. It focuses on a demonstration site in the cotton<br />

industry in Queensland, but contains valuable information for potential investors throughout Australia.<br />

The report includes detailed analysis of the research undertaken on site and would be of interest to the<br />

Australian aquaculture industry and researchers interested in environmental impacts on Australian<br />

native fish.<br />

Background<br />

There are many thousands of hectares of water storage on cotton farms in Australia. Australia<br />

consumes approximately 22,185 GL of water annually of which about seventy percent (15,502 GL) of<br />

the total water used is consumed for agricultural production and approximately 11.9 per cent (or 1,840<br />

GL) of this is consumed by the cotton industry (Dalton, Raine, & Broadfoot, 2001). In Queensland<br />

cotton farmers are the second major industry user of freshwater in the State.<br />

The opportunity to utilise large water storage infrastructure for aquaculture is well recognised and is a<br />

common practice in many countries. However, the scale of these activities is often limited with largescale<br />

integrated agri-aquaculture being non-existent in Australia. A clear opportunity exists to utilise<br />

these resources, diversify farming operations, and deliver significant socio-economic benefits.<br />

To test this opportunity in Australia, an integrated aquaculture demonstration site at an irrigated cotton<br />

enterprise, ‘Loch Eaton’, 14 KM south of Dalby on the Darling Downs in Queensland was used. The<br />

development of the aquaculture enterprise was managed by the farm operators, McVeigh Brothers Inc.<br />

as were the farm’s irrigation activities and chemical spray events.<br />

The aquaculture trial screened a number of native fish species for their suitability to culture conditions<br />

in the farm’s existing on site cotton irrigation water storages or ‘ring tanks’, which are common to the<br />

area. These storages received water by pumping riverine flows and also from the farm’s groundwater<br />

supplies.<br />

Aims<br />

The aim of the project was to study how aquaculture was introduced into the irrigated cotton<br />

enterprise. This site was used as a demonstration facility for industry and to record the progress of the<br />

site’s development, its challenges and potential for replication.<br />

Specifically the aims of the study were to:<br />

• Develop an integrated agri-aquaculture demonstration site in on-farm water storages typically used<br />

for irrigated agriculture on the Darling Downs.<br />

• Conduct on-farm extensive production trials using Silver and Golden Perch and intensive<br />

production trials using Silver Perch and Murray Cod.<br />

• Demonstrate the potential for improved utilisation of water resources and the resultant economic<br />

and environmental benefits, by developing and quantifying robust farm diversification strategies.<br />

• Utilise the demonstration site for practical extension activities highlighting the needs and potential<br />

of integrated farming systems across rural Australia.<br />

x

Methods used<br />

Assessment of the site occurred over three years and involved monitoring fish growth, stocking<br />

practices, pesticide events, water quality, fish health, general husbandry needs and practices. Included<br />

in this assessment was consideration of how the aquaculture operation impacted on the farm’s existing<br />

cotton operations, its management, maintenance of water resources and use of water on farm. An<br />

important component of this study assessed how the farm’s pesticide management practices changed<br />

to comply with the needs of the site’s aquaculture operations<br />

Results<br />

The results from the three seasons of site development, monitoring, trials and training exercises<br />

demonstrated that cotton irrigators can integrate aquaculture/irrigation operations, but only with<br />

careful site selection, and the appropriate level of investment and technical expertise.<br />

The on-farm extensive production trials using Silver and Golden Perch and intensive production trials<br />

using Silver Perch and Murray Cod had unsatisfactory rates of growth for commercial production<br />

primarily due to problems with poor water quality following significant riverine pumping events. The<br />

harvest of water from the Condamine River occurred typically during flow events that resulted in large<br />

volumes of water with high turbidity and low dissolved oxygen levels to be pumped into the ring tank<br />

where the aquaculture trial was situated. These events not only resulted in significant mortalities<br />

associated with the low dissolved oxygen levels but also served to retard growth over an extended<br />

period because of the longer term impacts on water quality.<br />

These poor fish growth rates, clearly showed that aquaculture systems used must be located in a<br />

storage that does not directly receive flood or tail waters. Alternatively, these systems should<br />

incorporate capacity to be isolated from poor quality surface waters for short periods in order to avoid<br />

severe fluctuations in water quality.<br />

The study also showed that aquaculture sites must be protected from potential pesticide spray drifts<br />

from adjacent cotton production. There was only one detection of a compound in fish through the<br />

monitoring period. This event was most likely due to an off site aerial application of pesticide that<br />

drifted across the ring tank. Once identified and addressed no further spray drift events were detected.<br />

In addition to improved on farm pesticide management practices, pesticide use within the cotton<br />

industry has fallen significantly since the study was implemented. Such trends are expected to<br />

continue as industry Best Management Practices including Integrated Pest Management strategies and<br />

the introduction of disease resistant seed strains continue to be adopted by the cotton industry. Overall,<br />

the pesticide risk from adjacent cotton production was shown to be low and manageable.<br />

Significantly, the study developed and refined a more cost effective in-pond floating raceway system<br />

suitable for intensive production in environments not specifically designed for aquaculture. Although<br />

initially focusing on cage culture of native fish, the floating raceway system developed through the<br />

course of the project provided benefits of more efficient operation and greater security of stock. This<br />

was due to their cost effectiveness and the improved management they offer in terms of stock<br />

inventory, feeding, growth and disease monitoring, predator control and harvesting. Cage systems by<br />

comparison proved difficult to manage and were abandoned by the operator.<br />

Although the raceway system proved to be a durable approach to intensive fish culture, the primary<br />

factor limiting the aquaculture production in ring tanks is the availability and quality of surface water.<br />

The raceways demonstrated an ability to hold freshwater fish at high density but growth of larger fish<br />

in this system still was not commercial, due to the riverine pumping event outlined above.<br />

The issue of whole of farm water supply during periods of drought has serious implications for the<br />

integrated fish/cotton farmer. During this study, water for irrigation of cotton was limited and the farm<br />

relied heavily on its groundwater allocations. This allowed maintenance of low levels of surface water<br />

within the ring tank to maintain the aquaculture operation. However, for farms without access to<br />

sufficient groundwater supplies the cost of maintaining surface water in ring tanks may outstrip the<br />

return from the aquaculture facility. Therefore, the size of aquaculture operations in cotton ring tanks<br />

must provide a higher return from available water supplies than is returned from an irrigated cotton<br />

xi

crop. This is much higher than simply the cost of producing the cotton in a given year because of the<br />

need to absorb ongoing costs associated with the investment into the infrastructure and machinery<br />

associated with the cotton operation. Therefore, in order to achieve profitable integration through<br />

multiple use of water storages, an aquaculture operation must not place significant demands on the<br />

farm’s water resources. Systems like the floating raceways used in this study enable the water depth in<br />

ring tanks to be lowered to a minimal depth. This is beneficial as unlike cages that require a greater<br />

functional water depth, the raceway systems can operate in less water and therefore make more water<br />

available for irrigation.<br />

The economics of farm integration are complex as many of the inputs, resources and infrastructure are<br />

shared across the farm’s operations. As part of this study an Excel based spreadsheet decision tool was<br />

developed to assist growers investigate the potential for integrating aquaculture into their farm<br />

operations. Intended as a guide only, this model indicates that the demonstration farm’s overall<br />

profitability could be improved substantially if the documented technical and operational challenges<br />

faced during this study can be overcome.<br />

Implications and Recommendations<br />

It is clear from this study that while the aquaculture potential of these regions and infrastructure is<br />

high, there are existing issues concerning the methods and timing of water harvesting, the species<br />

used, the method of farming and the associated demands on the farm operators. The level of intensity<br />

and scale of production must be well matched to the skill of the proponent and the available<br />

infrastructure. Considered placement of the aquaculture operation will determine the success of the<br />

operation and its ability to expand.<br />

In conclusion, the irrigation industry is well placed to invest in the production of additional crops from<br />

their available water resources and infrastructure, the cotton industry is particularly well placed<br />

because of its commitment to environmental management and sustainability.<br />

It is recommended that irrigators seeking to introduce aquaculture into their existing farming<br />

enterprises investigate:<br />

• The impact of retaining up to 3m of water within the aquaculture storage on the farms irrigated<br />

crops.<br />

• The risk associated with servicing a new and highly technical farming enterprise.<br />

• The cost of additional training requirements for new and existing staff.<br />

• The minimum size that the aquaculture enterprise must achieve compared to the capacity that<br />

exists within their farm infrastructure.<br />

• The species that is optimal for their proposed system (extensive, semi-intensive or intensive).<br />

• The ability of the farm to maintain water supplies indefinitely.<br />

xii

1. Introduction<br />

1.1 General Background<br />

Large volumes of water are harvested in southern Queensland and stored for production of agricultural<br />

crops. On the Darling Downs hundreds of water storage or ‘ring tanks’ have been built by irrigators to<br />

hold many thousands of mega litres water. The major irrigated crop in this region is cotton. In<br />

Queensland 2001/2002 there were 96,700 hectares (ha) planted with cotton of which 79,800ha was<br />

irrigated production, of this the Darling Downs accounted for a total of 44,000ha of which 28,00ha<br />

was irrigated (ACG, 2006).<br />

Australia consumes approximately 22,185 GL of water annually of which about seventy percent<br />

(15,502 GL) of the total water used is consumed for agricultural production of which approximately<br />

11.9 per cent (or 1,840 GL) is consumed by the cotton industry (Dalton, Raine, & Broadfoot, 2001).<br />

The cotton industry is second only to the horticultural industry in terms of value derived from the<br />

water resource (ABS, 2000) returning a farm gate value of approximately $613 per ML consumed<br />

(Dalton, et.al, 2001).<br />

The Australian Bureau of Statistics (ABS) reports that for 2002/2003 Australian irrigated cotton<br />

farmers used an average of 6.5 ML/ha of water (ABS, 2006). The cost of water in real terms is<br />

increasing for growers and farm diversification is becoming an increasingly important consideration<br />

for farmers seeking to obtain more value from their water allocations and infrastructure. As a<br />

consequence of the cotton industry’s access to water and associated infrastructure, opportunity exists<br />

to integrate aquaculture into established cotton farming operations. Successful integration would<br />

provide significant socio-economic benefits for cotton growers as well as a number of other rural<br />

industries and their communities.<br />

Estimates of surface water storage capacities for the Condamine River catchment (Darling Downs<br />

region) are as follows. There are approximately 2,679 ring tank type storages with a total surface area<br />

of 6,115 ha with individual storages being about 2.28 ha in size on average. Palustrine/lacustrine<br />

water bodies that have been converted, completely or mostly, to a ring tank or other controlled storage<br />

account for an additional 305 storages with a total surface area of 763 ha with individual storages<br />

being about 2.5 ha in size (EPA, 2006).<br />

Fish farming as an integrated operation with irrigated cotton production is not a new concept and has<br />

been successfully practised with furrow and drip schemes in the United States and Israel. Potential<br />

exists to incorporate the same practices on Australian farms. Existing cotton water storages or ‘ring<br />

tanks’ vary in size from 10 to 50 ha with depths ranging from 4 to 7 m. These storages are usually<br />

filled by pumping riverine and overland flows when available. In some cases, a farms groundwater<br />

supplies are also used to supplement surface water supplies. In assessing the potential of individual<br />

ring tanks for fish production not only must the location and design of the ring tank be considered but<br />

so must the availability, source and quality of the farms water supplies and its use of agricultural<br />

chemicals.<br />

The depth of water held in any ring tank varies in accordance with a farms irrigation schedule, river<br />

flows, on farm rainfall patterns, evaporation rates and seepage. The depth of most storages means that<br />

there is potential for stratification of the water body which can result in oxygen levels in the deeper<br />

portion of the storage to become depleted while the levels in surface layers remain normal. This lack<br />

of mixing has the potential to cause problems for aquaculture when seasonal climatic conditions cause<br />

the water body to ‘turn’. Such an event brings the low oxygen water to the surface and in contact with<br />

fish and can result in death of fish in severe cases. The risks posed to aquaculture in cotton ring tanks<br />

by seasonal stratification needs to be assessed and any means of mitigating its impact determined.<br />

The timing and path by which water enters a ring tank will be of critical importance in determining the<br />

quality and quantity of water available for aquaculture. Water bodies that are highly turbid (has high<br />

levels of suspended solids such as fine clays) and have low dissolved oxygen levels are usually<br />

unsuitable for fish culture. Studies on catchments with predominant agricultural developments have<br />

1

documented such waters types as being associated with river flow or flood events (CBWC, 2002).<br />

Low dissolved oxygen levels will slow fish growth, can induce stress (which leads to disease<br />

outbreaks) and if severe enough, will result in significant to total mortality of the farms stock. The<br />

optimal range for native fish culture is recommended to be 4.5 mg/L or above (PIRSA, 2003). In<br />

ponds specifically built for aquaculture, algal growth is managed to provide such levels of oxygen.<br />

However, in water bodies that receive highly turbid waters algal growth is suppressed and problems<br />

associated with low dissolved oxygen levels become difficult to manage. Turbidity can also result in<br />

sediment build up within the gills of fish and in some cases even damage the gill themselves, resulting<br />

in further problems associated with fish growth, disease and survival. The short and long term impacts<br />

of water harvesting activities on the quality of water in a cotton storage needs to be assessed in order<br />

to determine their potential use for commercial aquaculture. The reliability of water supplies will also<br />

be an issue for an aquaculture operation that is integrated with a cotton farm. Most cotton storages are<br />

fully utilised by growers during the cropping cycle. Water consumption per hectare of production for<br />

cotton consumes about 8 ML/ha, of water (Mc Veigh, 2003). This water is accessed from seasonal<br />

flows which in some years may not be adequate to fulfil the needs of both the aquaculture and cotton<br />

farming enterprises. Therefore, although the cotton industry as a whole has access to a large volume of<br />

water, only farms that have appropriately located water storages, reliable pumping conditions and<br />

adequate groundwater allocations are likely to be suitable for large scale integrated aquaculture<br />

development. On these farms water management practices are likely to change significantly in order to<br />

enable aquaculture to co-exist with traditional crops. Assessment of the commercial development of<br />

aquaculture on a cotton farm with a favourable layout, an adequate natural resource base and the<br />

necessary infrastructure support is required to demonstrate the true potential of integrated farming<br />

practices within Australia’s cotton industry.<br />

Water harvesting during periods of high riverine flow also raises the risk of exposure to agricultural<br />

pollutants such as pesticides that can be highly toxic to fish (Kelly & Kohler, 1997). Endosulfan, is<br />

one pesticide that has been widely used historically on cotton farms in NSW and Queensland to treat<br />

for heliothis caterpillar infestations (Constable, Llewellyn, & Reid, 1998.). Endosulfan is recognised<br />

as being associated with several fish kills within the Murray Darling Basin (Napier, Fairweather &<br />

Scott, 1998). Chlorpyrifos is also toxic to fish and has been detected in 10.5 per cent of farmed catfish<br />

in the Untied States of America (Wan, Santerre & Deardoff, 2000). It is the aerial application of these<br />

pesticides that is likely to pose the major route of contamination and therefore threat, to any<br />

aquaculture operation. Spray drifts of agents like endosulfan and chlorpyrifos are highly toxic to fish<br />

and can move up to 500 m from the point of their application (Craig, Woods & Dorr, 1998). Yet it is<br />

not only the short term distress and damage these agents can do to fish that is of concern to an<br />

integrated fish farmer. It is the possibility that these agents can also rapidly accumulate in fish tissues<br />

to unacceptable levels either from direct absorption from the water column or through the food chain.<br />

As these compounds have not been approved for use on fish, an unacceptable level is any detection of<br />

these compounds as this will render market fish unsuitable for sale.<br />

The issue of pesticide management within the cotton industry is being addressed through industry<br />

programs that improve the application and reduce the reliance on agricultural chemicals. This program<br />

is the Best Management Practices (BMP) program. The BMP program represents the industries<br />

commitment to reducing the impacts of cotton farming on the natural environment, its neighbours,<br />

workers and the wider community. The BMP program has been designed to assist growers identify<br />

and manage risks, design farms that minimise environmental impact, use pesticide in a safe and<br />

responsible manner as well as use all available options to control pests (Cotton Australia). This<br />

includes encouraging thus introduction of new cotton varieties that require less pesticide than<br />

conventional varieties. During the last decade, the use of new cotton varieties has provided a<br />

foundation for the rapid adoption of Integrated Pest Management (IPM) practices, which in turn have<br />

helped reduce overall insecticide use by 70 per cent (CRDC, 2005). The introduction of Ingard cotton<br />

and more recently Bollgard II, have reduced chemical use significantly. The direction of the Australian<br />

cotton industry towards IPM and reduced reliance on chemicals is favourable for the long term<br />

development of aquaculture in cotton growing regions. However, the current risks associated with<br />

pesticide use need to be assessed in order to understand the future benefits of changing pesticide use<br />

patterns on the viability of aquaculture development in cotton catchments.<br />

2

1.2 Objectives<br />

This project was undertaken to demonstrate the potential for integrating an aquaculture operation into<br />

an established cotton farm in Queensland. It was undertaken in collaboration with an industry partner<br />

McVeigh Enterprises, who were in the first stages of establishing a pilot commercial aquaculture<br />

enterprise at their Loch Eaton Property on the Darling Downs in southern Queensland. Specifically the<br />

aims of the study were to:<br />

• Develop an integrated agri-aquaculture demonstration site in on-farm water storages typically used<br />

for irrigated agriculture on the Darling Downs.<br />

• Conduct on-farm extensive production trials using Silver and Golden Perch and intensive<br />

production trials using Silver Perch and Murray Cod.<br />

• Demonstrate the potential for improved utilisation of water resources and the resultant economic<br />

and environmental benefits, by developing and quantifying robust farm diversification strategies.<br />

• Utilise the demonstration site for practical extension activities highlighting the needs and potential<br />

of integrated farming systems across rural Australia.<br />

3

2. Demonstration Farm<br />

2.1 Background<br />

The key objective of this project was to establish a demonstration site in collaboration with industry<br />

partner McVeigh Brothers P/L. The purpose of this site was to present the concept of integrated<br />

farming to other irrigators while providing a facility where the benefits, issues and challenges of farm<br />

integration could be studied in detail. The farm, ‘Loch Eaton’, is a 270 ha cotton and grains farm<br />

located on Grassdale Road, 14 km south of Dalby on the Darling Downs, Queensland.<br />

Operated by Paul and Debbie McVeigh, Loch Eaton is positioned in an established irrigated cotton<br />

producing area. Like many in the area the farm was originally developed for wool and beef<br />

production. Since the mid 1980’s the farm has been used primarily for the production of cotton, grain<br />

and cereal crops. At present approximately 80 per cent of the farm is used for cotton production. At<br />

the time of this study McVeigh Brothers P/L operated a cooperative of farms along Grassdale Road of<br />

which Loch Eaton was the central property. There are 4 water storage cells or “ring tanks” on this<br />

property all of which share one border with the riparian zone of the Condamine River which flows<br />

along the eastern edge of the property (Fig 2.1.1). These ring tanks have a combined surface area of<br />

48.6 ha. Surface water is harvested from the adjacent river when water levels are above a regulated<br />

height using two pumping stations according to the farm’s general pumping licence. At the first<br />

pumping station water is pumped directly into the storage used for aquaculture. As this first ring tank<br />

is filled water overflows by gravity into the adjacent ring tank until it too is full or pumping is ceased.<br />

The second pumping station fills the lower but much shallower (

The ring tank used for fish culture (marked with arrow on map and shown in Fig 2.1.2) is 5.5 Ha and<br />

is a maximum of 7m deep at its deepest point when at capacity. At capacity the ring tank holds<br />

approximately 385ML.<br />

Ring Tank used for demonstration<br />

aquaculture facility<br />

Figure 2.1.2 Layout of the McVeigh Brothers properties showing farm infrastructure<br />

2.2 Aquaculture Systems<br />

The focus at Loch Eaton was to produce an additional crop, in this case fish, using the farms existing<br />

water infrastructure and resources. This was to be achieved without any detrimental impact on the<br />

farm’s existing cotton and grains operations. As such the use of earthen ponds were considered but<br />

deemed inappropriate as they would significantly reduce the area available for cotton production. Not<br />

only would the ponds cover a significant proportion of the farm but the need to install additional<br />

electrical, pumping and water transfer infrastructure meant the other costs were prohibitive.<br />

The aquaculture operation was therefore established in the farms primary ring tank which could<br />

receive both surface and groundwater inputs. Initially, a combination of small nursery cages (8 m 3 )<br />

and larger circular grow out cages (100 m 3 ) were installed within the storage and were serviced by a<br />

central walkway (Fig 2.2.3). Difficulties experienced with net cages in the ring tank led the operators<br />

to develop their own version of in-pond floating raceway technology (Fig 2.2.4).<br />

This system was released commercially by the Total Aquaculture Management Company (TAMCO)<br />

in 2003. Termed modular plastic raceways (MPRs) the product is a roto-moulded high density<br />

polyethylene (HDPE) construction which uses a bank of air uplifts at one end to drive water through<br />

the raceway. Water flow is evenly distributed through the unit and while the rate of water exchange is<br />

high the velocity of water is optimal for fish growth and removal of wastes.<br />

5

Figure 2.2.3 Net cages used for silver perch and Murray cod production in the ring tank at Loch<br />

Eaton<br />

Figure 2.2.4 Floating raceway system developed for intensive fish production deployed in the<br />

ring tank at Loch Eaton<br />

6

2.3 Fish Species<br />

Silver perch (Bidyanus bidyanus) were selected for initial trials as they are readily available from<br />

hatcheries as fingerlings. This species forms the majority of native freshwater fish production in<br />

Australia with the majority of product being sold live to markets and restaurants. Although primarily<br />

grown in pond systems this species has shown promise in net cages and other more intensive tank<br />

based production systems.<br />

Murray cod (Maccullochella peelii peelii) was selected because it has a demonstrated potential for<br />

higher density production particularly in tank systems (Gooley and Gavine, 2003). It is an emerging<br />

species which has a higher value than silver perch although the relative cost of fingerlings for Murray<br />

cod are also higher.<br />

Golden perch (Macquaria ambigua ambigua) is another emerging native freshwater fish. While<br />

hatchery production of this species is well established virtually all stock is used for recreational<br />

stocking activities. The primary issue for this species is the weaning of fingerlings onto artificial diets.<br />

Recent research by DPI&F has demonstrated successful weaning strategies and good growth<br />

characteristics of this species under culture conditions (Herbert and Graham, 2004ab).<br />

7

3. Water Use and Quality<br />

3.1 Background<br />

The opportunity to utilise large water storage infrastructure for aquaculture is well recognised and is a<br />

common practice in many countries. However, the scale of these activities is often limited with largescale<br />

integrated agri-aquaculture being non-existent in Australia. A clear opportunity exists to utilise<br />

these resources, diversify farming operations, and provide significant socio-economic benefits for rural<br />

Queensland and other areas of the country.<br />

In assessing the potential of a farms water infrastructure for aquaculture, the availability and quality of<br />

water must be considered. The origin of the water (the timing and means by which the water enters the<br />

water storage) will be of critical importance in determining the quantity and quality of water that will<br />

be used for aquaculture.<br />

Many factors determine the quality of water for use in freshwater fish culture. These include factors<br />

such as water temperature, dissolved oxygen levels, turbidity, pH and nutrient levels. Fluctuations in<br />

these factors will impact on the growth rate of fish or in severe instances can result in the onset of<br />

disease and fish death. Integrating aquaculture with an industry that relies heavily on the collection of<br />

riverine water, typically during flood events, poses significant challenges with respect to the<br />

maintenance of suitable water quality. This study aimed to monitor the changes in ring tank water<br />

quality over consecutive seasons in a ring tank that received water from both riverine flood pumping<br />

events and also from the farms groundwater supply.<br />

3.2 Materials and Methods<br />

3.2.1 Water Harvesting<br />

Water harvested during flow events from the Condamine River and from the farms bore adjacent to the<br />

ring tank events were recorded. Three pumps can be used for water harvesting (4, 12 and 16″) with the<br />

size of pump dictated by the height of the river. All water harvested from the river and bore was<br />

pumped into the aquaculture ring tank in its raw form did not receive any treatment such as settling,<br />

the addition of flocculants or aeration.<br />

3.2.2 Water Quality<br />

In order to monitor diurnal and seasonal changes in ring tank water quality measures of dissolved<br />

oxygen, water temperature and pH were recorded up to twice daily (morning and late afternoon).<br />

Given the variable water level within the ring tank (dependent on the amount being harvested and that<br />

being used for watering crops), these readings were taken as surface and bottom readings only. The<br />

average depth of the ring tank was also recorded. The pH was only recorded for surface waters (

Samples were collected from a central point in the middle of the dam to ensure all samples were well<br />

mixed and that localised effects of sampling near the aquaculture operations were avoided. A sample<br />

was also collected from the Condamine River adjacent to the farms pumping infrastructure. Both<br />

samples were immediately frozen following collection and stored at -20°C until analyses.<br />

Nutrient analyses were conducted on the Lachat QC8000 Flow Injection Analyser (Zellweger<br />

Analytics Inc. Milwaukee WI 53218) following standard methods (APHA, 1995.).<br />

3.3 Results<br />

3.3.1 Water Harvesting and Movement<br />

There were 11 separate water movement events from the beginning of the study period (Table 3.3.1).<br />

These included 7 periods where water was harvested from the Condamine River and 4 from the bore<br />

adjacent to the storage.<br />

Table 3.3.1 Source, timing and duration of water harvesting activities at Loch Eaton from<br />

October 2000 to February 2004<br />

Event Source Date Started Date Finished<br />

Duration<br />

(days)<br />

River pumps used<br />

1 Bore 27/10/00 27/11/00 31 Adjacent to ring tank<br />

2 Bore 28/12/00 11/01/01 14 Adjacent to ring tank<br />

3 River 04/02/01 10/02/01 6 4 and 12″<br />

4 River 14/03/01 14/04/01 31 4″<br />

5 Bore 12/09/01 23/09/01 11 Adjacent to ring tank<br />

6 Bore 15/11/01 22/11/01 7 Adjacent to ring tank<br />

7 River 28/11/01 10/12/01 12 4 and 12”<br />

8 River 26/02/03 02/03/03 4 4 and 12”<br />

9 River 07/12/03 20/12/03 13 4 and 12”<br />

10 River 14/01/04 28/01/04 14 4, 12 and 16″<br />

11 River 03/02/04 15/02/04 12 4, 12 and 16″<br />

Riverine water harvesting is an opportunistic and generally seasonal activity while pumping bore<br />

water occurs during periods of low rainfall. The ring tank has three different sized river pumps with<br />

diameters of 4, 12 and 16″ inches. These pumps are activated when water levels rise to a height that<br />

permits their use. Not all of this pumping capacity was used for each of the recorded pumping events.<br />

For riverine pumping activities lasting longer than 14 days only the 4″ pump was used. Pumping<br />

activity lasting 14 days or less used a combination of 4, 12 and 16″ pumps. In early February 2001 a<br />

short term pumping event lasted for six days using both the 4 and 12″ pumps. Another more prolonged<br />

pumping event occurred one month later and lasted 31days. The last riverine pumping event occurred<br />

in late November 2001 and lasted for 12 days. After this event, no riverine water harvesting activities<br />

took place for over 14 months (443 days). This event was brief as water levels only permitted pumping<br />

to occur for a total of 4 days. Late in 2003 water levels within the ring tank had fallen to less than 30<br />

per cent of its capacity and all other storages on the farm were fully drained. As a consequence the<br />

next three pumping events, December 2003, January 2004 and February 2004 represented a period of<br />

significant water exchange and turnover within the ring tank. The two smaller pumps (4 and 12) were<br />

used for 13 days during the December 2003 event while all three pumps (4, 12 and 16″) where used<br />

for a total of 39 days in January and February 2004.<br />

In Dalby the highest rainfalls typically occur from November through to February with December<br />

having the highest average total monthly falls of 95 mm (AGBOM, 2005). The annual rainfall average<br />

for the Dalby region is 676 mm (AGBOM, 2005). Despite an increased reliance on the farms<br />

groundwater allocation during this study due to extended periods of little to no riverine pumping<br />

activity, the majority of the farms water needs were met from riverine supplies harvested during high<br />

flow events. Water pumped into the ring tank during these events was typical of flood waters for<br />

9

inland Australia with high levels of suspended sediments and low levels of dissolved oxygen. Other<br />

small fish and debris were also introduced to the ring tank during water harvesting activities.<br />

Unlike riverine water, the groundwater that was pumped into the ring tank was of high quality and<br />

contained no particulate or suspended matter. The volumes of bore water added to the ring tank did not<br />

appear large enough to influence ring tank water quality.<br />

Of the water harvested from the Condamine River, virtually all passed through the aquaculture ring<br />

tank before being transferred to other on-farm storages. Water can be drained from the aquaculture<br />

ring tank via a gate valve into an adjacent head ditch that can be used to irrigate adjacent fields or the<br />

water can be moved to the lagoon dam. This drainpipe draws directly from underneath the aquaculture<br />

infrastructure (cages/raceways). The ring tank can also overflow into the adjacent cell which again is<br />

set up to move water either to the lagoon dam or the irrigation head ditch.<br />

3.3.2 Water Quality<br />

3.3.2.1 Dissolved Oxygen<br />

Flood harvesting events were the most influential factor governing the variability in dissolved oxygen<br />

(DO) levels. The ring tank morning DO levels for surface water (SF) in January 2001 averaged 9.21 ±<br />

0.61mg/L (Table 3.3.2). On the 04/02/01 a major riverine pumping event commenced. At the end of<br />

this 10 day pumping event the morning SF DO levels had fallen to just 3.5 mg/L. They remained<br />

below 5 mg/L until the 23/02/01 after which they began to slowly rise reaching an average of 6.50 ±<br />

1.09 mg/L in May.<br />

In late 2001 a series of riverine and bore pumping events that occurred between the 15/11/01 and the<br />

10/12/01 were again associated with a decrease in ring tank DO levels. The average morning SF DO<br />

level was 7.14 ± 0.48 mg/L for the month prior to the first 4 day riverine pumping event. Two<br />

subsequent riverine pumping events on the 20th and 28th of November lasted two and six days<br />

respectively. These riverine pumping events also coincided with bore water pumping activity on the<br />

11th and the 22nd of the same month. The morning SF DO level for the week following this series of<br />

pumping events averaged 4.53 ± 0.54mg/L.<br />

For an extended period between the 10/12/01 and the 26/02/03 there were no riverine pumping events.<br />

In early December 2003 a pumping event lasting 13 days resulted in an immediate drop in SF DO<br />

levels. The morning DO level in SF waters In November 2003 averaged 5.23 ± 0.95 mg/L compared<br />

to the December average of 3.83 ± 1.34 mg/L. The lowest morning DO level observed during the<br />

pump event in December was 1.92 mg/L on the 16/12/03. Low DO levels were maintained in January<br />

and February 2004 with another two pumping events. The January, February and March 2004 morning<br />

SF DO levels averaged 3.22 ± 0.33, 3.02 ± 0.38 and 4.08 ± 0.79 mg/L respectively. Afternoon DO<br />

levels for these months were similar and averaged 3.41 ± 0.42, 3.38 ± 0.42 and 4.23 ± 0.58 mg/L<br />

respectively.<br />

In contrast to riverine pumping events, isolated bore water pumping events were not associated with<br />

any decrease in ring tank DO. A 31 day bore pumping event that commenced on the 27/10/00 was not<br />

associated with any fall in DO levels. The morning surface DO levels prior to this pumping activity<br />

averaged 9.54 ± 0.77 mg/L. The DO concentration during this pumping event averaged 9.13 ±<br />

0.69 mg/L and was 8.2 mg/L the day after pumping ceased. Similarly a 12 day bore pumping event<br />

that commenced on the 12/09/00, also had no detrimental impact on ring tank DO levels. The morning<br />

surface DO level in the ring tank on the 24/09/00, the day after pumping ceased, was 8.39 ±<br />

0.17 mg/L. This compares favourably with the DO levels observed in surface waters in the week prior<br />

to this pumping event which averaged 9.07 ± 0.46 mg/L. Similar observations were made for DO<br />

levels following bore pumping events on the 12/09/01 and the 15/11/2001.<br />

10

Table 3.3.2 Average monthly morning surface (SF) and floor (FL) dissolved oxygen levels<br />

(mg/L) in the aquaculture ring tank from November 2000 to March 2004 (mean ± standard<br />

deviation)<br />

Month<br />

2000 2001 2002 2003 2004<br />

SF FL SF FL SF FL SF FL SF FL<br />

January<br />

9.21 8.56 6.34 5.45 6.50 4.20 3.22 3.00<br />

±0.61 ±0.84 ±0.65 ±0.73 ±1.33 ±1.77 ±0.33 ±0.35<br />

February<br />

4.58 3.28 6.67 4.75 6.27 4.58 3.02 2.62<br />

±1.17 ±0.67 ±0.55 ±0.87 ±1.14 ±1.13 ±0.38 ±0.48<br />

March<br />

4.73 3.68 7.09 5.16 5.85 4.83 4.08 3.85<br />

±0.66 ±1.45 ±0.58 ±1.47 ±0.99 ±0.97 ±0.79 ±0.78<br />

April<br />

5.77 5.12 6.17 5.44 6.39 4.62<br />

±0.32 ±0.59 ±0.39 ±0.50 ±1.29 ±0.87<br />

May<br />

9.18 6.50 6.08 7.00 6.51 6.66 5.49<br />

±0.41 ±1.09 ±1.13 ±0.46 ±0.61 ±0.71 ±1.13<br />

June<br />

10.13 8.29 8.01 7.74 6.84 7.49 6.43<br />

±1.06 ±0.43 ±0.44 ±0.73 ±0.85 ±0.84 ±1.35<br />

July<br />

10.35 9.95 9.63 9.44 8.54 7.43 8.05 7.45<br />

±0.22 ±0.27 ±1.02 ±1.05 ±0.54 ±0.55 ±0.77 ±0.65<br />

August<br />

11.35 10.55 9.22 8.80 8.04 6.87 7.29 6.62<br />

±0.21 ±0.35 ±0.70 ±0.60 ±0.84 ±0.59 ±0.92 ±0.87<br />

September<br />

10.09 5.85 8.87 8.33 5.92 4.95 6.18 5.14<br />

±0.80 ±2.33 ±0.52 ±0.74 ±0.69 ±0.63 ±0.59 ±0.75<br />

October<br />

9.48 8.32 7.36 6.10 6.34 4.22 4.93 3.67<br />

±0.58 ±0.99 ±0.50 ±0.79 ±0.76 ±0.93 ±0.65 ±1.33<br />

November<br />

9.03 7.78 5.92 5.38 6.27 2.98 5.23 4.02<br />

±0.59 ±1.24 ±0.92 ±0.88 ±0.45 ±0.58 ±0.95 ±1.57<br />

December<br />

8.65 7.64 4.78 4.50 6.61 3.53 3.83 2.95<br />

±0.35 ±0.95 ±0.96 ±1.04 ±0.71 ±1.58 ±1.34 ±1.10<br />

Average differences in the morning surface and bottom dissolved oxygen levels in the ring tank was<br />

1.14 ± 1.25 mg/L over the duration of this study. The difference in the average afternoon surface and<br />

bottom DO levels was 1.64 ± 1.78 mg/L. The only extended period where pronounced differences in<br />

surface and bottom DO levels were observed were over summer months from October through to<br />

March in both 2002 and 2003. In both years these differences were greatest for afternoon readings.<br />

During this period, the afternoon surface water DO levels averaged 7.85 ± 2.04 mg/L compared to the<br />

bottom readings that averaged 3.97 ± 1.37 mg/L. This equates to an average difference in the daily<br />

surface and bottom DO levels of 3.85 ± 2.39 mg/L. Although low over summer, the DO levels at the<br />

floor of the ring tank increased from 4.73 ± 1.06 mg/L in March 2003 to 4.98 ± 0.78 mg/L and 5.73 ±<br />

1.24 mg/L in April and May respectively of that year.<br />

Afternoon DO levels followed the same pattern as morning DO levels but afternoon values were<br />