BALL LOCK ® MOUNTING SYSTEM QUICK CHANGE ... - Jergens Inc.

BALL LOCK ® MOUNTING SYSTEM QUICK CHANGE ... - Jergens Inc.

BALL LOCK ® MOUNTING SYSTEM QUICK CHANGE ... - Jergens Inc.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

www.jergensinc.com<br />

<strong>BALL</strong> <strong>QUICK</strong> <strong>LOCK</strong> ®<br />

<strong>CHANGE</strong> <strong>MOUNTING</strong> FIXTURING <strong>SYSTEM</strong><br />

1<br />

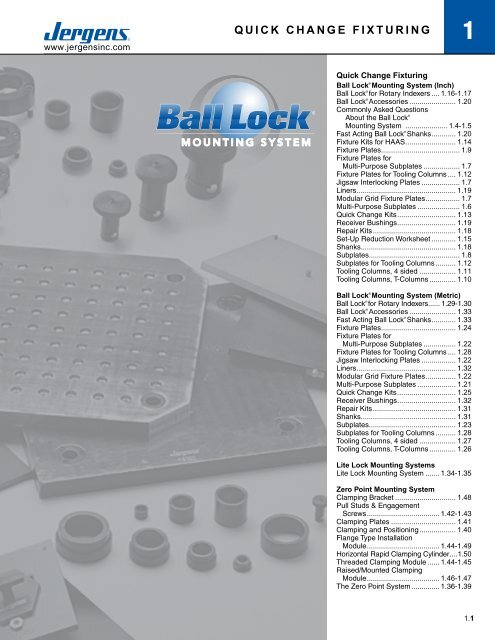

Quick Change Fixturing<br />

Ball Lock ® Mounting System (<strong>Inc</strong>h)<br />

Ball Lock ® for Rotary Indexers..... 1.16-1.17<br />

Ball Lock ® Accessories........................ 1.20<br />

Commonly Asked Questions<br />

About the Ball Lock ®<br />

Mounting System ...................... 1.4-1.5<br />

Fast Acting Ball Lock ® Shanks............. 1.20<br />

Fixture Kits for HAAS.......................... 1.14<br />

Fixture Plates........................................ 1.9<br />

Fixture Plates for<br />

Multi-Purpose Subplates................... 1.7<br />

Fixture Plates for Tooling Columns..... 1.12<br />

Jigsaw Interlocking Plates.................... 1.7<br />

Liners.................................................. 1.19<br />

Modular Grid Fixture Plates.................. 1.7<br />

Multi-Purpose Subplates...................... 1.6<br />

Quick Change Kits.............................. 1.13<br />

Receiver Bushings.............................. 1.19<br />

Repair Kits.......................................... 1.18<br />

Set-Up Reduction Worksheet............. 1.15<br />

Shanks................................................ 1.18<br />

Subplates.............................................. 1.8<br />

Subplates for Tooling Columns........... 1.12<br />

Tooling Columns, 4 sided................... 1.11<br />

Tooling Columns, T-Columns.............. 1.10<br />

Ball Lock ® Mounting System (Metric)<br />

Ball Lock ® for Rotary Indexers...... 1.29-1.30<br />

Ball Lock ® Accessories........................ 1.33<br />

Fast Acting Ball Lock ® Shanks............. 1.33<br />

Fixture Plates...................................... 1.24<br />

Fixture Plates for<br />

Multi-Purpose Subplates................. 1.22<br />

Fixture Plates for Tooling Columns..... 1.28<br />

Jigsaw Interlocking Plates.................. 1.22<br />

Liners.................................................. 1.32<br />

Modular Grid Fixture Plates................ 1.22<br />

Multi-Purpose Subplates.................... 1.21<br />

Quick Change Kits.............................. 1.25<br />

Receiver Bushings.............................. 1.32<br />

Repair Kits.......................................... 1.31<br />

Shanks................................................ 1.31<br />

Subplates............................................ 1.23<br />

Subplates for Tooling Columns........... 1.28<br />

Tooling Columns, 4 sided................... 1.27<br />

Tooling Columns, T-Columns.............. 1.26<br />

Lite Lock Mounting Systems<br />

Lite Lock Mounting System........ 1.34-1.35<br />

Zero Point Mounting System<br />

Clamping Bracket............................... 1.48<br />

Pull Studs & Engagement<br />

Screws..................................... 1.42-1.43<br />

Clamping Plates................................. 1.41<br />

Clamping and Positioning................... 1.40<br />

Flange Type Installation<br />

Module..................................... 1.44-1.49<br />

Horizontal Rapid Clamping Cylinder.....1.50<br />

Threaded Clamping Module....... 1.44-1.45<br />

Raised/Mounted Clamping<br />

Module..................................... 1.46-1.47<br />

The Zero Point System............... 1.36-1.39<br />

Phone 800-537-4367 or +1 216-486-5540 • Fax: +1 216-481-6193 • E-mail: info@jergensinc.com • www.jergensinc.com 1.1

1 <strong>BALL</strong> <strong>LOCK</strong> ® <strong>MOUNTING</strong> <strong>SYSTEM</strong><br />

www.jergensinc.com<br />

We Put It All Together… In Seconds.<br />

Maximize productivity levels and<br />

dramatically increase throughput with<br />

Ball Lock ® .<br />

Looking to realize the full benefits of lean manufacturing? Then<br />

you need the one system that puts it all together, so you can put<br />

it all together…and that’s Ball Lock ® .<br />

Ball Lock ® is the industry’s most popular quick-change, fixturingflexible<br />

mounting system that can be configured to create leanoptimized<br />

solutions for your most demanding needs.<br />

The Ball Lock ® Mounting System is used as a<br />

Quick Change Solution on the following:<br />

• CNC Machines<br />

• Palletized Fixtures<br />

• Stamping<br />

• Fabricating<br />

• Injection Molding<br />

• Packaging Machines<br />

• Assembly Machines<br />

• EDM<br />

• Robotics<br />

• Welding Fixtures<br />

1.2<br />

<strong>Jergens</strong>, <strong>Inc</strong>. • <strong>Jergens</strong> Way • 15700 S. Waterloo Road • Cleveland, Ohio 44110-3898 USA

www.jergensinc.com<br />

<strong>BALL</strong> <strong>LOCK</strong> ®<br />

<strong>MOUNTING</strong> <strong>SYSTEM</strong><br />

1<br />

Lean Manufacturing and Set Up Reduction Applications<br />

Accurately Locate and Lock Fixture Plates to Subplates in Seconds…<br />

With No Indicating Required.<br />

Machining Cast Part<br />

Previous Set Up Method:<br />

Located part with dowel pins, bolted part to tombstone<br />

fixture. Indicated part to zero datum point.<br />

Set Up Using Ball Lock ® System:<br />

Mount parts to fixture plate while machining other<br />

parts. Mount fixture plate to tombstone using Ball<br />

Lock ® shanks. No indicating required because<br />

system provides + 0.0005 (±0.013mm)repeatability.<br />

Previous Set-Up Time:<br />

15 minutes<br />

Set Up Time With Ball Lock ® System:<br />

60 seconds<br />

CNC Machine Base:<br />

Drilling and reaming forged part.<br />

Previous Set Up Method:<br />

Fixture plate located with dowel pins bolted to<br />

machine base. Fixture plate and parts indicated.<br />

Set Up Using Ball Lock ® System:<br />

Parts are pre-mounted on fixture plate, which is<br />

then mounted to machine base using Ball Lock ®<br />

shanks. No need to indicate.<br />

Previous Set Up Time:<br />

7 minutes<br />

Set Up Time with Ball Lock ® System:<br />

60 seconds<br />

CNC Vertical Machining Center<br />

Machining aircraft valve parts<br />

Previous Set Up Method:New Project. New<br />

Machine.No Prior History.<br />

Set Up Using Ball Lock ® System:Using Ball<br />

Lock ® Jig Saw Plate on Multi-Purpose Subplate<br />

enables operator to mount two more vises on<br />

the fixture. No indicating needed.<br />

Previous Set Up Time:<br />

New Set Up.<br />

Set Up Time With Ball Lock ® System:<br />

80 seconds setting up six vises.<br />

Two-Sided Tombstone<br />

Drilling and tapping cylindrical bodies.<br />

Previous Set Up Method:<br />

Fixture located and bolted to tombstone. Had to<br />

be indicated.<br />

Set Up Using Ball Lock ® System:<br />

Fixture plate mounted and located with Ball Lock ®<br />

shanks. No need to indicate.<br />

Previous Set Up Time:<br />

12 minutes<br />

Set Up Time with Ball Lock ® System:<br />

45 seconds<br />

Phone 800-537-4367 or +1 216-486-5540 • Fax: +1 216-481-6193 • E-mail: info@jergensinc.com • www.jergensinc.com 1.3

1 <strong>BALL</strong> <strong>LOCK</strong> ® <strong>MOUNTING</strong> <strong>SYSTEM</strong><br />

www.jergensinc.com<br />

Locates<br />

The Ball Lock ® System accurately positions<br />

your fixtureplate with a repeatability of<br />

±0.0005" (±0.013mm) or better, minimizing<br />

the need to indicate your fixture.<br />

Locks<br />

The Ball Lock ® System securely holds fixture<br />

plates to subplates with up to 20,000 lbs.<br />

(9000 kg) of hold-down force per shank.<br />

The Ball Lock ® Mounting System is designed<br />

to speed the accurate locating and locking<br />

of fixture plates to subplates. The system<br />

consists of three parts: a Locating Shank,<br />

a Liner Bushing, and a Receiver Bushing.<br />

Using the Ball Lock ® Mounting System is<br />

a simple process: Install a subplate with<br />

receiver bushings on your machine table;<br />

add your fixture plate with two locating liner<br />

bushings; then insert two locating shanks<br />

through the liners and into the receiver<br />

bushings to provide accurate location.<br />

2 1 / 2 turns of the set screw in each of the<br />

locating shanks provides positive holding<br />

force. Additional Ball Lock ® Shanks are<br />

inserted through clearance holes in the<br />

fixture plate and set screws tightened for<br />

additional holding force distributed across<br />

the fixture plate.<br />

It is recommended that the use of<br />

the Ball Lock ® Mounting System for<br />

locating and clamping of fixture plates<br />

be incorporated in a systematic<br />

process. All fixture plates should<br />

have two locating points positioned<br />

as far apart as possible. There is no<br />

advantage to having more than two<br />

The Ball Lock ® Mounting System<br />

provides a method of quickly and<br />

accurately locating fixtures onto<br />

machine tables. The Ball Lock ®<br />

Mounting System has done for<br />

machining centers what the Japanese<br />

SMED concept did for presses.<br />

Instead of single minute exchange of<br />

dies, Ball Lock ® provides single minute<br />

exchange of fixtures. Fixtures can<br />

often be exchanged in less than a<br />

minute and with position repeatability<br />

of ±0.0005” (±0.013mm). Fixtures<br />

can be exchanged between different<br />

machines when both are using the<br />

<strong>Jergens</strong> Ball Lock ® Mounting System.<br />

Commonly Asked Questions<br />

Q. What is the Ball Lock ®<br />

Mounting System?<br />

A. It is a means of locating and locking<br />

two flat surfaces together, normally a<br />

fixture plate and a sub-plate.<br />

Q. How does it locate?<br />

A. Similar to locating pins, two Ball<br />

Lock ® shanks (pins) pass through two<br />

precision liner bushings on the fixture<br />

plate and into two precision receiver<br />

bushings on the subplate.<br />

Q. How does it lock?<br />

A. Inside the shank are three balls that<br />

expand into a tapered groove in the<br />

receiver bushing. This action draws<br />

the plates together. The locking balls<br />

are activated by turning a setscrew in<br />

the head of the shank, which pushes<br />

a 4th ball to distribute the clamping<br />

forces between the 3 locking balls.<br />

Q. How many shanks are required<br />

to locate and lock each fixture?<br />

A. Only two shanks, passing through<br />

bushings in the fixture plates, are<br />

required for location. However,<br />

additional shanks passing through<br />

clearance holes in the fixture plate<br />

will provide additional holding force<br />

distributed across the plate.<br />

1.4<br />

<strong>Jergens</strong>, <strong>Inc</strong>. • <strong>Jergens</strong> Way • 15700 S. Waterloo Road • Cleveland, Ohio 44110-3898 USA

www.jergensinc.com<br />

<strong>BALL</strong> <strong>LOCK</strong> ®<br />

<strong>MOUNTING</strong> <strong>SYSTEM</strong><br />

1<br />

Ball Lock ®<br />

Shank<br />

Liner Bushing<br />

Ball Lock ®<br />

Shank<br />

Liner Bushing<br />

Fixture Plate<br />

Fixture Plate<br />

Slip Fit Hole<br />

Socket Head Cap<br />

Screws (3)<br />

Press Fit Hole<br />

Machine<br />

Table or<br />

Subplate<br />

Face Mount<br />

Bushing<br />

Drilled Hole<br />

Subplate<br />

Counter-Bored<br />

Hole<br />

Back Mount Bushing<br />

Mounting Method With<br />

Face Mount Bushing<br />

Mounting Method With<br />

Back Mount Bushing<br />

locating points. If more than two flanged<br />

shanks are required to provide additional<br />

hold- down force, omit liner bushings in<br />

the additional holes in the fixture plate and<br />

allow 0.030" (0.76mm) over the nominal<br />

size. The additional clearance will insure<br />

that these holes have no influence on the<br />

locating holes.<br />

How accurate should positioning be?<br />

The center distance of the receiver bushings<br />

in the machine table, tombstone, or subplate<br />

should be as accurate as possible ±0.0002"<br />

(±0.005mm) recommended. Accurate<br />

location will assure interchangeability of<br />

numerous fixture plates. For accurate<br />

repeatability within ±0.0005" (±0.013mm)<br />

of true position, both liner bushings in the<br />

fixture plate should be primary liners and<br />

the center distance tolerance should be<br />

±0.0002" (±0.005mm). For a slightly looser<br />

fit, repeatability within 0.0015" (0.04mm)<br />

of true position, use one primary and one<br />

secondary liner with a center distance<br />

tolerance of ±0.001" (±0.003mm).<br />

Q. Is there a preferable location for<br />

the liner bushing?<br />

A. System repeatability is improved<br />

if the liners are located at opposite<br />

corners of a rectangular fixture plate.<br />

For consistency, we recommend<br />

locating the liner bushings at top left<br />

and bottom right.<br />

Q. What are the advantages of using<br />

the Ball Lock ® System over the<br />

conventional method of dowel<br />

pins and cap screws?<br />

A. Both locating and locking are<br />

accomplished in the same motion. Ball<br />

Lock ® shanks require only 2.5 turns<br />

to lock a 1/2–13 (M12) screw with ¾"<br />

(18mm) of thread engagement require<br />

10 turns to lock. On CNC machines,<br />

the repeatability of fixture locations<br />

makes indicating of the fixture<br />

unnecessary.<br />

Q. How do I recess the fixtureplate<br />

for a clear surface ?<br />

A. Counterbore the fixture plate to a<br />

diameter large enough to allow easy<br />

removal of the shank.<br />

Note: The thickness of the plate section<br />

under the head of the shank is critical and<br />

must conform to mounting instructions .<br />

Q. What if my plate is thinner than<br />

the recommended thickness?<br />

A. By adjusting the depth of the<br />

counterbore for the receiver bushing<br />

in the subplate, you can still use the<br />

Ball Lock ® System. If there are any<br />

questions on this type of application,<br />

please call 1-800-JERGENS.<br />

Q. Can I use the shanks in a heated<br />

environment?<br />

A. The shank is made of alloy steel,<br />

heat treated to 40-45Rc and should<br />

with stand temperatures up to 400°F.<br />

(200°C).<br />

Note: Thermal expansion of fixture plates<br />

may affect the center distance tolerance<br />

and repeatability.<br />

Phone 800-537-4367 or +1 216-486-5540 • Fax: +1 216-481-6193 • E-mail: info@jergensinc.com • www.jergensinc.com 1.5

1 <strong>BALL</strong> <strong>LOCK</strong> ® <strong>MOUNTING</strong> <strong>SYSTEM</strong><br />

INCH DIMENSIONS<br />

www.jergensinc.com<br />

INCH PRE-MACHINED FIXTURE/SUBPLATES<br />

Multi-Purpose Subplates<br />

40x20 Multi-Purpose Subplate<br />

Part Number Wt. (lbs)<br />

49112 285<br />

The <strong>Jergens</strong> Multi-Purpose Subplate accommodates<br />

a wide variety of fixture plates and vises. This<br />

versatility facilitates using the same VMC for<br />

diverse products in repetitive runs, long and short<br />

batch sizes.<br />

• FreMax 15 Steel or Equivalent<br />

• Thickness: 1 1/4” ±0.005"<br />

• Parallel within 0.001"<br />

28706<br />

28801<br />

49406<br />

28719<br />

28713 or 28715<br />

28727<br />

49112<br />

17.0000<br />

12.0000<br />

17.0000<br />

12.0000<br />

(18) 20MM FACE MOUNT<br />

BUSHINGS<br />

INSTALLED<br />

5/8" BORED HOLE<br />

FOR SINE<br />

FIXTURE KEYS<br />

(2) PLACES<br />

6.0000<br />

12.0000<br />

20<br />

17.0000<br />

(8) 25MM FACE MOUNT<br />

BUSHINGS<br />

INSTALLED<br />

8.0000<br />

8.0000<br />

8.0000<br />

8.0000<br />

40<br />

Fixture Plate Options for Multi-Purpose Subplates – Aluminum or Steel<br />

Number of Fixture Receiver Required Number<br />

Plates/Vises That Mount Bushing Receiver Ball Lock ® of Shanks<br />

Fixture Plate*/Vise Thickness of on Multi-Purpose Center Bushing Shank Required Per<br />

Part Number Fixture Plate Subplate Distance Size Part Number Fixture Plate/Vise<br />

28713 (14 x 14)<br />

Fixture Plate<br />

28715 (16 x 16)<br />

Fixture Plate<br />

28801 (16 x 16)<br />

Modular Grid Plate<br />

28706 Jigsaw<br />

Interlocking Plate<br />

28727 (20 x 20)<br />

Fixture Plate<br />

28719 (20 x 16)<br />

Fixture Plate<br />

49406<br />

6" Jigsaw Base Vise<br />

3/4” 2 12 x 12 20 mm 49601 4<br />

3/4” 2 12 x 12 20 mm 49601 4<br />

1 1/8”** 2 12 x 12 20 mm 49602 4<br />

3/4” 4 8 x 12 20 mm 49601 3<br />

1” 2 17 x 17 25 mm 49612 4<br />

3/4" 1 16 x 12 20 mm 49601 4<br />

3/4" 4 8 x 12 20 mm 49601 3<br />

* See next page for dimensional data on fixture plates. Part numbers shown for aluminum plates, also available in steel.<br />

** Counterbored to 1" at mounting holes.<br />

1.6<br />

<strong>Jergens</strong>, <strong>Inc</strong>. • <strong>Jergens</strong> Way • 15700 S. Waterloo Road • Cleveland, Ohio 44110-3898 USA

www.jergensinc.com<br />

<strong>BALL</strong> <strong>LOCK</strong> ®<br />

<strong>MOUNTING</strong> <strong>SYSTEM</strong><br />

INCH DIMENSIONS<br />

1<br />

Fixture Plates for Multi-Purpose Subplate<br />

14x14x3/4" Fixture Plate<br />

Aluminum Plate<br />

Part Number Wt. (lbs)<br />

28713 14<br />

16x16x3/4" Fixture Plate<br />

Aluminum Plate<br />

Part Number Wt. (lbs)<br />

28715 18<br />

Steel Plate<br />

Part Number Wt. (lbs)<br />

28813 42<br />

Steel Plate<br />

Part Number Wt. (lbs)<br />

28815 55<br />

• Cast Aluminum or FreMax 15 Steel or equivalent<br />

• Thickness: 3/4" ±0.005"<br />

• Parallel within 0.001" Steel<br />

• Mounts to subplates with Ball Lock ® Shank 49601 (20 X 3/4")<br />

16x16 Modular Grid Fixture Plate<br />

Steel Plate<br />

Part Number Wt. (lbs)<br />

28801 80<br />

(2) 20MM<br />

PRIMARY LINERS<br />

• FreMaxINSTALLED<br />

(2) PLACES<br />

15 Steel or equivalent<br />

• Thickness: 1 1/8” ±0.005"<br />

• Parallel within 0.001"<br />

• Mounts to subplates with Ball Lock ®<br />

Shank 49602 (20 x 1")<br />

(2) 20MM<br />

PRIMARY LINERS<br />

INSTALLED<br />

CLEARANCE HOLES<br />

FOR HOLDDOWN<br />

CLEARANCE<br />

12.0000<br />

HOLES<br />

FOR HOLDDOWN<br />

(2) PLACES 16.0000<br />

-0.000<br />

.625 +0.0005 x .25 Deep<br />

COUNTERBORE<br />

1/2-13<br />

TAPPED HOLE<br />

-0.000<br />

.625 +0.0005 x .25 Deep<br />

COUNTERBORE<br />

INCH PRE-MACHINED FIXTURE/SUBPLATES<br />

12.0000<br />

12.0000<br />

Clearance holes for<br />

holddown (2)<br />

places<br />

5/8” Bored hole for<br />

sine fixture keys<br />

(2) places<br />

12.0000<br />

16.0000<br />

1.50<br />

TYP<br />

12.0000<br />

16.0000<br />

1/2-13<br />

TAPPED HOLE<br />

6.000<br />

(2) 20mm Primary<br />

Liners Installed<br />

12.0000<br />

16.0000<br />

1.50<br />

TYP<br />

Jigsaw Interlocking Fixture Plate<br />

Aluminum Steel Plate <strong>Jergens</strong> Vise<br />

Plate Part No Wt. Part No Wt. A B C D P/N<br />

28705 6 - - 7.97 5.97 15.00 6.0000 49401<br />

28706 11 28806 34 9.97 7.97 16.00 8.0000 49402<br />

• Cast Aluminum or FreMax 15 Steel or equivalent<br />

• Thickness: 3/4” ±0.005"<br />

• Parallel within 0.001" Steel<br />

• For use with narrow base 4" or 6" vise models<br />

• Design allows close vise spacing for more parts per run<br />

• Easily mounts to Subplates using the<br />

Ball Lock ® Shank 49601 (20 x 3/4")<br />

• Useful for high density fixturing of small parts<br />

20x20x1" Fixture Plate<br />

Aluminum Plate<br />

Part Number Wt. (lbs)<br />

28727 38<br />

• Cast Aluminum or FreMax 15 Steel or equivalent<br />

• Thickness: 1” ±0.005"<br />

• Parallel within 0.001" Steel<br />

• Mounts to subplates with Ball Lock ® Shank 49612 (25 X 1")<br />

17.0000<br />

Steel Plate<br />

Part Number Wt. (lbs)<br />

28827 114<br />

Clearance<br />

Clearance<br />

hole<br />

hole for<br />

for holddown<br />

17.0000<br />

Clearance holes for<br />

holddown (2) places<br />

5/8” Bored hole<br />

for sine fixture key<br />

(2) places<br />

A<br />

B<br />

(2) 20mm Primary<br />

Liners Installed<br />

12.0000<br />

6.0000<br />

D<br />

8.500<br />

(2) 25mm Primary<br />

Liners Installed<br />

C<br />

Phone 800-537-4367 or +1 216-486-5540 • Fax: +1 216-481-6193 • E-mail: info@jergensinc.com • www.jergensinc.com 1.7

1 <strong>BALL</strong> <strong>LOCK</strong> ® <strong>MOUNTING</strong> <strong>SYSTEM</strong><br />

INCH DIMENSIONS<br />

www.jergensinc.com<br />

Ball Lock ® Standard Subplates<br />

INCH PRE-MACHINED FIXTURE/SUBPLATES<br />

12.0000<br />

6.000<br />

• •<br />

•<br />

• •<br />

•<br />

12.0000<br />

5/8 Bored holes for<br />

sine fixture keys<br />

(2) places<br />

(2) 20mm face mount<br />

bushings installed<br />

• •<br />

•<br />

• •<br />

•<br />

16x16 Subplate<br />

Part Number Wt (lbs)<br />

49101 81<br />

Equipped with four 20mm receiver bushings for use<br />

with 14x14 or 16x16 fixture plates. Ideal for horizontal<br />

machining centers or multiple pallet machining centers.<br />

• Fremax 15 steel plate or equivalent<br />

• Thickness: 1-1/8" ±0.005"<br />

• Parallel within 0.001"<br />

1.600<br />

9.0000 12.5<br />

25x16 Dual Station Subplate<br />

• •<br />

•<br />

• •<br />

•<br />

• •<br />

•<br />

• •<br />

•<br />

• •<br />

•<br />

• •<br />

•<br />

Part Number Wt (lbs)<br />

49111 128<br />

12.0000<br />

11.000<br />

28713 or 28715<br />

16<br />

6.000<br />

5/8 Bored holes for<br />

sine fixture keys<br />

(2) places<br />

(12) 20mm face mount<br />

bushings installed<br />

28711<br />

2.0<br />

• •<br />

•<br />

• •<br />

•<br />

• •<br />

•<br />

• •<br />

•<br />

• •<br />

•<br />

• •<br />

•<br />

49111<br />

6.000<br />

12.0000<br />

Aluminum Steel Plate Number Plate<br />

Plate Part Part of Fixture Width and<br />

Number Number Plates Length<br />

28713 28813 1 14"x14"<br />

28715 28815 1 16"x16"<br />

28711 28811 2 12"x14"<br />

25<br />

Equipped with twelve installed 20mm receiver bushings to<br />

easily locate and mount <strong>Jergens</strong> Standard Fixture Plates:<br />

• Fremax 15 steel plate or equivalent<br />

• Thickness: 1-1/8" ±0.005"<br />

• Parallel within 0.001"<br />

3/4<br />

˚˚˚<br />

˚<br />

5/8 Bored holes for<br />

sine fixture keys<br />

(2) places<br />

(4)1/2 dia. for<br />

mounting to table<br />

(2) 16mm face mount<br />

bushings installed<br />

12.0000<br />

15<br />

˚˚˚<br />

2.50<br />

8.0000 10<br />

2.50<br />

˚<br />

15x10 Bridgeport - Style Subplate<br />

Part Number Wt (lbs)<br />

49121 32<br />

Equipped with four installed 16mm receiver bushings<br />

and 1/2" mounting holes. Used with the Bridgeport style<br />

fixture plates 28731 or 28831.<br />

• Thickness: 3/4" ±0.005"<br />

• Parallel within 0.001"<br />

Ball Lock ® Quick Change Kits include all components needed in a single package. See page 1.13 for details.<br />

1.8<br />

<strong>Jergens</strong>, <strong>Inc</strong>. • <strong>Jergens</strong> Way • 15700 S. Waterloo Road • Cleveland, Ohio 44110-3898 USA

www.jergensinc.com<br />

<strong>BALL</strong> <strong>LOCK</strong> ®<br />

<strong>MOUNTING</strong> <strong>SYSTEM</strong><br />

INCH DIMENSIONS<br />

1<br />

Ball Lock ® Fixture Plates<br />

• Cast Aluminum or FreeMax 15 Steel or equivalent<br />

• Thickness tolerance ±0.005"<br />

• Parallel within 0.001" Steel<br />

• 6061–T-651 Aluminum plates, within .001 available upon request<br />

Aluminum Ball Lock ® Fixture Plates with 2 Primary Liners Installed<br />

Plate Part<br />

Plate Part<br />

Number Weight Number Weight<br />

Aluminum (lbs) Steel (lbs)<br />

Plate<br />

Dimensions<br />

(in.)<br />

Plate<br />

Thickness<br />

(in.)<br />

±.005<br />

Shank Size<br />

Dia. (mm)<br />

Ball Lock ®<br />

Shank<br />

Part<br />

Number<br />

28706 9 28806 34 9.97 x 16 3/4 20 49601<br />

28711 12 28811 36 12 x14 3/4 20 49601<br />

28713 14 28813 42 14 x14 3/4 20 49601<br />

28715 18 28815 55 16 x 16 3/4 20 49601<br />

28722 16 28822 48 12 x 14 1 25 49612<br />

28724 19 28824 56 14 x 14 1 25 49612<br />

28726 24 28826 73 16 x 16 1 25 49612<br />

28719 23 28819 68 20 x 16 3/4 20 49601<br />

28727 38 28827 114 20 x 20 1 25 49612<br />

28731 11 28831 32 15 x 10 3/4 16 49608<br />

– – 28801 80 16 x 16 1 1/8 20 49602<br />

• Machined to close tolerances<br />

• Repeatability ±0.0005" or better<br />

• Reduces fixture set-up and<br />

assembly time<br />

• Provided with 5/8" bored holes for<br />

sine fixture keys<br />

• For horizontal or vertical machining<br />

centers, Tool Room Mills, or<br />

multiple pallet machining centers<br />

INCH PRE-MACHINED FIXTURE/SUBPLATES<br />

Custom Sizes Available<br />

<strong>Jergens</strong> will make Ball Lock ® fixture plate or subplates to your<br />

specifications. Call 1-800-JERGENS for further information.<br />

15x10x3/4" Fixture Plate Bridgeport Style<br />

12x14x3/4" Fixture Plate<br />

Aluminum Plate<br />

Part Number Wt. (lbs)<br />

28731 11<br />

Steel Plate<br />

Part Number Wt. (lbs)<br />

28831 32<br />

Aluminum Plate<br />

Part Number Wt. (lbs)<br />

28711 12<br />

Steel Plate<br />

Part Number Wt. (lbs)<br />

28811 36<br />

9.0000<br />

4.000<br />

Clearance Hole for<br />

Holddown (2) Places<br />

5/8 Bored Holes for<br />

Sine Fixture Keys<br />

(2) Places<br />

(2) 16mm Primary<br />

Liners Installed<br />

8.0000<br />

12.0000<br />

Clearance Hole for<br />

Holddown (2) Places<br />

5/8 Bored holes for<br />

sine fixture keys<br />

(2) places<br />

12.0000<br />

6.000<br />

(2) 20mm Primary<br />

Liners Installed<br />

Phone 800-537-4367 or +1 216-486-5540 • Fax: +1 216-481-6193 • E-mail: info@jergensinc.com • www.jergensinc.com 1.9

1 <strong>BALL</strong> <strong>LOCK</strong> ® <strong>MOUNTING</strong> <strong>SYSTEM</strong><br />

INCH DIMENSIONS<br />

www.jergensinc.com<br />

Ball Lock ® T-Columns<br />

Fixture<br />

Plate<br />

INCH PRE-MACHINED FIXTURE/SUBPLATES<br />

• Class 40 Cast Iron<br />

• Also available in Aluminum<br />

• Ball Lock ® Receiver Bushings and Liner Bushings installed<br />

• Perpendicularity is 0.001" per foot<br />

Custom Sizes Available with or without Ball Lock ®<br />

We are able to quote you on your special requirement<br />

with or without the Ball Lock ® Mounting System.<br />

Call 1-800-JERGENS for design specification information.<br />

Subplate<br />

Tooling<br />

Column<br />

Cast Iron T-Columns With<br />

Ball Lock ® Receiver Bushings Installed<br />

See page 1.12 for Fixture Plates and Subplates<br />

Pallet Part O P Wt.<br />

Size (mm) Number C D E F G H I J K L M N (mm) (mm) (lbs)<br />

400 69101 16.375 1 16 16 14 14 14 14 4 19.875 4.875 3.5 20 20 425<br />

500 69111 22.375 1 20 20 19 17 17 17 4.7 25.875 5.375 3.5 25 25 700<br />

630 69121 26.375 1.5 25 25 23 22 21 21 4 29.875 5.375 3.5 35 25 1125<br />

*Note: Window sections are also available on T-Columns. Specify window size and location (Q and R Dimensions).<br />

Corresponding Fixture Plates, Subplates and Ball Lock ® Shanks<br />

Pallet T-Column Aluminum Steel Fixture Fixture Plate Subplate<br />

Size Part Fixture Plate Fixture Plate Plate Ball Lock ® Shank Shank Subplate Ball Lock ® Shank Shank<br />

(mm) Number Part Number Part Number Size Part Number Size Part Number Part Number Size<br />

400 69101 28717 28817 16 x 16 49601 20mm x 3/4 49102 49602 20mm x 1<br />

500 69111 28745 28845 20 x 22 49612 25mm x 1 49103 49612 25mm x 1<br />

630 69121 28746 28846 25 x 26 49612 25mm x 1 49104 49633 35mm x 1-1/2<br />

Use Hoist Ring 23411, see page 11.8 for lifting and handling – Order separately.<br />

Engineering Changes<br />

Product improvement is a continuing process at <strong>Jergens</strong>. Specifications and engineering data are subject to change<br />

after publishing. Contact <strong>Jergens</strong> Technical Sales Department to verify any dimensions or specifications.<br />

1.10<br />

<strong>Jergens</strong>, <strong>Inc</strong>. • <strong>Jergens</strong> Way • 15700 S. Waterloo Road • Cleveland, Ohio 44110-3898 USA

www.jergensinc.com<br />

<strong>BALL</strong> <strong>LOCK</strong> ®<br />

<strong>MOUNTING</strong> <strong>SYSTEM</strong><br />

INCH DIMENSIONS<br />

1<br />

Ball Lock ® 4-Sided Tooling Columns<br />

• Class 40 Cast Iron<br />

• Also available in Aluminum<br />

• Ball Lock ® Receiver Bushings and Liners installed<br />

• Provides accurate fixturing base for CNC machining centers<br />

• Perpendicularity is 0.001" per foot<br />

Custom Sizes Available with or without Ball Lock ®<br />

We are able to quote you on your special requirement<br />

with or without the Ball Lock ® Mounting System.<br />

Call 1-800-JERGENS for design specification information.<br />

Tooling<br />

Column<br />

Subplate<br />

Fixture<br />

Plate<br />

INCH PRE-MACHINED FIXTURE/SUBPLATES<br />

Cast Iron 4-Sided Tooling Columns With<br />

Ball Lock ® Receiver Bushings Installed<br />

See page 1.12 for Fixture Plates and Subplates<br />

Pallet Part O P Wt.<br />

Size (mm) Number A B C D E F G H I J K L M N (mm) (mm) (lbs)<br />

400 69001 10 10 20 1 16 16 18 6.75 14 14 1.75 23.875 4.875 3.875 20 20 510<br />

500 69011 12 12 25 1 20 20 22 8 17 17 1.625 28.875 5.375 3.875 25 25 736<br />

630 69021 16 16 26 1.5 25 25 23 11.50 21 21 2 29.875 5.375 3.875 35 25 1122<br />

Corresponding Fixture Plates, Subplates and Ball Lock ® Shanks<br />

Pallet T-Column Aluminum Steel Fixture Fixture Plate Subplate<br />

Size Part Fixture Plate Fixture Plate Plate Ball Lock ® Shank Shank Subplate Ball Lock ® Shank Shank<br />

(mm) Number Part Number Part Number Size Part Number Size Part Number Part Number Size<br />

400 69001 28741 28841 10 x 20 49601 20mm x 3/4 49102 49602 20mm x 1<br />

500 69011 28742 28842 12 x 25 49612 25mm x 1 49103 49612 25mm x 1<br />

630 69021 28743 28843 16 x 26 49612 25mm x 1 49104 49633 35mm x 1-1/2<br />

Use Hoist Ring 23411, see page 11.8 for lifting and handling – Order separately.<br />

Engineering Changes<br />

Product improvement is a continuing process at <strong>Jergens</strong>. Specifications and engineering data are subject to change<br />

after publishing. Contact <strong>Jergens</strong> Technical Sales Department to verify any dimensions or specifications.<br />

Phone 800-537-4367 or +1 216-486-5540 • Fax: +1 216-481-6193 • E-mail: info@jergensinc.com • www.jergensinc.com 1.11

1 <strong>BALL</strong> <strong>LOCK</strong> ® <strong>MOUNTING</strong> <strong>SYSTEM</strong><br />

INCH DIMENSIONS<br />

www.jergensinc.com<br />

INCH PRE-MACHINED FIXTURE/SUBPLATES<br />

Subplates For Tooling Columns and Fixture Plates<br />

5/8 Bored holes<br />

for sine fixture<br />

keys (2) places<br />

Receiver<br />

Bushings<br />

Installed<br />

A<br />

5/8 Bored holes<br />

for sine fixture keys<br />

(2) places<br />

Clearance Hole<br />

for Holddown<br />

(2) Places<br />

(2) Primary Liners<br />

Installed<br />

B<br />

Standard Steel Subplates for Tooling Columns<br />

Subplate Mounting holes can be provided per customer specification.<br />

Supplied with Ball Lock ® Receiver Bushings installed.<br />

Ball Lock ® Pattern Receiver Thickness of<br />

Part Pallet Size For Tooling A B Size Subplate Wt<br />

Number (mm) Columns (in.) (in.) (mm) (in.) ±.005 (lbs)<br />

49102 400 69001, 69101 14 14 20 1 1/8 79<br />

49103 500 69011, 69111 17 17 25 1 1/4 137<br />

49103-C* 500 69101, 69001 14/17 14/17 20/25 1 1/4 137<br />

69111, 69011 Dual Dual Dual 1 1/4<br />

49104 630 69021, 69121 21 21 35 1 3/8 240<br />

*49103-C is a dual pattern subplate. Please contact <strong>Jergens</strong> Technical Service at 1-800-<strong>Jergens</strong> for<br />

design specific information.<br />

Fixture Plates for Standard Tooling Columns and T-Columns<br />

Supplied with 2 primary Ball Lock ® Liner Bushings installed.<br />

Fixture Fixture Plate Ball Lock ® Pattern Liner<br />

Pallet Part Number For Tooling Plate Size Thickness H G Size<br />

Size (mm) Aluminum (lbs) Steel (lbs) Columns Type (in.) ±0.005" (In.) (In.) (mm)<br />

400 28741 14 28841 43 69001 4-S 10x20 3/4 6.75 18 20<br />

500 28742 28 28842 85 69011 4-S 12x25 1 8 22 25<br />

630 28743 39 28843 118 69021 4-S 16x26 1 11.50 23 25<br />

400 28717 18 28817 55 69101 T 16x16 3/4 14 14 20<br />

500 28745 41 28845 125 69111 T 20x22 1 17 19 25<br />

630 28746 61 28846 184 69121 T 25x26 1 22 23 25<br />

Clearance Hole<br />

for Holddown<br />

(2) Places<br />

5/8 Bored holes<br />

for sine fixture<br />

keys (2) places<br />

(2) Primary Liners<br />

Installed<br />

J<br />

E<br />

I<br />

F<br />

Fixture Plates for Tooling Column Subplates<br />

Supplied with 2 primary Ball Lock ® Liner Bushings installed.<br />

Ball Lock ®<br />

Pallet Part Number Plate Dim. Fixture Plate Pattern Liner<br />

Size For E F Thickness I J Size<br />

(mm) Aluminum (lbs) Steel (lbs) Subplate (In.) (in.) ±0.005" (In.) (In.) (mm)<br />

400 28717 18 28817 55 49102 16 16 3/4 14 14 20<br />

500 28727 38 28827 114 49103 20 20 1 17 17 25<br />

630 28732 58 28832 177 49104 25 25 1 21 21 35<br />

Difference between Aluminum and Steel<br />

Difference between Aluminum and Steel<br />

(inches)<br />

(inches)<br />

0.00015<br />

0.000125<br />

0.0001<br />

0.000075<br />

0.00005<br />

0.000025<br />

Aluminum and Steel Expansion<br />

(per (per inch) inch)<br />

0 0<br />

0 0 5 5 10 10 15 15 20 20 25 25 30 30<br />

Change in Degrees in F F<br />

NOTE: Aluminum and steel expand at different rates. Please take this information into<br />

consideration when creating your own Ball Lock ® fixture and subplates.<br />

1.12<br />

<strong>Jergens</strong>, <strong>Inc</strong>. • <strong>Jergens</strong> Way • 15700 S. Waterloo Road • Cleveland, Ohio 44110-3898 USA

www.jergensinc.com<br />

<strong>BALL</strong> <strong>LOCK</strong> ®<br />

<strong>MOUNTING</strong> <strong>SYSTEM</strong><br />

INCH DIMENSIONS<br />

1<br />

Quick Change Kits<br />

The <strong>Jergens</strong> Ball Lock ® Quick Change Kits speed fixture changeover in<br />

all types of manufacturing operations. Each kit includes two aluminum<br />

fixture plates with two primary liner bushings installed; one steel<br />

subplate with receiver bushings installed, and four 20mm Ball Lock ®<br />

shanks with working loads of 3000 lbs. each. While one fixture plate is<br />

on the machine, the operator can load parts on the other. This minimizes<br />

downtime for true set-up reduction. To enable the subplate to be<br />

mounted on a slotted table without the need to indicate the subplate,<br />

sine fixture keys can be used. The sine fixture key bored holes are<br />

oriented parallel to the receiver bushings on the subplate and to the<br />

liner bushings on the fixture plate. These also allow the fixture plate<br />

to be mounted on a toolroom mill<br />

without the need to indicate it. This<br />

is extremely useful when machining<br />

location points on your fixture.<br />

INCH PRE-MACHINED FIXTURE/SUBPLATES<br />

Everything You Need to Change Fixtures in Less Than One Minute<br />

Aluminum Fixture Plate<br />

Steel Subplate<br />

5/8" Bored<br />

Hole for Sine<br />

Fixture Keys<br />

5/8" Bored<br />

Hole for Sine<br />

Fixture Keys<br />

Ball Lock ® Shank<br />

Primary Liner<br />

Bushings (2 places)<br />

Receiver<br />

Bushings<br />

(4 places)<br />

Quick Change Kits<br />

Part No. Kit <strong>Inc</strong>ludes<br />

49001 2 - 28713 (14"x14"x3/4") aluminum<br />

fixture plates with 20mm liner<br />

bushings installed<br />

1 - 49101 (16"x16"x1-1/8") steel subplate<br />

with receiver bushings installed<br />

4 - 49601 (20mm) Ball Lock ® Shanks<br />

49002 2 - 28715 (16"x16"x3/4") aluminum<br />

fixture plates with 20mm liner<br />

bushings installed<br />

1 - 49101 (16"x16"x1-1/8") steel subplate<br />

with receiver bushings installed<br />

4 - 49601 (20mm) Ball Lock ® Shanks<br />

49004 Bridgeport-Style<br />

2 - 28731 (10"x15"x3/4") aluminum fixture<br />

plates with 16mm liner bushings<br />

installed<br />

1 - 49121 (10"x15"x3/4") steel subplate<br />

with receiver bushings installed<br />

4 - 49608 (16mm) Ball Lock ® Shanks<br />

Phone 800-537-4367 or +1 216-486-5540 • Fax: +1 216-481-6193 • E-mail: info@jergensinc.com • www.jergensinc.com 1.13

Mounting<br />

System<br />

*HAAS is a trademark of HAAS Automation, <strong>Inc</strong>.<br />

1 <strong>BALL</strong> <strong>LOCK</strong> ® <strong>MOUNTING</strong> <strong>SYSTEM</strong><br />

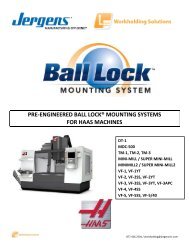

Pre-Engineered Ball Lock ® Fixture Kits for HAAS*<br />

www.jergensinc.com<br />

PRE-MACHINED FIXTURE/SUBPLATES<br />

Ball Lock<br />

Ball Lock ® Mounting System<br />

<strong>Jergens</strong> Introduces Another Piece to the Quick Change Puzzle<br />

Ball Lock ®<br />

Fixture Kits<br />

For HAAS *<br />

HAAS models:<br />

• MINI MILL<br />

• VF-E<br />

• VF-O<br />

• VF-1<br />

• VF-OE<br />

• VF-2<br />

• VF-3<br />

• VF-4<br />

• VF-5<br />

Changes Fixtures in 60 Seconds<br />

Kits for other machine ...or Less<br />

manufacturers available.<br />

Pre-Engineered HAAS Kits<br />

available. PDF Catalog<br />

Available at<br />

www.jergensinc.com<br />

These kits include:<br />

• Steel Subplate with receiver bushings<br />

• Aluminum Fixture Plate(s) with 2 primary liner bushings<br />

• Pre installed receiver and Liner Bushings<br />

• Ball Lock ® Shanks<br />

• T-Slot nuts for mounting subplate to machine table<br />

• 2 Sine Fixture Keys for accurate subplate locating<br />

• Socket head cap screws<br />

Benefits:<br />

• Save time specifying and ordering<br />

• Saves installation time and cost<br />

• Eliminates potential installation errors<br />

Ask about these other machine manufacturers where<br />

Ball Lock ® kits can be utilized.<br />

Call customer support at 1-800-537-4367<br />

Acer<br />

Bridgeport<br />

Brother<br />

Chevalier<br />

Chiron<br />

DMG<br />

Enshu<br />

Excel<br />

Fanuc Robodrill<br />

HAAS<br />

Hardinge<br />

Hitachi<br />

Hitachi Seiki<br />

Hurco<br />

Hyundai-Kia<br />

Johnsford<br />

Kira Mill<br />

Kitamura<br />

Leadwell<br />

MAG<br />

Makino<br />

Matsuura<br />

Mazak<br />

Milltronics<br />

Miyano<br />

Mori-Seiki<br />

OKK<br />

Okuma<br />

Republic Lagun<br />

Toyoda<br />

Tree<br />

YCI<br />

*HAAS is a trademark of HAAS Automation, <strong>Inc</strong>.<br />

1.14<br />

<strong>Jergens</strong>, <strong>Inc</strong>. • <strong>Jergens</strong> Way • 15700 S. Waterloo Road • Cleveland, Ohio 44110-3898 USA

www.jergensinc.com<br />

<strong>BALL</strong> <strong>LOCK</strong> ®<br />

<strong>MOUNTING</strong> <strong>SYSTEM</strong><br />

1<br />

Set-Up Reduction Worksheet<br />

Benefits of Set-Up Reduction (Capacity)<br />

Current Method<br />

Minutes per set-up = minutes<br />

Number of set-ups<br />

per 8 hour shift = set-ups<br />

Total minutes of set-up per shift<br />

(set-up minutes x number of set-ups) = minutes<br />

Using the Ball Lock ® System<br />

Minutes per set-up = minutes<br />

Example (actual case study):<br />

60 minutes<br />

1.5 set-ups<br />

90 minutes<br />

8 minutes<br />

INCH PRE-MACHINED FIXTURE/SUBPLATES<br />

Number of set-ups<br />

per 8 hour shift = set-ups<br />

Total minutes of set-up per shift<br />

(set-up minutes x number of set-ups) = minutes<br />

<strong>Inc</strong>reased capacity per machine per shift<br />

(current method - Ball Lock ® method) = minutes<br />

Savings per machine per shift = minutes<br />

<strong>Inc</strong>reased capacity<br />

(number of minutes / 60) = hours<br />

1.5 set-ups<br />

12 minutes<br />

78 minutes<br />

78 minutes<br />

1.3 hours<br />

Benefits of Set-Up Reduction (Profit)<br />

Machine cost per hour = $ $80.00<br />

<strong>Inc</strong>reased production hours per shift<br />

(increased capacity from above) = hours 1.3 hours<br />

Savings (profit) per machine per shift<br />

(machine cost per hour x increased = $ per machine $104.00 per machine<br />

production hours) per shift per shift<br />

Phone 800-537-4367 or +1 216-486-5540 • Fax: +1 216-481-6193 • E-mail: info@jergensinc.com • www.jergensinc.com 1.15

INCH PRE-MACHINED FIXTURE/SUBPLATES<br />

1 <strong>BALL</strong> <strong>LOCK</strong> ® <strong>MOUNTING</strong> <strong>SYSTEM</strong><br />

INCH DIMENSIONS<br />

Ball Lock ® For 4th Axis Rotary Indexers<br />

Problem:<br />

Rotary indexers increase the versatility of vertical machining<br />

centers, yet they offer one major challenge: set-up is so timeconsuming<br />

that it may limit a machine’s flexibility. In many cases,<br />

machinists dedicate their 4th Axis tool to a single machine to<br />

avoid the agony of an extended set-up and changeover.<br />

Benefits:<br />

• Maximize indexer utilization<br />

• Eliminate lengthy set-ups<br />

• Accurate fixture plate changover in seconds<br />

www.jergensinc.com<br />

Jergen’s Solution:<br />

Ball Lock ® Mounting System for Indexers provides a double<br />

solution.<br />

First, Ball Lock ® mounting plates free up your machine for<br />

additional work by allowing a fast and accurate installation<br />

and removal of the complete indexer. Avoid hours of set up.<br />

The Ball Lock ® System does it in minutes, with repeatability at<br />

±.0005" (±.013mm). Low profile, positive clamping, proven in<br />

over many years of field use.<br />

Second, the Ball Lock ® System provides your fixture plate<br />

changeover. By mounting the round subplate to the indexer<br />

faceplate, you’ll “plug-in” new fixtures in record time<br />

(less than 60 seconds).<br />

Indexer Face Plate<br />

Ball Lock ®<br />

Subplate<br />

Ball Lock ®<br />

Shanks<br />

Ball Lock ®<br />

Fixture Plate<br />

For Holding<br />

Production<br />

Workpiece<br />

Workpiece<br />

Ball Lock ® Fixture Plate<br />

For Mounting Indexer<br />

to Subplate and<br />

Machine Table<br />

Subplates and fixture plates come with bushings pre-installed.<br />

1.16<br />

<strong>Jergens</strong>, <strong>Inc</strong>. • <strong>Jergens</strong> Way • 15700 S. Waterloo Road • Cleveland, Ohio 44110-3898 USA

<strong>BALL</strong> <strong>LOCK</strong> ®<br />

<strong>MOUNTING</strong> <strong>SYSTEM</strong><br />

INCH DIMENSIONS<br />

www.jergensinc.com<br />

Round Ball Lock ® Fixture Plates and Subplates<br />

1<br />

Standard Round<br />

Cast Aluminum, FreeMax or Steel equivalent<br />

Custom Round Plates<br />

Fixture Plate<br />

Part Thickness Ball Lock ® Ball Lock ® Weight<br />

No. A B ±0.005" Liner Shank (lbs)<br />

28707 8" 6" 3/4 16mm 49608 3.5<br />

28708 10" 8" 1 20mm 49602 7.0<br />

28709 12" 10" 1 20mm 49602 11.0<br />

Subplate<br />

Part Thickness Ball Lock ® Center Weight<br />

No. A B ±0.005" Receiver Hole (lbs)<br />

49107 8" 6" 3/4 16mm 1.00" 11.0<br />

49108 10" 8" 1 20mm 2.00" 21.0<br />

49109 12" 10" 1 20mm 2.00" 33.0<br />

Metric sizes also available; please call for information.<br />

INCH PRE-MACHINED FIXTURE/SUBPLATES<br />

Indexer:<br />

Make:<br />

Model:<br />

Diameter:<br />

Light Duty or Heavy Duty:<br />

Through Hole Bore:<br />

CNC Machine:<br />

Make:<br />

Model:<br />

Weight Capacity:<br />

Indexer Faceplate:<br />

T-Slot Size:<br />

Configuration/Orientation:<br />

or<br />

Drilled Tapped Hole Size:<br />

Configuration/Orientation:<br />

Engineering Changes<br />

Product improvement is a continuing process at <strong>Jergens</strong>. Specifications and engineering data are subject to change without notice.<br />

If current information is critical to your design, it is suggested that you contact <strong>Jergens</strong> Technical Sales Department to verify any<br />

dimensions or specifications.<br />

Phone 800-537-4367 or +1 216-486-5540 • Fax: +1 216-481-6193 • E-mail: info@jergensinc.com • www.jergensinc.com 1.17

1 <strong>BALL</strong> <strong>LOCK</strong> ® <strong>MOUNTING</strong> <strong>SYSTEM</strong><br />

INCH DIMENSIONS<br />

www.jergensinc.com<br />

Locating and Clamping Shanks<br />

• Material: Shank/Bushing, 4340<br />

Liner, 52100<br />

• Finish: Black Oxide<br />

• Heat Treat: Shanks, RC 40-45<br />

Bushings, RC 50-54<br />

Liners, RC 62-64<br />

• Operating Temperature Range<br />

-20° to 400°F, -30° to 200°C<br />

D<br />

C<br />

B<br />

Stainless Steel available<br />

A<br />

INCH <strong>BALL</strong> <strong>LOCK</strong> ® COMPONENTS<br />

Ball Lock ® Repair Kits<br />

Each Kit <strong>Inc</strong>ludes:<br />

• Replacement Screw<br />

• Locking Balls<br />

• Drive Ball<br />

• O-Ring<br />

Locating and Clamping Shank Dimensions<br />

Shank<br />

Diameter<br />

(mm)<br />

A<br />

Fixture<br />

Plate<br />

Thickness<br />

± 0.005<br />

Shank<br />

Part<br />

Number<br />

Head of Shank<br />

Height<br />

B<br />

Diameter<br />

C<br />

Length<br />

Under Head<br />

D<br />

Hex Wrench<br />

Size for<br />

Set Screw<br />

Any Ball Lock ® application requires at least two sets of<br />

shanks, receiver bushings and liners. The liners are<br />

placed into the fixture plate to insure extremely accurate<br />

positioning. If more than two shanks are required (to<br />

provide additional hold down force), omit the liner<br />

bushing so that these additional holes will not interfere<br />

with your primary locating holes.<br />

See page 1.20 for Fast Acting Shanks.<br />

Screw<br />

Torque<br />

(Ft/lb)<br />

Maximum<br />

Hold-Down<br />

Force<br />

(lbs)<br />

Recommended<br />

Screw<br />

Torque<br />

(Ft/lb)<br />

Hold-Down<br />

Force<br />

(lbs)<br />

Shank<br />

Repair Kit<br />

Part<br />

Number<br />

13 0.50 49605 0.25 0.87 1.08 3/32 1.2 750 1 625 49905<br />

0.75 49606 1.33 49906<br />

16 0.50 49607 0.32 1.50 1.15 1/8 3 1200 2 800 49907<br />

0.75 49608 1.40 49908<br />

20 0.75 49601 0.38 1.75 1.53 1/8 4 3000 3 2250 49901<br />

1.00 49602 1.78 49902<br />

25 0.75 49611 0.38 2.00 1.70 5/32 9 7000 7 5444 49911<br />

1.00 49612 1.95 49912<br />

30 0.75 49621 0.50 2.25 1.88 3/16 15 10000 12 8000 49921<br />

1.00 49622 2.13 49922<br />

35 0.75 49631 0.50 2.25 1.97 1/4 25 15500 19 11780 49931<br />

1.00 49632 2.22 49932<br />

1.50 49633 2.72 49933<br />

2.00 49634 3.22 49934<br />

50 0.75 49641 0.75 3.00 2.45 3/8 50 20000 38 15200 49941<br />

1.00 49642 2.70 49942<br />

1.50 49643 3.20 49943<br />

2.00 49644 3.70 49944<br />

1.18<br />

<strong>Jergens</strong>, <strong>Inc</strong>. • <strong>Jergens</strong> Way • 15700 S. Waterloo Road • Cleveland, Ohio 44110-3898 USA

www.jergensinc.com<br />

<strong>BALL</strong> <strong>LOCK</strong> ®<br />

<strong>MOUNTING</strong> <strong>SYSTEM</strong><br />

INCH DIMENSIONS<br />

1<br />

Receiver Bushings<br />

Two styles of receiver bushings are available.<br />

Generally, the face mount receiver bushing is<br />

utilized in blind hole applications (Slip Fit).<br />

The back mount receiver bushing is used in<br />

through hole applications (Light Press Fit).<br />

Note: Installed bushings should be approximately<br />

.012" below subplate surface.<br />

See reference below for installation of back mount<br />

style bushings.<br />

Back Mount<br />

Face Mount<br />

Installation Dimensions<br />

Face Mount<br />

Shank<br />

Dia.<br />

(mm)<br />

Face<br />

Mount<br />

Part<br />

Number<br />

Actual<br />

O.D.<br />

+0.0000<br />

-0.0004<br />

Clearance<br />

Drill<br />

Diameter<br />

E<br />

Bore<br />

+0.0005<br />

-0.0000<br />

F<br />

Face Mount Bushing<br />

Installation Instructions<br />

Depth<br />

+0.002<br />

-0.000<br />

G<br />

Tap<br />

Size &<br />

Depth 1<br />

H<br />

13 49506 1.3750 11/16 1.3750 0.469 8-32x5/16 0.984<br />

16 49507 1.4370 13/16 1.4370 0.469 8-32x5/16 1.125<br />

20 49501 1.6873 13/16 1.6873 0.637 10-32x3/8 1.362<br />

25 49502 2.0623 1 2.0623 0.799 1/4-28x1/2 1.644<br />

30 49503 2.2654 1 3/16 2.2654 0.871 1/4-28x3/4 1.876<br />

35 49504 2.6873 1 9/16 2.6873 0.904 5/16-24x7/8 2.178<br />

50 49505 3.4998 2 5/32 3.4998 1.239 3/8-24x1 2.916<br />

Cap Screws Supplied with Face Mount Bushings.<br />

1<br />

Bolt Circle Min.<br />

Diameter Subplate<br />

3 PL Equally Thickness<br />

Spaced D<br />

3/4<br />

3/4<br />

1<br />

1-1/4<br />

1-3/8<br />

1-1/2<br />

2<br />

Back Mount<br />

Shank<br />

Dia.<br />

(mm)<br />

Back Mount Bushing<br />

Installation Instructions<br />

Back<br />

Mount<br />

Part<br />

Number<br />

Actual<br />

O.D.<br />

+0.0000<br />

-0.0004<br />

A<br />

Depth<br />

+0.000<br />

-0.002<br />

B<br />

C-Bore<br />

±0.006<br />

C<br />

13 49516 0.7870 .277 1.000<br />

16 49517 0.8760 .285 1.155<br />

20 49511 1.0950 .345 1.280<br />

25 49512 1.3763 .416 1.593<br />

30 49513 1.6264 .432 1.906<br />

35 49514 1.8764 .493 2.155<br />

50 49515 2.6269 .621 2.988<br />

Min.<br />

Subplate<br />

Thickness<br />

D<br />

3/4<br />

3/4<br />

7/8<br />

1<br />

1-1/4<br />

1-5/16<br />

1-3/4<br />

INCH <strong>BALL</strong> <strong>LOCK</strong> ® COMPONENTS<br />

Liner Bushings for Fixture Plates<br />

Liner Dimensions<br />

Locating repeatability will determine if one primary and one<br />

secondary or two primary liners are needed. With two primary<br />

liners, repeatability of ±.0005" can be maintained if the two<br />

holes for receiver bushings are held to a centerline distance<br />

of ±.0002" tolerance.<br />

Note on Installation of Press Fit Liners &<br />

Back Mount Style Receiver Bushings:<br />

To alleviate the possibility of binding the<br />

shank in the bore, the maximum interference<br />

fit between bore and bushing O.D. should not<br />

exceed .0005".<br />

Fixture Plate<br />

Thickness<br />

±0.005<br />

Shank<br />

Diameter<br />

(mm)<br />

Primary<br />

Liner<br />

Part<br />

Number<br />

Secondary<br />

Liner<br />

Part<br />

Number<br />

Liner O.D.<br />

+0.0000<br />

-0.0004<br />

.50 13 49705 49805 0.7518<br />

.75 13 49706 49806 0.7518<br />

.50 16 49707 49807 1.0018<br />

.75 16 49708 49808 1.0018<br />

.75 20 49701 49801 1.3772<br />

1.00 20 49702 49802 1.3772<br />

.75 25 49711 49811 1.3772<br />

1.00 25 49712 49812 1.3772<br />

.75 30 49721 49821 1.7523<br />

Fixture Plate<br />

Thickness<br />

±0.005<br />

Shank<br />

Diameter<br />

(mm)<br />

Primary<br />

Liner<br />

Part<br />

Number<br />

Secondary<br />

Liner<br />

Part<br />

Number<br />

Liner O.D.<br />

+0.0000<br />

-0.0004<br />

1.00 30 49722 49822 1.7523<br />

.75 35 49731 49831 1.7523<br />

1.00 35 49732 49832 1.7523<br />

1.50 35 49733 49833 1.7523<br />

2.00 35 49734 49834 1.7523<br />

.75 50 49741 49841 2.5025<br />

1.00 50 49742 49842 2.5025<br />

1.50 50 49743 49843 2.5025<br />

2.00 50 49744 49844 2.5025<br />

Phone 800-537-4367 or +1 216-486-5540 • Fax: +1 216-481-6193 • E-mail: info@jergensinc.com • www.jergensinc.com 1.19

1 <strong>BALL</strong> <strong>LOCK</strong> ® <strong>MOUNTING</strong> <strong>SYSTEM</strong><br />

INCH DIMENSIONS<br />

Accessories<br />

www.jergensinc.com<br />

Tapered Caps<br />

and Plugs<br />

Keep debris out<br />

of your subplate’s<br />

receiver bushings<br />

when not in use.<br />

Polyethylene caps<br />

snap in and out easily.<br />

Packaged<br />

10 per<br />

pack.<br />

Receiver<br />

Bushing Part<br />

Diameter Number<br />

13 49201<br />

16 49202<br />

20 49203<br />

25 49204<br />

30 49205<br />

35 49206<br />

50 49207<br />

Lifting Handles<br />

For easy handling of fixture plates up<br />

to 500 lbs.<br />

Part Number Length Ht. W Mounting Distance<br />

33701 4.21 1.42 0.83 3.68<br />

Sine Fixture Keys<br />

INCH <strong>BALL</strong> <strong>LOCK</strong> ® COMPONENTS<br />

Locate subplates or fixture<br />

plates to slotted machine tables<br />

without having to slot the plate.<br />

Available in inch sizes from 1/2"<br />

to 7/8" slots, and in metric sizes<br />

from 14mm to 22mm slots.<br />

NOTE: See page 4.21 for<br />

dimensions.<br />

Fast Acting Ball Lock ® Shanks<br />

B<br />

B<br />

Table<br />

Table Slot<br />

A Slot Size A Size (mm)<br />

Part +0.000 +0.000 Part +0.000 +0.000<br />

Number -0.0005 -0.0005 C Number -0.013 -0.013 C<br />

39501 .625 1/2 1 39562 16 14 1<br />

39502 .625 9/16 1 39563 16 16 1<br />

39503 .625 5/8 1 39564 16 18 1<br />

39504 .625 11/16 1 39565 16 20 1-1/8<br />

39505 .625 3/4 1-1/8 39566 16 22 1-1/8<br />

39506 .625 13/16 1-1/8<br />

39507 .625 7/8 1-1/8<br />

NOTE: All shanks are 5/8" diameter<br />

Fast Acting<br />

Ball Lock ®<br />

Shank<br />

Diameter<br />

(mm)<br />

Fixture<br />

Plate<br />

Thickness<br />

(in.)<br />

<strong>Jergens</strong> Ball Lock ® <strong>Jergens</strong> Ball Lock ®<br />

Shank w/<strong>Jergens</strong><br />

Shank<br />

Thumb Screw<br />

Adjustable Handle<br />

Part Number<br />

Part Number<br />

Assembly T-Screw Assembly Handle<br />

16 1/2 49607-S 43904 49607-H 34314<br />

3/4 49608-S 43904 49608-H 34315<br />

20 3/4 49601-S 43904 49601-H 34315<br />

1 49602-S 43905 49602-H 34316<br />

25 3/4 49611-S 43907 49611-H 34328<br />

1 49612-S 43908 49612-H 34329<br />

30 3/4 49621-S 43910 49621-H 34334<br />

1 49622-S 43911 49622-H 34335<br />

35 3/4 49631-S 43913 49631-H 34339<br />

1 49632-S 43913 49632-H 34339<br />

1-1/2 49633-S 43914 N/A<br />

2 49634-S 43914 N/A<br />

Thumb<br />

Screw<br />

Adjustable<br />

Handle<br />

• Fast acting thumb<br />

screws 2 1/2 turns.<br />

No tools needed.<br />

• Handle can be<br />

moved out of the<br />

work area to avoid<br />

interference.<br />

1.20<br />

<strong>Jergens</strong>, <strong>Inc</strong>. • <strong>Jergens</strong> Way • 15700 S. Waterloo Road • Cleveland, Ohio 44110-3898 USA

www.jergensinc.com<br />

Multi-Purpose Subplate<br />

1000x500 Multi-Purpose Subplate<br />

Part Number Wt. (kg)<br />

59112 130<br />

The <strong>Jergens</strong> Multi-Purpose Subplate<br />

accommodates a wide variety of fixture plates and<br />

vises. This versatility facilitates using the same<br />

VMC for diverse products in repetitive runs-long<br />

and short batch sizes.<br />

<strong>BALL</strong> <strong>LOCK</strong> ®<br />

58706<br />

58801<br />

69406<br />

<strong>MOUNTING</strong> <strong>SYSTEM</strong><br />

METRIC DIMENSIONS<br />

1M<br />

• FreMax TM 15 Steel or Equivalent<br />

• Thickness: 31.75mm ±0.13mm<br />

• Parallel within 0.025mm<br />

58713 or 58715<br />

58727<br />

59112<br />

425 425<br />

300 300<br />

(18) 20MM FACE MOUNT<br />

BUSHINGS I NSTALLED<br />

16MM BORED HOLE<br />

FOR SINE FIXTURE KEYS<br />

(2) PLACES<br />

(8) 25MM FACE MOUNT<br />

BUSHINGS I NSTALLED<br />

Fixture Plate Options for Multi-Purpose Subplates – Aluminum or Steel<br />

1000<br />

Number of Fixture Receiver Required Number<br />

Plates/Vise That Mount Bushing Receiver Ball Lock ® of Shanks<br />

Fixture Plate*/Vise Thickness of on Multi-Purpose Center Bushing Shank Required Per<br />

Part Number Fixture Plate Subplate Distance Size Part Number Fixture Plate/Vise<br />

200<br />

150<br />

300<br />

425<br />

500<br />

METRIC PRE-MACHINED FIXTURE/SUBPLATES<br />

58713 (350 x 350) 20mm 2 300 x 300 20 mm 49651 4<br />

Fixture Plate<br />

58715 (400 x 400) 20mm 2 300 x 300 20 mm 49651 4<br />

Fixture Plate<br />

58801 (400 x 400) 30mm** 2 300 x 300 20 mm 49652 4<br />

Modular Grid Plate<br />

58706 Jigsaw 20mm 4 300 x 200 20 mm 49651 3<br />

Interlocking Plate<br />

58727 (500 x 500) 25mm 2 425 x 425 25 mm 49662 4<br />

Fixture Plate<br />

69406 20mm 4 300 x 200 20 mm 49651 3<br />

150mm Jigsaw Vise<br />

* See next page for dimensional data on fixture plates. Part numbers shown for aluminum plates, also available in steel.<br />

** Counterbored to 25mm at mounting holes.<br />

Phone 800-537-4367 or +1 216-486-5540 • Fax: +1 216-481-6193 • E-mail: info@jergensinc.com • www.jergensinc.com 1.21

1M <strong>BALL</strong> <strong>LOCK</strong> ® <strong>MOUNTING</strong> <strong>SYSTEM</strong><br />

METRIC DIMENSIONS<br />

Fixture Plates for Use on Multi-Purpose Subplate<br />

350x350x20mm Fixture Plate<br />

www.jergensinc.com<br />

400x400 Modular Grid Fixture Plate<br />

Aluminum Plate<br />

Part Number Wt. (kg)<br />

58713 6<br />

Steel Plate<br />

Part Number Wt. (kg)<br />

58813 19<br />

Aluminum Plate<br />

Part Number Wt. (kg)<br />

58801 38<br />

400x400 Fixture Plate<br />

Aluminum Plate<br />

Part Number Wt. (kg)<br />

58715 8<br />

• Cast Aluminum or FreMax 15 Steel or equivalent<br />

• Thickness: 20mm ±0.13mm<br />

• Parallel within 0.025mm Steel<br />

• Mounts to subplates with BallLock ® Shank 49651 (20x20mm)<br />

300<br />

Steel Plate<br />

Part Number Wt. (kg)<br />

58815 25<br />

• FreMax 15 Steel or equivalent<br />

• Thickness: 28.57mm ±0.13mm<br />

• Parallel within 0.025mm Steel<br />

(2) 20MM<br />

PRIMARY LINERS<br />

INSTALLED<br />

CLEARANCE HOLES<br />

FOR HOLDDOWN<br />

(2) PLACES<br />

16MM X 6MM DEEP<br />

COUNTERBORE<br />

M12 X 1.75<br />

TAPPED HOLE<br />

METRIC PRE-MACHINED FIXTURE/SUBPLATES<br />

300<br />

150<br />

CLEARANCE HOLES<br />

FOR HOLDDOWN<br />

(2) PLACES<br />

16MM BORED HOLE<br />

FOR SINE FIXTURE KEYS<br />

(2) PLACES<br />

(2) 20MM<br />

PRIMARY LINERS<br />

INSTALLED<br />

Jigsaw Interlocking FixturePlate<br />

Aluminum Plate<br />

Part Number Wt. (kg)<br />

58706 4<br />

Steel Plate<br />

Part Number Wt. (kg)<br />

58806 12<br />

• Material: Cast Aluminum or FreMax 15 Steel or equivalent<br />

• Thickness: 20mm ±0.13mm<br />

• Parallel within 0.025mm Steel<br />

• For use with narrow base 100mm or 150mm vise models<br />

• Design allows close spacing of vises for more parts per run<br />

• Mounts to Subplates using Ball Lock ® Shank 44651 (20x20mm)<br />

• Useful for high density fixturing<br />

300<br />

400<br />

50<br />

TYP<br />

500x500x25mm Fixture Plate<br />

Aluminum Plate<br />

Part Number Wt. (kg)<br />

58727 17<br />

• Cast Aluminum or FreMax 15 Steel or equivalent<br />

• Thickness: 25mm ±0.13mm<br />

• Parallel within 0.025mm Steel<br />

• Mounts to Subplates using Ball Lock ® Shank 49662 (25x25mm)<br />

500<br />

425<br />

300<br />

400<br />

Mounts to Subplate<br />

with BallLock ® Shank<br />

49652 (20x25mm)<br />

Steel Plate<br />

Part Number Wt. (kg)<br />

58827 48<br />

CLEARANCE HOLE FOR<br />

HOLDDOWN<br />

500 425<br />

CLEARANCE HOLES<br />

FOR HOLDDOWN<br />

(2) PLACES<br />

16MM BORED HOLE<br />

FOR SINE FIXTURE KEYS<br />

(2) PLACES<br />

250<br />

200<br />

(2) 20MM<br />

PRIMARY LINERS<br />

INSTALLED<br />

300<br />

150<br />

200<br />

212.50<br />

(2) 25MM<br />

PRIMARY LINERS<br />

INSTALLED<br />

400<br />

1.22<br />

<strong>Jergens</strong>, <strong>Inc</strong>. • <strong>Jergens</strong> Way • 15700 S. Waterloo Road • Cleveland, Ohio 44110-3898 USA

www.jergensinc.com<br />

<strong>BALL</strong> <strong>LOCK</strong> ®<br />

Pre-Machined Ball Lock ® Steel Subplate<br />

<strong>MOUNTING</strong> <strong>SYSTEM</strong><br />

METRIC DIMENSIONS<br />

1M<br />

400<br />

400 x400 Subplate<br />

300<br />

Part Number Wt. (kg)<br />

59101 37<br />

(4) 20MM<br />

FACE MOUNT BUSHINGS<br />

INSTALLED<br />

Equipped with four 20mm receiver bushings for use with<br />

350x350 or 400x400 (mm) fixture plates. Ideal for horizontal<br />

machining centers or multiple pallet machining centers.<br />

400<br />

300<br />

150<br />

16MM BORED HOLE<br />

FOR SINE FIXTURE KEYS<br />

(2) PLACES<br />

• FreMax 15 steel plate or equivalent<br />

• Thickness: 28.57mm ±0.13mm<br />

• Parallel within 0.025mm<br />

250<br />

25<br />

650<br />

325<br />

650x400 Dual Station Subplate<br />

Part Number Wt. (kg)<br />

59111 58<br />

400<br />

300<br />

150<br />

16MM BORED HOLE<br />

FOR SINE FIXTURE KEYS<br />

(2) PLACES<br />

Aluminum Steel Plate Number Plate<br />

Plate Part Part of Fixture Width and<br />

Number Number Plates Length (mm)<br />

58713 58813 1 350x350<br />

58715 58815 1 400x400<br />

58711 58811 2 300x350<br />

150<br />

300<br />

(12) 20MM<br />

FACE MOUNT BUSHINGS<br />

INSTALLED<br />

Equipped with twelve installed 20mm receiver<br />

bushings to easily locate and mount <strong>Jergens</strong><br />

Standard Fixture Plates.<br />

• Ideal for vertical machining centers<br />

• Thickness: 28.57mm ±0.13mm<br />

• Parallel within 0.025mm<br />

58713 or<br />

58715<br />

58711<br />

59111<br />

METRIC PRE-MACHINED FIXTURE/SUBPLATES<br />

20<br />

˚˚˚<br />

˚<br />

16mm Bored Holes For<br />

Sine Fixture Keys<br />

(2) Places<br />

12mm Dia. For Mounting To<br />

Table (4) Places<br />

(4) 16mm Face Mount<br />

Bushings Installed<br />

300<br />

˚˚˚<br />

63.5<br />

200 250<br />

63.5<br />

˚<br />

250x375 Bridgeport - Style Subplate<br />

Part Number Wt. (kg)<br />

59121 15<br />

Equipped with four installed 16mm receiver bushings and<br />

12mm mounting holes. Used with the Bridgeport style<br />

fixture plates 58731 or 58831.<br />

• Thickness: 19.05mm ±0.13mm<br />

• Parallel within 0.025mm<br />

375<br />

Ball Lock ® Quick Change Kits include all components needed in a single package. See page 1.25 for details.<br />

Phone 800-537-4367 or +1 216-486-5540 • Fax: +1 216-481-6193 • E-mail: info@jergensinc.com • www.jergensinc.com 1.23

1M <strong>BALL</strong> <strong>LOCK</strong> ® <strong>MOUNTING</strong> <strong>SYSTEM</strong><br />

METRIC DIMENSIONS<br />

Ball Lock ® Fixture Plates<br />

• Cast Aluminum; or FreMax 15 Steel or equivalent<br />

• Thickness ±0.13mm<br />

• Parallel within .025mm Steel<br />

• 6061–T-651 plates, flat within 0.03mm available upon request<br />

Ball Lock ® Fixture Plates with 2 Primary Liners Installed<br />

Part Number<br />

Weight<br />

Weight<br />

Aluminum (Kgs) Steel (Kgs)<br />

Plate<br />

Dimensions<br />

(mm)<br />

Plate<br />

Thickness<br />

±0.13(mm)<br />

Ball Lock ®<br />

Shank Size<br />

(mm)<br />

Ball Lock ®<br />

Shank Part<br />

Number<br />

58706 4 58806 12 250 x400 20 20 49651<br />

58711 5 58811 16 300 x350 20 20 49651<br />

58713 6 58813 19 350 x 350 20 20 49651<br />

58715 8 58815 25 400 x 400 20 20 49651<br />

58727 17 58827 48 500 x 500 25 25 49662<br />

58801 38 400 x 400 28.57 20 49652<br />

58731 5 58831 15 375x250 20 16 49657<br />

www.jergensinc.com<br />

• Machined to close tolerances<br />

• Repeatability ±0.013mm or better<br />

• Reduces fixture set-up and<br />

assembly time<br />

• Provided with 16mm bored holes<br />

for sine fixture keys<br />

• For horizontal or vertical<br />

machining centers, Tool Room<br />

Mills machines, or multiple pallet<br />

machining centers<br />

METRIC PRE-MACHINED FIXTURE/SUBPLATES<br />

Custom Sizes Available<br />

<strong>Jergens</strong> will make Ball Lock ® fixture plates or subplates to your<br />

specifications. Call 1-216-486-5540 for further information.<br />

375x250x20mm Fixture Plate Bridgeport Style<br />

Aluminum Plate<br />

Part Number Wt. (kg)<br />

58731 5<br />

Steel Plate<br />

Part Number Wt. (kg)<br />

58831 15<br />

300x350x20mm Fixture Plate<br />

Aluminum Plate<br />

Part Number Wt. (kg)<br />

58711 5<br />

Steel Plate<br />

Part Number Wt. (kg)<br />

58811 16<br />

Clearance Hole For<br />

Holddown (2) Places<br />

300<br />

250<br />

100<br />

16mm Bored Holes For<br />

Sine Fixture Keys<br />

(2) Places<br />

(2) 16mm Primary<br />

Liners Installed<br />

300<br />

375<br />

200<br />

250<br />

350 300<br />

150<br />

Clearance Holes For<br />

Holddown (2) Places<br />

16mm Bored Holes<br />

For Sine Fixture Keys<br />

(2) Places<br />

(2) 20mm Primary<br />

Liners Installed<br />

1.24<br />

<strong>Jergens</strong>, <strong>Inc</strong>. • <strong>Jergens</strong> Way • 15700 S. Waterloo Road • Cleveland, Ohio 44110-3898 USA

www.jergensinc.com<br />

<strong>BALL</strong> <strong>LOCK</strong> ®<br />

<strong>MOUNTING</strong> <strong>SYSTEM</strong><br />

METRIC DIMENSIONS<br />

1M<br />

Quick Change Kits<br />

The <strong>Jergens</strong> Ball Lock ® Quick Change Kits speed fixture changeover in<br />

all types of manufacturing operations. Each kit includes two aluminum<br />

fixture plates with 2 primary liner bushings installed; one steel subplate<br />

with receiver bushings installed, and four 20mm Ball Lock ® shanks<br />

with working loads of 3000 lbs. each. While one fixture plate is on the<br />

machine, the operator can load parts on the other. This minimizes<br />

downtime for true set-up reduction. To enable the subplate to be<br />

mounted on a slotted table without the need to indicate the subplate,<br />

sine fixture keys can be used. The sine fixture key reamed holes are<br />

oriented parallel to the receiver bushings on the subplate and to the<br />

liner bushings on the fixture plate. These also allow the fixture plate<br />

to be mounted on a toolroom mill<br />

without the need to indicate it. This<br />

is extremely useful when machining<br />

location points on your fixture.<br />

Everything You Need to Change Fixtures in Less Than One Minute<br />

Aluminum<br />

Fixture Plate<br />

16mm Bored<br />

Hole for Sine<br />

Fixture Keys<br />

20mm Ball Lock ®<br />

Shank<br />

Quick Change Kits<br />

Part No.<br />

Kit <strong>Inc</strong>ludes<br />

59002 2 - 58715 (400x400x20) aluminum<br />

fixture plates with 20mm liner<br />

bushings installed<br />

1 - 59101 (400x400x25) steel subplate<br />

with receiver bushings installed<br />

4 - 20mm Ball Lock ® Shanks (49651)<br />

METRIC PRE-MACHINED FIXTURE/SUBPLATES<br />

Steel Subplate<br />

16mm Bored<br />

Hole for Sine<br />

Fixture Keys<br />

(2) 20mm Primary Liner<br />

Bushings Installed<br />

(4) 20mm<br />

Receiver<br />

Bushings<br />

Installed<br />

Custom Kits Available<br />

<strong>Jergens</strong> manufactures ready to use kits including<br />

Ball Lock ® subplate and fixture plates.<br />

For a special kit tailored to your CNC machine,<br />

please provide:<br />

Name and Type of Machine __________________<br />

Travel of Machine Table (x, y, z) ______________<br />

Dimensions of Machine Table (x and y) _________<br />

Maximum Weight allowed on Machine Table _____<br />

T-slot Width and Center to Center Distance _____<br />

Phone 800-537-4367 or +1 216-486-5540 • Fax: +1 216-481-6193 • E-mail: info@jergensinc.com • www.jergensinc.com 1.25

1M <strong>BALL</strong> <strong>LOCK</strong> ® <strong>MOUNTING</strong> <strong>SYSTEM</strong><br />

METRIC DIMENSIONS<br />

Pre-Machined Ball Lock ® T-Columns<br />

• Class 40 Cast Iron<br />

• Also available in Aluminum<br />

• Ball Lock ® Receiver Bushings and Liners installed<br />

• Provides accurate fixturing base for CNC machining centers<br />

• Perpendicularity is 0.025 mm per 250 mm<br />

www.jergensinc.com<br />

Fixture<br />

Plate<br />

Custom Sizes Available with or without Ball Lock ®<br />

We are able to quote you on your special requirement<br />

with or without the Ball Lock ® Mounting System.<br />

Call 1-216-486-5540 for design specification information.<br />

Subplate<br />

Tooling<br />

Column<br />

METRIC PRE-MACHINED TOOLING COLUMNS<br />

Cast Iron T-Columns With<br />

Ball Lock ® Receiver Bushings Installed<br />

Pallet Part O P Wt.<br />

Size (mm) Number C D E F G H I J K L M N (mm) (mm) (kg)<br />

400 69151 410 25 400 400 350 350 350 350 100 500 125 90 20 20 190<br />

500 69161 560 25 500 500 475 425 425 425 120 650 137.5 90 25 25 310<br />

630 69171 660 40 630 630 575 550 525 525 100 750 137.5 90 35 25 500<br />

M12<br />

See page 1.28 for Metric Fixture Plates and Subplates<br />

*Note: Window sections are also available on T-Columns. Specify window size and location (Q and R Dimensions).<br />

Corresponding Fixture Plates, Subplates and Ball Lock ® Shanks<br />

Pallet T-Column Aluminum Steel Fixture Fixture Plate Subplate<br />

Size Part Fixture Plate Fixture Plate Plate Ball Lock ® Shank Shank Subplate Ball Lock ® Shank Shank<br />