Your Partner in terms of Drying - Eberl Trocknungsanlagen Gmbh

Your Partner in terms of Drying - Eberl Trocknungsanlagen Gmbh

Your Partner in terms of Drying - Eberl Trocknungsanlagen Gmbh

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Your</strong> <strong>Partner</strong> <strong>in</strong> <strong>terms</strong> <strong>of</strong> Dry<strong>in</strong>g<br />

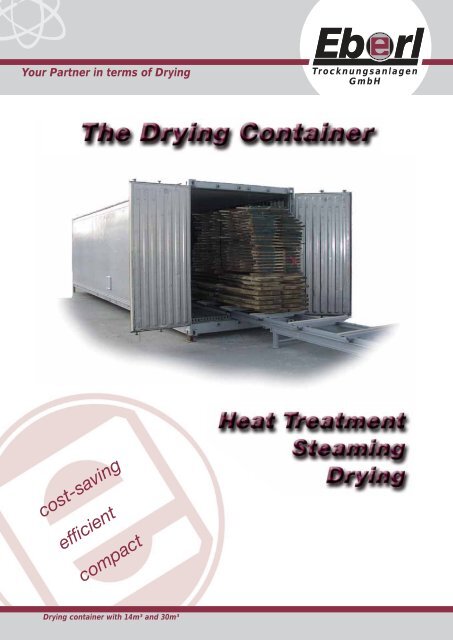

cost-sav<strong>in</strong>g<br />

efficient<br />

compact<br />

Dry<strong>in</strong>g conta<strong>in</strong>er with 14m³ and 30m³<br />

<strong>Trocknungsanlagen</strong><br />

GmbH

is a used <strong>in</strong>sulat<strong>in</strong>g conta<strong>in</strong>er with a l<strong>in</strong><strong>in</strong>g that has been varnished <strong>in</strong> white<br />

alum<strong>in</strong>ium RAL 9006. The <strong>in</strong>terior consists <strong>of</strong> an alum<strong>in</strong>ium section floor, the walls<br />

are made <strong>of</strong> sta<strong>in</strong>less steel. There are four lock<strong>in</strong>g rods at the two-w<strong>in</strong>ged door.<br />

The conta<strong>in</strong>ers hav<strong>in</strong>g lengths <strong>of</strong> 6m and 12m are available <strong>in</strong> different stages <strong>of</strong><br />

expansion:<br />

● As heat treatment conta<strong>in</strong>er HC6 or HC12<br />

For heat treatment purposes for packag<strong>in</strong>g wood accord<strong>in</strong>g to IPPC standard ISPM No. 15 only<br />

● As heat treatment conta<strong>in</strong>er with dehumidification option HC6E or HC12E<br />

For heat treatments and manually controlled dry<strong>in</strong>g procedures<br />

● As dry<strong>in</strong>g conta<strong>in</strong>er TC6 or TC12<br />

In order to dry and steam different types <strong>of</strong> wood and obviously for heat treatments<br />

● Compact system with extraord<strong>in</strong>ary <strong>in</strong>sulation.<br />

● Uniform ventilation due to ideal arrangement <strong>of</strong> the fans and<br />

sufficiently dimensioned space for circulat<strong>in</strong>g air.<br />

● Variable partition walls and a rubber flash<strong>in</strong>g <strong>in</strong> order to avoid air<br />

short circuits.<br />

● Lower energy consumption and good dehumidification performance<br />

due to position<strong>in</strong>g the exhaust air fan and the <strong>in</strong>let air flaps ideally.

is located at the tower immediately next to the energy-efficient fans.<br />

It is available as hot water heat<strong>in</strong>g register and/or as electronic<br />

heat<strong>in</strong>g system. The dry<strong>in</strong>g system can also be operated us<strong>in</strong>g<br />

a heat pump.<br />

is suitable for us<strong>in</strong>g the exhaust heat <strong>of</strong> CHP, biological gas plants,<br />

or other aggregates. Dry<strong>in</strong>g procedures and/or heat treatments<br />

<strong>of</strong> trimmed timber <strong>of</strong> all types, pallets, boxes, firewood, or any similar<br />

types <strong>of</strong> wood are possible.<br />

obviously can also be <strong>in</strong>stalled <strong>in</strong>to exist<strong>in</strong>g build<strong>in</strong>gs or chambers<br />

and are available as adjusted assembly with EBERL.<br />

A PLC from Siemens controls the whole dry<strong>in</strong>g procedure. Hav<strong>in</strong>g<br />

more than 50 programmes for steam<strong>in</strong>g, heat treatments, and dry<strong>in</strong>g<br />

<strong>of</strong> the most different types <strong>of</strong> wood, the climate <strong>in</strong> the chamber is<br />

monitored, controlled, and logged <strong>in</strong> dependency <strong>of</strong> the degree <strong>of</strong><br />

humidity <strong>of</strong> the correspond<strong>in</strong>g wood.<br />

The visualisation allows for start<strong>in</strong>g and monitor<strong>in</strong>g the dry<strong>in</strong>g<br />

procedure and for pr<strong>in</strong>t<strong>in</strong>g out protocols comfortably from the <strong>of</strong>fice.<br />

This also provides for the possibility <strong>of</strong> monitor<strong>in</strong>g the dry<strong>in</strong>g<br />

procedure from home.<br />

The dry<strong>in</strong>g procedure/heat treatment is logged on the memory card<br />

and/or a pr<strong>in</strong>ter and meets all provisions <strong>of</strong> the ISPM No. 15.<br />

The heat treatment is implemented <strong>in</strong> accordance with the provisions<br />

<strong>of</strong> the ISPM No. 15 Germany. In do<strong>in</strong>g so, the wood core temperature<br />

is brought to 56°C and this temperature is ma<strong>in</strong>ta<strong>in</strong>ed for half an hour.

We would be pleased to <strong>in</strong>form you. Please do not hesitate to contact us <strong>in</strong> case <strong>of</strong> any<br />

questions regard<strong>in</strong>g technical details, the dry<strong>in</strong>g procedure, or the energy consumption for<br />

example.<br />

We are at your disposal via mail, phone, or email. We would like to provide you with personal<br />

consultation services.<br />

<strong>Trocknungsanlagen</strong> GmbH<br />

Hauptstr. 57a Phone: 0049 8745 919593<br />

84155 Bodenkirchen, Germany Fax: 0049 8745 919594<br />

www.eberl-trocknungsanlagen.de<br />

eM@il: <strong>in</strong>fo@eberl-trocknungsanlagen.de<br />

EBERL company premises <strong>in</strong> Bodenkirchen, Germany<br />

Type HC6 HC12 HC6E HC12E TC6 TC12<br />

Stack chamber length [m] 5,55 11,6 5,55 11,6 5,55 11,6<br />

Stack chamber width [m] 1,25 1,25 1,25 1,25 1,25 1,25<br />

Stack chamber height [m] 2 2,2 2 2,2 2 2,2<br />

Stack chamber gross volume [m 3 ] 13,9 31,9 13,9 31,9 13,9 31,9<br />

Wood volume at 50% utilisation [m 3 ] 6,9 16,0 6,9 16,0 6,9 16,0<br />

Overall length [m] 6,1 12,2 6,1 12,2 6,1 12,2<br />

Overall width [m] 2,4 2,4 2,4 2,4 2,4 2,4<br />

Overall height [m] 2,6 2,9 2,6 2,9 2,6 2,9<br />

Overall length <strong>in</strong>cl. track [m] 13 25 13 25 13 25<br />

Weight <strong>in</strong>cl. rail and track [kg] 4000 6600 4000 6600 4000 6600<br />

Connected load with electronic heat<strong>in</strong>g system [kW] 23,0 45,0 23,6 46,3 23,6 46,3<br />

Average consumption with electronic heat<strong>in</strong>g system [kW] 19,8 38,6 20,8 40,6 12,1 23,2<br />

Connected load with hot water heat<strong>in</strong>g system [kW] 7,0 13,0 7,6 14,3 7,6 14,3<br />

Average consumption with hot water heat<strong>in</strong>g system [kW] 3,8 6,6 4,1 7,2 4,1 7,2<br />

Boiler connected load [kW] 40 80 40 80 40 80<br />

Boiler average consumption<br />

Technical modifications reserved<br />

[kW] 40 80 40 80 20 40<br />

EBERL dry<strong>in</strong>g conta<strong>in</strong>er – a compact matter