HND FOOD TECH - Governing Council - Yaba College of Technology

HND FOOD TECH - Governing Council - Yaba College of Technology

HND FOOD TECH - Governing Council - Yaba College of Technology

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

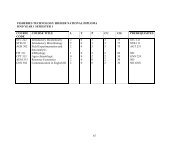

HIGHER NATIONAL DIPLOMA<br />

<strong>FOOD</strong> <strong>TECH</strong>NOLOGY<br />

FIRST SEMESTER<br />

Course Code Course Title L T P CU CH Prerequisite<br />

FST 311<br />

FUEL COMBUSTION AND STEAM GENERATION<br />

2<br />

-<br />

-<br />

2<br />

30<br />

FST 312<br />

<strong>FOOD</strong> QUALITY CONTROL (STATISTICS) 11<br />

2<br />

-<br />

-<br />

-<br />

30<br />

FST 313<br />

UNIT OPERATIONS I<br />

2<br />

-<br />

3<br />

3<br />

75<br />

FST 314<br />

ADVANCED <strong>FOOD</strong> CHEMISTRY<br />

2<br />

-<br />

3<br />

3<br />

75<br />

FST 315<br />

<strong>FOOD</strong> PLANT SANITATION<br />

1<br />

-<br />

-<br />

1<br />

15<br />

FST 316<br />

<strong>FOOD</strong> AND NUTRITION<br />

1<br />

-<br />

2<br />

2<br />

45<br />

GLT 321<br />

BIOLOGICAL AND CHEMICAL<br />

INSTRUMENTATION<br />

1<br />

-<br />

4<br />

3<br />

75<br />

COM 311<br />

OPERATING SYSTEM 1<br />

2<br />

-<br />

1<br />

2<br />

45<br />

GNS 311<br />

COMMUNICATION IN ENGLISH 1<br />

2<br />

-<br />

-<br />

2<br />

30<br />

18 420<br />

GLT: General Laboratory Techniques<br />

GNS: General Studies Syllabus<br />

. COM: Computer Science<br />

112

HIGHER NATIONAL DIPLOMA<br />

<strong>FOOD</strong> <strong>TECH</strong>NOLOGY<br />

SECOND SEMESTER<br />

Course<br />

Code<br />

Course Title L T P CU CH Prerequisite<br />

FST 321<br />

FST 322<br />

<strong>FOOD</strong> QUALITY CONTROL (PLANT PRODUCTS)<br />

<strong>FOOD</strong> QUALITY CONTROL [PLANT PRODUCTS]<br />

2<br />

2<br />

-<br />

-<br />

6<br />

4<br />

4<br />

4<br />

120<br />

90<br />

FST 323<br />

UNIT OPERATIONS II<br />

1<br />

-<br />

4<br />

3<br />

75<br />

FST 324<br />

INTRODUCTION TO BIOCHEMICAL ENGINEERING<br />

2<br />

-<br />

3<br />

3<br />

75<br />

FST 325<br />

<strong>FOOD</strong> PROCESS ENGINEERING<br />

2<br />

-<br />

-<br />

2<br />

30<br />

FST 326<br />

CANNING <strong>TECH</strong>NOLOGY<br />

2<br />

-<br />

3<br />

3<br />

75<br />

GNS: See General Studies Syllabus<br />

COM: See Computer Science Syllabus<br />

19 469<br />

113

HIGHER NATIONAL DIPLOMA<br />

<strong>FOOD</strong> <strong>TECH</strong>NOLOGY<br />

Course<br />

Code<br />

Course Title L T P CU CH Prerequisite<br />

FST 411<br />

ADVANCED <strong>FOOD</strong> MICROBIOLOGY<br />

1<br />

-<br />

4<br />

3<br />

75<br />

FST 412<br />

PROCESS AND EQUIPMENT DESIGN<br />

1<br />

-<br />

-<br />

1<br />

15<br />

FST 413<br />

<strong>FOOD</strong> LEGISLATION AND SAFETY<br />

1<br />

-<br />

-<br />

1<br />

15<br />

FST 414<br />

<strong>FOOD</strong> PACKAGING AND STORAGE<br />

1<br />

-<br />

3<br />

2<br />

60<br />

FST 415<br />

PROCESSING AND PRESERVATION OF PLANT <strong>FOOD</strong><br />

PRODUCTS<br />

2<br />

-<br />

4<br />

4<br />

90<br />

FST 416<br />

PROCESSING AND PRESERVATION OF ANIMAL<br />

<strong>FOOD</strong> PRODUCTS<br />

2<br />

-<br />

4<br />

4<br />

90<br />

FST 417<br />

INDUSTRIAL MICROBIOLOGY<br />

1<br />

-<br />

4<br />

3<br />

75<br />

FST 418<br />

RESEARCH METHODOLOGY<br />

1<br />

-<br />

-<br />

1<br />

15<br />

19 435<br />

114

FOURTH SEMESTER<br />

HIGHER NATIONAL DIPLOMA<br />

<strong>FOOD</strong> <strong>TECH</strong>NOLOGY<br />

Course<br />

Code<br />

Course Title L T P CU CH Prerequisite<br />

STM 421<br />

WATER AND WASTE MANAGEMENT<br />

2<br />

-<br />

2<br />

3<br />

60<br />

FST 422<br />

<strong>FOOD</strong> PRODUCT AND PROCESS DEVELOPMENT<br />

2<br />

-<br />

-<br />

2<br />

30<br />

FST 423<br />

OPERATION RESEARCH<br />

2<br />

-<br />

-<br />

2<br />

30<br />

FST 424<br />

SEMINAR<br />

-<br />

-<br />

-<br />

1<br />

15<br />

FST 425<br />

RESEARCH PROJECT<br />

-<br />

-<br />

-<br />

4<br />

-<br />

COM 312<br />

DATABASE DESIGN<br />

2<br />

-<br />

3<br />

3<br />

75<br />

GNS 302<br />

COMMUNICATION IN ENGLISH III<br />

2<br />

-<br />

-<br />

2<br />

45<br />

17 165<br />

115

PROGRAMME: <strong>FOOD</strong> SCIENCE AND <strong>TECH</strong>NOLOGY HIGHER NATIONAL DIPLOMA<br />

COURSE: FUEL’ COMBUSTION AND STEAM GENERATION<br />

CODE: FST 311<br />

DURATION: (hour/Week) lecture: 2 Tutorial 0 Practical 0<br />

UNIT: 2.0<br />

Goal:<br />

This course is designed to provide the students with the basic knowledge <strong>of</strong> energy sources and their use in<br />

food industry<br />

General Objectives:<br />

On completion <strong>of</strong> this course the diplomates should be able to:<br />

1.0 Understand the types properties and uses <strong>of</strong> steam in the food industry<br />

2.0 Know various types <strong>of</strong> boilers and their application in food industry.<br />

3.0 Know types <strong>of</strong> fuels, their methods <strong>of</strong> analysis and specific uses<br />

4.0 Know the application <strong>of</strong> ideal gass law to mixtures <strong>of</strong> gass and vapour<br />

5.0 Understand the first law <strong>of</strong> thermodynamics<br />

6.0 Understand the second law <strong>of</strong> thermodynamics<br />

116

FOURTH SEMESTER<br />

Programme: HIGHER NATIONAL DIPLOMA IN <strong>FOOD</strong> <strong>TECH</strong>NOLOGY<br />

Course: FUEL COMBUSTION AND STEAM Course Code: FST 311 Contact Hours: 2 – 0 - 0<br />

GENERATION<br />

Course Goal: Know the importance <strong>of</strong> fuel combustion and steam in the food industry<br />

Week General Objectives:<br />

Special Learning Objective: Teachers Activities Resources<br />

1.0 Understand the types, properties and uses <strong>of</strong> steam in food<br />

industry.<br />

2.0 Know various types <strong>of</strong> boilers and their application in the food<br />

industry.<br />

3.0 Know types <strong>of</strong> fuels, their methods <strong>of</strong> analysis and specific uses<br />

4.0 Know the application <strong>of</strong> ideal gas laws to mixtures <strong>of</strong> gases and<br />

vapours.<br />

5.0 Understand the first law <strong>of</strong> thermodynamics.<br />

6.0 Understand the second law <strong>of</strong> thermodynamics.<br />

117

Week<br />

General Objective: 1.0 UNDERSTAND THE TYPES, PROPERTIES AND USE OF STEAM IN <strong>FOOD</strong> INDUSTRY<br />

Special Learning Objectives: Teachers Activities Resources<br />

USES OF STEAM IN <strong>FOOD</strong> INDUSTRY<br />

1 - 2<br />

1.1 Explain the uses <strong>of</strong> steam in the food industry e.g. drying,<br />

canning, sterilization, pasteurization.<br />

1.2 List possible sources and types <strong>of</strong> steam.<br />

Show students examples <strong>of</strong><br />

uses <strong>of</strong> steam in food<br />

industry<br />

Teaching Tools<br />

“<br />

1.3 Define saturated and unsaturated liquid and vapour, super heated<br />

steam, saturation temperature, due point, boiling point, wet and<br />

dry vapour.<br />

“<br />

“<br />

“<br />

1.4 Explain the differences between high pressure and low-pressure<br />

steam.<br />

1.5 Define the terms enthalpy quality and specific volume <strong>of</strong> steam.<br />

“<br />

“<br />

“<br />

1.6 Calculate heating requirements <strong>of</strong> selected unit operations using<br />

steam tables.<br />

“<br />

“<br />

“<br />

118

Week<br />

General Objective: 2.0 KNOW VARIOUS TYPES OF BOILERS AND THEIR APPLICATION IN THE <strong>FOOD</strong> INDUSTRY<br />

Special Learning Objectives: Teachers Activities Resources<br />

TYPES OF BOILERS AND THEIR USES<br />

3 - 5<br />

2.1 Identify various boilers.<br />

2.2 Explain the process <strong>of</strong> generating steam-using boilers.<br />

2.3 Define boiler ratings and boiler horsepower.<br />

2.4 Explain the difference between fire tube and water tube boilers.<br />

2.5 Calculate the capacity <strong>of</strong> a boiler<br />

2.6 Describe boiler accessories.<br />

2.7 Describe methods <strong>of</strong> boiler care and management.<br />

Practical identification <strong>of</strong><br />

boiler<br />

“<br />

“<br />

“<br />

“<br />

Identification <strong>of</strong> the<br />

accessories<br />

Boilers<br />

“<br />

“<br />

“<br />

“<br />

“<br />

Boiler parts<br />

“<br />

2.8 Describe various methods <strong>of</strong> feed water treatment for special<br />

applications e.g. steam s<strong>of</strong>t drinks, brewing.<br />

2.9 Explain methods <strong>of</strong> de-fouling and descaling heat transfer surfaces in<br />

boiler tubes.<br />

2.10 State the important criteria employed in each method <strong>of</strong> feed water<br />

treatment described in 2.8 above.<br />

2.11 Describe methods <strong>of</strong> producing culinary steam<br />

“<br />

“<br />

“<br />

“<br />

“<br />

“<br />

“<br />

“<br />

“<br />

119

Week<br />

General Objective: 3.0 KNOW TYPES OF FUELS, THEIR METHODS OF ANALYSIS AND SPECIFIC USES<br />

Special Learning Objectives: Teachers Activities Resources<br />

TYPES OF FUEL<br />

3.1 List and classify fuels into natural and artificial; solid, liquid and<br />

gaseous fuels e.g. coal, wood, charcoal, bagasse, natural gas,<br />

petroleum.<br />

Teaching Tools<br />

6 - 8<br />

3.2 Explain the differences between ultimate and proximate methods <strong>of</strong><br />

analysis.<br />

3.3 Determine the proximate composition and estimate the calorific value<br />

<strong>of</strong> fuels.<br />

Laboratory practical<br />

“<br />

Fuel samples, Bomb<br />

calorimeter, oven<br />

3.4 Define heat <strong>of</strong> combustion and standard heat <strong>of</strong> combustion.<br />

3.5 Define the following terms:- excess air for combustion, degree <strong>of</strong><br />

combustion, thermal efficiency.<br />

3.6 Determine requirements for complete and incomplete combustion <strong>of</strong><br />

fuels.<br />

3.7 Calculate heat losses from gases and combustion products.<br />

3.8 Determine the chemical composition <strong>of</strong> combustion gases.<br />

3.9 Identify and describe the various types <strong>of</strong> combustion equipment –<br />

oxidizer, grate-fired furnace, chamber type furnace.<br />

“<br />

“<br />

“<br />

“<br />

Practical identification <strong>of</strong> equipment<br />

Teaching Tools<br />

“<br />

“<br />

“<br />

“<br />

120

Week<br />

General Objective: 4.0 KNOW THE APPLICATION OF IDEAL GAS LAWS TO MIXTURES OF GASES AND VAPOURS<br />

Special Learning Objectives: Teachers Activities Resources<br />

APPLICATION OF IDEAL GAS LAWS<br />

4.1 State ideal gas laws and its application to mixtures <strong>of</strong> gases.<br />

Teaching Tools<br />

9 - 10<br />

4.2 Define partial pressure, mole fraction, volume percent and weight<br />

percent.<br />

4.3 Convert partial pressure to mole fraction, volume percent or any<br />

combustion and convert weight to volume percent.<br />

“<br />

Supervise and grade<br />

calculations<br />

“<br />

“<br />

4.4 Calculate average weight <strong>of</strong> gas mixtures.<br />

4.5 Define vapour pressure and distinguish between vapour and gas.<br />

4.6 Define critical conditions (pressure volume and temperature).<br />

4.7 Calculate pressure, volume and temperature <strong>of</strong> gases using<br />

compressibility factors.<br />

“<br />

“<br />

“<br />

“<br />

“<br />

“<br />

“<br />

“<br />

4.8 Convert gas compositions from dry to wet and vice versa.<br />

Supervise calculation<br />

“<br />

121

Week<br />

11 - 12<br />

General Objective: 5.0 UNDERSTAND THE FIRST LAW OF THERMODYNAMICS<br />

Special Learning Objectives: FIRST LAW OF THERMODYNAMICS Teachers Activities Resources<br />

FIRST LAW OF THERMODYNAMICS<br />

Explain with charts/models<br />

5.1 Define open and closed systems, environment, phase, isothermal,<br />

adiabatic, intensive properties; enthalpy, internal energy etc.<br />

“<br />

“<br />

5.2 Explain heat and work as applied to thermodynamic systems and the<br />

signs associated with them.<br />

“<br />

“<br />

5.3 Define heat capacity at constant volume and constant pressure. “<br />

“<br />

5.4 State the first law <strong>of</strong> thermodynamics.<br />

Supervise and grade<br />

calculations<br />

“<br />

5.5 Carry out calculations on conversion <strong>of</strong> energy for batch and<br />

continuous processes.<br />

General Objective: 6.0 UNDERSTAND THE SECOND LAW OF THERMODYNAMICS<br />

SECOND LAW OF THERMODYNAMICS<br />

13 - 14<br />

6.1 State the second law <strong>of</strong> thermodynamics.<br />

Teaching Tools<br />

6.2 Explain the thermodynamic basis for temperature scale.<br />

6.3 Define spontaneous, reversible and irreversible changes, equilibrium<br />

and maximum work.<br />

6.4 Explain the concept <strong>of</strong> heat engines, refrigerator cycles as it applies to<br />

second law.<br />

6.5 Derive expressions for work done in a carnot cycle and efficiency <strong>of</strong><br />

the carnot cycle.<br />

“<br />

“<br />

“<br />

“<br />

“<br />

“<br />

“<br />

“<br />

122

PRACTICAL CONTENTS<br />

WEEK PRACTICALS TEACHERS ACTIVITIES RESOURCES<br />

6-8 3.3 Determine the proximate composition and<br />

estimate the calorific value <strong>of</strong> fuel.<br />

Practical identification <strong>of</strong><br />

boilers<br />

Broilers<br />

3.6 Determine requirement for complete and<br />

incomplete combustion <strong>of</strong> fuel.<br />

3.8 Determine the chemical composition <strong>of</strong><br />

combustion gases.<br />

Fuel samples, Bomb<br />

calorimeter, oven<br />

3.9 Identify and describe the various practical<br />

identification <strong>of</strong> types <strong>of</strong> combustion<br />

equipment oxidizer grate – fixed furnance<br />

chamber type furnance<br />

Practical identification <strong>of</strong><br />

equipment<br />

123

PROGRAMME: <strong>FOOD</strong> SCIENCE AND <strong>TECH</strong>NOLOGY HIGHER NATIONAL DIPLOMA<br />

COURSE: <strong>FOOD</strong> QUALITY CONTROL (STATISTICS) 11<br />

CODE: FST 312<br />

DURATION: (Hour/Week) lecture 2 Tutorial 0 Practical 0<br />

UNIT: 2<br />

GOAL: This course is designed to enable students carry out food sampling and statistical analysis <strong>of</strong> sample<br />

General Objectives:<br />

1.0 Understand elementary statistical concepts<br />

2.0 Understand the principles <strong>of</strong> sampling and acceptance sampling.<br />

3.0 Know principle <strong>of</strong> inspection<br />

4.0 Understand the construction <strong>of</strong> quality control charts<br />

5.0 Understand organoleptic quality assessment <strong>of</strong> food<br />

124

Programme: HIGHER NATIONAL DIPLOMA IN <strong>FOOD</strong> <strong>TECH</strong>NOLOGY<br />

Course: <strong>FOOD</strong> QUALITY CONTROL (STATISTICS) Course No: FST 312 Contact Hours: 2-0-0<br />

Course Goal: This course is designed to enable diplomats carry out food sampling and statistical analysis <strong>of</strong> samples<br />

Week General Objectives:<br />

Special Learning Objectives: Teachers Activities Resources<br />

On completion <strong>of</strong> this course, the student should be able to:<br />

1.0 Understand elementary statistical concepts.<br />

2.0 Understand the principles <strong>of</strong> sampling and acceptance sampling.<br />

3.0 Know principles <strong>of</strong> inspection.<br />

4.0 Understand the construction <strong>of</strong> quality control Charts.<br />

5. 0 Understand organoleptic quality assessment <strong>of</strong> foods.<br />

125

Week<br />

1 - 3<br />

General Objective: UNDERSTAND ELEMENTARY STATISTICAL CONCEPTS<br />

Special Learning Objectives: Teachers Activities Resources<br />

STATISTICAL CONCEPTS<br />

1.1 Define statistics and explain its role in quality control.<br />

1.2 Identify the basic forms <strong>of</strong> data presentation and representing data<br />

obtained during quality control.<br />

1.3 Explain the steps involved in grouping data.<br />

1.4 List the properties <strong>of</strong> mean as a measure for representing data.<br />

Show students data presentation<br />

form e.g. graph, histogram, etc.<br />

“<br />

“<br />

Charts<br />

“<br />

“<br />

1.5 Group data from sampling.<br />

1.6 Define the arithmetic mean and compute mean for grouped data.<br />

1.7 Define median for odd and even array <strong>of</strong> observations.<br />

1.8 Compute median using common methods.<br />

1.9 Define mode and compute the mode for grouped and ungrouped<br />

data.<br />

1.10 Define range and determine range for some observations.<br />

1.11 List the disadvantages <strong>of</strong> range as a measure <strong>of</strong> representing<br />

data.<br />

“<br />

“<br />

“<br />

“<br />

“<br />

“<br />

“<br />

“<br />

“<br />

“<br />

“<br />

“<br />

126

Week<br />

General Objectives:<br />

Special Learning Objectives: Teachers Activities Resources<br />

1.12 Compute standard deviation and coefficient <strong>of</strong> variation <strong>of</strong> data<br />

and list their uses.<br />

Teaching Tools<br />

1.13 Construct histogram and frequency polygons from frequency<br />

distributions.<br />

1.14 Draw cumulative frequency polygons or ogive for data<br />

1.15 Explain the relationship between mean, standard deviation and<br />

distribution curve<br />

Grade constructed histograms,<br />

etc from given data.<br />

“<br />

“<br />

“<br />

“<br />

“<br />

127

General Objectives: UNDERSTANDING THE PRINCIPLES OF SAMPLING AND ACCEPTANCE SAMPLING<br />

PRINCIPLES OF SAMPLING<br />

2.1 Explain the terms sampling and 100% inspection.<br />

2.2 List the advantages and disadvantages <strong>of</strong> sampling over 100%<br />

inspection.<br />

2.3 Define consumers and producers risks.<br />

2.4 Enumerate the desirable features <strong>of</strong> sampling and the factors for<br />

adhering them.<br />

2.5 Explain the term acceptance sampling and list the characteristics <strong>of</strong><br />

acceptance sampling plans.<br />

2.6 List and explain the principles <strong>of</strong> common sampling plans.<br />

“<br />

“<br />

“<br />

“<br />

“<br />

“<br />

“<br />

“<br />

“<br />

“<br />

128

Week<br />

General Objectives:<br />

Special Learning Objectives: Teachers Activities Resources<br />

Week<br />

2.7 Enumerate the factors that influence choice <strong>of</strong> sampling plans.<br />

2.8 Calculate probabilities acceptance <strong>of</strong> batches using Binomial and<br />

Poisson distributions.<br />

2.9 Explain operating characteristics curve and list its features.<br />

2.10 Draw operating characteristics curve and use it to compute<br />

characteristics acceptance <strong>of</strong> sampling plans.<br />

2.11 List the desirable features <strong>of</strong> a good and efficient acceptance<br />

sampling plan.<br />

General Objective: KNOW PRINCIPLES OF INSPECTION<br />

PRINCIPLES OF INSPECTION<br />

3.1 Define inspection and explain its scope.<br />

3.2 List the reasons for and uses <strong>of</strong> inspection.<br />

3.3 List the stages in the inspection <strong>of</strong> industrial goods.<br />

3.4 Define normal reduced and tightened inspection.<br />

3.5 Represent the Levels <strong>of</strong> inspection defined in 3.4 above on operating<br />

characteristics curve.<br />

3.6 List common errors in inspection.<br />

“<br />

“<br />

Supervise students’ draw<br />

curves from data.<br />

“<br />

“<br />

“<br />

“<br />

“<br />

“<br />

Teaching Tools<br />

“<br />

“<br />

“<br />

“<br />

“<br />

“<br />

“<br />

“<br />

129

Week<br />

General Objectives: UNDERSTAND THE CONSTRUCTION OF QUALITY CONTROL CHARTS<br />

Special Learning Objectives: Teachers Activities Resources<br />

QUALITY CONTROL CHARTS<br />

4.1 Explain the principles <strong>of</strong> control charts.<br />

4.2 List the objectives <strong>of</strong> control charts in quality control.<br />

4.3 List the type <strong>of</strong> control charts.<br />

4.4 List the steps in construction <strong>of</strong> average (X) and range (R) control<br />

charts.<br />

4.5 Calculate control limit for variable and attribute charts.<br />

4.6 Construct control charts using the control limits calculated in 4.5<br />

above to construct control charts.<br />

4.7 List the advantages and limitations <strong>of</strong> attributes and variable.<br />

4.8 List the conditions for in control.<br />

4.9 Explain the term and principles <strong>of</strong> process capability.<br />

“<br />

“<br />

“<br />

“<br />

Supervise student construct<br />

control charts.<br />

“<br />

“<br />

“<br />

Teaching Tools<br />

“<br />

“<br />

“<br />

“<br />

“<br />

“<br />

“<br />

“<br />

130

Week<br />

General Objectives: UNDERSTAND ORGANOLEPTIC QUALITY ASSESSMENT OF <strong>FOOD</strong>S<br />

Special Learning Objectives: Teachers Activities Resources<br />

ORGANOLEPTIC QUALITY ASSESSMENT OF <strong>FOOD</strong>S<br />

5.1 Define sensory or organoleptic food quality.<br />

5.2 Explain the relationship between the chemical and biological<br />

characteristics <strong>of</strong> food and its sensory quality.<br />

5.3 Explain the differences between objective method and sensory<br />

methods <strong>of</strong> food analysis.<br />

5.4 Explain quality attributes <strong>of</strong> foods and their characteristics and<br />

perception.<br />

5.5 Explain flavour pr<strong>of</strong>ile technique<br />

5.6 Explain the differences between difference and preference tests <strong>of</strong><br />

foods.<br />

5.7 Explain the principles <strong>of</strong> the tests explained in 5.6 above.<br />

5.8 Explain uses <strong>of</strong> sensory evaluation.<br />

5.9 Explain the importance <strong>of</strong> a suitable environment and paper sample<br />

presentation in the conduct <strong>of</strong> reliable sensory evaluation <strong>of</strong> foods.<br />

“<br />

“<br />

“<br />

“<br />

“<br />

“<br />

“<br />

“<br />

Teaching Tools<br />

“<br />

“<br />

“<br />

“<br />

“<br />

“<br />

“<br />

“<br />

131

Week<br />

General Objectives:<br />

Special Learning Objectives: Teachers Activities Resources<br />

5.10 Conduct sensory evaluation <strong>of</strong> food. Describe the principles <strong>of</strong> the<br />

following difference tests:<br />

(i) Paired comparison<br />

(ii) Triangle test<br />

(iii) Duo-trio test<br />

(iv) Ranking test<br />

(v) Scoring test<br />

(vi) Multiple comparison test<br />

5.11 Carry out statistical analysis and interpretation <strong>of</strong> the tests listed in<br />

5.10 above.<br />

5.12 Explain the screening and selection <strong>of</strong> list for the conduct <strong>of</strong> a<br />

typical sensory evaluation test.<br />

5.13 Conduct sensory evaluation <strong>of</strong> food.<br />

5.14 Explain the use and interpretation <strong>of</strong> the following in the analysis<br />

<strong>of</strong> result <strong>of</strong> sensory evaluation:<br />

(i) Analysis <strong>of</strong> variance (ANOVA).<br />

(ii) Least square difference (LSD).<br />

(iii) Students t-test.<br />

(iv) Turkey’s Duncan’s multiple range test.<br />

Supervise practical sensory<br />

evaluation<br />

“<br />

Grade statistical analysis <strong>of</strong> the<br />

result <strong>of</strong> sensory evaluation<br />

“<br />

Test panel<br />

Teaching Tools<br />

“<br />

“<br />

“<br />

Taste panel facilities<br />

“<br />

132

PROGRAMME: <strong>FOOD</strong> SCIENCE AND <strong>TECH</strong>NOLOGY HIGHER NATIONAL DIPLOMA<br />

COURSE: UNIT OPERATIONS 1<br />

CODE: FST 313<br />

DURATION: (Hour/Week) lecture 2 Tutorial 0 Practical 3<br />

UNIT; 3<br />

GOAL: This course is designed to provide the students with an understanding <strong>of</strong> the principles and techniques<br />

involved in various physical operations in the food industry<br />

General Objectives: On completion <strong>of</strong> the course the students should be able to know:<br />

1.0 The principles and techniques <strong>of</strong> cleaning raw materials<br />

2.0 The principles and techniques <strong>of</strong> sorting and grading<br />

3.0 Size reduction operations in the food industry<br />

4.0 The principles and techniques <strong>of</strong> grinding operations<br />

5.0 Understand sieve analysis and screening by serving<br />

6.0 Understand the principles and techniques <strong>of</strong> mixing and blending<br />

7.0 Understand the principles and techniques <strong>of</strong> emulsification<br />

8.0 Understand the principles and methods <strong>of</strong> food drying<br />

9.0 Understand the principles and application <strong>of</strong> solar drier<br />

133

Programme: HIGHER NATIONAL DIPLOMA IN <strong>FOOD</strong> <strong>TECH</strong>NOLOGY<br />

Course: UNIT OPERATIONS 1 Course Code: FST 313 Contact Hours: 2 – 0 - 3<br />

Course Goal: This course is designed to enable the student understand and carry out various unit operations in food processing<br />

Week General Objectives:<br />

Special Learning Objective: Teachers Activities Resources<br />

On completion <strong>of</strong> this course, the student should be able to:<br />

1.0 Know the principles and techniques <strong>of</strong> cleaning raw materials.<br />

2.0 Know the principles and techniques <strong>of</strong> sorting and grading.<br />

3.0 Know size reduction operations in the food industry.<br />

4.0 Know the principles and techniques <strong>of</strong> grinding operations<br />

5.0 Understand sieve analysis and screening by sieving.<br />

6.0 Understand the principles and techniques <strong>of</strong> mixing and blending.<br />

7.0 Understand emulsification process in the food industry.<br />

8.0 Understand the principles and methods <strong>of</strong> food drying.<br />

9.0 Understand the principles and application <strong>of</strong> solar drier.<br />

134

Week<br />

1<br />

General Objectives: 1.0 KNOW THE PRINCIPPLES AND <strong>TECH</strong>NIQUES OF CLEANING RAW MATERIALS<br />

Special Learning Objective: Teachers Activities Resources<br />

CLEANING RAW MATERIALS<br />

1.1 List the cleaning operations <strong>of</strong> food as carried out in food<br />

industries.<br />

Supervise physical identification <strong>of</strong><br />

bacteria and other contaminants.<br />

Teacher<br />

1.2 Identify the classes <strong>of</strong> contaminants usually encountered in foods.<br />

Contaminated foods<br />

1.3 Explain the advantages and disadvantages <strong>of</strong> wet and dry cleaning.<br />

1.4 Describe the primary features <strong>of</strong> a cleaning equipment.<br />

Supervise fruits and vegetable<br />

cleaning. Grade reports’<br />

Practical, laboratory screen<br />

1.5 Clean fruits, vegetables etc using conventional tools and<br />

sorters/cleaners, weight<br />

equipment.<br />

sorters, spray washers.<br />

General Objectives: 2.0 KNOW THE PRINCIPLES AND <strong>TECH</strong>NIQUES OF SORTING AND GRADIING<br />

SORTING AND GRADING<br />

2<br />

2.1 Explain the differences between sorting and grading.<br />

Use sketches to explain<br />

Teaching Tools<br />

2.2 Describe the general principles <strong>of</strong> sorting and grading.<br />

2.3 List the grading criteria used in food industries.<br />

2.4 List the methods <strong>of</strong> sorting and grading applied in the food<br />

industry.<br />

“<br />

“<br />

“<br />

“<br />

2.5 Describe various methods <strong>of</strong> sorting and grading.<br />

“<br />

“<br />

2.6 Identify and describe the various machines and tools used in sorting<br />

and grading.<br />

Supervise practical identification <strong>of</strong><br />

tools.<br />

Sorting/grading<br />

sieves, etc.<br />

machine,<br />

135

Week<br />

General Objectives:<br />

Special Learning Objective: Teachers Activities Resources<br />

2.7 Describe the criteria for choice <strong>of</strong> sorting equipment.<br />

2.8 Sort and grade fruits and other food items using sorting/grading<br />

machines.<br />

Lecture<br />

Supervise practical on sorting and<br />

grading,<br />

Teaching Tools<br />

Sorting/grading machine<br />

Rotary screen, Flat bed<br />

screen<br />

3<br />

General Objective: 3.0 KNOW SIZE REDUCTION OPERATIONS IN THE <strong>FOOD</strong> INDUSTRY<br />

Special Learning Objective: Teachers Activities Resources<br />

SIZE REDUCTION<br />

3.1 Explain size reduction.<br />

Use sketches to explain<br />

Teaching Tools/sketches<br />

3.2 Describe the size reduction operations in food industry.<br />

3.3 Define percent size reduction <strong>of</strong> a food material and size reduction<br />

ratio.<br />

3.4 Describe wet and dry milling operations.<br />

3.5 Identify the tools and equipment used in size reduction operations<br />

in the food industry.<br />

3.6 Classify the size reduction tools and equipment listed in 3.5 above.<br />

3.7 Describe the features and working process <strong>of</strong> 3.6 above.<br />

3.8 Explain the criteria for choosing equipment in size reduction<br />

operations.<br />

“<br />

“<br />

Conduct students to identify the tools<br />

and equipment possible in a food<br />

industry.<br />

“<br />

“<br />

Size reduction equipment<br />

and tools.<br />

136

Week<br />

General Objective:<br />

Special Learning Objectives: Teachers Activities Resources<br />

3.9 Describe a typical size reduction plant.<br />

Visit flour mill industry/others<br />

Visiting<br />

4<br />

3.10 Reduce sizes <strong>of</strong> food using mills (dry or wet)<br />

Carry out practical on both dry/wet<br />

milling <strong>of</strong> raw materials<br />

General Objective: 4.0 KNOW THE PRINCIPLES AND <strong>TECH</strong>NIQUES OF GRINDING OPERATIONS<br />

GRINDING OPERATIONS<br />

4.1 Describe Kicks, Nittinger and Bonds equations, noting the range <strong>of</strong><br />

their applications.<br />

Hammer mill, Attrition<br />

mill etc.<br />

Teaching Tools<br />

4.2 Calculate energy required for a grinding operation using equations 4.1<br />

above.<br />

Grade calculations<br />

4.3 Define shape factor, specific area, and specific volume.<br />

4.4 State equations for calculating surface area and calculate surface area.<br />

4.5 Reduce particle size <strong>of</strong> various food items by grinding.<br />

Supervise grinding operations.<br />

Grade reports.<br />

Grinding mills.<br />

137

Week<br />

General Objective: 5.0 UNDERSTAND SIEVE ANALYSIS AND SCREENIING BY SIEVING<br />

Special Learning Objectives: Teachers Activities Resources<br />

SIEVING<br />

5 - 6<br />

5.1 Define terms used in sieve analysis.<br />

Teaching<br />

5.2 State factors affecting rate <strong>of</strong> sieving.<br />

Sieves<br />

5.3 Identify standard sieves in use.<br />

Supervise practical identification<br />

and sketching <strong>of</strong> sieves.<br />

5.4 List and describe methods for particle size analysis.<br />

Grade reports.<br />

Particles, standard sieves,<br />

5.5 Compute mean particle size from fraction distribution data for screen<br />

milling equipment, shakers<br />

analysis obtained through experiment.<br />

Practical and grade report.<br />

Various sizes <strong>of</strong> sieves<br />

5.6 Sieve size reduced food materials using various sieve sizes.<br />

Sieving <strong>of</strong> milled samples for<br />

particle size distribution<br />

General Objective: 6.0 UNDERSTAND THE PRINCIPLES AND <strong>TECH</strong>NIQUES OF MIXING AND BLENDING<br />

MIXING AND BLENDING<br />

Explain with examples<br />

Teaching Tools<br />

6.1 Explain the purpose <strong>of</strong> mixing operations in the food industry.<br />

7 - 8<br />

6.2 Describe the mechanism for the mixing <strong>of</strong> liquids <strong>of</strong> low and high<br />

viscosity, thick paste and dry powders.<br />

6.3 Identify and classify mixing equipment into mixers for liquids,<br />

powders, pastes, plastics etc.<br />

Supervise practical identification <strong>of</strong><br />

equipment<br />

Mixers<br />

6.4 Describe diagrammatically the features <strong>of</strong> mixing equipments.<br />

6.5 Express relationship for Reynold number, Fraude number, and Power<br />

number.<br />

Describe from sketches<br />

Teaching<br />

Various mixing equipment<br />

138

Week<br />

General Objectives:<br />

Special Learning Objective: Teachers Activities Resources<br />

6.6 Express the equation for power requirement for liquid mixing<br />

applying the dimensions number in 6.5 above.<br />

6.7 Mix wet and dry food items using various mixing and blending<br />

machines.<br />

Supervise practical on mixing and<br />

blending.<br />

Grade report<br />

General Objectives: 7.0 UNDERSTAND EMULSIFICATION PROCESS IN THE <strong>FOOD</strong> INDUSTRY<br />

EMULSIFICATION PROCESS<br />

Mixers<br />

9 - 10<br />

7.1 Define emulsion, dispersion, suspension and colloid.<br />

7.2 Define and explain water in oil emulsion and oil in water emulsion.<br />

Lectures<br />

Lecture and exhibition<br />

7.3 Identify foods that are either O/W or W/O emulsions.<br />

7.4 Identify the common emulsifying agents in the food industry.<br />

7.5 Describe the application principles and techniques <strong>of</strong> emulsifying<br />

agents.<br />

7.6 Identify and describe the various equipment used in emulsion<br />

production.<br />

7.7 Produce emulsion products and determine emulsion stability viz:<br />

mayonnaise, ice cream, margarine, milk etc.<br />

Supervise practical identification <strong>of</strong><br />

emulsions<br />

Practical identification <strong>of</strong><br />

emulsification agents.<br />

Teaching<br />

Practical identification and sketches<br />

Practical produce mayonnaise, ice<br />

cream, etc. Check their stability<br />

O/W, W/O emulsions<br />

Various emulsifying agents.<br />

Teaching Tools<br />

Emulsifying equipment.<br />

Egg, oil, starch, milk etc.<br />

Laboratory/workshop<br />

equipment.<br />

139

Week<br />

General Objective: 8.0 UNDERSTAND THE PRINCIPLES AND METHODS OF <strong>FOOD</strong> DRYING<br />

Special Learning Objectives: Teachers Activities Resources<br />

<strong>FOOD</strong> DRYING<br />

11 - 12<br />

8.1 Explain the purposes <strong>of</strong> drying operations in the food industry.<br />

Teaching<br />

Teaching Tools<br />

8.2 List all methods <strong>of</strong> drying applied to food locally.<br />

8.3 Identify the common drying equipment and classify them into air, hot<br />

surface, freeze dryer etc.<br />

8.4 Describe the principle <strong>of</strong> operation <strong>of</strong> the equipment in 8.3 above.<br />

Visit workshop and food industry<br />

to identify and sketch drying<br />

equipment and tools.<br />

Drying equipment<br />

8.5 Explain the influence <strong>of</strong> the moisture content <strong>of</strong> food on the choice <strong>of</strong><br />

drying process.<br />

8.6 Explain the rate <strong>of</strong> drying and critical moisture content and EMS.<br />

Teaching<br />

Teaching Tools<br />

“<br />

13 - 14<br />

8.7 Classify food materials according to drying behaviour.<br />

Lectures<br />

“<br />

8.8 Calculate drying time under constant rate, falling rate and total drying<br />

period.<br />

8.9 Dry food materials.<br />

“<br />

“<br />

Practical drying <strong>of</strong> food materials<br />

and confirm their moisture content.<br />

“<br />

Drying oven and other<br />

drying equipment and<br />

Moisturemeter.<br />

140

Week<br />

15<br />

General Objectives: 9.0 UNDERSTAND THE PRINCIPLES AND APPLICATION OF SOLAR DRIER<br />

Special Learning Objectives: Teachers Activities Resources<br />

SOLAR DRYER<br />

9.1 State sources <strong>of</strong> solar drier<br />

- the sun<br />

- the solar radiant energy<br />

9.2 Explain sources <strong>of</strong> solar radiation.<br />

9.3 Identify forms <strong>of</strong> solar energy collectors: - luminance, flat plate<br />

collectors, optical collectors, flat plate collectors.<br />

9.4 Dry fruit and vegetables using solar driers.<br />

9.5 Determine solar drier efficiency.<br />

Supervise practical identification <strong>of</strong><br />

driers and trying <strong>of</strong> fruits and<br />

vegetables check moisture content <strong>of</strong><br />

product.<br />

Solar driers.<br />

Moisturemeter<br />

141

PRACTICAL CONTENTS<br />

WEEK PRACTICALS TEACHERS ACTIVITIES RESOURCES<br />

1<br />

1.2 Identify the classes <strong>of</strong> contaminants usually<br />

Contamination foods<br />

encountered in foods.<br />

2<br />

1.5 Clean truits, vegetables etc using<br />

convectional tools and equipments.<br />

2.6 Identify and describe the various machines<br />

and tools used in sorting and grading<br />

Supervise physical<br />

identification <strong>of</strong> bacteria and<br />

other contaminants<br />

Supervise fruits and vegetables<br />

cleaning grade report<br />

Supervise practical<br />

identification <strong>of</strong> tools<br />

Practical, laboratory screen<br />

sorters/cleaners weight sorters<br />

spray washers<br />

Sorting/grading machine<br />

sieves etc<br />

2.8 Sort and grade fruits and other food items<br />

using sorting /grading machine<br />

Supervise practical on sorting<br />

and grading<br />

”<br />

3<br />

3.5 Identify tools and equipment used in size<br />

reduction operations in the food industry.<br />

Conduct students to identify<br />

the tools and equipment<br />

possibly in a food industry<br />

Size reduction equipment and<br />

tool<br />

3.10 Reduce sizes <strong>of</strong> food using mills(dry or<br />

wet)<br />

Carry out practical on both<br />

dry/wet milling raw materials<br />

Hammer mill, attrition mill etc<br />

4.5 Reduce particle size <strong>of</strong> various food items<br />

by grinding<br />

Supervise grinding operations<br />

Grade report<br />

Grinding mill<br />

5-6<br />

5.3 Identify standard sieve in use<br />

Supervise practical<br />

identification from and<br />

sketching <strong>of</strong> sieves<br />

Sieves<br />

5.5 Compute mean particle size from fraction<br />

distribution data for screen analysis obtained<br />

through experiment<br />

Practical and grade report<br />

Milling equipment shakers<br />

142

5.6 Sieve size reduced food materials using<br />

various sieve sizes.<br />

6.3 Identify and classify mixing equipment into<br />

mixed for liquids, powder, paste, plastics<br />

etc<br />

6.7 Mix wet and dry food items using various<br />

mixing and blending machines<br />

7.3 Identify foods that are O/W or W/O<br />

emulsions<br />

7.4 Identify the common emulsifying agents in<br />

the food industry.<br />

Sieving <strong>of</strong> milled samples for<br />

particle size distribution<br />

Supervise identification <strong>of</strong><br />

equipment<br />

Supervise practical on mixing<br />

and blending Grade report<br />

Supervise practical<br />

identification <strong>of</strong> emulsion<br />

Practical identification <strong>of</strong><br />

emulsifying agent<br />

Various sieve sizes<br />

Mixers<br />

O/W. W/O emulsion<br />

Various emulsifying agent<br />

7.6 Identify and describe the various<br />

equipment used in emulsion production.<br />

7.7 Produce emulsion products and determine<br />

emulsion stability Viz. mayonnaise, ice<br />

cream, margarine milk etc.<br />

8.9 Dry food materials<br />

9.3 Identify forms <strong>of</strong> solar energy collectors,<br />

optical collectors, flat plat collector.<br />

Practical identification and<br />

sketches<br />

Practical produce mayonnaise,<br />

ice cream etc check their<br />

stability<br />

Practical drying <strong>of</strong> food<br />

materials and their moisture<br />

conten<br />

Supervise practical<br />

identification <strong>of</strong> driers and<br />

drying <strong>of</strong> fruits and vegetables<br />

and check moisture content <strong>of</strong><br />

Emulsifying equipment<br />

Egg, otc starch mock etc.<br />

Laboratory/Workshop<br />

equipment<br />

Drying oven and phe drying<br />

equipment moisturmeter.<br />

Solar drier<br />

143

9.4 Dry fruit and vegetables using solar driers product<br />

PROGRAMME: <strong>FOOD</strong> AND <strong>TECH</strong>NOLOGY HIGHER NATIONAL DIPLOMA<br />

COURSE: ADVANCED <strong>FOOD</strong> CHEMISTRY<br />

CODE: FST 314<br />

DURATON: (Hours/Week) lecture 2 Tutorial 0 Practical 3<br />

COURSE UNIT 3.0<br />

GOAL: This course is designed to provide the students with better understanding <strong>of</strong> the chemical components and<br />

reactions in food materials during storage processing and preservations.<br />

General Objectives<br />

1.0 Understand the nature <strong>of</strong> water in food<br />

2.0 Understand the nature and properties <strong>of</strong> carbohydrate in foods<br />

3.0 Understand the nature and properties <strong>of</strong> protein in food<br />

4.0 Understand nature and properties <strong>of</strong> lipids<br />

5.0 Understand the types, nature and control <strong>of</strong> browning reaction in foods<br />

6.0 Understand the fundamentals <strong>of</strong> flavour chemistry<br />

7.0 Understand the nature and properties <strong>of</strong> compounds that give colour to food products.<br />

144

Programme: HIGHER NATIONAL DIPLOMA IN <strong>FOOD</strong> <strong>TECH</strong>NOLOGY<br />

Course: ADVANCED <strong>FOOD</strong> CHEMISTRY Course Code: FST 314 Contact Hours: 2 – 0 - 3<br />

Course Goal: This course is designed to enable student acquire better knowledge <strong>of</strong> the chemical nature <strong>of</strong> food.<br />

Week General Objective:<br />

Special Learning Objectives: Teachers Activities Resources<br />

1.0 Understand the nature <strong>of</strong> water in food.<br />

2.0 Understand the nature and properties <strong>of</strong> carbohydrates in foods.<br />

3.0 Understand the nature and properties <strong>of</strong> protein in food.<br />

4.0 Understand the nature and properties <strong>of</strong> lipids in food.<br />

5.0 Understand the types, nature and control <strong>of</strong> browning reaction in<br />

food.<br />

6.0 Understand the fundamentals <strong>of</strong> flavour chemistry.<br />

7.0 Understand the nature and properties <strong>of</strong> compound that give colour<br />

to food products.<br />

145

Week<br />

General Objectives: UNDERSTAND THE NATURE OF WATER IN <strong>FOOD</strong><br />

Special Learning Objective: Teachers Activities Resources<br />

WATER IN <strong>FOOD</strong><br />

1<br />

1.1 Draw a diagram <strong>of</strong> water molecule enclosed in an imaginary<br />

tetraedron showing bond angles and charge separation.<br />

Grade drawings<br />

Teaching Tools<br />

1.2 Describe the association <strong>of</strong> water molecule by its bonding.<br />

Explain with models.<br />

“<br />

1.3 Explain the two main types <strong>of</strong> theories for structure <strong>of</strong> water:<br />

continuum and mixture theories.<br />

“<br />

“<br />

1.4 Explain the abnormal properties <strong>of</strong> water with respect to freezing,<br />

boiling points, surface tension.<br />

“<br />

“<br />

1.5 Describe the interaction between water molecules and dissolved<br />

solutes.<br />

“<br />

“<br />

1.6 Distinguish between free and bound water in foods.<br />

“<br />

“<br />

1.7 Explain the controversy on the use <strong>of</strong> the two terms (free and<br />

bound water).<br />

“<br />

“<br />

1.8 Define water activity.<br />

“<br />

“<br />

1.9 Determine the moisture sorption isotherms (MSI) <strong>of</strong> food<br />

materials.<br />

Supervise practical determination <strong>of</strong><br />

MSI.<br />

Furnace, crucible,<br />

laboratory wares<br />

1.10 Explain the significance <strong>of</strong> MSI.<br />

“<br />

146

Week<br />

General Objectives:<br />

Special Learning Objectives: Teachers Activities Resources<br />

1.11 Explain the relationship between water activity and various<br />

deteriorative changes in foods.<br />

Lecture<br />

2<br />

General Objectives: UNDESTAND THE NATURE AND PROPERTIES OF CARBOHYDRATES IN <strong>FOOD</strong>S<br />

CARBOHYDRATES IN <strong>FOOD</strong><br />

2.1 Explain optical Isomerism.<br />

Lecture<br />

Teaching Tools<br />

2.2 Measure the rotatory power <strong>of</strong> sugars by means <strong>of</strong> polarimeter.<br />

2.3 Designate optical Isomers appropriately by means <strong>of</strong> the letters ‘D’<br />

and ‘L’ and the signs (+) and (-).<br />

2.4 Explain the phenomenon <strong>of</strong> mutarotation and write the ‘D’ and ‘L’<br />

formulae <strong>of</strong> the main simple sugars.<br />

2.5 Explain the characteristics reaction <strong>of</strong> sugars (enolization, oxidation,<br />

reduction, esterification, glycoside formation and ozazone formation<br />

etc.)<br />

2.6 Explain the preparation <strong>of</strong> syrup from invert sugar.<br />

2.7 Distinguish between polysaccharides, oligo and monosaccharide<br />

starch, glycogen, cellulose, hemicelluloses, pectin, qumsancilage.<br />

2.8 Describe the use <strong>of</strong> carbohydrates as food sweeteners and functional<br />

ingredients.<br />

Supervise practical determination.<br />

Lecture<br />

“<br />

Lecture and practical<br />

“<br />

“<br />

Describe with examples.<br />

Polarimeter,<br />

Laboaratory wares.<br />

Teaching Tools<br />

“<br />

“<br />

“<br />

“<br />

147

Week<br />

General Objectives:<br />

Special Learning Objective: Teachers Activities Resources<br />

2.9 List the factors influencing the choice <strong>of</strong> sweeteners in the<br />

confectionery industry.<br />

2.10 Describe the action <strong>of</strong> starch enzymes, their role in mashing and<br />

bread making.<br />

2.11 Explain the phenomenon <strong>of</strong> starch gelanization and retro<br />

gradation.<br />

2.12 Identify starches by microscope.<br />

2.13 Determine the gelatinization temperature <strong>of</strong> starches.<br />

2.14 Describe the role <strong>of</strong> gelatinization and retro gradation <strong>of</strong> starchy<br />

foods.<br />

Lecture<br />

“<br />

“<br />

Supervise practical identification <strong>of</strong><br />

starch.<br />

Supervise practical determination<br />

Lecture<br />

Teaching Tools<br />

“<br />

“<br />

Microscope, laboratory<br />

wares<br />

Laboratory wares<br />

Teaching Tools<br />

2.15 Isolate and demonstrate the physico-chemical properties <strong>of</strong><br />

pectin.<br />

2.16 Explain the role <strong>of</strong> pectin in the formation <strong>of</strong> jam, jelliers and<br />

fruit juices.<br />

2.17 Explain the theories <strong>of</strong> gel formation.<br />

2.18 Measure jell strength using gelometer.<br />

Supervise practical isolation and<br />

grade reports.<br />

Lecture<br />

“<br />

Supervise practical measurement and<br />

grade reports.<br />

“<br />

“<br />

Gelometer,<br />

wares<br />

laboratory<br />

148

Week<br />

General Objectives: UNDERSTAND THE NATURE AND PROPERTIES OF PROTEINS IN <strong>FOOD</strong>S<br />

Special Learning Objectives: Teachers Activities Resources<br />

PROTEIN IN <strong>FOOD</strong><br />

5 - 7<br />

3.1 List and explain the significant properties <strong>of</strong> proteins and amino acids.<br />

Lecture<br />

Teaching Tools<br />

3.2 List the classes <strong>of</strong> proteins.<br />

“<br />

“<br />

3.3 Fractionate and isolate the proteins in foods e.g. milk, egg, meat,<br />

wheat flour, cowpeas, sorghum.<br />

Practical fractionating and isolation<br />

Equipment and glassware<br />

Keldhal apparatus<br />

3.4 List the physico-chemical properties <strong>of</strong> the prolate in 3.3 above.<br />

3.5 Evaluate the physico-chemical properties <strong>of</strong> the isolated protein.<br />

Conduct practical<br />

3.6 Explain the roles <strong>of</strong> proteins in food processing technology and eating<br />

quality <strong>of</strong> the processed products.<br />

Lecture<br />

Teaching Tools<br />

8 - 9<br />

3.7 List the limiting amino acids <strong>of</strong> each <strong>of</strong> the main food proteins. “<br />

General Objectives: 4.0 UNDERSTAND THE NATURE AND PROPERTIES OF LIPIDS IN <strong>FOOD</strong><br />

LIPIDS IN <strong>FOOD</strong><br />

4.1 List the different classes <strong>of</strong> lipids and explain their natural<br />

occurrences.<br />

Lecture<br />

“<br />

Teaching Tools<br />

4.2 Describe the structure <strong>of</strong> the naturally occurring tri-glycerides.<br />

4.3 Determine lipids in foods.<br />

4.4 Explain the chemical basis <strong>of</strong> analysis <strong>of</strong> lipids e.g. saponification<br />

iodine polenske numbers (value).<br />

Week General Objectives:<br />

“<br />

Supervise practical determination <strong>of</strong><br />

lipids<br />

Lecture<br />

“<br />

Soxhlet apparatus<br />

Teaching Tools<br />

149

Special Learning Objective: Teachers Activities Resources<br />

4.5 Describe other methods <strong>of</strong> fat determination e.g. acid and the<br />

method using Boten apparatus, the alkali method.<br />

4.6 Determine peroxide, acid, saponification, iodine value.<br />

4.7 Determine the followings in lipid: water content; density; refractive<br />

index; melting point; colour; rancidity.<br />

4.8 Describe the process <strong>of</strong> the manufacture <strong>of</strong> fat products e.g. butter,<br />

margarine, salad cream and cooking oils.<br />

4.9 Explain the term Rancidity <strong>of</strong> fats.<br />

4.10 Explain the causes and types <strong>of</strong> rancidity in plam. Groundnut<br />

oil.<br />

4.11 Distinguish between types <strong>of</strong> rancidity.<br />

4.12 Explain the problems created by rancidity in foods.<br />

4.13 Describe the mechanism <strong>of</strong> rancidity.<br />

4.14 List antioxidant used in foods and explain the mode <strong>of</strong> action <strong>of</strong><br />

antioxidants.<br />

4.15 Explain neversiances applied to lipids.<br />

4.16 Explain the theory <strong>of</strong> Emulsion.<br />

Lecture and practical<br />

Conduct practical and grade<br />

reports.<br />

Conduct practicals and grade<br />

reports.<br />

Lecture<br />

“<br />

Show students rancid oil.<br />

“<br />

“<br />

“<br />

“<br />

“<br />

“<br />

“<br />

Boten apparatus<br />

Titrate (Acid-Bases)<br />

Refract meter, Colorimeter<br />

Teaching Tools<br />

“<br />

“<br />

“<br />

“<br />

“<br />

“<br />

“<br />

“<br />

150

Week<br />

Special Learning Objective: Teachers Activities Resources<br />

4.17 Identify important emulsifying agents used in food products. Conduct practical identification Emulsifying agents.<br />

<strong>of</strong> agents<br />

General Objective: 5.0 UNDERSTAND THE TYPES, NATURE AND CONTROL OF BROWNING REACTION IN <strong>FOOD</strong>S<br />

BROWNING REACTION IN <strong>FOOD</strong><br />

10 - 11<br />

5.1 Explain the occurrence and significance <strong>of</strong> browning reactions in<br />

foods.<br />

5.2 Distinguish between enzymic and non-enzymic browning reactions.<br />

Show students examples <strong>of</strong><br />

browning reaction e.g. cut<br />

yam.<br />

Conduct practicals and grade<br />

reports.<br />

5.3 Describe the main features <strong>of</strong> the mechanism <strong>of</strong> browning reactions.<br />

Lecture<br />

5.4 Explain the various methods for preventing the two types <strong>of</strong><br />

browning reactions in the food industry.<br />

“<br />

General Objective: 6.0 UNDERSTAND THE FUNDAMENTALS OF FLAVOUR CHEMISTRY<br />

FUNDAMENTALS OF FLAVOUR CHEMISTRY<br />

Teaching Tools<br />

Water bath for determining<br />

the effect <strong>of</strong> blanching on<br />

phenolase<br />

Teaching Tools<br />

“<br />

12 - 13<br />

6.1 Explain the term “flavour <strong>of</strong> foods”<br />

Lecture<br />

Teaching Tools<br />

6.2 List the primary taste and demonstrate which area <strong>of</strong> the tongue<br />

detects them.<br />

“<br />

“<br />

6.3 Determine the taste threshold <strong>of</strong> compounds.<br />

Lecture and practical<br />

6.4 Explain the influence <strong>of</strong> chemical constitution on taste.<br />

Lecture<br />

Teaching Tools<br />

6.5 Explain the role <strong>of</strong> salt and sugar in food flavouring<br />

“<br />

“<br />

151

Week<br />

General Objectives:<br />

Special Learning Objective: Teachers Activities Resources<br />

6.6 Explain the role <strong>of</strong> volatiles in food flavours.<br />

Lecture<br />

Teaching Tools<br />

6.8 Explain the role <strong>of</strong> added flavours – essential oils and synthetic<br />

substances in food flavouring.<br />

“<br />

“<br />

6.9 Explain the role <strong>of</strong> saccharine, cyclamates an aspartam in food<br />

flavour.<br />

6.10 Describe the process <strong>of</strong> sensory evaluation <strong>of</strong> food.<br />

“<br />

“<br />

“<br />

“<br />

General Objectives: 7.0 UNDERSTAND THE NATURE AND PROPERTIES OF COMPOUNDS THAT GIVE COLOUR TO <strong>FOOD</strong><br />

PRODUCTS<br />

<strong>FOOD</strong> COLOURING COMPOUNDS<br />

7.1 Explain the importance <strong>of</strong> colour in the acceptability <strong>of</strong> foods.<br />

7.2 Describe the system for measuring the colour <strong>of</strong> food (Hunter and<br />

Munsell)<br />

7.3 Classify food pigments on the basis <strong>of</strong> their basic chemical<br />

structure.<br />

7.4 Describe the changes in food pigments during cooking and<br />

processing.<br />

7.5 Identify the colouring matter permitted in foods.<br />

7.6 Describe the role <strong>of</strong> carmine and colouring matters <strong>of</strong> vegetable<br />

origin in food.<br />

Lecture<br />

Lecture and practical<br />

Lecture<br />

“<br />

Practical identification<br />

“<br />

Teaching Tools<br />

Teaching Tools<br />

“<br />

Colouring matters<br />

“<br />

152

Week<br />

General Objectives:<br />

Special Learning Objective: Teachers Activities Resources<br />

7.7 Separate and identify water and oils soluble colours by paper<br />

chromatography.<br />

7.8 Confirm identity <strong>of</strong> dye using spectrophotometer.<br />

Supervise practical separation by<br />

paper chromatography.<br />

Supervise practical identification.<br />

Paper chromatography<br />

Spectropho meter<br />

153

PRACTICAL CONTENTS<br />

WEK PRACTICALS TEACHERS ACTIVITIES RESOURCES<br />

1.9 Determine the moisture sorption isoterms<br />

(MSI) <strong>of</strong> food materials<br />

Supervise practical<br />

determination <strong>of</strong> MSI<br />

Furnance, crucible laboratory<br />

wares<br />

2.2 Measure the rotary power <strong>of</strong> sugars by<br />

means <strong>of</strong> polarimeter<br />

2.12 Identify starches by microscope<br />

2.13 Determine the gelatinization temperature<br />

<strong>of</strong> starches<br />

2.15 Isolate and demonstrate the physicochemical<br />

properties <strong>of</strong> pactrus<br />

2.18 Measure jell strength using felometer<br />

Supervise practical<br />

determination<br />

Supervise practical<br />

identification <strong>of</strong> starch<br />

Supervise practical<br />

determination<br />

Supervise practical isolation<br />

and grade report<br />

Super practical measurement<br />

and grade report<br />

Polarimeter laboratory wares<br />

Microscope laboratory wares<br />

Laboratory wares<br />

Gelometer laboratory wares<br />

3.3 Fractionate and isolate the proteins in foods<br />

eg milk, egg, meat, wheat flour cowpeas,<br />

sorghum<br />

3.5 Evaluate the physico-chemical properties <strong>of</strong><br />

the isolated protein<br />

4.3 Determine lipids in food<br />

4.6 Determine peroxide, acid saponification<br />

iodine value<br />

Practical fractionating and<br />

isolation<br />

Conduct practical<br />

Supervise practical<br />

determination <strong>of</strong> lipids<br />

Conduct practical and grade<br />

report<br />

Equipment and glassware<br />

hjeldhal apparatus<br />

Soxhlet apparatus<br />

Titrate (Acid-Based)<br />

154

4.7 Determine the following in lip; water<br />

content density, refractive index; melting<br />

point colour vancity<br />

4.17 Identify important emulsifying agents used<br />

in food products<br />

5.2 Distinguish between enzymic and nonenzymic<br />

7.5 Identify the colouring matter permitted in<br />

food<br />

7.7 Separate and identify water oil solulole<br />

colours by paper chromatrography<br />

7.8 Confirm identify <strong>of</strong> dye using<br />

spectrophotometer<br />

Conduct practical and grade<br />

report<br />

Conduct practical<br />

identification <strong>of</strong> agents<br />

Conduct practicals and grade<br />

report<br />

Practical identification<br />

Supervise practical separation<br />

by paper chromatograph<br />

Supervise practical<br />

identification<br />

Refractometer colorimeter<br />

Emulsifying agent<br />

Water bath for determining the<br />

effort <strong>of</strong> blanching on<br />

phenolase<br />

Colouring matter<br />

Paper chromatograph<br />

Spectrophotameter<br />

155

PROGRAMME: <strong>FOOD</strong> <strong>TECH</strong>NOLOGY HIGHER NATIONAL DIPLOMA<br />

COURSE: <strong>FOOD</strong> PLANT SANITATION<br />

CODE: FST 315<br />

DURATION: Hours/Week lecture 1 Tutorial 0 Practical 0<br />

UNIT: 1.0<br />

GOAL: This course is designed to provide students with a knowledge <strong>of</strong> the principles and techniques <strong>of</strong> keepint food<br />

processing plants hygienic and free from contaminations<br />

General Objectives: On completion <strong>of</strong> this course the students should be able to:<br />

1.0 Understand the need for plant sanitation<br />

2.0 Understand sanitation programme procedures<br />

3.0 Know methods <strong>of</strong> handling waste water and industrial effluent<br />

4.0 Know the scope <strong>of</strong> food legislation<br />

156

Programme: HIGHER NATIONAL DIPLOMA IN <strong>FOOD</strong> <strong>TECH</strong>NOLOGY<br />

Course: <strong>FOOD</strong> PLANT SANITATION Course Code: FST 315 Contact Hours: 1 – 0 – 0<br />

Course Goal: this course is designed to enable diplomats know the need and process <strong>of</strong> keeping food plants in hygienic conditions.<br />

Week General Objective:<br />

Special Learning Objective: Teachers Activities Resources<br />

1 - 4 1.0 Understand the need for plant sanitation.<br />

2.0 Understand sanitation programme procedures.<br />

3.0 Know methods <strong>of</strong> handling waste water and industrial effluent.<br />

4.0 Know the scope <strong>of</strong> food legislation<br />

157

Week<br />

1 - 4<br />

General Objectives: UNDERSTAND THE NEED FOR PLANT SANITATION<br />

Special Learning Objective: Teachers Activities Resources<br />

NEED FOR PLANT SANITATION<br />

1.1 Explain the need for hygienic practices in:<br />

(a) Preparation, processing and packaging <strong>of</strong> food<br />

products.<br />

(b) Plant and its premises.<br />

Show students copies <strong>of</strong> the<br />

ordinances.<br />

Cleaning agents.<br />

1.2 Explain the ordinance specifying the following in the food industry:<br />

(a) Health an cleanliness <strong>of</strong> personnel,<br />

(b) Cleanliness, sanitation and protection <strong>of</strong> food utensils/materials,<br />

(c) Food service sanitation<br />

1.3 Explain the sanitary requirements <strong>of</strong> water for various uses in the<br />

food industry.<br />

“<br />

“<br />

“<br />

“<br />

158

Week<br />

5 - 8<br />

General Objectives: UNDERSTAND SANITATION PROGRAMME PROCEDURES<br />

Special Learning Objective: Teachers Activities Resources<br />

SANITATION PROGRAMME PROCEDURE<br />

2.1 Explain the properties <strong>of</strong> a cleaning agent.<br />

2.2 Describe methods <strong>of</strong> plant cleaning and disinfections.<br />

2.3 List factors influencing type <strong>of</strong> cleaning, to e adopted in a food<br />

plant.<br />

Show students samples <strong>of</strong> plant<br />

cleaning agents<br />

“<br />

“<br />

Cleaning agents<br />

“<br />

“<br />

2.4 Explain formulation and blending <strong>of</strong> cleaning agents.<br />

“<br />

“<br />

2.5 Describe basic principle for hygienic design <strong>of</strong> food plants.<br />

“<br />

“<br />

General Objectives: KNOW METHODS OF HANDLING WASTE WATER AND INDUSTRIAL EFFLUENT<br />

3.1 Explain general biological methods for waste disposal/ and or<br />

treatment.<br />

Lecture<br />

Teaching Tools<br />

9 - 12<br />

3.2 Explain Biological Oxygen Demand (BOD), Chemical Oxygen<br />

Demand (COD).<br />

“<br />

“<br />

3.3 Explain dilation <strong>of</strong> wastewater.<br />

“<br />

“<br />

3.4 Describe the use <strong>of</strong> wastewater for irrigation purposes.<br />

3.5 Describe disposed by running wastewater into shallow artificial<br />

ponds.<br />

Give examples <strong>of</strong> large scale use<br />

<strong>of</strong> waste water for irrigation.<br />

“<br />

“<br />

“<br />

159

Week<br />

General Objective:<br />

Special Learning Objective: Teachers Activities Resources<br />

3.6 Explain the use <strong>of</strong> trickling filters made <strong>of</strong> crushed rocks, etc. in<br />

water disposal.<br />

Conduct visit to waster water<br />

treatment plants.<br />

Visit.<br />

3.7 Explain the use <strong>of</strong> artificial sludge for wastewater treatment.<br />

“<br />

General Objectives: 4.0 KNOW THE SCOPE OF <strong>FOOD</strong> LEGISLATION<br />

<strong>FOOD</strong> LEGISLATION<br />

“<br />

4.1 Explain the need for food legislation and standard.<br />

“<br />

“<br />

13 - 15<br />

4.2 Explain the major provisions <strong>of</strong> the Food and Drug Act <strong>of</strong> 1974.<br />

4.3 Describe the importance <strong>of</strong> Codex Alimentarius.<br />

“<br />

“<br />

160

PROGRAMME: <strong>FOOD</strong> <strong>TECH</strong>NOLOGY HIGHER NATIONAL DIPLOMA<br />

COURSE: <strong>FOOD</strong> AND NUTRITION<br />

CODE: FST 316<br />

DURATION; (Hours/Week) Lecture 1 Tutorial 0 Practical 2<br />

UNIT: 2.0<br />

GOAL: This course is designed to enable the students understands the Nutritional constituent <strong>of</strong> food and the effect <strong>of</strong><br />

storage on thee nutritional quality <strong>of</strong> food.<br />

General Objectives:<br />

On completion <strong>of</strong> the course the students should be able to:<br />

1.0 Know the nutritional requirement and allowances for human<br />

2.0 Understand the method <strong>of</strong> nutritional esurient and the composition <strong>of</strong> foods<br />

3.0 Understand the effects <strong>of</strong> processing on the nutritional value <strong>of</strong> foods<br />

4.0 Understand the effects <strong>of</strong> storage method on the nutritional value <strong>of</strong> foods<br />

5.0 Understand the role <strong>of</strong> carbohydrate sweetner in nutritional disorders<br />

6.0 Understand the principles and problems <strong>of</strong> the biological evaluation <strong>of</strong> proteins<br />

161

Programme: HIGHER NATIONAL DIPLOMA IN <strong>FOOD</strong> <strong>TECH</strong>NOLOGY<br />

Course: <strong>FOOD</strong> AND NUTRITION Course Code: FST 316 Contact Hours: 1 - 0 - 2<br />

Course Goal: This course is designed to enable students know the importance <strong>of</strong> nutritional content <strong>of</strong> processed food.<br />

Week General Objectives:<br />

Special Learning Objectives: Teachers Activities Resources<br />

1.0 Know the nutritional requirements and allowances for humans.<br />

2.0 Understand the methods <strong>of</strong> nutritional assessment and the<br />

composition <strong>of</strong> food.<br />

3.0 Understand the effects <strong>of</strong> processing on the nutritional value <strong>of</strong><br />

foods.<br />

4.0 Understand the effect <strong>of</strong> storage methods on the nutritional value <strong>of</strong><br />

foods.<br />

5.0 Understand the role <strong>of</strong> carbohydrates, sweeteners in nutritional<br />

disorders.<br />

6.0 Understand the principles and problems <strong>of</strong> the biological evaluation<br />

<strong>of</strong> proteins.<br />

162

Week<br />

1 - 3<br />

General Objective: 1.0 KNOW THE NUTRITIONAL REQUIREMENT AND ALLOWANCES FOR HUMANS<br />

Special Learning Objective: Teachers Activities Resources<br />

NUTRITIONAL REQUIREMENTS FOR HUMANS<br />

1.1 Explain the importance <strong>of</strong> nutrients to the body.<br />

Explain using nutrition chart. Teaching Tools<br />

1.2 Explain the factors influencing the nutrient and energy requirement<br />

<strong>of</strong> adults, children, infants, pregnant and lactating women.<br />

1.3 Describe the working principle <strong>of</strong> the bomb calorimeter.<br />

1.4 Measure energy constant <strong>of</strong> food using the bomb calorimeter.<br />

1.5 Explain the difference between calorie energy, faecel energy,<br />

digestible energy, and metabolism energy.<br />

1.6 State the energy partition equation and explain its significance.<br />

“<br />

Lecture and practical<br />

Supervise measurement <strong>of</strong><br />

energy content using bomb<br />

calorimeter<br />

“<br />

“<br />

“<br />

Bomb calorimeter<br />

“<br />

“<br />

163

Week<br />

General Objective: 2.0 UNDERSTAND THE METHODS OF NUTRITIONAL ASSESSMENT AND THE COMPOSITION OF <strong>FOOD</strong>S<br />

Special Learning Objective: Teachers Activities Resources<br />

COMPOSITION OF <strong>FOOD</strong>S<br />

2.1 List the classes <strong>of</strong> food on the basis <strong>of</strong> their biological characteristic<br />

and give local example.<br />

Explain using chart.<br />

Nutrition charts.<br />

4 - 6<br />

2.2 Identify local examples <strong>of</strong> each <strong>of</strong> 2.1 above.<br />

Display the local examples.<br />

Food samples<br />

2.3 Describe the nutritional composition <strong>of</strong>: cereals, root crops, fruits<br />

and vegetables, animal foods.<br />

“<br />

“<br />

2.4 Explain the following methods <strong>of</strong> nutritional assessment: clinical<br />

observation, biochemical, anthropothetrical method, evaluation <strong>of</strong><br />

nutrient intake<br />

“<br />

“<br />

“<br />

General Objective: 3.0 UNDERSTAND THE EFFECTS OF PROCESSING ON THE NUTRITIONAL VALUE OF <strong>FOOD</strong>S<br />

EFFECT OF PROCESSING ON NUTRITIONAL VALUE OF <strong>FOOD</strong><br />

3.1 Describe the effect <strong>of</strong> heat processing on the nutritional value <strong>of</strong><br />

vitamins and minerals.<br />

Lecture<br />

Teaching Tools<br />

7 – 9<br />

3.2 Describe the effects <strong>of</strong> the following processing operations on the<br />

nutritional value <strong>of</strong> foods: milling; fermentation; drying.<br />

“<br />

“<br />

3.3 Measure the progressive drop in vitamin C content <strong>of</strong> vegetable<br />

during sun drying by spectrophotometer.<br />

Supervise<br />

practical<br />

measurement <strong>of</strong> vitamin C<br />

Spectrophotometer<br />

164

Week<br />

10 - 12<br />

General Objective: 4.0 UNDERSTAND THE EFFECT OF STORAGE METHODS ON THE NUTRIONAL VALUE OF <strong>FOOD</strong>S<br />

Special Learning Objective: Teachers Activities Resources<br />

EFFECT OF STORAGE ON NUTRITIONAL VALUE OF <strong>FOOD</strong><br />

4.1 Describe the common storage methods (traditional and modern). Show students models <strong>of</strong> Traditional and modern storage<br />

storage structures for grain structures.<br />

4.2 Explain the effect <strong>of</strong> storage methods in 1.4 above on the fruits, vegetable grade sketches.<br />

nutritional value <strong>of</strong> foods.<br />

“<br />

Supervise<br />

practical<br />

4.3 Measure the progressive drop in vitamin C content <strong>of</strong> vegetable measurement <strong>of</strong> vitamin C.<br />

during wet storage using spectrophotometer.<br />

Spectrophotometer<br />

General Objective: 5.0 UNDERSTAND THE ROLE OF CARBOHYDRATES SWEETENERS IN NUTRITIONAL DISORDERS<br />

CARBOHYDRATE SWEETENERS IN NUTRITIONAL DISORDER<br />

5.1 Identify the different important carbohydrate sweeteners in the food<br />

industry.<br />

Show students samples <strong>of</strong><br />

sweeteners<br />

Common sweeteners.<br />

13 - 14<br />

5.2 Describe the contribution <strong>of</strong> carbohydrates in the occurrence <strong>of</strong><br />

diabetes, obesity, dental caries.<br />

General Objectives: 6.0 UNDERSTAND THE PRINCIPLES AND PROBLEMS OF THE BIOLOGICAL EVALUATION OF PROTEINS<br />

BIOLOGICAL EVALUATION OF PROTEINS<br />

“<br />

“<br />

15<br />

6.1 Describe the evaluations <strong>of</strong> protein quality by the following<br />