Mining: A Bright OppOrtunitY - Parsons Brinckerhoff

Mining: A Bright OppOrtunitY - Parsons Brinckerhoff

Mining: A Bright OppOrtunitY - Parsons Brinckerhoff

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

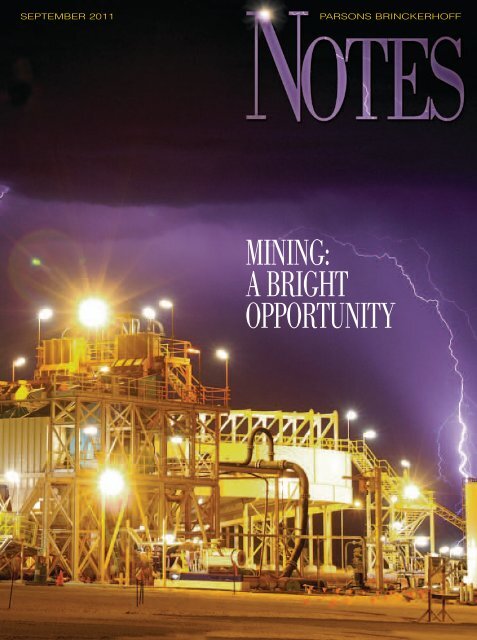

SEPTEMBER 2011<br />

PARSONS BRINCKERHOFF<br />

<strong>Mining</strong>:<br />

A <strong>Bright</strong><br />

OpportunitY

Letter<br />

from the<br />

CEO<br />

Inside<br />

Page<br />

14<br />

© 2011 DAVID SAILORS<br />

The urbanization and industrialization of developing nations, including China and India, is driving the<br />

demand for mineral resources around the globe. Transformed, these minerals provide the necessary<br />

building blocks (steel, electronics, power, etc.) for the development of these nations for current and future<br />

generations. To aid in that development, <strong>Parsons</strong> <strong>Brinckerhoff</strong> is expanding our services in the mining<br />

industry to support the efficient, safe, and sustainable extraction of mineral resources around the world.<br />

<strong>Parsons</strong> <strong>Brinckerhoff</strong> has been active in mining for four decades, particularly in eastern and southern<br />

Australia. Recently, the firm has sought to leverage this capability by creating a global business focused<br />

on the mineral resources sector. This business operates across all commodities including coal, iron ore,<br />

and base and precious metals—and has expanded its geographical footprint to Western Australia, Africa,<br />

South America, and Asia.<br />

We offer a broad range of services in support of mining projects from concept studies through to<br />

construction and operational support. Through our long history in infrastructure development, we<br />

are able to provide “pit to port” solutions that include the full range of services required to develop,<br />

operate, and maintain a sustainable mining project.<br />

The firm’s aspirations in the mining sector will build on the success of recent projects such as the<br />

Mangoola Coal Project in New South Wales and the Jacinth-Ambrosia Mineral Sands Mine in South<br />

Australia. For Mangoola, <strong>Parsons</strong> <strong>Brinckerhoff</strong> was part of an alliance with Xstrata Coal that successfully<br />

delivered the project, including rail, road, and industrial facilities. For Jacinth-Ambrosia, the firm was<br />

part of a delivery alliance with Iluka for the development of the mine processing plant as well as<br />

the associated infrastructure for the project—including roads, a desalination plant, an airstrip, a<br />

remote water source, and a construction and mining village. Jacinth-Ambrosia was also developed<br />

in a sensitive environmental area with the continuous engagement and cooperation of the local<br />

Indigenous communities.<br />

We envision mining as a major market for <strong>Parsons</strong> <strong>Brinckerhoff</strong>. Our strategy for growth in this sector<br />

includes organic expansion of our core capabilities, acquisition of companies with specialized mining<br />

expertise, and leveraging the broad range of capabilities within <strong>Parsons</strong> <strong>Brinckerhoff</strong> and Balfour Beatty.<br />

With a commitment to enhance communities for current and future generations as our goal, <strong>Parsons</strong><br />

<strong>Brinckerhoff</strong> is expanding its mining business to support our clients in the efficient, safe, and sustainable<br />

extraction of mineral resources.<br />

George J. Pierson<br />

President and Chief Executive Officer<br />

<strong>Parsons</strong> <strong>Brinckerhoff</strong> Inc.<br />

Page 4<br />

Page 10<br />

2<br />

Mark Dimmock on<br />

<strong>Mining</strong> Opportunities<br />

The Managing Director of Global<br />

<strong>Mining</strong> discusses his mission.<br />

4<br />

Unearthing Zircon in<br />

Remote South Australia<br />

The Jacinth-Ambrosia mine<br />

illustrates strong client-consultant<br />

cooperation.<br />

10<br />

More Opportunities in<br />

Coal <strong>Mining</strong> Country<br />

Hunter Valley, in New South<br />

Wales, is the scene of new<br />

and expanding mines.<br />

13<br />

Shining <strong>Bright</strong>ly in<br />

The Philippines<br />

With a wealth of copper in<br />

Mindanao, Philippines, <strong>Parsons</strong><br />

<strong>Brinckerhoff</strong> studied the<br />

feasibility of obtaining it.<br />

14<br />

A Boom in Iron Ore<br />

Working in Western Australia’s<br />

Pilbara region, the firm’s mining<br />

experts help clients meet growing<br />

demand for the metal.<br />

16<br />

Notes on Projects<br />

20<br />

Notes on the Firm<br />

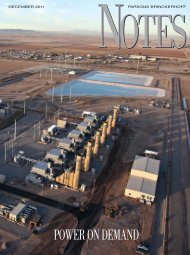

ON THE COVER:<br />

The mineral sands processing<br />

plant at the Jacinth-Ambrosia<br />

Mineral Sands Mine in South<br />

Australia.<br />

<strong>Parsons</strong> <strong>Brinckerhoff</strong>, founded in 1885,<br />

is recognized as a leader in strategic<br />

consulting, planning, engineering, program<br />

management, construction management,<br />

and operations and maintenance for all<br />

types of infrastructure. The firm has<br />

approximately 14,000 people worldwide<br />

in more than 150 offices on six continents.<br />

<strong>Parsons</strong> <strong>Brinckerhoff</strong> is part of Balfour<br />

Beatty plc, the international infrastructure<br />

Group operating in professional services,<br />

construction services, support services, and<br />

infrastructure investments.<br />

Editorial Board<br />

George J. Pierson<br />

Nick Flew<br />

Chuck Kohler<br />

David McAlister<br />

Pat Schaffner<br />

Judy Cooper<br />

Executive Editor<br />

Tom Malcolm<br />

Editor<br />

Muriel Adams<br />

Contributors<br />

Muriel Adams<br />

Leon Erlanger<br />

Charlotte Forbes<br />

Terry Kuflik<br />

Tom Malcolm<br />

Jerry Mannarino<br />

Graphics Services Manager<br />

Richard Mangini<br />

Graphic Design<br />

Jamie Dugan<br />

Director of Corporate<br />

Communications<br />

Judy Cooper<br />

<strong>Parsons</strong> <strong>Brinckerhoff</strong> Inc.<br />

One Penn Plaza<br />

New York, NY 10119<br />

1-212-465-5000<br />

www.pbworld.com<br />

www.facebook.com/pbworld<br />

www.twitter.com/pbworld<br />

pbinfo@pbworld.com<br />

NOTES is published three times a year by<br />

<strong>Parsons</strong> <strong>Brinckerhoff</strong> for the employees,<br />

affiliates, and friends of <strong>Parsons</strong> <strong>Brinckerhoff</strong>.<br />

Please contact the Executive Editor in the New<br />

York office for permission to reprint articles.<br />

© 2011 <strong>Parsons</strong> <strong>Brinckerhoff</strong> Inc.<br />

All rights reserved.<br />

Notes • 1

Mark Dimmock on <strong>Mining</strong> Opportunities<br />

Mark Dimmock, Managing Director of Global <strong>Mining</strong>, is taking the firm’s expertise<br />

in infrastructure for mining operations worldwide. Sydney-based Mark has been<br />

with <strong>Parsons</strong> <strong>Brinckerhoff</strong> for 21 years, and was named to his current position<br />

at the end of last year. He discussed his mission with NOTES.<br />

What is your vision for the mining<br />

business for <strong>Parsons</strong> <strong>Brinckerhoff</strong>?<br />

Our vision is to be a leading<br />

provider of EPCM [engineeringprocurement-construction<br />

management] services to the<br />

resources sector, leveraging Balfour<br />

Beatty companies in delivery of<br />

the infrastructure, participating<br />

along the development spectrum<br />

from concept through delivery. The<br />

objective of the business is a turnover<br />

of $1 billion dollars annually<br />

by 2015.<br />

How will you achieve your goals?<br />

Our growth strategy is in three<br />

parts. The first is to continue our<br />

organic growth. The second<br />

is to complement our<br />

current capabilities by<br />

adding mine planning capability<br />

and process engineering—by<br />

acquisition. And the third is<br />

to leverage the Balfour Beatty<br />

companies, in particular Balfour<br />

Beatty’s construction capabilities<br />

in rail and utilities, with<br />

<strong>Parsons</strong> <strong>Brinckerhoff</strong> ’s existing<br />

engineering, environmental, and<br />

water capabilities. The mining<br />

business provides a single point<br />

for delivery of the breadth of<br />

services available from all Balfour<br />

Beatty groups to mining clients.<br />

Balfour Beatty brings construction<br />

and construction management<br />

capability and <strong>Parsons</strong><br />

<strong>Brinckerhoff</strong> brings project<br />

management and engineering<br />

capability.<br />

How large is the mining market?<br />

The mining market is clearly a<br />

huge market and expenditure in<br />

2010 was about $150 billion. In<br />

professional services alone it<br />

was about $8.4 billion. The market<br />

continues to grow, driven by the<br />

growth of China and India, and<br />

that growth curve will continue. It<br />

is absolutely a huge opportunity.<br />

Clearly there is a lot of room for<br />

<strong>Parsons</strong> <strong>Brinckerhoff</strong> to grow into<br />

that market especially in EPCM.<br />

How will <strong>Parsons</strong> <strong>Brinckerhoff</strong><br />

approach this work?<br />

We employ study managers<br />

to assess a project as early<br />

as possible—and to stay<br />

with that project through the<br />

whole development cycle.<br />

Study managers will employ<br />

the capabilities of <strong>Parsons</strong><br />

<strong>Brinckerhoff</strong>—particularly<br />

engineering, environmental<br />

planning, and water capability—<br />

and carry that through to deliver<br />

projects for clients.<br />

Have there been any standout<br />

projects?<br />

We couldn’t have asked for a<br />

better reference project and<br />

better platform than the Jacinth-<br />

Ambrosia Mineral Sands Mine.<br />

It typifies the way in which we<br />

want to deliver projects. It was<br />

collaborative with the client,<br />

collaborative within all parts of<br />

<strong>Parsons</strong> <strong>Brinckerhoff</strong>, and that is<br />

the way we want to do business<br />

with our clients—in a very open<br />

manner. I really appreciate the<br />

work the team did to deliver<br />

that project. It was a fabulous<br />

outcome.<br />

What are some other key<br />

projects?<br />

There are a few other projects that<br />

exemplify the way that the global<br />

mining business works. Mangoola,<br />

which we recently completed for<br />

Xstrata Coal in Hunter Valley,<br />

New South Wales, was delivered<br />

ahead of schedule and ahead of<br />

budget by an integrated team<br />

with the client. Our team did a<br />

great job delivering it and it also<br />

exemplifies the way in which<br />

we want to do business, in a<br />

collaborative open-book type of<br />

way where we build relationships<br />

with our clients for the long term.<br />

A project we are currently in<br />

the process of delivering is the<br />

Bengalla mine for Rio Tinto<br />

in Hunter Valley. It’s being<br />

delivered using a similar kind<br />

of model. There is focus on a<br />

collaborative working environment<br />

and it is well-organized, has<br />

a strong safety culture driven<br />

by Bruce Mitchell, our Project<br />

Manager, and has all the<br />

hallmarks of success.<br />

Another project we have<br />

completed in Hunter Valley was<br />

actually a combined project—the<br />

Glendell-Liddell project. It was<br />

completed in 2010 and again,<br />

the reference there is that we<br />

continued on to do the Mangoola<br />

project for Xstrata.<br />

Geographically, where are the<br />

opportunities?<br />

The business for us now is in<br />

Australia, especially Western<br />

Australia. But we are following<br />

our clients to the locations they<br />

operate in all around the world.<br />

There are a couple of coal projects<br />

that we’ve undertaken in southern<br />

Africa. In Mozambique we<br />

completed a feasibility study for<br />

Talbot Resources. In South Africa<br />

we worked with Xstrata as part of<br />

an integrated team doing EPCM.<br />

In Botswana we completed a<br />

feasibility study. We are looking<br />

at Indonesia and we have a small<br />

start-up there. And we are working<br />

with Balfour Beatty to develop<br />

the mining business in South<br />

America.<br />

What is the short-term outlook<br />

for the mining business at<br />

<strong>Parsons</strong> <strong>Brinckerhoff</strong>?<br />

We are working at a very fast pace<br />

and we are going to grow more in<br />

the next 12 months as we seek to<br />

gain market share. Our objectives<br />

are ambitious, they’re bold. We<br />

are absolutely determined to make<br />

them. At the same time we are<br />

committed to delivering projects<br />

in a safe manner, in a professional<br />

manner, and delivering excellent<br />

outcomes for our clients whilst<br />

we build relationships for the<br />

future. n<br />

2 • Notes<br />

Notes • 3

Unearthing Zircon in Remote South Australia<br />

<strong>Parsons</strong> <strong>Brinckerhoff</strong> supports a world-class mining project<br />

Zircon … It is a mineral with high<br />

temperature resistance used to whiten<br />

products from toothpaste to ceramic<br />

tile. With world reserves dwindling and<br />

demand skyrocketing, particularly in<br />

developing countries, Australian mining<br />

giant Iluka Resources looked to remote<br />

South Australia for additional supply.<br />

There, Iluka found the world’s richest<br />

zircon deposit with the potential to<br />

supply 25 percent of the global market.<br />

Rushing to capitalize on global demand,<br />

Iluka built the AU $420 million Jacinth-<br />

Ambrosia Mineral Sands Mine in just five<br />

years from discovery to commissioning.<br />

Opened in February 2010, the mine is<br />

exceeding anticipated production rate in<br />

a booming market.<br />

The story of the Jacinth-Ambrosia<br />

mine is one of strong client-consultant<br />

cooperation, in which global mining<br />

giant Iluka and <strong>Parsons</strong> <strong>Brinckerhoff</strong><br />

collaborated on a complex project in a<br />

remote and environmentally sensitive<br />

desert area where temperatures regularly<br />

hit 40 degrees C (104 degrees F),<br />

completing the mine several weeks ahead<br />

of time—and below budget. It’s also the<br />

story of a planned disappearing act, as the<br />

alliance of Iluka and <strong>Parsons</strong> <strong>Brinckerhoff</strong><br />

designed and built the mine to operate<br />

for an 11-year period, after which the area<br />

would be returned to its natural state, with<br />

hardly a trace of mining<br />

activity left.<br />

The Allied Mission<br />

While alliancing<br />

may be common in<br />

urban infrastructure<br />

projects, it is relatively<br />

rare in mining. But<br />

<strong>Parsons</strong> <strong>Brinckerhoff</strong>’s<br />

Project Manager Scot<br />

Coleman credits the<br />

Jacinth-Ambrosia<br />

mine’s various successes to the firm’s<br />

alliance arrangement with Iluka,<br />

which covered all project phases from<br />

feasibility through government approvals<br />

and commissioning. “To Iluka, the<br />

mine represented more than just a<br />

project,” says Coleman. “It represented<br />

a significant portion of the company’s<br />

future revenue. So the project had to<br />

be expertly delivered with high levels<br />

of operational efficiency. It was really<br />

the integration and co-location of<br />

personnel that facilitated a<br />

team culture dedicated to<br />

establishing a business, not<br />

just a project, with a sense<br />

of urgency championed<br />

by Iluka that made a real<br />

difference.” Coleman cites<br />

easy access to Iluka’s General<br />

Manager Hans Umlauff and<br />

Operations Manager Andrew<br />

Whatham as a valuable<br />

advantage. “Decisions could<br />

be made quickly, and<br />

feedback provided as to<br />

what would and wouldn’t<br />

work operationally,” he says.<br />

“Everyone was very focused<br />

on clear targets.”<br />

License to Operate<br />

Early on, the alliance focused on<br />

obtaining a “social license to operate,”<br />

given the mine’s location within<br />

the Yellabinna Regional Reserve, its<br />

proximity to Indigenous communities,<br />

and its economic importance to the<br />

region. “We coined the term to reflect<br />

Iluka’s insistence that the alliance<br />

team act like a guest in the region.<br />

Engagement with local stakeholders to<br />

gain community trust was important<br />

The Jacinth-Ambrosia alliance had to build all<br />

infrastructure for the site including its own airstrip.<br />

Craig Ryan, Principal Metallurgist for Iluka, and David Cruickshanks-Boyd, Regional Director for <strong>Parsons</strong> <strong>Brinckerhoff</strong><br />

South Australia, in May 2009, when the first cutting of the mine took place.<br />

initially and maintained throughout the<br />

project,” says Coleman.<br />

In addition to ongoing presentations<br />

to local councils, community groups,<br />

and park rangers, the alliance patronized<br />

local businesses from cafes to car rentals,<br />

sponsored local sporting activities, and<br />

even brought a haul truck to a school,<br />

explaining the importance of safety<br />

around these large vehicles. Coleman<br />

calls the rapport with the community<br />

“excellent and unusual,” adding that it<br />

was a linchpin of Iluka’s ability to do<br />

business in the region. “Constructing a<br />

mine in a regional reserve was a major<br />

achievement,” Coleman says. “And<br />

this was the first mine to be granted a<br />

license to operate in a protected area<br />

under South Australia’s Natural Parks<br />

and Wildlife Act. The State government<br />

recognizes it as a benchmark for future<br />

developments.”<br />

Iluka’s Samantha Doudle,<br />

Rehabilitation Specialist, collects<br />

seeds to use in rehabilitating the<br />

Jacinth-Ambrosia site after its 11-year<br />

use as a mine. The new desert shrubs<br />

will be grown in nurseries.<br />

Building … and Unbuilding<br />

Before Iluka, the Jacinth-Ambrosia<br />

Mineral Sands Mine site was a tabula<br />

rasa. “We had nothing to start with—<br />

no infrastructure at all. So we had to<br />

do everything from scratch,” he says.<br />

“It was desert, 200 kilometers [124<br />

miles] from anywhere,” he says, noting<br />

that potable water was non-existent.<br />

“The only available water was too<br />

saline for human consumption, so we<br />

built a desalination plant. But until<br />

it was up and running, freshwater<br />

had to be trucked in several times a<br />

week.” In addition to water supply<br />

facilities, the alliance designed and<br />

built a water treatment plant; a power<br />

station and 33kV overhead line; a<br />

90-kilometer (56-mile) access road;<br />

a 120-person village with provision<br />

for an additional 200 people during<br />

construction; a satellite phone system<br />

and microwave links; and an airstrip—all<br />

with great attention to sustainability and<br />

harmony with the environment. The<br />

nearby port of Thevenard was upgraded<br />

to enable the shipment of heavy mineral<br />

concentrate to Western Australia.<br />

In developing the infrastructure, the<br />

alliance mantra was “fit for purpose.”<br />

“That was how we maximized value<br />

and ensured the budget was properly<br />

managed,” says Coleman, noting that<br />

the mantra applied right down to<br />

the smallest details. For example,<br />

the alliance retained native<br />

vegetation around the housing<br />

4 • Notes<br />

Scot Coleman<br />

Housing was constructed for more than 300 people who would build and operate<br />

the mine.<br />

Notes • 5

A Unique Purpose-Built<br />

<strong>Mining</strong> Machine<br />

Most mining unit plants consist of several<br />

components—the dozer trap/receiver, the<br />

vibrating screen, and the trommel/slurry<br />

pump, all of which operate separately and<br />

have to be dragged from one location to<br />

another along the length of the mine. To<br />

maximize productivity, the Iluka <strong>Parsons</strong><br />

<strong>Brinckerhoff</strong> Alliance pioneered an innovative<br />

approach at the Jacinth-Ambrosia Mineral<br />

Sands Mine. All three components were<br />

combined on a single chassis with its own<br />

power and steering. With self-propulsion,<br />

the unit could be relocated in hours instead<br />

of days, requiring less energy while still<br />

exceeding the expected processing capacity.<br />

However, as with all first-of-a-kind<br />

machinery, there were design and fabrication<br />

complications. While the contractor chosen<br />

was highly experienced in traditional mining<br />

units, that expertise did not extend to the<br />

electrical controls that would allow selfpropulsion.<br />

The alliance team came forward<br />

with the right technical and managerial<br />

resources to get the job done. Pre-assembly<br />

planning and testing was conducted off site<br />

so that when the equipment arrived on site<br />

it was “shovel ready.” The 1,000-ton unit was<br />

erected in 14 days with minimal hitches. “This<br />

unique structure was engineered specifically<br />

to meet the requirements of the mine, and<br />

it has set a new benchmark for the mineral<br />

sands industry,” says <strong>Parsons</strong> <strong>Brinckerhoff</strong><br />

Project Manager Scot Coleman.<br />

units, which cost more, but reduced dust—a key consideration<br />

in an already dusty environment where the slightest breeze<br />

could kick up a fine powder that would drastically reduce<br />

visibility. Also, many of the roads and services were designed<br />

just for the limited 11-year mine life, with the focus on easy site<br />

rehabilitation rather than long-term maintainability. “In building<br />

the roads, only the uppermost layer of topsoil was removed,<br />

and is being maintained in piles, so that when we cap the<br />

mine, the topsoil can be put back,” says Coleman. “There<br />

will be little evidence that we were even there.” The alliance<br />

enlisted the expertise of Indigenous residents in starting a<br />

nursery of native plants to eventually re-vegetate the entire site.<br />

Ahead of Schedule<br />

“For Iluka, delivering the project on or before schedule meant<br />

that the ore mined at Jacinth-Ambrosia could be processed at<br />

the company’s Western Australia plant, and the resultant zircon<br />

sold on the open market as soon as possible to offset the<br />

upfront capital outlay,” says Coleman. “So we strived to beat,<br />

not just meet, the schedule. We were always reaching for the<br />

‘stretch’ target, rather than the base target dates.”<br />

Rigorously managing critical path activities was crucial. Case<br />

in point: the wet concentrator plant, which was scheduled to<br />

be relocated from Iluka’s U.S. site to dovetail with finalization of<br />

construction permits. But when it became apparent that there<br />

Construction of the Jacinth-Ambrosia process plant, where ore pumped from the mining<br />

unit plant is screened, washed, and processed to remove clay and sand to produce heavy<br />

mineral concentrate for shipping.<br />

Mobile mining unit in operation in the mine. Bulldozers push ore into the dozer trap for<br />

initial screening in the trommel, and then the ore is pumped as slurry through the white<br />

pipes to the process plant.<br />

were delays in designing and finding<br />

parts for the mining unit plant, staff<br />

switched gears—the Deputy Project<br />

Manager Gary Neave and Contract<br />

Administrator Gerry Schmied changed<br />

focus to concentrate on that unit’s<br />

delivery, providing extra mechanical/<br />

electrical support to the contractor,<br />

packaging work to multiple fabricators,<br />

Iluka is looking for additional<br />

mineral sands deposits in the<br />

vicinity of the Jacinth-Ambrosia<br />

site, hoping to discover deposits<br />

that can be processed there<br />

rather than having to build<br />

a new mine.<br />

and planning and scheduling of<br />

transport and erection of<br />

the unit. (See sidebar.)<br />

“You obviously can’t start<br />

processing ore without<br />

first mining it. So<br />

the mining unit<br />

plant became the<br />

critical path<br />

activity,” says Coleman. “Ultimately, the<br />

focus on the changing critical path was<br />

what enabled us to achieve ahead-ofschedule<br />

completion.”<br />

Scrutinizing Cost<br />

With the original project cost estimate<br />

of more than AU $500 million<br />

unacceptable to Iluka, the alliance value<br />

engineered the proposal, managing<br />

to reduce the capital cost to a more<br />

palatable AU $420 million, attributable<br />

mainly to matching the plant to achieve<br />

a design throughput in accordance with<br />

Iluka’s requirements.<br />

“‘Have we overdesigned this? Did<br />

we design it for 20 years when we<br />

only need 10? Is there a better way<br />

of building it? These were the kinds<br />

of questions that we asked of every<br />

item initially, especially during the<br />

bid process, and continued to ask<br />

throughout,” says Coleman.<br />

Another key to keeping costs<br />

down was the alliance’s focus<br />

on relatively small manageable<br />

6 • Notes<br />

Notes • 7

A pump station circulates water through the process plant, with the result that all process water is recycled.<br />

A transfer tower, part of the ship loading facility at the port of Thevenard, 270 kilometers<br />

(168 miles) from the mine by road.<br />

construction packages. “Rather<br />

than avoid risk by hiring<br />

large construction companies,<br />

we deliberately used midtier<br />

contractors and actively<br />

managed the increase in risk,”<br />

says Coleman. “It may have<br />

required more attention on our<br />

part overseeing the contractors<br />

in terms of safety, environmental<br />

regulations, and expediting,<br />

but because the packages<br />

represented a significant portion<br />

of these contractors’ work, we<br />

had more immediate access to<br />

their key decision makers.”<br />

We’re All in it Together<br />

Coleman recalls when a<br />

manufacturing defect was<br />

detected in a major piece of<br />

installed equipment during<br />

commissioning. The team and<br />

The first heavy mineral concentrate to be transferred from the Port Thevenard stockpile to ship for final processing at Iluka’s<br />

plant in Western Australia.<br />

its contractors pooled resources,<br />

and a replacement part was<br />

designed, manufactured, freighted<br />

to the site, installed, and ready for<br />

commissioning within two weeks.<br />

“There may have been more than<br />

a few late nights,” says Coleman.<br />

“But the emphasis was always<br />

on fixing the problem, rather<br />

than laying blame. This ‘we all<br />

win or we all lose’ philosophy<br />

was constant throughout the<br />

project—and that’s what drove<br />

the outstanding results.”<br />

Indeed, the project won a Gold<br />

Award in the project management<br />

category in Consult Australia’s<br />

2010 Awards for Excellence,<br />

a Program Management<br />

Excellence Award at the 2010<br />

South Australian Engineering<br />

Excellence Awards, and the<br />

Project Management Achievement<br />

Award for South Australia from<br />

the Australian Institute of Project<br />

Management. It was also <strong>Parsons</strong><br />

<strong>Brinckerhoff</strong>’s 2009 Project of<br />

the Year. n<br />

Recession-Proofing the Local Economy<br />

The Jacinth-Ambrosia Mineral Sands Mine is located by<br />

road 270 kilometers (168 miles) northwest of Ceduna, in<br />

remote South Australia. Yet a top priority for the alliance<br />

was supporting the local Ceduna economy. The team<br />

focused on using local services and employing Indigenous<br />

and non-Indigenous residents both directly and through<br />

contractors. Some 300 people were employed during<br />

construction, with the Indigenous workforce exceeding the<br />

employment target of 20 percent—an impressive outcome<br />

recognized by South Australia Members of Parliament,<br />

municipal councils, and the community. Ceduna Mayor<br />

Allan Suter commented that, to some extent, the local<br />

economy had been “recession-proofed” by the economic<br />

activity stemming from the development of the mine.<br />

8 • Notes Notes • 9

More Opportunities in Coal <strong>Mining</strong> Country<br />

In the south and east of Australia there is coal to unearth<br />

Hunter Valley, in New South Wales,<br />

is an area rich in coal mines. There is<br />

still more coal to be mined and, with<br />

demand high, additional coal mines<br />

are being developed, several with the<br />

expertise of <strong>Parsons</strong> <strong>Brinckerhoff</strong>.<br />

Eric Rattray<br />

History in Hunter Valley<br />

<strong>Parsons</strong> <strong>Brinckerhoff</strong> has been working<br />

on mining projects in Hunter Valley for<br />

more than 40 years. The firm recently<br />

expanded its Newcastle office to meet<br />

the continued growth of project work<br />

in the heart of coal mining country and<br />

now employs more than 160 engineers<br />

and scientists in Hunter Valley. “Our<br />

increasing involvement in the design<br />

and delivery of infrastructure projects<br />

in this area means company growth<br />

is projected to continue,” says Glenn<br />

Thornton, General Manager for the<br />

Hunter Valley region.<br />

Xstrata Coal Co., a major<br />

global diversified mining group,<br />

is an important client for <strong>Parsons</strong><br />

<strong>Brinckerhoff</strong>. The firm has worked on<br />

open-cut projects for Xstrata in Hunter<br />

Valley, among them the Glendell,<br />

Liddell, and Mangoola mines—<br />

performing such activities as feasibility<br />

Xstrata Coal engaged <strong>Parsons</strong> <strong>Brinckerhoff</strong> to support its expansion of the open-cut<br />

Liddell mine in Hunter Valley.<br />

studies and environmental impact<br />

assessment, engineering, procurement,<br />

and construction management.<br />

Liddell and Glendell<br />

In 2007, <strong>Parsons</strong> <strong>Brinckerhoff</strong> was<br />

engaged to support Xstrata Coal with<br />

the expansion of its coal mining<br />

operations in Hunter Valley. <strong>Parsons</strong><br />

<strong>Brinckerhoff</strong> provided engineering,<br />

procurement, construction management,<br />

and detailed design services for the<br />

expansion of Xstrata’s existing open-cut<br />

Liddell mine and the establishment of<br />

the new Glendell mine 20 kilometers<br />

(12 miles) away. This involved moving<br />

the Liddell mine infrastructure area<br />

(MIA) south 2 kilometers (1.2 miles)<br />

and establishing a new MIA area.<br />

<strong>Parsons</strong> <strong>Brinckerhoff</strong>’s analysis<br />

indicated that the two sites had<br />

similar requirements. “Efficiencies<br />

were achieved by ensuring<br />

consistent and simultaneous design<br />

<strong>Parsons</strong> <strong>Brinckerhoff</strong> was part of an alliance with Xstrata coal to manage design and on-site construction supervision of Mangoola,<br />

a new mine, which achieved operational completion in April 2011.<br />

and delivery of work at both sites,”<br />

says Eric Rattray, Project Manager for<br />

these two mines and Development<br />

Manager for the coal mining<br />

operation in the region. He adds<br />

that environmental initiatives were<br />

key. Water was recycled where<br />

possible and energy use reduced<br />

through passive building design<br />

features and energy-efficient<br />

devices.<br />

Work at both sites involved<br />

clearing and earthworks; access<br />

road and intersection works;<br />

a new office, administration<br />

and bathhouse compound for<br />

240 employees; new and relocated<br />

fuel and lube facilities; a new<br />

high-voltage power supply; a<br />

three-bay heavy vehicle workshop;<br />

tire change pads; heavy and light<br />

vehicle wash bays; raw water<br />

supply pipeline; fire protection;<br />

and wastewater treatment and<br />

recycling to the process-water dam.<br />

Final works for Liddell were<br />

completed under budget and on time<br />

in April 2008. Works for Glendell<br />

were completed and the entire site<br />

handed over under budget and on<br />

time in December 2010.<br />

Mangoola<br />

The Mangoola coal mine in the<br />

upper Hunter Valley achieved<br />

operational completion on April<br />

20, 2011, two years after <strong>Parsons</strong><br />

<strong>Brinckerhoff</strong> began preliminary<br />

work on the project for Xstrata<br />

Coal New South Wales.<br />

“<strong>Parsons</strong> <strong>Brinckerhoff</strong> was<br />

engaged in an alliance with Xstrata<br />

Coal, where we managed the design<br />

and on-site construction supervision<br />

of the early works and the major<br />

project works,” says Project Manager<br />

Malcolm McPhan. These consisted<br />

of 7 kilometers (4 miles) of<br />

provincial road upgrade, mine<br />

access road; and initial preparation<br />

of the site. It also included<br />

engineering, design, procurement,<br />

and on-site construction management<br />

of all the bulk earthworks and haul<br />

roads, MIA consisting of a five-bay<br />

workshop, fuel and lube facility,<br />

heavy vehicle and light vehicle<br />

wash bays, sewage and water<br />

treatment plants, as well as an<br />

administration and stores building<br />

complete with bathhouse, and the<br />

mine bulk water system supplied<br />

from the Hunter River.<br />

<strong>Parsons</strong> <strong>Brinckerhoff</strong> was also<br />

responsible for procurement and<br />

construction management for the<br />

raw water and pit water dams and<br />

the rail loop and signaling contracts.<br />

Additionally, the firm was charged<br />

with managing the master schedule,<br />

total project budget, and all major<br />

project interfaces. “All works were<br />

executed well ahead of time and<br />

well below the forecast cost<br />

at completion with zero losttime<br />

incidents,” reports McPhan.<br />

Development consent<br />

was granted in<br />

November 2009; first<br />

coal was processed in<br />

February 2011.<br />

The scope was to<br />

establish a 10.5-millionton<br />

per year open-cut<br />

mine averaged over<br />

a 20-year operating<br />

life. “This target is<br />

well on the way to<br />

being realized, with<br />

operational completion<br />

achieved some eight<br />

weeks ahead of the<br />

original milestone,”<br />

says McPhan.<br />

Malcolm McPhan<br />

10 • Notes<br />

<strong>Parsons</strong> <strong>Brinckerhoff</strong> was also engaged by Xstrata to deliver a new mine, Glendell,<br />

not far from Liddell. Glendell opened in December 2010.<br />

Notes • 11

Shining <strong>Bright</strong>ly in the Philippines<br />

Copper lies beneath the ground<br />

The Bengalla <strong>Mining</strong> Company’s expansion of its mine was intended to increase capacity to process more coal.<br />

Bengalla<br />

Phase 1 of the Bengalla Expansion<br />

Project commenced in November<br />

2010 to increase Bengalla’s capacity<br />

from 7.8 million tons of run-of-mine<br />

coal production to 9.3 million tons<br />

by the first quarter of 2012.<br />

Overall, the project involves<br />

three main contracts: civil works,<br />

coal handling and preparation<br />

plant (CHPP) upgrade, and the<br />

mining infrastructure area upgrade.<br />

The scope of work includes: two<br />

additional heavy vehicle workshop<br />

bays to accommodate additional<br />

trucks and temporary/permanent tire<br />

bays; expansion of the bathhouse;<br />

extension of existing offices;<br />

increased car parking capacity;<br />

improved outdoor stores facilities;<br />

upgraded heavy vehicle wash<br />

station; and oil/water separation<br />

plant. The CHPP is being upgraded<br />

to handle the higher throughput of<br />

coal. Also in the scope of work are<br />

improved tailings de-watering with<br />

six additional belt press filters; coal<br />

handling; and preparation plant<br />

drain realignment. Additional<br />

Phase 1 tasks were purchases of<br />

heavy mining equipment such as<br />

four new trucks, one excavator,<br />

one grader, one dozer, one water<br />

cart, and a fleet of light vehicles.<br />

“The project team was an integrated<br />

team consisting of 26 staff from both<br />

Bengalla <strong>Mining</strong> Company and<br />

<strong>Parsons</strong> <strong>Brinckerhoff</strong>,” says Bruce<br />

Mitchell, Project Manager.<br />

Indeed, mining in the Hunter<br />

Valley region is growing. “We are<br />

well-poitioned to take advantage<br />

of it,” notes Thornton. n<br />

One of the largest undeveloped coppergold<br />

deposits in Southeast Asia has<br />

the potential to significantly brighten<br />

the economy of the Philippines and,<br />

in particular, the Mindanao region, the<br />

second largest island in the country.<br />

Sagittarius Mines Incorporated<br />

(SMI) set out to learn if a mine at<br />

Tampakan was feasible, and engaged<br />

<strong>Parsons</strong> <strong>Brinckerhoff</strong> to contribute to<br />

the extended pre-feasibility study and<br />

subsequent feasibility study. <strong>Parsons</strong><br />

<strong>Brinckerhoff</strong>’s services for the $6 billion<br />

Tampakan project were delivered<br />

through 2010 under the direction of<br />

Project Manager Kate Gilchrist, based<br />

in Brisbane.<br />

Comprehensive Studies<br />

For the extended pre-feasibility study,<br />

the firm produced a project definition<br />

report; project delivery schedule for the<br />

entire project; capital cost estimate; and<br />

infrastructure design for a wide range<br />

of facilities—mine area power supply<br />

and distribution; mine area facilities<br />

(workshops, warehouses, etc.); waste<br />

and ore crushing and conveying; roads,<br />

mass earthworks; administration facilities;<br />

information technology; communications;<br />

and water distribution.<br />

Next, for the feasibility study, the firm<br />

provided feasibility<br />

level engineering<br />

for on-site roads;<br />

off-site roads; mass<br />

earthworks; buildings<br />

and structures; water<br />

distribution; electrical;<br />

communications; and<br />

control distribution in<br />

addition to port and<br />

power station layout<br />

support; geotechnical<br />

support and review;<br />

In the Mindanao region of the Philippines, <strong>Parsons</strong> <strong>Brinckerhoff</strong> studied site conditions,<br />

topography, and altitude to determine if a copper mine would be feasible.<br />

independent review of design criteria;<br />

and administrative and technical support<br />

to the SMI team. <strong>Parsons</strong> <strong>Brinckerhoff</strong>’s<br />

3D visualization services were used to<br />

produce models to support community<br />

consultation.<br />

“Staff from the Manila office worked<br />

on the studies, which reduced the cost<br />

and demonstrated in-country capability,”<br />

says Gilchrist.<br />

There were challenges along the way.<br />

The team overcame a range of technical<br />

obstacles including working in areas<br />

of high rainfall where the topography<br />

ranges from 450 to 1,550 meters<br />

(1,500 to 5,000 feet) above sea level.<br />

The studies identified open-pit<br />

mining as the most appropriate and<br />

safest extraction method, given the<br />

location and the geology of the site.<br />

The development of a mine, however,<br />

is subject to necessary community,<br />

government, and company approvals.<br />

SMI submitted the Tampakan <strong>Mining</strong><br />

Project Feasibility Study to the<br />

Philippines government in April 2010<br />

and estimates production could start<br />

in 2016.<br />

<strong>Parsons</strong> <strong>Brinckerhoff</strong>’s Manila office<br />

is currently assisting SMI through the<br />

resettlement and approvals phase of<br />

the Tampakan project. The firm has<br />

undertaken a validation assessment<br />

of proposed resettlement sites and is<br />

currently providing engineering services<br />

for resettlement sites and providing<br />

technical support to the owner’s team.<br />

In addition to its involvement in the<br />

Tampakan project, <strong>Parsons</strong> <strong>Brinckerhoff</strong><br />

personnel are strongly represented in an<br />

integrated owner’s team on the feasibility<br />

study for the Frieda River Project, a<br />

proposed copper/gold mine in<br />

Papua New Guinea. n<br />

At the Bengalla Expansion Project site are Construction Manager George Anderson and<br />

Project Manager Bruce Mitchell.<br />

Kate Gilchrist<br />

12 • Notes Notes • 13

A Boom in Iron Ore<br />

<strong>Mining</strong> in Australia’s Pilbara region<br />

Ray Stocker<br />

<strong>Mining</strong> has taken off in Western<br />

Australia’s Pilbara region—-one of the<br />

richest sources of iron ore on earth—<br />

thanks to massive demand for steel<br />

from China and other rapidly<br />

developing economies.<br />

<strong>Parsons</strong> <strong>Brinckerhoff</strong> is providing<br />

environmental consulting and groundwater<br />

hydrogeology engineering<br />

services, including environmental<br />

impact assessments, health and safety<br />

monitoring, groundwater resource<br />

identification and de-watering options<br />

for areas where iron ore sits below the<br />

water table. The firm is also working on<br />

engineering-procurement-construction<br />

management (EPCM) projects; developing<br />

engineering designs; procuring<br />

equipment, contractors, and suppliers<br />

for construction; and managing the<br />

construction process.<br />

“Lots of consultants do structural,<br />

civil, and water engineering,” says<br />

Ray Stocker, General Manager, Metals,<br />

Global <strong>Mining</strong> for <strong>Parsons</strong> <strong>Brinckerhoff</strong>.<br />

“<strong>Parsons</strong> <strong>Brinckerhoff</strong> does all that as<br />

well, but where we feel we excel is in<br />

project and construction management<br />

particularly for the infrastructure to<br />

support the mine, including workshops,<br />

miner accommodations, roads, water<br />

supply, power generation<br />

and distribution,<br />

desalination plants,<br />

and materials<br />

handling.”<br />

Another strength<br />

of the firm is its<br />

reputation for<br />

BHP Billiton’s Rapid Growth Project 5, Yandi mine, where <strong>Parsons</strong> <strong>Brinckerhoff</strong> has<br />

provided services in Western Australia’s Pilbara region.<br />

expertise in all aspects of sustainability.<br />

“Sustainability is a major aspect of<br />

everything we do,” says Stocker.<br />

“We don’t look at sustainability as an<br />

additional feature but as a key part of<br />

the process including the materials we<br />

choose.” This approach, Stocker says, is<br />

important to mining companies because<br />

today’s mining projects have a raft of<br />

stringent regulations, environmental<br />

requirements, and safety challenges that<br />

must be addressed.<br />

Some of the biggest investors in<br />

Western Australian mining are also some<br />

of the largest mining enterprises in the<br />

world, including BHP Billiton and Rio<br />

Tinto. There are also companies such as<br />

Fortescue Metals Group (FMG) that are<br />

rapidly growing. All of these companies<br />

intend to invest billions of dollars, with<br />

the bigger players each looking to<br />

“Sustainability is<br />

a major aspect<br />

of everything<br />

we do.”<br />

—Ray Stocker<br />

significantly expand its operations to<br />

meet the increasing demand for iron<br />

ore, particularly from China.<br />

“With iron ore prices at record levels,<br />

profits being generated by the industry<br />

are also at record levels, and this is<br />

driving the huge capital investment<br />

in mine expansion to meet increasing<br />

demand,” says Paul Reed, Regional<br />

Director of <strong>Mining</strong> in Western Australia.<br />

BHP Billiton<br />

BHP Billiton has a number of new<br />

mining operations in Pilbara that it calls<br />

Rapid Growth Projects 1 through 6.<br />

<strong>Parsons</strong> <strong>Brinckerhoff</strong>’s involvement has<br />

been with Rapid Growth Projects 5 and<br />

6, where BHP Billiton is expanding its<br />

iron ore production.<br />

As part of this effort, <strong>Parsons</strong><br />

<strong>Brinckerhoff</strong> worked together<br />

with another global engineering,<br />

procurement, and construction<br />

company, to deliver the prefeasibility<br />

study for the Yandi mine portion<br />

of Rapid Growth Project 5 and the<br />

non-process infrastructure section<br />

of the more detailed feasibility study.<br />

Train loading facilities at Yandi mine in Pilbara, Western Australia, where <strong>Parsons</strong><br />

<strong>Brinckerhoff</strong> was part of the team that delivered infrastructure prefeasibility and<br />

feasibility studies, detailed design, and construction support services.<br />

<strong>Parsons</strong> <strong>Brinckerhoff</strong> was also involved<br />

with EPCM for infrastructure construction.<br />

Tasks included a review of mineral<br />

processing options, including crushing,<br />

screening, materials handling, stacking,<br />

and train loading, and a recommended<br />

strategy and cost estimation at the<br />

detailed feasibility stage for several nonprocessing<br />

support facilities, including a<br />

1,500-person mining village, workshops,<br />

roads, and structures for refueling,<br />

explosives, and laboratory work.<br />

<strong>Parsons</strong> <strong>Brinckerhoff</strong> was also<br />

involved in the delivery of the nonprocess<br />

infrastructure portion of the<br />

prefeasibility study for Rapid Growth<br />

Project 6 and Quantum projects.<br />

Currently <strong>Parsons</strong> <strong>Brinckerhoff</strong> is<br />

providing hydrogeology services to<br />

BHP Billiton for its future mine<br />

developments including groundwater<br />

studies to identify environmental impacts<br />

of mining operations, sources for a<br />

reliable water supply, and requirements<br />

for de-watering.<br />

Rio Tinto<br />

<strong>Parsons</strong> <strong>Brinckerhoff</strong> has been involved<br />

with several aspects of Rio Tinto’s<br />

expansion projects in the Pilbara region<br />

over the past year, helping the company<br />

upgrade materials handling equipment<br />

to speed production and providing<br />

engineering design for an ammonium<br />

nitrate storage facility. The firm is also<br />

assisting with integrity work for the<br />

port facility assets, which are more<br />

than 40 years old and due for a major<br />

upgrade.<br />

Fortescue Metals Group<br />

<strong>Parsons</strong> <strong>Brinckerhoff</strong> will be providing<br />

EPCM services for FMG’s Rowley<br />

Yard T155 Rail Infrastructure Project<br />

over the next two years, overseeing<br />

numerous contractors for the design and<br />

construction of rail maintenance facilities<br />

and various other smaller rail elements<br />

for the owner. “We’ll provide engineering<br />

services, project and construction<br />

management, and technical support for<br />

procurement, particularly for equipment,”<br />

says Reed.<br />

Part of the firm’s technical support is<br />

intended to help FMG introduce more<br />

automation capability to speed up the<br />

removal and maintenance of railroad<br />

car wheels and running gear when<br />

necessary.<br />

Challenges Ahead<br />

With an explosion in Australian mining,<br />

including major projects not only in iron<br />

ore but in coal, oil, and gas, the principal<br />

challenge, according to Stocker, is to<br />

secure resources to meet the design and<br />

construction milestones. “Every contractor<br />

is very busy and has huge demand for<br />

its services.” Recently contractors from<br />

China, India, Spain, and the U.S. have<br />

become involved in Australian mining<br />

projects. “China has massive investment<br />

in Australian mining to fund and protect<br />

its source of supply,” says Stocker.<br />

Another challenge is simply building<br />

credibility in iron ore mining projects<br />

where <strong>Parsons</strong> <strong>Brinckerhoff</strong> brings<br />

its long experience and expertise in<br />

engineering project management to the<br />

table. “We’re in the process of building<br />

relationships, and we aim to deliver well<br />

and build on our reputation as a trusted<br />

advisor in these areas of engineering,”<br />

says Stocker. “The name of the game<br />

is trust, and trust is built on delivery.<br />

Well-delivered projects will build<br />

credibility and credentials with larger<br />

and mid-tier players.”<br />

Boosting the Economy<br />

Stocker maintains that mining projects<br />

bring economic benefits to the specific<br />

region and the larger Australian economy<br />

as well.<br />

“We’re helping to build the Australian<br />

economy,” says Stocker. Each mining<br />

project employs hundreds or thousands<br />

of mining personnel and support staff<br />

and requires workers for facilities in the<br />

mining villages under construction and<br />

the general community.<br />

“This drives employment throughout<br />

the community, including retail stores,<br />

restaurants, bakeries, taxis, trucking,<br />

airlines, and airports,”<br />

says Stocker. The<br />

major mining<br />

companies have<br />

been making<br />

efforts to increase<br />

employment<br />

opportunities<br />

for the local<br />

Indigenous<br />

population,<br />

as much of<br />

what’s being<br />

built right now<br />

is located on<br />

Aboriginal land. n<br />

Paul Reed<br />

14 • Notes<br />

Notes • 15

Notes<br />

on<br />

Projects<br />

Bus stop: In Reno, a 1960s-era bus<br />

makes it clear that the new building<br />

is a bus transit center.<br />

Reno Bus Station<br />

Rides into Town<br />

The new RTC 4th Street Station<br />

in the heart of Reno, Nevada,<br />

offers modern and efficient bus<br />

transportation and amenities for<br />

passengers, passersby, tourists,<br />

and neighborhood residents.<br />

Funded by the Federal Transit<br />

Administration, it replaced<br />

CitiCenter, a smaller bus station<br />

located two blocks away.<br />

<strong>Parsons</strong> <strong>Brinckerhoff</strong> provided<br />

planning, architectural,<br />

preliminary engineering, and<br />

final design services for its client,<br />

the Regional Transportation<br />

Commission (RTC) of Washoe<br />

County.<br />

Opened in October 2010, the<br />

station, located on 4th Street<br />

and part of the historic Lincoln<br />

Highway, is adjacent to several<br />

rail facilities dating from the<br />

early 1900s. “Our mission was to<br />

provide a design that reflected<br />

Reno’s place in early railroad<br />

history in a form capable of<br />

achieving LEED [Leadership<br />

in Energy and Environmental<br />

Design] Silver certification,”<br />

says Tom Brooks-Pilling,<br />

Architectural Practice Leader<br />

for <strong>Parsons</strong> <strong>Brinckerhoff</strong>. “The<br />

twin-arch canopies that span<br />

the station evoke the imagery<br />

of train sheds, and the building<br />

façades are in harmony with the<br />

neighboring Barengo Building,<br />

built as a passenger and freight<br />

depot in 1910.”<br />

The <strong>Parsons</strong> <strong>Brinckerhoff</strong><br />

team projected there would be<br />

16,300 daily riders at opening<br />

and planned the facility for<br />

28,300. Nearly a year after its<br />

opening, Lee Gibson, Executive<br />

Director of the RTC, says, “The<br />

system’s overall ridership has<br />

increased 8 percent and this<br />

is directly attributable to the<br />

location and convenience of<br />

our new transit center.”<br />

On a 1-hectare (2.5-acre) site,<br />

the new transit center consists of<br />

two, one-story buildings situated<br />

on three islands, surrounded by<br />

23 bus bays. The station contains<br />

passenger waiting areas,<br />

restrooms, retail outlets, and<br />

operations and maintenance<br />

facilities.<br />

The transit center is marked<br />

by a striking piece of public art:<br />

an actual 1960s General Motors<br />

bus, modified for its installation.<br />

“The thought was for the work<br />

to act not only as a sculpture,<br />

but as a sign, indicating the<br />

bus station,” according to the<br />

sculptor, Donald Lipski, who<br />

worked with RTC to develop<br />

the concept.<br />

RTC 4th Street Station was<br />

recognized as the Outstanding<br />

Structural Project of the Year<br />

for 2010 by the Truckee<br />

Meadows (Nevada) Branch of<br />

the American Society of Civil<br />

Engineers.<br />

UK Agency Studies<br />

New Energy Source<br />

On behalf of Britain’s Energy<br />

Coast and North West Regional<br />

Development Agency,<br />

both of the UK, <strong>Parsons</strong><br />

<strong>Brinckerhoff</strong> has confirmed<br />

that tidal power generation<br />

is technically achievable on<br />

the Duddon Estuary in North<br />

West England by building<br />

a tidal barrage—a structure<br />

that captures energy from the<br />

change in tide levels. <strong>Parsons</strong><br />

<strong>Brinckerhoff</strong>’s report indicated<br />

that more energy could be<br />

generated than previously<br />

suggested by an earlier study.<br />

It also found, however, that<br />

many protected environmental<br />

areas and wildlife—including<br />

the natterjack toad—could<br />

be adversely affected by the<br />

proposal, requiring extensive<br />

and expensive mitigation.<br />

The study was to determine<br />

if tidal power generation on<br />

the Duddon was still practical,<br />

given changes to UK energy<br />

policy that encourage greater<br />

use of renewable power,<br />

projected costs for renewable<br />

energy in the future, and the<br />

introduction of more stringent<br />

environmental legislation.<br />

<strong>Parsons</strong> <strong>Brinckerhoff</strong> was<br />

appointed in February 2010<br />

to examine various options<br />

and locations for power<br />

generation, the cost of<br />

construction, operation and<br />

maintenance, and job creation<br />

potential. Environmental<br />

and socioeconomic impacts<br />

were analyzed and the study<br />

examined opportunities for<br />

combining a road crossing<br />

with any option. Stakeholder<br />

engagement meetings began<br />

in March 2010 and continued<br />

throughout the study period,<br />

which ended with a report in<br />

August 2010. These meetings<br />

provided valuable input regarding<br />

issues that would need<br />

resolution if any tidal power<br />

project were to be developed.<br />

“The study highlighted the<br />

environmental challenges of<br />

the project,” says Peter Kydd,<br />

Director of Strategic Consulting<br />

for <strong>Parsons</strong> <strong>Brinckerhoff</strong> in<br />

the UK. “It also showed that<br />

280,000 MW per year of lowcarbon<br />

electricity could be<br />

generated by the new 160-MW<br />

facility, enough to power<br />

50,000 homes.”<br />

The study concluded that<br />

combining the barrage with<br />

a new 10-kilometer (6-mile)<br />

road crossing would improve<br />

the cost-benefit ratio of the<br />

project but that it would not<br />

be economical in the current<br />

market.<br />

Wastewater Treatment<br />

And Recycling Plant<br />

At Work in Australia<br />

Construction and commissioning<br />

is complete on the Gippsland<br />

Water Factory, a wastewater<br />

treatment and recycling plant<br />

in Victoria, Australia, that<br />

processes 35 million liters (9<br />

million gallons) of residential<br />

and industrial wastewater each<br />

day from more than 15,000<br />

households and businesses.<br />

The Gippsland Water Factory<br />

project was delivered by an<br />

alliance comprised of Gippsland<br />

Water and three specialized<br />

companies: Transfield Services<br />

Limited, CH2M Hill, and <strong>Parsons</strong><br />

<strong>Brinckerhoff</strong>. The firm provided<br />

multidisciplinary engineering<br />

and environmental design and<br />

stakeholder engagement services<br />

for the $260 million plant.<br />

The plant, the first of its<br />

kind in Australia, produces<br />

8 million liters (2 million<br />

gallons) of high-quality recycled<br />

water daily that is sold to a<br />

nearby producer of paper<br />

products for use in its industrial<br />

processes. The remaining highly<br />

treated odor-free wastewater<br />

is discharged into the ocean<br />

until a suitable customer can<br />

be sourced.<br />

By selling recycled water<br />

to the paper manufacturer, the<br />

Gippsland Water Factory frees<br />

up an equivalent amount of<br />

freshwater—about 3 billion liters<br />

(800 million gallons) annually—<br />

from the region’s rivers and<br />

reservoirs, enough to service<br />

a town of 40,000 people for<br />

an entire year.<br />

The Gippsland Water<br />

Factory uses a three-stage<br />

treatment process that<br />

features biological treatment,<br />

membrane filtration, and<br />

reverse osmosis. “By relying<br />

on biological methods rather<br />

than chemical treatment,<br />

and locating the plant close<br />

to the paper manufacturer<br />

and residential development,<br />

we minimize the use of<br />

electricity in transport and<br />

wastewater processing,”<br />

says Andrew Hodgkinson,<br />

<strong>Parsons</strong> <strong>Brinckerhoff</strong>’s Gippsland<br />

Water Factory Alliance Technical<br />

Director.<br />

Biogas produced by the<br />

treatment of the paper mill waste<br />

and plant sludge, plus a microhydro<br />

plant constructed nearby,<br />

are used to generate 20 percent<br />

of the plant’s electricity needs.<br />

Also constructed on the site is<br />

the Vortex Centre, which provides<br />

visitors the opportunity to learn<br />

about water conservation and<br />

sustainable water management.<br />

Clear water: At the Gippsland<br />

Water Factory in Victoria,<br />

Australia, the sedimentation tank<br />

is part of the process of recycling<br />

wastewater for industrial use.<br />

It’s educational: Gippsland’s<br />

Vortex Centre teaches visitors<br />

about water conservation and<br />

sustainable water management,<br />

enabling future security of the<br />

local water supply.<br />

16 • Notes<br />

Notes • 17

Notes<br />

on<br />

Projects<br />

Going underground: Seattle’s seismically vulnerable Alaskan Way Viaduct will<br />

be replaced by a bored tunnel, the largest ever constructed by a tunnel boring<br />

machine. Shown here is the approach to the south portal.<br />

Rent-A-Car: The Miami Intermodal Center-Rental Car Center is capable of<br />

washing and fueling up to 7,200 cars per day.<br />

Making tracks: Two new light rail lines<br />

nearly doubled the length of tracks<br />

of Salt Lake‘s TRAX system.<br />

© 2011 david sailors<br />

Salt Lake City<br />

Opens New Rail<br />

New trains burst through a<br />

banner proclaiming “everything’s<br />

falling into place” at inaugural<br />

ceremonies in August for Salt<br />

Lake City’s new West Valley<br />

City and Mid-Jordan TRAX light<br />

rail extensions. Officials and<br />

riders celebrated the extensions,<br />

which were completed ahead<br />

of schedule and significantly<br />

under budget. The new lines<br />

nearly double the length of<br />

track and number of train cars<br />

in service.<br />

<strong>Parsons</strong> <strong>Brinckerhoff</strong> is<br />

program manager for the newly<br />

opened lines, as well as for<br />

the Utah Transit Authority’s<br />

(UTA) entire FrontLines 2015<br />

program, which is one of the<br />

largest and most aggressive rail<br />

expansion programs in the U.S.<br />

To accommodate Utah’s fastgrowing<br />

population, FrontLines<br />

2015 will expand UTA’s existing<br />

103-kilometer (64-mile) transit<br />

network with two additional<br />

new light rail lines and a second<br />

commuter rail line (the first<br />

opened in April 2008), totaling<br />

113 kilometers (70 miles) of<br />

added service. These new<br />

services will provide residents<br />

with transportation options and<br />

enhance mobility for non-riders<br />

by decreasing traffic congestion.<br />

Kevin Cox, Project Manager<br />

for <strong>Parsons</strong> <strong>Brinckerhoff</strong>,<br />

credits the ability to meet an<br />

accelerated schedule to an<br />

integrated approach. “From the<br />

beginning, <strong>Parsons</strong> <strong>Brinckerhoff</strong><br />

teamed with UTA to develop a<br />

management plan that placed a<br />

premium on integrated teams and<br />

partnering and used a range of<br />

creative approaches to contract<br />

packaging, scheduling, and<br />

funding,” says Cox, noting that<br />

the agency is a strong advocate<br />

for a collaborative arrangement.<br />

“<strong>Parsons</strong> <strong>Brinckerhoff</strong> has<br />

been a partner with the Utah<br />

Transit Authority for the past<br />

30 years,” says Mike Allegra,<br />

UTA General Manager. “They<br />

share our commitment to the<br />

community.”<br />

Projects of the Year<br />

Illustrate Innovation<br />

<strong>Parsons</strong> <strong>Brinckerhoff</strong>’s 2010<br />

Projects of the Year demonstrate<br />

innovation in the use of new<br />

materials and technologies and<br />

a creative approach to problemsolving<br />

on behalf of the firm’s<br />

clients.<br />

“The four winning projects<br />

demonstrate the breadth of practices<br />

of <strong>Parsons</strong> <strong>Brinckerhoff</strong>—<br />

highways, tunnels, buildings,<br />

transit, and bridges,” says George<br />

J. Pierson, President and Chief<br />

Executive Officer. “In addition to<br />

innovation, they exemplify teamwork<br />

and strong leadership.”<br />

The four Projects of the Year<br />

are as follows:<br />

Alaskan Way Viaduct and<br />

Seawall Replacement<br />

As general engineering<br />

consultant for the Alaskan<br />

Way Viaduct and Seawall<br />

Replacement, <strong>Parsons</strong><br />

<strong>Brinckerhoff</strong> served for<br />

10 years as lead strategic<br />

advisor assisting the Washington<br />

Department of Transportation<br />

in eliminating its greatest public<br />

safety risk — the seismically<br />

vulnerable viaduct running<br />

along the Seattle waterfront that<br />

carries 110,000 vehicles daily.<br />

Conceptual design was<br />

prepared for replacement of<br />

the 2,000-meter- (6,500-foot-)<br />

long Elliott Bay seawall. The<br />

firm’s responsibilities included<br />

preparing an environmental<br />

impact statement and bid<br />

documents in connection with<br />

the replacement of the viaduct.<br />

The proposed 3-kilometer-<br />

(2-mile-) long tunnel will be<br />

17 meters (56 feet) in diameter,<br />

the largest ever constructed<br />

by a tunnel boring machine.<br />

The team met challenging<br />

technical obstacles and a<br />

demanding schedule.<br />

Mike Rigsby was Project<br />

Manager and Jared Smith was<br />

Principal-in-Charge.<br />

Miami Intermodal Center-<br />

Rental Car Center<br />

On behalf of the Florida Department<br />

of Transportation, District<br />

VI, Heery International provided<br />

architecture, overall architecture/<br />

engineering coordination, and<br />

construction administration services<br />

for the Miami Intermodal<br />

Center-Rental Car Center.<br />

The rental car center is a $355<br />

million, 300,000-square-meter<br />

(3.4 million-square-foot) facility<br />

in the Miami Intermodal Center,<br />

offering passengers one location<br />

for rental car agencies with rapid<br />

transportation to and from Miami<br />

International Airport and connectivity<br />

among several transportation<br />

systems.<br />

Heery was the architect of<br />

record for a four-story structure<br />

that includes the first multi-level<br />

fueling, fluid top-off, and wash<br />

bay facility in the U.S. The 120<br />

fuel dispensers required special<br />

approvals from fire prevention<br />

officials; the team devised and<br />

executed a sophisticated performance-based<br />

design using computer<br />

simulations of fire scenarios<br />

and solutions. The result: capacity<br />

to fuel and wash up to 7,200<br />

cars per day.<br />

Rosendo E. Marcet Jr. was<br />

Project Manager and Roberto<br />

Sequeira was Principal-in-Charge.<br />

Project Architect was Roberto<br />

Vich. Heery is the U.S. buildings<br />

operating company of <strong>Parsons</strong><br />

<strong>Brinckerhoff</strong>.<br />

Dearborn Subway<br />

Track Renewal<br />

For the Dearborn Subway<br />

Track Renewal project, <strong>Parsons</strong><br />

<strong>Brinckerhoff</strong> was the construction<br />

manager representing<br />

the Chicago Transit Authority<br />

(CTA). The $87.8 million project<br />

involved the rail replacement<br />

and extensive tunnel rehabilitation<br />

of the Dearborn (Blue Line)<br />

Subway, a 6-kilometer (4-mile)<br />

segment connecting the Chicago<br />

downtown business district with<br />

O’Hare International Airport.<br />

Most of the work on the<br />

60-year-old tunnel was performed<br />

during 54-hour weekend<br />

track outages. The CTA limited<br />

the number of outages to 23<br />

scheduled around the city’s<br />

summer and fall public events.<br />

The system was returned to full<br />

service on Monday mornings in<br />

time to support the rush-hour<br />

commute. The team, led by<br />

<strong>Parsons</strong> <strong>Brinckerhoff</strong> and the<br />

CTA, completed the project on<br />

time and below budget—with<br />

minimal disruptions in service.<br />

Ken Davidson was the Project<br />

Manager. Tom Nutter was the<br />

Principal-in-Charge.<br />

Fort Eustis<br />

Railroad Bridges<br />

The Fort Eustis Railroad Bridges<br />

project involved design of the<br />

world’s first railroad bridges<br />

made of recycled plastics—at<br />

the U.S. Army base at Fort<br />

Making it new again: The Dearborn Subway Track Renewal rehabilitated a<br />

key segment of Chicago’s Dearborn (Blue Line) Subway.<br />

Eustis, Virginia—applying a new<br />

sustainable construction material<br />

to major bridge components.<br />

The two new bridges,<br />

12 meters (40 feet) and<br />

24 meters (80 feet) long,<br />

respectively, replaced halfcentury-old<br />

structurally deficient<br />

timber railroad bridges.<br />

The thermoplastic material,<br />

developed by scientists at<br />

New Jersey’s Rutgers University<br />

and manufactured by Axion<br />

International, uses post-consumer<br />

plastics that would otherwise be<br />

deposited into landfills. Although<br />

this material had been in the<br />

marketplace for 20 years, this<br />

was its first application to major<br />

infrastructure. One challenge<br />

was convincing the U.S. Army<br />

that plastic could support<br />

120-ton locomotives. Another<br />

was meeting the aggressive<br />

schedule set by the Army;<br />

the design-build team handed<br />

complete construction plans<br />

to the contractor two months<br />

after the contract was signed.<br />

John S. Kim was Project<br />

Manager. Vijay Chandra<br />

was Principal-in-Charge. n<br />

Thermoplastic: One of the railroad<br />

bridges made of recycled plastics at the<br />

U.S. Army base at Fort Eustis, Virginia.<br />

18 • Notes Notes • 19

© 2011 david sailors<br />

Mike Abrahams<br />

Notes<br />

on the<br />

Firm<br />

OPAL Award to<br />

Mike Abrahams<br />

Mike Abrahams has won the<br />

OPAL (Outstanding Projects<br />

and Leaders) award from<br />

the American Society of<br />

Civil Engineers for lifetime<br />

achievement in design. He<br />

will receive the award in<br />

March 2012 at an awards gala.<br />

Established in 1999, the OPAL<br />

award recognizes individuals<br />

for lifelong accomplishments<br />

and achievements that have<br />

made significant differences in<br />

five areas of civil engineering:<br />

construction, design, education,<br />

government, and management.<br />

This was the third time a<br />

<strong>Parsons</strong> <strong>Brinckerhoff</strong> employee<br />

garnered the award; Jim Lammie<br />

received it for achievement in<br />

management in 2001 and the late<br />

Lou Silano for design in 2005.<br />

Abrahams was also recently<br />