Wiring Diagrams - Docs.hvacpartners.com

Wiring Diagrams - Docs.hvacpartners.com

Wiring Diagrams - Docs.hvacpartners.com

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

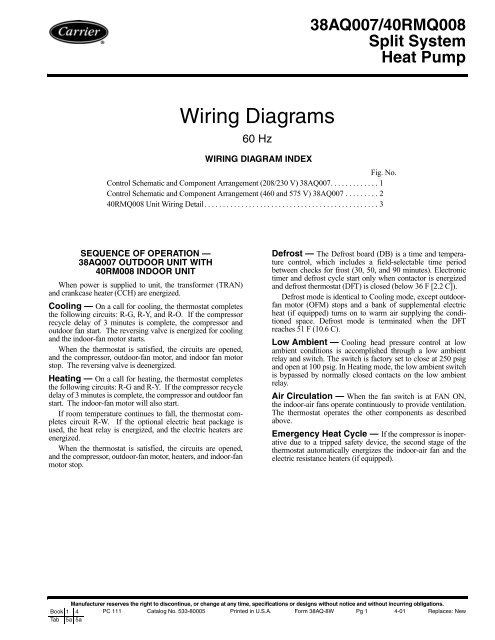

38AQ007/40RMQ008<br />

Split System<br />

Heat Pump<br />

<strong>Wiring</strong> <strong>Diagrams</strong><br />

60 Hz<br />

WIRING DIAGRAM INDEX<br />

Fig. No.<br />

Control Schematic and Component Arrangement (208/230 V) 38AQ007. . . . . . . . . . . . . 1<br />

Control Schematic and Component Arrangement (460 and 575 V) 38AQ007 . . . . . . . . . 2<br />

40RMQ008 Unit <strong>Wiring</strong> Detail. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3<br />

SEQUENCE OF OPERATION —<br />

38AQ007 OUTDOOR UNIT WITH<br />

40RM008 INDOOR UNIT<br />

When power is supplied to unit, the transformer (TRAN)<br />

and crankcase heater (CCH) are energized.<br />

Cooling — On a call for cooling, the thermostat <strong>com</strong>pletes<br />

the following circuits: R-G, R-Y, and R-O. If the <strong>com</strong>pressor<br />

recycle delay of 3 minutes is <strong>com</strong>plete, the <strong>com</strong>pressor and<br />

outdoor fan start. The reversing valve is energized for cooling<br />

and the indoor-fan motor starts.<br />

When the thermostat is satisfied, the circuits are opened,<br />

and the <strong>com</strong>pressor, outdoor-fan motor, and indoor fan motor<br />

stop. The reversing valve is deenergized.<br />

Heating — On a call for heating, the thermostat <strong>com</strong>pletes<br />

the following circuits: R-G and R-Y. If the <strong>com</strong>pressor recycle<br />

delay of 3 minutes is <strong>com</strong>plete, the <strong>com</strong>pressor and outdoor fan<br />

start. The indoor-fan motor will also start.<br />

If room temperature continues to fall, the thermostat <strong>com</strong>pletes<br />

circuit R-W. If the optional electric heat package is<br />

used, the heat relay is energized, and the electric heaters are<br />

energized.<br />

When the thermostat is satisfied, the circuits are opened,<br />

and the <strong>com</strong>pressor, outdoor-fan motor, heaters, and indoor-fan<br />

motor stop.<br />

Defrost — The Defrost board (DB) is a time and temperature<br />

control, which includes a field-selectable time period<br />

between checks for frost (30, 50, and 90 minutes). Electronic<br />

timer and defrost cycle start only when contactor is energized<br />

and defrost thermostat (DFT) is closed (below 36 F [2.2 C]).<br />

Defrost mode is identical to Cooling mode, except outdoorfan<br />

motor (OFM) stops and a bank of supplemental electric<br />

heat (if equipped) turns on to warm air supplying the conditioned<br />

space. Defrost mode is terminated when the DFT<br />

reaches 51 F (10.6 C).<br />

Low Ambient — Cooling head pressure control at low<br />

ambient conditions is ac<strong>com</strong>plished through a low ambient<br />

relay and switch. The switch is factory set to close at 250 psig<br />

and open at 100 psig. In Heating mode, the low ambient switch<br />

is bypassed by normally closed contacts on the low ambient<br />

relay.<br />

Air Circulation — When the fan switch is at FAN ON,<br />

the indoor-air fans operate continuously to provide ventilation.<br />

The thermostat operates the other <strong>com</strong>ponents as described<br />

above.<br />

Emergency Heat Cycle — If the <strong>com</strong>pressor is inoperative<br />

due to a tripped safety device, the second stage of the<br />

thermostat automatically energizes the indoor-air fan and the<br />

electric resistance heaters (if equipped).<br />

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.<br />

Book 1 4 PC 111 Catalog No. 533-80005 Printed in U.S.A. Form 38AQ-8W Pg 1 4-01 Replaces: New<br />

Tab 5a 5a

LOW AMBIENT<br />

SWITCH<br />

BL<br />

3<br />

LOW 1<br />

AMBIENT<br />

RELAY<br />

COIL<br />

CONNECTION DIAGRAM<br />

2<br />

BK<br />

R<br />

BL<br />

PL<br />

G<br />

BL (WHEN<br />

USED)<br />

PRI<br />

TRANS<br />

SEC<br />

CAP<br />

BL BR<br />

BK BR R<br />

FM<br />

T3 T2<br />

COMP<br />

T1<br />

R<br />

R<br />

BL<br />

R<br />

BK<br />

R<br />

BL<br />

BL<br />

BL<br />

T3<br />

T2<br />

T1<br />

DEFROST Y-RV<br />

CONTROL<br />

FAN<br />

R-RV<br />

O<br />

R<br />

COIL<br />

BK<br />

R<br />

DANGER: ELECTRICAL SHOCK HAZARD<br />

DISCONNECT POWER BEFORE SERVICING<br />

R<br />

L3<br />

L2<br />

L1<br />

C<br />

O<br />

BL<br />

RV<br />

CC<br />

PS2<br />

PS1<br />

DF<br />

BK<br />

Y<br />

W<br />

W<br />

Y<br />

O<br />

L2<br />

BK<br />

L1<br />

CCH<br />

BK<br />

BK<br />

BL<br />

BL<br />

Y<br />

Y<br />

BK<br />

BK<br />

L3<br />

RV<br />

COIL<br />

SEN<br />

POWER SUPPLY PER<br />

N.E.C. AND LOCAL<br />

CODES 208/230 VAC,<br />

60 HZ, 3 PH.<br />

GROUND EQUIPMENT<br />

PER N.E.C. AND<br />

LOCAL CODES.<br />

ATTACH GROUND<br />

PS2<br />

PS1<br />

LP/HP<br />

LP/HP<br />

TWO SWITCH WIRING<br />

DEFROST HEAT<br />

COMPRESSOR<br />

HEAT/COOL<br />

COMMON<br />

24 VAC<br />

L3<br />

T3<br />

RESET<br />

+t°<br />

CONTACTOR<br />

LADDER<br />

FAN<br />

Y-RV<br />

RV<br />

DIAGRAM<br />

208/230 VAC, 60 HZ, 3 PH POWER SUPPLY<br />

T3<br />

CAP<br />

FM<br />

COMPRESSOR<br />

T1 L1<br />

CONT.<br />

RV<br />

COIL<br />

C<br />

CC<br />

DEFROST<br />

COIL<br />

CONTROL PS2<br />

R-<br />

RV<br />

208/230V<br />

24V<br />

CONTACTOR<br />

T2<br />

T1<br />

CCH<br />

PS1<br />

DF<br />

R C O Y W<br />

LAR<br />

1<br />

L2<br />

T2<br />

LAS<br />

2<br />

LOW AMBIENT<br />

RELAY<br />

LP/HP<br />

SEN<br />

DFC<br />

FAN<br />

(WHEN<br />

USED)<br />

TRANSFORMER NOTE 4<br />

DEFROST HEAT<br />

COMPRESSOR<br />

HEAT/COOL<br />

COMMON<br />

24 VAC<br />

LEGEND<br />

C — Contactor LP — Low-Pressure Switch<br />

CAP — Capacitor PL — Plug<br />

CCH — Crankcase Heater PS — Pressure Switch<br />

COMP — Compressor RV — Reversing Valve<br />

DFC — Defrost Control TRANS — Transformer<br />

DFR — Defrost Relay Factory Power <strong>Wiring</strong><br />

FM — Fan Motor Factory Control <strong>Wiring</strong><br />

HP — High-Pressure Switch Field Control <strong>Wiring</strong><br />

LAS — Low Ambient Switch Field Power <strong>Wiring</strong><br />

LAR — Low Ambient Relay<br />

NOTES:<br />

1. Factory wiring is in accordance with National Electrical Code (NEC). Field<br />

modifications or additions must be in <strong>com</strong>pliance with all applicable codes.<br />

2. Use copper conductors only.<br />

3. CAUTION: Not suitable for use on systems exceeding 150 volts to ground.<br />

4. Manual reset circuit breaker is integeral to the transformer.<br />

Fig. 1 — Control Schematic and Component Arrangement — 38AQ007 (208/230 V)<br />

2

BL<br />

R<br />

LOW AMBIENT<br />

SWITCH<br />

3<br />

LOW 1<br />

AMBIENT<br />

RELAY<br />

COIL<br />

CONNECTION DIAGRAM<br />

2<br />

BL<br />

PL<br />

G<br />

CAP<br />

BL BR<br />

BK BR R<br />

FM<br />

R<br />

BL<br />

PRI<br />

TRANS<br />

SEC<br />

BL<br />

BL<br />

R<br />

BK<br />

COIL<br />

FAN<br />

3<br />

1<br />

DEFROST<br />

RELAY<br />

R<br />

BL<br />

2<br />

R-RV<br />

O<br />

R<br />

T3 T2<br />

COMP<br />

T1<br />

DANGER: ELECTRICAL SHOCK HAZARD<br />

DISCONNECT POWER BEFORE SERVICING<br />

BK<br />

Y<br />

DEFROST<br />

CONTROL<br />

R<br />

BK<br />

C<br />

O<br />

BL<br />

R<br />

Y-RV<br />

RV<br />

CC<br />

PS2<br />

PS1<br />

DF<br />

T3<br />

T2<br />

T1<br />

Y<br />

COIL<br />

W<br />

W<br />

Y<br />

O<br />

LEGEND<br />

C — Contactor LP — Low-Pressure Switch<br />

CAP — Capacitor PL — Plug<br />

CCH — Crankcase Heater PS — Pressure Switch<br />

COMP — Compressor RV — Reversing Valve<br />

DFC — Defrost Control TRANS — Transformer<br />

DFR — Defrost Relay Factory Power <strong>Wiring</strong><br />

FM — Fan Motor Factory Control <strong>Wiring</strong><br />

HP — High-Pressure Switch Field Control <strong>Wiring</strong><br />

LAS — Low Ambient Switch Field Power <strong>Wiring</strong><br />

LAR — Low Ambient Relay<br />

L3<br />

L2<br />

L1<br />

BK<br />

BK<br />

BL<br />

BL<br />

Y<br />

Y<br />

BK<br />

BK<br />

L2<br />

BK<br />

L1<br />

ATTACH<br />

BK<br />

GROUND<br />

RV<br />

COIL<br />

SEN<br />

NOTES:<br />

1. Factory wiring is in accordance with National Electrical Code (NEC). Field<br />

modifications or additions must be in <strong>com</strong>pliance with all applicable codes.<br />

2. Use copper conductors only.<br />

3. CAUTION: Not suitable for use on systems exceeding 150 volts to ground.<br />

4. Manual reset circuit breaker is integeral to the transformer.<br />

Y<br />

BL<br />

R<br />

575/460 VAC<br />

60 HZ 3PH<br />

L3<br />

CCH<br />

PS2<br />

PS1<br />

LP/HP<br />

LP/HP<br />

TWO SWITCH WIRING<br />

DEFROST HEAT<br />

COMPRESSOR<br />

HEAT/COOL<br />

COMMON<br />

24 VAC<br />

L3<br />

T3<br />

RESET<br />

T3<br />

CAP<br />

FM<br />

24V<br />

LADDER DIAGRAM<br />

575/460 VAC 60 HZ 3PH<br />

T2<br />

T1<br />

COMPRESSOR<br />

DFR<br />

RV<br />

Y-RV<br />

COIL<br />

FAN<br />

RV<br />

C<br />

DEFROST CC<br />

COIL<br />

CONTROL PS2<br />

R-<br />

RV<br />

+t°<br />

CONTACTOR<br />

575/460V<br />

CCH<br />

CONTACTOR<br />

PS1<br />

DF<br />

R C O Y W<br />

LAR<br />

L2<br />

T2<br />

LAS<br />

1 2 3<br />

LOW AMBIENT<br />

RELAY<br />

TRANSFORMER NOTE 4<br />

Fig. 2 — Control Schematic and Component Arrangement — 38AQ007 (460 and 575 V)<br />

T1 L1<br />

CONT.<br />

LP/HP<br />

SEN<br />

1<br />

DEFROST<br />

RELAY<br />

DEFROST HEAT<br />

COMPRESSOR<br />

HEAT/COOL<br />

COMMON<br />

24 VAC<br />

3

LEGEND<br />

IFC — Indoor-Fan Contactor Factory <strong>Wiring</strong><br />

IFM — Indoor-Fan Motor Field Control <strong>Wiring</strong><br />

TB — Terminal Block<br />

TSTAT — Thermostat<br />

NOTES:<br />

1. Factory wiring is in accordance with National Electrical Code (NEC). Field<br />

modifications or additions must be in <strong>com</strong>pliance with all applicable codes.<br />

2. Use copper conductors only.<br />

Fig. 3 — 40RMQ008 <strong>Wiring</strong> Detail<br />

Copyright 2001 Carrier Corporation<br />

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.<br />

Book 1 4 PC 111 Catalog No. 533-80005 Printed in U.S.A. Form 38AQ-8W Pg 4 4-01 Replaces: New<br />

Tab 5a 5a