THIS IS HOW THE PATH IS BUILT - Odebrecht Informa

THIS IS HOW THE PATH IS BUILT - Odebrecht Informa

THIS IS HOW THE PATH IS BUILT - Odebrecht Informa

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

involve more than 30 conditions required by environmental<br />

permits. These measures include conserving<br />

natural resources, social/environmental and archeological<br />

issues, environmental quality, and programs<br />

directly related to the work on the terminal building, in<br />

addition to social responsibility initiatives undertaken in<br />

the communities surrounding the port terminal.<br />

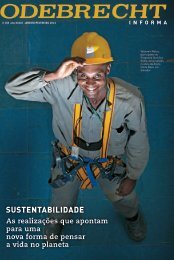

Pedro Brito (left) during a visit to the<br />

jobsite at the Port of Santos. With him,<br />

from left, are Rodrigo Leite, CFO of<br />

Embraport, Alexandrino de Alencar,<br />

Responsible for Business Development<br />

and Institutional Support at <strong>Odebrecht</strong><br />

Infraestrutura, and Project Director<br />

Henrique Marchesi, also from <strong>Odebrecht</strong><br />

Infraestrutura: essential investments in<br />

port logistics<br />

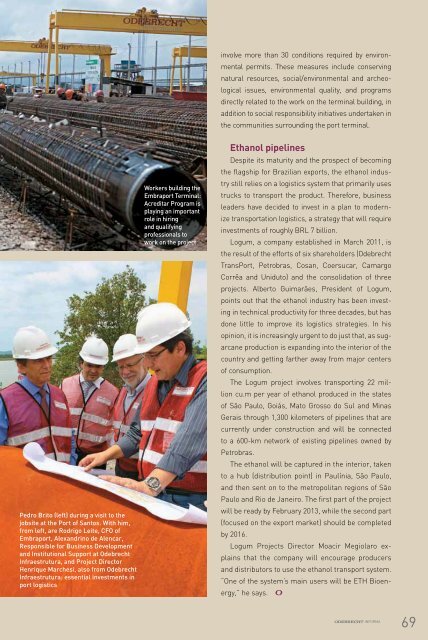

Workers building the<br />

Embraport Terminal:<br />

Acreditar Program is<br />

playing an important<br />

role in hiring<br />

and qualifying<br />

professionals to<br />

work on the project<br />

Ethanol pipelines<br />

Despite its maturity and the prospect of becoming<br />

the flagship for Brazilian exports, the ethanol industry<br />

still relies on a logistics system that primarily uses<br />

trucks to transport the product. Therefore, business<br />

leaders have decided to invest in a plan to modernize<br />

transportation logistics, a strategy that will require<br />

investments of roughly BRL 7 billion.<br />

Logum, a company established in March 2011, is<br />

the result of the efforts of six shareholders (<strong>Odebrecht</strong><br />

TransPort, Petrobras, Cosan, Coersucar, Camargo<br />

Corrêa and Uniduto) and the consolidation of three<br />

projects. Alberto Guimarães, President of Logum,<br />

points out that the ethanol industry has been investing<br />

in technical productivity for three decades, but has<br />

done little to improve its logistics strategies. In his<br />

opinion, it is increasingly urgent to do just that, as sugarcane<br />

production is expanding into the interior of the<br />

country and getting farther away from major centers<br />

of consumption.<br />

The Logum project involves transporting 22 million<br />

cu.m per year of ethanol produced in the states<br />

of São Paulo, Goiás, Mato Grosso do Sul and Minas<br />

Gerais through 1,300 kilometers of pipelines that are<br />

currently under construction and will be connected<br />

to a 600-km network of existing pipelines owned by<br />

Petrobras.<br />

The ethanol will be captured in the interior, taken<br />

to a hub (distribution point) in Paulínia, São Paulo,<br />

and then sent on to the metropolitan regions of São<br />

Paulo and Rio de Janeiro. The first part of the project<br />

will be ready by February 2013, while the second part<br />

(focused on the export market) should be completed<br />

by 2016.<br />

Logum Projects Director Moacir Megiolaro explains<br />

that the company will encourage producers<br />

and distributors to use the ethanol transport system.<br />

“One of the system’s main users will be ETH Bioenergy,”<br />

he says.<br />

informa<br />

69