Polski Koncern Naftowy - PKN Orlen

Polski Koncern Naftowy - PKN Orlen

Polski Koncern Naftowy - PKN Orlen

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

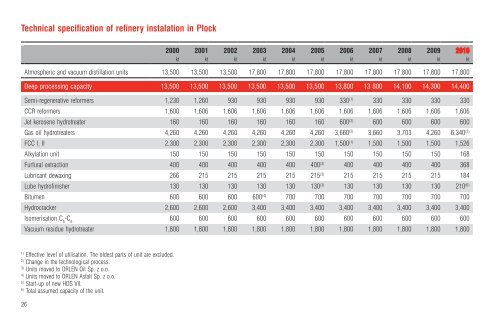

Technical specification of refinery instalation in Płock<br />

2000 2001 2002 2003 2004 2005 2006 2007 2008 2009 2010<br />

kt kt kt kt kt kt kt kt kt kt kt<br />

Atmospheric and vacuum distillation units 13,500 13,500 13,500 17,800 17,800 17,800 17,800 17,800 17,800 17,800 17,800<br />

Deep processing capacity 13,500 13,500 13,500 13,500 13,500 13,500 13,800 13 800 14,100 14,300 14,400<br />

Semi-regenerative reformers 1,230 1,260 930 930 930 930 330 (1) 330 330 330 330<br />

CCR reformers 1,600 1,606 1,606 1,606 1,606 1,606 1,606 1,606 1,606 1,606 1,606<br />

Jet kerosene hydrotreater 160 160 160 160 160 160 600 (2) 600 600 600 600<br />

Gas oil hydrotreaters 4,260 4,260 4,260 4,260 4,260 4,260 3,660 (2) 3,660 3,703 4,260 6,340 (5)<br />

FCC I, II 2,300 2,300 2,300 2,300 2,300 2,300 1,500 (1) 1,500 1,500 1,500 1,526<br />

Alkylation unit 150 150 150 150 150 150 150 150 150 150 168<br />

Furfural extraction 400 400 400 400 400 400 (3) 400 400 400 400 368<br />

Lubricant dewaxing 266 215 215 215 215 215 (3) 215 215 215 215 184<br />

Lube hydrofinisher 130 130 130 130 130 130 (3) 130 130 130 130 210 (6)<br />

Bitumen 600 600 600 600 (4) 700 700 700 700 700 700 700<br />

Hydrocracker 2,600 2,600 2,600 3,400 3,400 3,400 3,400 3,400 3,400 3,400 3,400<br />

Isomerisation C 5<br />

-C 6<br />

600 600 600 600 600 600 600 600 600 600 600<br />

Vacuum residue hydrotreater 1,800 1,800 1,800 1,800 1,800 1,800 1,800 1,800 1,800 1,800 1,800<br />

1)<br />

Effective level of utilisation. The oldest parts of unit are excluded.<br />

2)<br />

Change in the technological process.<br />

3)<br />

Units moved to ORLEN Oil Sp. z o.o.<br />

4)<br />

Units moved to ORLEN Asfalt Sp. z o.o.<br />

5)<br />

Start-up of new HDS VII.<br />

6)<br />

Total assumed capacity of the unit.<br />

26<br />

Technical specification of petrochemical instalation in Płock<br />

2000 2001 2002 2003 2004 2005 2006 2007 2008 2009 2010<br />

kt kt kt kt kt kt kt kt kt kt kt<br />

Acetone 29 29 29 29 29 32 32 32 32 32 32<br />

Benzene / PGH-2 115 115 115 115 115 256 (1) 256 256 256 256 240<br />

Butadiene 55 55 55 55 55 55 60 60 69 (6) 69 69<br />

Aromatic petrochemicals 480 480 480 480 480 550 (2) 550 550 550 550 550<br />

MTBE (Methyl Tert Butyl Ether) 100 120 120 120 120 115 (3) 115 115 115 115 115<br />

Phenol 45 45 45 45 45 51 51 51 51 51 51<br />

Glycols 105 106 106 106 106 106 106 106 106 106 (8) 88<br />

Olefins 360 360 360 360 360 700 (4) 700 700 700 700 700<br />

Paraxylene 32 32 32 32 32 32 32 32 32 – (7) –<br />

Ethylene oxide 100 105 105 105 105 105 105 105 105 105 (9) 85<br />

Pyrolitic gasoline hydrogenation 288 270 270 270 270 523 (5) 523 523 523 523 523<br />

1)<br />

Unit was stopped in May 2005. From first half of 2005 the unit works as 2nd level of pyrolitic gasoline hydrogenetion (PGH-2). From 2005 BT fraction production (benzene-toluene).<br />

2)<br />

Modernisation of Aromatic extraction instalation in 2005. Capacity in terms of benzene production is 178 kt.<br />

3)<br />

Production of EETB (ethyl-tert-butiric ester).<br />

4)<br />

Ethylene production 700 kt pa and propylene production 485 kt pa (Including FCC – Fluid Catalytic Cracker).<br />

5)<br />

Modernisation finalized by mid July 2005.<br />

6)<br />

Intensification of instalation in July 2008.<br />

7)<br />

Instalation stopped in December 2008.<br />

8)<br />

In September 2009 Ethylene Oxide I instalation was stopped. Capacity decreased to 77 kt.<br />

9)<br />

In August 2009 Glycols Oxide I instalation was stopped. Capacity decreased to 85 kt.<br />

27