Joe Justice: Managing a Collaborative Multi-National Team in Real ...

Joe Justice: Managing a Collaborative Multi-National Team in Real ...

Joe Justice: Managing a Collaborative Multi-National Team in Real ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Joe</strong> <strong>Justice</strong>: <strong>Manag<strong>in</strong>g</strong> a <strong>Collaborative</strong> <strong>Multi</strong>-<strong>National</strong> <strong>Team</strong> <strong>in</strong> <strong>Real</strong> Time – Transcript of 52-92 m<strong>in</strong> video<br />

Agile2012 Dallas, TX 13-17Aug2012, www.agilealliance.org/resources/learn<strong>in</strong>g-center/agile2012-keynote-joe-justice<br />

00:00 – [<strong>Joe</strong> <strong>Justice</strong> <strong>in</strong>troduces himself and then <strong>in</strong>troduces Christopher Gong from Deloitte’s Center for the Edge. Not<br />

transcribed]<br />

00:29 – [Christopher Gong, Deloitte Center for the Edge, makes the general argument for agility by review<strong>in</strong>g the<br />

2011 Shift Index material. Not transcribed.]<br />

04:15 – [Gong then moves to cars and <strong>Team</strong> WikiSpeed. Low value, not transcribed].<br />

07:03 – [Gong still] The more time you spend with the team you realize it’s not so much about the tools that they<br />

use, but the better practices and the better cultures they’ve created around these tools. It’s not that WikiSpeed uses a<br />

KanBan board. It’s that WikiSpeed has created a culture that promotes enthusiasm and draws people <strong>in</strong> who are<br />

eager to participate <strong>in</strong> solv<strong>in</strong>g problems. It’s not that <strong>Joe</strong> uses social media, it’s that he’s committed to radical<br />

transparency, and openness <strong>in</strong> a way that compels people from across the world to participate. And it’s not that they<br />

have a CNC mach<strong>in</strong>e, but that they are committed to rapidly iterat<strong>in</strong>g on their vehicle, which they do every seven<br />

days. So it’s the comb<strong>in</strong>ation of these tools and these practices that has created the results that <strong>Team</strong> WikiSpeed has<br />

been able to achieve. Now see<strong>in</strong>g the way these tools have been applied <strong>in</strong> the auto <strong>in</strong>dustry begs the question, how<br />

much better would the world be if we were to apply these agile methodologies and <strong>Joe</strong>’s methodologies, not only <strong>in</strong><br />

the auto <strong>in</strong>dustry, but across the economy to solve all of the problems that we are fac<strong>in</strong>g as a society today. Now as<br />

<strong>Joe</strong> walks you more through his methodology, and how that applies to different clients and different situations that<br />

he’s worked <strong>in</strong>, I want you to th<strong>in</strong>k about that, just that. I would <strong>in</strong>vite you to th<strong>in</strong>k about where we can apply these<br />

methodologies and these tools to make society a better place.<br />

08:25 – [Return to <strong>Joe</strong>] Thanks so much Christopher. Now Christopher’s day job at Deloitte’s Center for the Edge and<br />

my day job at Solutions IQ are basically competitors. What we found, though, is that there’s a trend which I’m go<strong>in</strong>g<br />

to call and expla<strong>in</strong> as agile – agile project management, agile delivery, that seems to be disrupt<strong>in</strong>g all <strong>in</strong>dustry now.<br />

It’s already disrupted software. I just looked through Google F<strong>in</strong>ance aga<strong>in</strong>, and looked at the top IPO generat<strong>in</strong>g<br />

companies of all time. And if I look at the tech companies where agile already has a strong foothold, all of the top ten<br />

have agile teams or are agile companies. Agile is dom<strong>in</strong>at<strong>in</strong>g <strong>in</strong> returns and <strong>in</strong> <strong>in</strong>vestor confidence right now <strong>in</strong> tech,<br />

and that trend is beg<strong>in</strong>n<strong>in</strong>g to happen outside of software companies.<br />

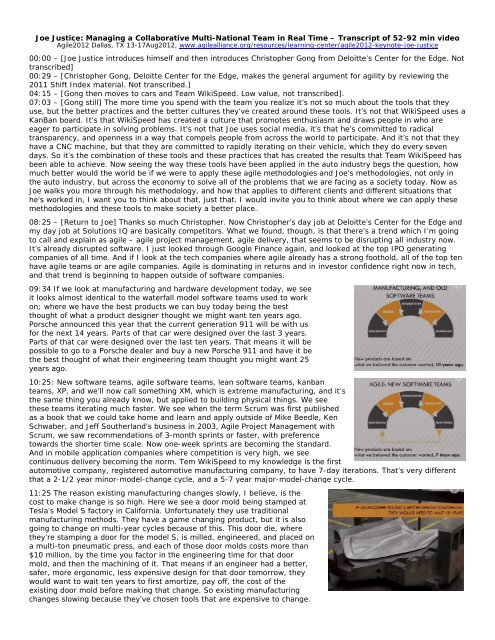

09:34 If we look at manufactur<strong>in</strong>g and hardware development today, we see<br />

it looks almost identical to the waterfall model software teams used to work<br />

on; where we have the best products we can buy today be<strong>in</strong>g the best<br />

thought of what a product designer thought we might want ten years ago.<br />

Porsche announced this year that the current generation 911 will be with us<br />

for the next 14 years. Parts of that car were designed over the last 3 years.<br />

Parts of that car were designed over the last ten years. That means it will be<br />

possible to go to a Porsche dealer and buy a new Porsche 911 and have it be<br />

the best thought of what their eng<strong>in</strong>eer<strong>in</strong>g team thought you might want 25<br />

years ago.<br />

10:25: New software teams, agile software teams, lean software teams, kanban<br />

teams, XP, and we’ll now call someth<strong>in</strong>g XM, which is extreme manufactur<strong>in</strong>g, and it’s<br />

the same th<strong>in</strong>g you already know, but applied to build<strong>in</strong>g physical th<strong>in</strong>gs. We see<br />

these teams iterat<strong>in</strong>g much faster. We see when the term Scrum was first published<br />

as a book that we could take home and learn and apply outside of Mike Beedle, Ken<br />

Schwaber, and Jeff Southerland’s bus<strong>in</strong>ess <strong>in</strong> 2003, Agile Project Management with<br />

Scrum, we saw recommendations of 3-month spr<strong>in</strong>ts or faster, with preference<br />

towards the shorter time scale. Now one-week spr<strong>in</strong>ts are becom<strong>in</strong>g the standard.<br />

And <strong>in</strong> mobile application companies where competition is very high, we see<br />

cont<strong>in</strong>uous delivery becom<strong>in</strong>g the norm. Tem WikiSpeed to my knowledge is the first<br />

automotive company, registered automotive manufactur<strong>in</strong>g company, to have 7-day iterations. That’s very different<br />

that a 2-1/2 year m<strong>in</strong>or-model-change cycle, and a 5-7 year major-model-change cycle.<br />

11:25 The reason exist<strong>in</strong>g manufactur<strong>in</strong>g changes slowly, I believe, is the<br />

cost to make change is so high. Here we see a door mold be<strong>in</strong>g stamped at<br />

Tesla’s Model S factory <strong>in</strong> California. Unfortunately they use traditional<br />

manufactur<strong>in</strong>g methods. They have a game chang<strong>in</strong>g product, but it is also<br />

go<strong>in</strong>g to change on multi-year cycles because of this. This door die, where<br />

they’re stamp<strong>in</strong>g a door for the model S, is milled, eng<strong>in</strong>eered, and placed on<br />

a multi-ton pneumatic press, and each of those door molds costs more than<br />

$10 million, by the time you factor <strong>in</strong> the eng<strong>in</strong>eer<strong>in</strong>g time for that door<br />

mold, and then the mach<strong>in</strong><strong>in</strong>g of it. That means if an eng<strong>in</strong>eer had a better,<br />

safer, more ergonomic, less expensive design for that door tomorrow, they<br />

would want to wait ten years to first amortize, pay off, the cost of the<br />

exist<strong>in</strong>g door mold before mak<strong>in</strong>g that change. So exist<strong>in</strong>g manufactur<strong>in</strong>g<br />

changes slow<strong>in</strong>g because they’ve chosen tools that are expensive to change.

12:29 In <strong>Team</strong> WikiSpeed we had to try a different approach, and I have a<br />

software development background as do most of the people <strong>in</strong> this room. I<br />

was used to th<strong>in</strong>k<strong>in</strong>g I can’t design a whole solution at once, it was to big to<br />

even have <strong>in</strong> my head at once. I had to split it up <strong>in</strong>to pieces, modules.<br />

Object Oriented Programm<strong>in</strong>g says: first have a clear <strong>in</strong>terface, and then<br />

have classes, then you can change those classes, and you have hotswappable<br />

loosely-coupled modules. That’s exactly how we eng<strong>in</strong>eered the<br />

car. The car’s built <strong>in</strong> eight parts, or modules, and they switch <strong>in</strong>dependently.<br />

This means we can roll out the gasol<strong>in</strong>e eng<strong>in</strong>e and roll <strong>in</strong> an electric drive<br />

tra<strong>in</strong>, a bio-diesel drive tra<strong>in</strong>, a methanol or ethanol drive tra<strong>in</strong>, <strong>in</strong> about the<br />

time it takes to change a tire. This means we can change the entire car body<br />

from a convertible to a pick-up truck. This lets us change quickly, and this<br />

also gives a level of flexibility for our customers that they’ve never had <strong>in</strong> the<br />

automotive space before.<br />

13:29 The team works us<strong>in</strong>g agile, lean, scrum, kanban, XP, and what I’ll call<br />

XM, but its really just exactly the same processes, and we’ve taken the word<br />

“software” and changed it to “customer visible value”. Here we see the team<br />

do<strong>in</strong>g a swarm. They’ve just taken the car apart <strong>in</strong>to its eight pieces, and<br />

now they’re putt<strong>in</strong>g them back together. This picture was taken at the X-<br />

Prize. The X-Prize was a $10 million dollar prize purse, to see if it was even<br />

possible to build road-legal cares that were safe, that achieved over 100<br />

miles per gallon. Nobody knew if it could even happen. 136 cars entered<br />

from all over the world, and we tied for 10 th place <strong>in</strong> the ma<strong>in</strong>stream class.<br />

We didn’t w<strong>in</strong>. We didn’t get the $10 million prize. but we cam <strong>in</strong> ahead of<br />

over 100 other cars, <strong>in</strong>clud<strong>in</strong>g cars from companies like Tesla, MIT, and Tata<br />

motors <strong>in</strong> India. I th<strong>in</strong>k the only reason this was possible is because we used<br />

agile project management and agile delivery, and we had a modular car.<br />

14:33 When other teams were figur<strong>in</strong>g out their plann<strong>in</strong>g phase, say<strong>in</strong>g how much is this go<strong>in</strong>g to cost, how long is<br />

this go<strong>in</strong>g to take, what materials are we go<strong>in</strong>g to make it out of, who’s go<strong>in</strong>g to do it, who’s our team – we just built<br />

tests, test-driven development, say<strong>in</strong>g we need to pass the side impact test, we need to pass the offset frontal test,<br />

we need to achieve more than 100 miles per gallon on the EPA UDDS city driv<strong>in</strong>g cycle. And we had fail<strong>in</strong>g tests, and<br />

said all right what’s the fastest leanest th<strong>in</strong>g we can build that will pass this test, how about this test? And never<br />

asked ourselves how much cost will this be, where will we build it, what materials will we build it out of, who will do<br />

the work – <strong>in</strong>stead we just had clear tests to know when we were done, and iterated as rapidly as possible on those.<br />

And we had a Scrum master as a servant-leader. They are a process steward, but more importantly they’re there to<br />

do anyth<strong>in</strong>g they can do to accelerate the speed of the team. They’ll hand someone a screwdriver if they see they<br />

might need it, they’ll run and get coffee, they’ll run and get lemonade, they’ll change the lights, they’ll see if they can<br />

adjust the temperature. Anyth<strong>in</strong>g they can do to <strong>in</strong>crease the velocity, they susta<strong>in</strong>able velocity of the team, without<br />

be<strong>in</strong>g <strong>in</strong> their way. And they’re a process steward. But by the time a team has done 10 daily stand-ups they’re call<strong>in</strong>g<br />

for the daily stand-ups themselves. And it only takes then a very savvy coach, scrum master, who studied some team<br />

psychology to be able to add additional value.<br />

15:56 – This is what a vertical slice of a car looks like <strong>in</strong> our<br />

world. We had to have someth<strong>in</strong>g on the road quickly to know<br />

if we were on the right track, and so we could iterate. That<br />

meant, just like <strong>in</strong> software, where we’ll have the user<br />

<strong>in</strong>terface layer, the bus<strong>in</strong>ess layer, the data layer, our n-tier<br />

design if that’s how we’re do<strong>in</strong>’ it. We had to have a complete<br />

version of someth<strong>in</strong>g that’s road legal to beg<strong>in</strong> test<strong>in</strong>g. We<br />

were able to develop this <strong>in</strong> three months. When we compare<br />

that with the design and development cycles of traditional<br />

automotive manufactur<strong>in</strong>g the difference is two orders of<br />

magnitude <strong>in</strong> time.<br />

15:45 – Two years later we have this. I hope what you’re able<br />

to see is that these methods might not only apply <strong>in</strong> broader<br />

<strong>in</strong>dustry, but that they might be able to accelerate the pace of<br />

new product development extremely, and that they might<br />

even yield products that people might want to use. What I hop<br />

you guys are start<strong>in</strong>g to get out of this is that everyone <strong>in</strong> this<br />

room is now not just on the avant guard of the transformation<br />

of the software <strong>in</strong>dustry. We might be, everyone <strong>in</strong> this room,<br />

on the transformation of what hardware development<br />

manufactur<strong>in</strong>g, enterta<strong>in</strong>ment, the f<strong>in</strong>ancial sector, energy and<br />

oil, government – might be do<strong>in</strong>g. It’s because it’s predicated

on the speed and quality that happens when we use all these<br />

processes together.<br />

17:40 – You’ve been <strong>in</strong> sessions on XP and here’s your first on XM, if this is XM. You’ve been <strong>in</strong> sessions on scrum.<br />

You’ve been <strong>in</strong> sessions on the agile umbrella that encompasses some or most of these methodologies depend<strong>in</strong>g on<br />

how you th<strong>in</strong>k about it. You’ve been <strong>in</strong> sessions on lean. Those same tools might apply to everyth<strong>in</strong>g we do. And we<br />

might be see<strong>in</strong>g, if the Big Shift (Deloitte start-of-presentation segment) is correct, the largest change s<strong>in</strong>ce before<br />

the <strong>in</strong>dustrial revolution. Nor everyone here might agree with Stephen Denn<strong>in</strong>g. I do, when he says the agile<br />

transformation is a larger shift then the <strong>in</strong>dustrial revolution. We’ll f<strong>in</strong>d out, we’re on the cusp of that right now.<br />

18:20 – Here’s one of our kanban boards. This is at<br />

our Seattle, Wash<strong>in</strong>gton shop that we’ve s<strong>in</strong>ce<br />

outgrown. Here we are talk<strong>in</strong>g to the team about what<br />

we’re go<strong>in</strong>g to do today. We’re go<strong>in</strong>g through tasks<br />

like: sand down car body two, take the Discovery<br />

Channel for a test drive, swar out eng<strong>in</strong>e module V4,<br />

reroute exhaust <strong>in</strong> eng<strong>in</strong>e module V2. These are<br />

hardware manufactur<strong>in</strong>g tasks.<br />

18:43 – The tools we use to do this are all free, and<br />

none of them existed ten years ago. Most of them<br />

didn’t even exist five years ago. Apply<strong>in</strong>g these<br />

methods with a radically distributed team like <strong>Team</strong><br />

WikiSpeed has to, with volunteers all over the world,<br />

would have been difficult or even impossible five years<br />

ago.<br />

19:05 – We now have 150 team members <strong>in</strong> 18 countries.<br />

You’ll see highlighted <strong>in</strong> red is our newest shop <strong>in</strong> New<br />

Zealand <strong>in</strong> Christchurch, New Zealand. Do we have a few<br />

folks from New Zealand here today? We do. Everybody<br />

please thank the Kiwi country for be<strong>in</strong>g KiWikiSpeed. Thanks<br />

guys very much for com<strong>in</strong>g down.<br />

19:28 – [<strong>Joe</strong> <strong>Justice</strong> <strong>in</strong>troduces a team member from Turkey, Emre Aras, who speaks about his newbie <strong>in</strong>sertion-<strong>in</strong>the-team<br />

experience. Not transcribed]<br />

23:10 – [<strong>Joe</strong>’s back] Thank you, Emre. We’re go<strong>in</strong>g to<br />

show you a sneak preview of someth<strong>in</strong>g a lot like this <strong>in</strong><br />

just a few m<strong>in</strong>utes. But before that I’d like too show you<br />

what the pace of development can look like <strong>in</strong> some other<br />

<strong>in</strong>dustries we’ve had a chance to work with s<strong>in</strong>ce the last<br />

time I was able to speak at an agile or a scrum gather<strong>in</strong>g.<br />

23:36 – If we look at the anthropological record, and we<br />

look at Homo ergaster, which may have been the first<br />

great ape to generate fire with fire mak<strong>in</strong>g tools; and we look at the tool set that is found associated with those<br />

rema<strong>in</strong>s and are carbon dated to have been the same date as the fossils next to them, we see that their tool set was<br />

very advanced compared to any of the other creatures on the planet at that time, and didn’t change fundamentally for<br />

over 2 million years. And then we see Homo neanderthalis and Homo erectus hav<strong>in</strong>g a very similar tool rate of<br />

change. And about 150 thousand years ago, we have through genetic randomization dat<strong>in</strong>g, essentially the same<br />

genetic structure as we have today. And we have Homo sapiens. And we also have modern chimpanzees, our closest<br />

liv<strong>in</strong>g relative. At that time the anthropological record <strong>in</strong>dicates there was about one million Homo sapiens and about<br />

one million chimpanzees. Homo sapiens began to change their toll set with<strong>in</strong> a s<strong>in</strong>gle generation. Homo sapiens began<br />

to change their tool set to be able to extract more energy from the world around them every generation, and now<br />

every m<strong>in</strong>ute. It’s been compound<strong>in</strong>g. We have a growth curve <strong>in</strong> the pace of mak<strong>in</strong>g change that is stand<strong>in</strong>g on its<br />

end. And we have the rate of adoption from hav<strong>in</strong>g a phone <strong>in</strong> your household to hav<strong>in</strong>g a cell phone be<strong>in</strong>g an order<br />

of magnitude less. It may be that the one th<strong>in</strong>g our species does very differently than any other species on this<br />

planet, is <strong>in</strong>crease the rate of change. There are now seven billon now, almost, Home sapiens on this planet, and<br />

there are 65,000 chimpanzees. You can look to ask, has our closest liv<strong>in</strong>g relative changed its tool set or the way it<br />

extracts energy from the environment around it? No. It hasn’t. And if you look at Homo sapiens over the last 150<br />

thousand years and ask have our life ways changed, and the way we gather energy from the world around us? Well,<br />

yes. Agile may be a natural expression of the very natural trend to <strong>in</strong>crease the pace of change, that our species is so<br />

good at it; and might be the s<strong>in</strong>gle most differentiat<strong>in</strong>g factor of our species from anyth<strong>in</strong>g else on this planet.<br />

26:01 – John Deere heard a TedX talk I gave and saw a magaz<strong>in</strong>e that <strong>Team</strong> WikiSpeed was <strong>in</strong>. They sent three

managers our garage <strong>in</strong> Seattle, Wash<strong>in</strong>gton, to take a look at what we<br />

were do<strong>in</strong>g. And then they <strong>in</strong>vited me to their world headquarters at<br />

Mol<strong>in</strong>e, Ill<strong>in</strong>ois, to give a talk about what they called “frugal eng<strong>in</strong>eer<strong>in</strong>g”<br />

and “frugal <strong>in</strong>novation”, and I had found this quote. And we talked about modular tractors. We talked about a start-up<br />

mak<strong>in</strong>g open-source agricultural equipment called Open Source Ecology. They’d already been familiar with Open<br />

Source Ecology and with this movement of much less expensive, quicker to make change, agricultural tools. They<br />

were very curious about it, and wanted to know about this trend.<br />

26:52 – And then, I gave them this quote. John Deere and their<br />

predecessors have been build<strong>in</strong>g tractors for 175 years. Their current<br />

iteration of the tractor is the 8030 large tractor platform. The head of<br />

that team had given us this quote <strong>in</strong> 2007: “The 8030 tractor<br />

development process is quite predictable. We expect to hit the capital<br />

plan perfectly and R&D spend<strong>in</strong>g with<strong>in</strong> 5 percent. We know how many<br />

resources we need and when we need them.” That’s from Mr. Wienkes,<br />

the large tractor eng<strong>in</strong>eer<strong>in</strong>g lead at John Deere <strong>in</strong> 2007. They’ve been<br />

do<strong>in</strong>g this for 175 years, they have a high level of confidence on how long<br />

it takes and how much it costs.<br />

27:32 – A Dartmouth study cam out that was handed to me by someone<br />

at John Deere about the same project, and they reported the project ran<br />

6 months over, and the eng<strong>in</strong>eers were work<strong>in</strong>g 12 to 14 hour days. Even<br />

still they dropped some of the key features. That tractor shipped and<br />

made an enormous amount of money. John Deere was very happy but<br />

they know that the pace of development was chang<strong>in</strong>g <strong>in</strong> the whole world<br />

around them. And it might be time to evaluate the way they forecast and<br />

predict projects. When I gave them this quote and compared it to this<br />

piece of evidence I thought I’d be thrown out of the build<strong>in</strong>g. I was quite<br />

scared. Instead, they put me on a boat to give this talk aga<strong>in</strong> at their<br />

annual budget<strong>in</strong>g cycle, to say maybe our budget<strong>in</strong>g shouldn’t be annual.<br />

28:24 – And I just got a call last week where they were say<strong>in</strong>g “what would Wiki-Deere look like?”<br />

28:42 – Then, Boe<strong>in</strong>g contacted <strong>Team</strong> WikiSpeed, and their just up<br />

the road, the largest aircraft manufacturer <strong>in</strong> the world, and they’re<br />

<strong>in</strong> Mulkiteo and Everett, Wash<strong>in</strong>gton, and all over the world, but<br />

that’s their headquarters. We’re <strong>in</strong> L<strong>in</strong>wood, Wash<strong>in</strong>gton now, just<br />

north of Seattle. So were about 20 m<strong>in</strong>utes away from each other.<br />

They said “we would like to give you a tour of our 787, 777, and 767<br />

manufactur<strong>in</strong>g l<strong>in</strong>es. We went <strong>in</strong>side the largest enclosed space <strong>in</strong><br />

the world. The build<strong>in</strong>g is so large, they’ve had clouds form <strong>in</strong>side<br />

and had it ra<strong>in</strong> <strong>in</strong>side the build<strong>in</strong>g. Here we are stand<strong>in</strong>g, not even<br />

directly <strong>in</strong> front, but near one of the jet eng<strong>in</strong>es. You see how<br />

massive the scale of th<strong>in</strong>gs is. It’s very easy to loose focus and it all<br />

seems small until you look at a person sized door, even just one<br />

quarter of the way down the build<strong>in</strong>g, and someone go<strong>in</strong>g <strong>in</strong> and<br />

out, it’s astound<strong>in</strong>g. It’s like the Arc of the Covenant scene from<br />

Indiana Jones, but all planes.<br />

29:40 – Then we talked about MakerPlane. MakerPlane is an agile<br />

aircraft company. They’re build<strong>in</strong>g four and size seat light passenger<br />

aircraft. They claim to be us<strong>in</strong>g the WikiSpeed method. Their team<br />

lead has emailed me and I’ve emailed them back, and as far as I can<br />

tell they’ve absolutely got it. I’m very excited to see what comes out<br />

of this group. And so Boe<strong>in</strong>g is look<strong>in</strong>g at these groups and say<strong>in</strong>g<br />

“What does that mean <strong>in</strong> terms of pace of development? How can<br />

we accelerate the pace of development with high quality?” And those<br />

are sessions that all of you have been attend<strong>in</strong>g all week.

30:16 – So after go<strong>in</strong>g to their enormous build<strong>in</strong>g, we took them to<br />

our Lynnwood shop. They hosted a d<strong>in</strong>er there and sent fifteen of<br />

the executives over. That’s the first time we’ve ever had a d<strong>in</strong>er<br />

hosted <strong>in</strong> <strong>Team</strong> WikiSpeed with table cloths and everyth<strong>in</strong>g. One of<br />

their double PhD computational fluid dynamacists said “You know,<br />

the mach<strong>in</strong>ery we’re us<strong>in</strong>g is more advanced than yours, but you<br />

guys are so far ahead of us culturally that we have so much to learn<br />

from you. I was very quick to say “Vice versa. We’re still very small.<br />

Let’s be good friends”. But the fact that they’re even <strong>in</strong>terested <strong>in</strong><br />

what a bunch of people are do<strong>in</strong>g <strong>in</strong> garages and storage units lets<br />

me know that maybe we are actually see<strong>in</strong>g a big shift across all<br />

<strong>in</strong>dustry.<br />

31:09 – Then I had the privilege to go to Tait Radio <strong>in</strong> New<br />

Zealand. Tim Myer went with me, another Solutions IQ<br />

employee, who also after work volunteer’s his time at <strong>Team</strong> WikiSpeed. Tim Myer’s expertise is test fixtures, and test<br />

fixtures now not just for software and cont<strong>in</strong>uous iterations and automated test coverage, but the same for physical<br />

manufactur<strong>in</strong>g. He paired with our electronics team <strong>in</strong> Mea, France, to develop and implements an accelerator pedal<br />

recorder, allow<strong>in</strong>g us to be driv<strong>in</strong>g and record accelerator pedal pulses and drive cycles, and play them back for<br />

automated test<strong>in</strong>g to see if the changes we’d made to emissions and fuel<strong>in</strong>g were mov<strong>in</strong>g us higher or lower with the<br />

same recorded test procedures. This type of device is not novel <strong>in</strong> the automotive <strong>in</strong>dustry, but it’s still fairly new and<br />

doesn’t have full adoption. Some of the test fixtures we use are wholly new, and the only reason they’re wholly new is<br />

because we design tests before we try to solve any problems. We practice TDD. Or, maybe it’s TDM?. Manufactur<strong>in</strong>g.<br />

It’s the same practice. It probably doesn’t even need another name. You folks are all experts on this now, just as<br />

you’re familiar with TDD.<br />

32:18 – In New Zealand Tait creates hardware goods. They make radio<br />

systems. Now they make digital encrypted radio systems for ambulatory,<br />

fire fight<strong>in</strong>g, and law enforcement services, among others. Here you see one<br />

of their P25 base stations. This unit sits <strong>in</strong> a rack and receives radio signals<br />

form other devices, performs digital signal process<strong>in</strong>g, and reemits the<br />

signals to transmit them at further distances than a hand-held or a mobile<br />

can do to each other.<br />

32:46 – This is what the scrum room for a hardware eng<strong>in</strong>eer<strong>in</strong>g team can<br />

look like. Tim and I landed and we told the team we’re do<strong>in</strong>g an experiment<br />

to see if we can develop products more quickly. Let’s have everyone needed<br />

to create this product be <strong>in</strong> one co-located space, a scrum room. And we<br />

had hardware eng<strong>in</strong>eers there, they were do<strong>in</strong>g solder<strong>in</strong>g, chip test<strong>in</strong>g, rapid<br />

circuit board simulation, And we had embedded software eng<strong>in</strong>eers. And we<br />

had application software eng<strong>in</strong>eers. And we had market<strong>in</strong>g. All <strong>in</strong> one room.<br />

We launched the team on Monday.<br />

33:31 – And the product owner [video of Tait employee David Jenks beg<strong>in</strong>s]: “As<br />

the product owner/manager I was able to get a very quick estimate of the scope<br />

of work and the impact that it might have if we were to choose one option vs<br />

another option. So the example was that I asked about the 50 100 Watt change<br />

do<strong>in</strong>g a 100 to 50 with respect to the different discipl<strong>in</strong>es <strong>in</strong> the stand-up and<br />

were <strong>in</strong> three m<strong>in</strong>utes able to get a good estimate of the impact on each of the<br />

discipl<strong>in</strong>es. That contrasts I th<strong>in</strong>k with weeks to get a feel for mak<strong>in</strong>g that choice.<br />

That was a real example for me.<br />

[Tim Meyer beh<strong>in</strong>d camera repeats for David’s confirmation]: “So <strong>in</strong> this case, be<strong>in</strong>g able to have the team <strong>in</strong> a colocated<br />

area, and simply ask the question of everyone at their workstations <strong>in</strong> this co-located area, you were able to<br />

get an answer <strong>in</strong> about three m<strong>in</strong>utes. In fact I th<strong>in</strong>k the decision was made <strong>in</strong> ten m<strong>in</strong>utes on a 50 Watt amplifier,<br />

and we ended up choos<strong>in</strong>g a 100 Watt amplifier, by know<strong>in</strong>g how this would impact each team member and what risk<br />

that would give. And it would have taken a couple of weeks <strong>in</strong> a non-collaborative work model.<br />

34:49 – [<strong>Joe</strong> <strong>Justice</strong>] The product owner reported see the same type of velocity <strong>in</strong>creases <strong>in</strong> terms of team decision<br />

mak<strong>in</strong>g, which was a novel concept entirely for a command/control culture previously <strong>in</strong> some of the organization. A<br />

decision/resolution made <strong>in</strong> three m<strong>in</strong>utes, and a decision ratified among the entire team <strong>in</strong> ten m<strong>in</strong>utes. Instead of<br />

the team be<strong>in</strong>g told what the answer was, the team came up and then spread consensus <strong>in</strong> ten m<strong>in</strong>utes, <strong>in</strong> what<br />

would have taken, he said, multiple weeks. A small w<strong>in</strong>. Later that same week, David Jenks aga<strong>in</strong>, the product owner,<br />

said <strong>in</strong>formation bubbled up by hav<strong>in</strong>g people from different discipl<strong>in</strong>es work<strong>in</strong>g together on this same problem,<br />

sav<strong>in</strong>g them more than one person year of work across a core team of seven people and a lot larger team of about 27<br />

people.

35:35 That team launched on Monday, and they had a work<strong>in</strong>g prototype <strong>in</strong> a proxy<br />

customer’s hands on Friday, mak<strong>in</strong>g calls through the radio system to test the system.<br />

The eng<strong>in</strong>eers <strong>in</strong> the same room had direct feedback from the customer for the first<br />

time ever. It normally takes three months, or <strong>in</strong> some cases I’m told longer, it can be<br />

on the order of years, to have a prototype be<strong>in</strong>g <strong>in</strong>terfaced with by a customer. It was<br />

able to be done <strong>in</strong> one week. And we didn’t, Tim and I, tell them what process to use.<br />

We walked <strong>in</strong> and said: You’re self organiz<strong>in</strong>g. You can do anyth<strong>in</strong>g you need to do to<br />

deliver quickly. Here’s the goal, let’s have a radio <strong>in</strong> a customer’s hand by Friday, and<br />

have them us<strong>in</strong>g it, a prototype of this product. You can use any practice, process you’d like to up to break<strong>in</strong>g the law,<br />

but Tim and I are here to coach you on agile, lean, scrum, Kanban, XP, XM if you’d like it. We ended up runn<strong>in</strong>g<br />

sessions on all of the above.<br />

36:33 – Tait was already do<strong>in</strong>g so many th<strong>in</strong>gs right, it helped. Their manufactur<strong>in</strong>g l<strong>in</strong>e, right next to it, has a rapid<br />

prototyp<strong>in</strong>g lab to make test fixtures for the automated l<strong>in</strong>e. Their test fixtures are cardboard, just like many of the<br />

parts that WikiSpeed cars start out as, as we iterate “stubs”. They already practices stand-ups <strong>in</strong> their l<strong>in</strong>e<br />

manufactur<strong>in</strong>g, <strong>in</strong> their HR department, and <strong>in</strong> their market<strong>in</strong>g and project management department. While we were<br />

there they started us<strong>in</strong>g retrospectives <strong>in</strong> those departments. While we were their we talked about adopt<strong>in</strong>g a product<br />

owner and a scrum master role to have a team steward servant-leader embedded <strong>in</strong> the team, and someone with a<br />

clear vision of the end-state of the product. And we saw the result of that with product owners and scrum masters <strong>in</strong><br />

HR and <strong>in</strong> the company change-management team.<br />

37:24 – Here we are conduct<strong>in</strong>g a cross discipl<strong>in</strong>e<br />

retrospective, with the C-suite, product eng<strong>in</strong>eers, two<br />

different types of hardware systems eng<strong>in</strong>eers, embedded<br />

software design eng<strong>in</strong>eers, and application software design<br />

eng<strong>in</strong>eers. There’s Tim Meyer on the far right <strong>in</strong> the blue<br />

shirt.<br />

37:42 – Why doesn’t every company do this? The number one reason that we<br />

hear as we come <strong>in</strong>to companies is: “I’m not sure that can fit with us”, and<br />

that’s cultural <strong>in</strong>ertia. Companies have been do<strong>in</strong>g it the same way for up to 175<br />

years. In some case even a little bit longer than that. Not the exact same way<br />

but some of their processes have been <strong>in</strong>herited across that time. The<br />

resistance we have comes from, often, middle management. We’re say<strong>in</strong>g, go<br />

back to l<strong>in</strong>e-fac<strong>in</strong>g work, create customer visible value directly, <strong>in</strong>stead of<br />

architecture documents that you hand down. Middle managers are typically<br />

resistant to this, but report higher job satisfaction <strong>in</strong> engagement when they do.<br />

They feel like they’re directly express<strong>in</strong>g themselves through the product that<br />

the customer <strong>in</strong>teracts with. Then we have enormous resistance from the f<strong>in</strong>ancial team, the budget<strong>in</strong>g team, and<br />

they’re say<strong>in</strong>g we have these very pa<strong>in</strong>ful annual budget<strong>in</strong>g cycles that we prepare reports months <strong>in</strong> advance, and<br />

then afterwards we prepare months of reports say<strong>in</strong>g why we went over or under our budgets. And we have to make<br />

the best bet we can as to what will be needed one year from now, as we apply budget. And we say no, it’s much<br />

simpler than that. It’s actually a short list of KPIs (key performance <strong>in</strong>dicators) used to <strong>in</strong>crementally fund budgets<br />

every week. Were not ask<strong>in</strong>g to do the big bang f<strong>in</strong>ancial allocation every week. We’re ask<strong>in</strong>g for a very small piece of<br />

it. The most essential piece of it. So that you can more accurately divide funds. And once they do, they report more<br />

nimble company management. And that they’re actually able to be f<strong>in</strong>ancial stewards of the companies resources.<br />

39:18 – For more <strong>in</strong>formation about XM or any of the other practices I’ve talked about, please contact my day job,<br />

that’s how I feed my family, at SolutionsIQ.com.<br />

39:30 – Now here’s how <strong>Team</strong> WikiSpeed applies these pr<strong>in</strong>ciples. Here’s a safety<br />

iteration of us go<strong>in</strong>g through an evolution of our car <strong>in</strong> seven days. The first time<br />

we did a safety iteration it took us months. So we had to divide it <strong>in</strong>to tasks and<br />

stories that composed the overall value if we completely iterated the safety<br />

systems of the car. Now we are able to iterate the safety systems of the car <strong>in</strong> seven days. Here’s how this happens.<br />

First we pick a test. In this case it’s the NHTSA Side Impact Test.

14:03 – Then we simulate that test <strong>in</strong> CAD. This is the side<br />

impact test where the the side impact barrier is collid<strong>in</strong>g<br />

with our chassis, and we see the stress spread across the<br />

frame, the chassis of the car. Then, to determ<strong>in</strong>e the<br />

accuracy of that test, we physically conduct crash test<strong>in</strong>g.<br />

14:17 This test costs us $10,000 every time we run it.<br />

Plus the cost of the car, plus the cost to deliver the car<br />

to the crash test<strong>in</strong>g facility. We can’t affors to run this<br />

test every seven days. So <strong>in</strong>stead of rely<strong>in</strong>g on this<br />

test every seven days, we conduct it whenever we can<br />

afford it it, and use it to make more accurate our<br />

simulations, which we do run every seven days. Then<br />

we iterate on that design.<br />

40:47 – In that side impact test we had four <strong>in</strong>ches of cab<strong>in</strong> penetration. That is<br />

survivable and that is common. There are many new vehicles on the road that have<br />

that level of side impact performance. We wanted to do better. We wanted top tier<br />

safety rat<strong>in</strong>g. We wanted no side impact penetration.<br />

41:03 - With<strong>in</strong> hours of that video circulat<strong>in</strong>g through the<br />

team, this father and son team iterated on a new side<br />

impact module and attached it to one of our chasses, and<br />

because of the modular architecture it’s able to be attached<br />

to every car we’ve ever made.<br />

41: 19 – Here’s an aesthetics iteration. First we start with<br />

CAD. Someone somewhere <strong>in</strong> the world downloads our<br />

chassis and our suspension design, and they start draw<strong>in</strong>g<br />

new parts for the car. In this case it’s a new exterior of the<br />

car drawn by Rob Mohrbacher of Mohr Composites <strong>in</strong><br />

Germantown, Maryland, who dur<strong>in</strong>g the day does<br />

composites <strong>in</strong> CAD, and nights and weekends he volunteers<br />

his time with <strong>Team</strong> WikiSpeed. I’d never met him <strong>in</strong> person<br />

<strong>in</strong> my life, when he drew this CAD.<br />

41:46 – The team decided they liked it, and we voted to<br />

make it. So we used a computer to control that router, that<br />

CNC mach<strong>in</strong>e, to mach<strong>in</strong>e it <strong>in</strong> foam <strong>in</strong> one day. So now we<br />

have a life-size buck of the car to walk around.<br />

41:56 – And then we lay it up <strong>in</strong> carbon fiber, <strong>in</strong> one day. So<br />

now we have a structural carbon fiber shell that we can use<br />

for aerodynamic test<strong>in</strong>g.

42:10 – Then we go to the largest auto show <strong>in</strong> the world, Detroit 2011 <strong>in</strong> January, and we put it on the mail floor<br />

between Ford and Chevrolet.<br />

I was terrified. I had no idea how it’d be received. I knew dur<strong>in</strong>g the first week, it’s the <strong>in</strong>dustry preview, where the<br />

executives and board members of every major automotive company and supplier are mix<strong>in</strong>g around because it’s the<br />

first time to see the competition’s new products. It’s their first chance to sit <strong>in</strong> the competitor’s vehicle. I got to meet<br />

many of those people. I thought we would be ignored, or that we would be dismissed, or talked down to, or even<br />

made fun of. Or that maybe it would even become confrontational. I never expected what happened. Every s<strong>in</strong>gle one<br />

of them shook my hand and said good job, go gettem. … I’ve had a lot of time to th<strong>in</strong>k about it s<strong>in</strong>ce then, and the<br />

best idea I have about why that might of happened, is, I th<strong>in</strong>k, they know this is someth<strong>in</strong>g they need to do, or<br />

someth<strong>in</strong>g like it. But their board and the rest of the C-suite is say<strong>in</strong>g “well cost account<strong>in</strong>g tells us to make the next<br />

version of the Ford F-150, not figure out how to rapidly iterate on designs. We need to be not focus<strong>in</strong>g on how to<br />

embrace crowd-design and crowd eng<strong>in</strong>eer<strong>in</strong>g, we need to be <strong>in</strong>stead figur<strong>in</strong>g out how to make more or the new<br />

version where our exist<strong>in</strong>g profits count.” So I th<strong>in</strong>k the C-suite and board members that came up and shook my hand<br />

were th<strong>in</strong>k<strong>in</strong>g “Yes, this needs to change and we need you to succeed to apply pressure on the f<strong>in</strong>ancial driven<br />

members of our board, on the cost account<strong>in</strong>g members of our board, so that we know we can make this change,<br />

because its go<strong>in</strong>g to take a long time to steer this big ship, and we need to start now, so make a big splash so we can.<br />

Okay?” That’s what I th<strong>in</strong>k they’re say<strong>in</strong>g to us. I’ll never know. But that’s what I’m read<strong>in</strong>g <strong>in</strong>to it, from all of them<br />

be<strong>in</strong>g so supportive.<br />

44:38 – Then, <strong>in</strong> the same aesthetics iteration, to be filmed<br />

by the discovery channel. And then launch a crowd-fund<strong>in</strong>g<br />

campaign to revolutionize the future of automotive<br />

manufactur<strong>in</strong>g.<br />

44:53 – [very well done crowd-fund<strong>in</strong>g campaign video – ignored here]<br />

46:40 – That crowd fund<strong>in</strong>g campaign recently ended and we raised enough money to perform our next round of<br />

crash test<strong>in</strong>g. What that lets us do is cont<strong>in</strong>ue on as a debt free company so we have no risk of be<strong>in</strong>g liquidated. And<br />

we can keep on iterat<strong>in</strong>g on the products we care about with safety as our priority. So we were able to successfully<br />

fund the next round of crash test<strong>in</strong>g, which is what we’re iterat<strong>in</strong>g on now. <strong>Team</strong> WikiSpeed is far more than <strong>Joe</strong><br />

justice. people see me talk about it because I’m very passionate and I want to worl to see and use these practices if<br />

they want to. but Tem WikiSpeed is massive. If it were just me it wouldn’t look anyth<strong>in</strong>g like it does now. The car<br />

would probably still be mostly steel with some cardboard because I wouldn’t have learned how to correctly and safely<br />

use alum<strong>in</strong>um and composites yet. It would probably be just half a car <strong>in</strong> my garage. I’d still be just as passionate but<br />

I wouldn’t have any evidence yet that this really works. With a team of more than 150 people <strong>in</strong> 18 countries we have<br />

brilliant ideas, hands on work, <strong>in</strong>novative approaches, appropriate use of practice. I learned so much from team<br />

members all over the world. We were lucky enough to have Mary and Tom Poppendieck come visit our shop and apply<br />

some coach<strong>in</strong>g. Thanks very much Mary and Tom. We were lucky enough to have Cory Ladas and Jim Benson become<br />

<strong>Team</strong> WikiSpeed members, and apply Personal Kanban and Scrumban to our shop, and level us up. because we’re<br />

open and embrac<strong>in</strong>g of the process community we’re able to cont<strong>in</strong>ue to level-up the practice. I know sometimes you<br />

hear people say “<strong>Joe</strong> says”, or “<strong>Joe</strong>’s project”. It’s def<strong>in</strong>itely not that. It wouldn’t look anyth<strong>in</strong>g like this, and everyone<br />

else has just as much to say about the project and I encourage you to email <strong>in</strong>fo@wikispeed.com and have a<br />

WikiSpeed member pan pal. Or even jo<strong>in</strong> the team yourself. With that said

48:39 – With that said I would like to unveil Mystro. Not many agile conferences have an automotive unveil, bet we’re<br />

at a unique <strong>in</strong>tersection between process and manufactur<strong>in</strong>g right now. I’d like to show you the 2013 WikiSpeed<br />

roadster. We’re determ<strong>in</strong><strong>in</strong>g its name. It was created by Rob Mohrbacher <strong>in</strong> Germantown, Maryland, and then<br />

collaboratively built by team members all over the world, And here team WikiSpeed members are go<strong>in</strong>g to show you<br />

the 2013 WikiSpeed Roadster 120 mile-per-gallon modular commuter car. […fan fare…]<br />

50:00 – This car was built by agile 2012 conference attendees<br />

yesterday. This car was built beh<strong>in</strong>d that screen by people <strong>in</strong> two<br />

sessions. So if you th<strong>in</strong>k about all you learned <strong>in</strong> two sessions here,<br />

and then th<strong>in</strong>k about how fast that allows you to go <strong>in</strong> software, we<br />

have some evidence that that allows us to go that fast <strong>in</strong> other areas<br />

as well, and <strong>in</strong> one example we have a car. These groups of people<br />

stepped <strong>in</strong> and we asked “how many of you have ever built a car<br />

before”. One of them said “I’ve rebuilt most of my old Volkswagen.<br />

And no one else raised their hand. We were from very diverse<br />

backgrounds. We created a backlog, a kanban board, say<strong>in</strong>g this is<br />

what needs to be done, and by us<strong>in</strong>g pair<strong>in</strong>g we were able to have<br />

people engage immediately. With<strong>in</strong> 25 m<strong>in</strong>utes we had swarms all<br />

over the car. Here you can see we don’t have someone po<strong>in</strong>t<strong>in</strong>g and stand<strong>in</strong>g, we don’t have a b<strong>in</strong>der of here’s how to<br />

build a car. We have people that have never built a car before engaged productively immediately. This is some of the<br />

th<strong>in</strong>gs we see when we use pair<strong>in</strong>g and swarm<strong>in</strong>g appropriately with a servant-leader, or scrum master, who’s<br />

facilitat<strong>in</strong>g as rapidly as possible.<br />

51:11 – The people who built this car I’ve never met before. The built a car we’re go<strong>in</strong>g to take back and perform<br />

safety test<strong>in</strong>g on. And verify it’s exactly what we need to do for correct spec. If we don’t have to do destructive safety<br />

test<strong>in</strong>g, this car will go <strong>in</strong> the Boe<strong>in</strong>g Future of Flight Innovation Center at Boe<strong>in</strong>g’s Pa<strong>in</strong>e Field. It will be an exhibit<br />

between the cockpit of the Airbus 380, the Rolls-Royce Trent jet eng<strong>in</strong>e, the barrel section of the first all composite<br />

Boe<strong>in</strong>g aircraft <strong>in</strong> the world, the 787, and the WikiSpeed 100 mile-per-gallon car. … And it was built by you guys, <strong>in</strong><br />

one day. Now that said I don’t want to take credit away from the Houston shop. The put the chassis together and<br />

verified the parts were there. And I can’t take credit away from Rob Mohrbacher who made the beautiful body and<br />

shipped it <strong>in</strong> via freight. It arrived on Wednesday and we hid it backstage. I’d never seen it before. This type of<br />

distributed collaborative team allows us to be constantly surprised by the successes of each other and help each<br />

other. … This is a picture of a gorilla high-fiv<strong>in</strong>g a shark <strong>in</strong> front of an explosion.<br />

52:30 – [<strong>Joe</strong> switches from cars to other social-good problem-solv<strong>in</strong>g also done by <strong>Team</strong> WikiSpeed – not transcribed]<br />

55:00 End of talk<br />

55:30 Q&A beg<strong>in</strong>s<br />

56:25 Q: What’s really stand<strong>in</strong>g <strong>in</strong> the way is the f<strong>in</strong>ancial system that stops us from gett<strong>in</strong>g to agile <strong>in</strong> the <strong>in</strong>dustrial<br />

scale. Software capitalization rules make us do stupid th<strong>in</strong>gs. You’ve just said it’s the same th<strong>in</strong>g <strong>in</strong> the <strong>in</strong>dustrial<br />

activities. What do we have to do as a community to change the generally accepted account<strong>in</strong>g practices that we can<br />

amortize th<strong>in</strong>gs that aren’t perfectly built, designed, and technically feasible before we start capitalization and<br />

amortization. A: (Pat and Walt’s session on Wednesday has a good start on agile account<strong>in</strong>g) ….<br />

58:26 Q: How do we get a car of our own. A: …

62:15 Q: To help fund WikiSpeed, where can e get a T-shirt with the Gorilla high fiv<strong>in</strong>g the shark. A: ….<br />

64:30 Q: What is your longer term vision for the care manufacturers. Do you see this scal<strong>in</strong>g up to a larger car<br />

manufacturer. Would it then turn <strong>in</strong>to a for-profit car operation. A: …Were not aga<strong>in</strong>st profit but that’s not what we do<br />

…….we want to make a difference for the environment … more customer relevant, more environmentally susta<strong>in</strong>able,<br />

and lower overall cost of ownership, we’ve done the right th<strong>in</strong>g. We see all of our current competitors as future<br />

partners.<br />

69:43 Q: I’ve been coach<strong>in</strong>g, so fac<strong>in</strong>g the pa<strong>in</strong> of transformation, and view this work as disruptive. What do you see<br />

of current manufactures succeed<strong>in</strong>g with this <strong>in</strong>stead of new disruptive manufacturers grow<strong>in</strong>g up around them and<br />

eat<strong>in</strong>g their lunch? A: That’s Steve Denn<strong>in</strong>g’s po<strong>in</strong>t exactly, if I followed you. He’s say<strong>in</strong>g it’s very pa<strong>in</strong>ful for an<br />

exist<strong>in</strong>g organization to change methods, and so what seems to be happen<strong>in</strong>g, and what has historically happened, <strong>in</strong><br />

the pace of bus<strong>in</strong>ess turnover that’s accelerat<strong>in</strong>g, is that some other company comes up, is radically disruptive, takes<br />

over the space, and then they become the complacent one. Then they’re raided and disrupted, and they’re raided and<br />

disrupted. My guess at what the answer is, what I’ve observed and have some evidence of what the answer might be,<br />

is that companies need to be good at change. Not be good at agile, not be good at scrum, not be good at l<strong>in</strong>e<br />

manufactur<strong>in</strong>g, not be good at lean, although all those th<strong>in</strong>gs do help them change quickly; but the actual good is not<br />

to figure out how to be an awesome scrum master. The actual good is to figure out how to make your team do<br />

someth<strong>in</strong>g different next week that’s better than what you’re do<strong>in</strong>g now. That’s what all these practices are all about.<br />

We all know this. But sometimes it’s easy to get dogmatic, and we know when that happens, the excitement starts to<br />

leave the team. The other part of that is, if there’s anyth<strong>in</strong>g <strong>Team</strong> WikiSpeed is do<strong>in</strong>g that’s actually new – because<br />

everyth<strong>in</strong>g we’re do<strong>in</strong>g is common across the agile space, it’s just the agile space is still boom<strong>in</strong>g, it’s still fly<strong>in</strong>g open<br />

and expand<strong>in</strong>g – is focus<strong>in</strong>g on moral as a multiplier for velocity. That’s not very common yet. I’ve heard a few<br />

sessions about it [here at the conference], and I didn’t come up with it either. But we apply that very seriously, and<br />

we apply that paired with reduced cost to make change. I bet that that’s what might serve these companies, be<strong>in</strong>g<br />

good at hav<strong>in</strong>g highly motivated teams that are mak<strong>in</strong>g changes quickly. They may be able to stay on top of their<br />

markets. But that doesn’t address how to conv<strong>in</strong>ce or encourage or support an exist<strong>in</strong>g company try to make change.<br />

There’s the thought that you have to give someone at least five compliments before you can ask them to change. It<br />

might be f<strong>in</strong>d<strong>in</strong>g out what’s really good about the companies we’re <strong>in</strong> before we f<strong>in</strong>d out what we might want to<br />

disrupt, and disrupt it very gently, and with support. And come at it, I amag<strong>in</strong>e, from a lov<strong>in</strong>g angle at what the<br />

company’s already good at, and a lov<strong>in</strong>g angle for the people <strong>in</strong> the bus<strong>in</strong>ess and what they’re already do<strong>in</strong>g, and help<br />

them do it better – to be higher morale, and to be able to make changes quickly. Then maybe we will see all<br />

companies be<strong>in</strong>g cont<strong>in</strong>ually disruptive. And we’ll all benefit from hav<strong>in</strong>g a radically different, maybe, pace of new<br />

product development that is customer focused. Did that talk to your question at all or did I go sideways and talk <strong>in</strong> a<br />

rant?<br />

72:42 Q quy responds: No, actually that was really good. But I th<strong>in</strong>k when you were talk<strong>in</strong>g there about, um, some<br />

people th<strong>in</strong>k I’m a nice guy. I’ve got them fooled. When you’re look<strong>in</strong>g at try<strong>in</strong>g to transform them, it seems to take<br />

an awful long time. So they th<strong>in</strong>k “I’m go<strong>in</strong>g to get this coach <strong>in</strong>, and oh by the way I want you to take these hundred<br />

teams and get them agile before the end of the year.” I just k<strong>in</strong>d of start to shiver and shake when I hear them talk<br />

that way, because it’s a lot of talk<strong>in</strong>g, help<strong>in</strong>g. When they feel like you’re there to help, then you get the ability to<br />

<strong>in</strong>fluence them. And that, to me, takes a long time to be able to build that up. That’s my fear, of them not actually<br />

transform<strong>in</strong>g. Then it takes a 2x4 to the head and that’s a lot more pa<strong>in</strong>ful for them then a nice transformation.<br />

73:39 A: I used to feel that level of resistance at the clients I’d go to <strong>in</strong> my day job. I don’t any more. That example<br />

at Tait radio – they were already do<strong>in</strong>g some strong practices that they had found by work<strong>in</strong>g with Mary and Tom<br />

Poppendieck, and Henrick [Kniberg] . Then when Tim Meyer and I were able to come <strong>in</strong>, we were able to set up a<br />

team on day one. We were able to have visible, radical progress <strong>in</strong> that team. The team was, and Tim and I were able<br />

to support it (we didn’t build those radios, we’re not radio eng<strong>in</strong>eers) <strong>in</strong> five days. We’re beg<strong>in</strong>n<strong>in</strong>g to see the pace of<br />

adoption, the pace of culture change, go through the roof too. What I see as a – I will get on my high horse for a just<br />

a m<strong>in</strong>ute – is I see people come <strong>in</strong> and talk about organizational change as if it’s this road map <strong>in</strong> this cycle. What?<br />

We’re agile.<br />

[excitedly] I run <strong>in</strong>to a client and say “You have permission to do what you need to do. They do, right? [said<br />

sideways, to management presumably]. Okay – and you won’t be fired for at least one week. Now we’re go<strong>in</strong>g to<br />

do someth<strong>in</strong>g really different and here’s the practices that support it. See that Q ball, just for this week, we’re<br />

go<strong>in</strong>g to move it aga<strong>in</strong>st the wall, okay? Please take these th<strong>in</strong>gs over here . Who has the clearest vision of what<br />

we’re do<strong>in</strong>g? Who can imag<strong>in</strong>e a day <strong>in</strong> the life of the customer,a nd what they’re do<strong>in</strong>g that day when they’re<br />

us<strong>in</strong>g your product or service, and what they ate for breakfast, and how it relates to the rest of the t<strong>in</strong>gs they do<br />

that day? Who is that? It’s your tester?! Oh wow, imag<strong>in</strong>e that, it’s not even someone from market<strong>in</strong>g but they<br />

really do. Do they? They do. Let’s talk about how to vote as a team. You’re now this th<strong>in</strong>g called the product<br />

owner. Who’s go<strong>in</strong>g to run get everybody screwdrivers and lemonade? Okay, for today at least you’re the scrum<br />

master. Do you have a background <strong>in</strong> team psychology? No. Well maybe go to a coach<strong>in</strong>g cl<strong>in</strong>ic next week.<br />

Week one we have results. That starts to have people from other teams come <strong>in</strong> and look, say<strong>in</strong>g “what’s go<strong>in</strong>g<br />

on.” And we have an all hands session say<strong>in</strong>g everyth<strong>in</strong>g you gave this team once a year, you’re no go<strong>in</strong>g to give<br />

them a little piece of it once a week, and everyth<strong>in</strong>g you used to get from this team once a year, once a quarter,

you’re go<strong>in</strong>g to get a little piece of it once a week. You need to support them by attend<strong>in</strong>g their demo of that<br />

product every week. Okay? Please, can you do that for a week? And we have radical transformation very very<br />

quickly. And I th<strong>in</strong>k it’s when people walk <strong>in</strong> and say “Let’s talk about transformation. Let’s talk about your<br />

quarterly plan. What’s on your five year budget?” And <strong>in</strong>stead, say<strong>in</strong>g, “Is your CEO really the vision holder for the<br />

company? If so, can they be the product owner for the company? By that I mean, can they be here every day to<br />

answer questions for the change management team?” No? Well then who is actually driv<strong>in</strong>g the vision? Nobody?<br />

Surprise! Okay, let’s marry that. let’s figure that out, on day one.<br />

And that can happen. I’ve been see<strong>in</strong>g it happen. So I don’t th<strong>in</strong>k change adoption has to be a long, slow process. In<br />

fact there’s some evidence that says that might be true. I’m now off that high horse. I could be completely wrong.<br />

Your mileage may vary. I need to soften that after gett<strong>in</strong>g that excited, because we’re on the cusp of change, and<br />

new th<strong>in</strong>gs are happen<strong>in</strong>g right now. And none of us are predictive. That’s why we’re agile. Instead we’re respond<strong>in</strong>g<br />

with as much <strong>in</strong>formation as we’re able to gather this week for what we’re go<strong>in</strong>g to do next week. But I’m glad I got<br />

to share some of the th<strong>in</strong>gs I’ve seen, and some of the th<strong>in</strong>gs I’ve tried, that seem to be work<strong>in</strong>g.<br />

77:11 Q: I have an eng<strong>in</strong>eer<strong>in</strong>g background and now I’m a scrum master. Your car doesn’t have doors. Is that by<br />

design or expediency, or how was that decision reached? A: …[Good discussion on iterat<strong>in</strong>g for crash test success<br />

start<strong>in</strong>g with a Honda front end. … we only pick designs that can be built with our cheap mill<strong>in</strong>g mach<strong>in</strong>e and metal<br />

band saw - $500 total – unless someth<strong>in</strong>g else is absolutely necessary.]<br />

84:15 Q: Will you make a tractor for next year’s Agile 2013 (I work for Deere). A:…somebody else is already work<strong>in</strong>g<br />

down that path …<br />

88:00 Q: Can you th<strong>in</strong>k of a moment <strong>in</strong> your journey when you had an epiphany about his project. A: …<br />

91:00 END