Oct/Dic '04 - N.41 PDF file - 2.3 - Pirelli

Oct/Dic '04 - N.41 PDF file - 2.3 - Pirelli

Oct/Dic '04 - N.41 PDF file - 2.3 - Pirelli

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

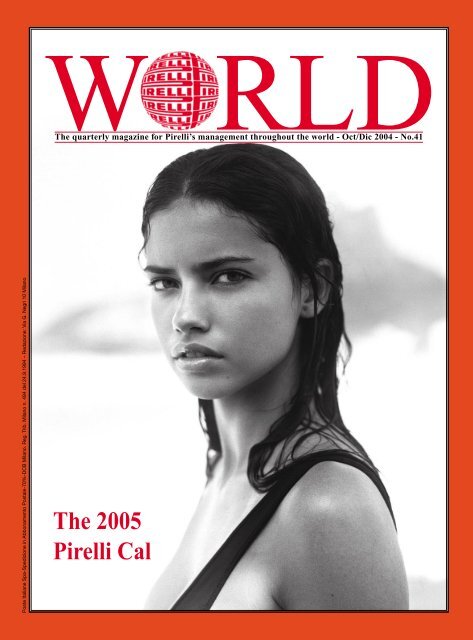

W RLD<br />

The quarterly magazine for <strong>Pirelli</strong>’s management throughout the world - <strong>Oct</strong>/<strong>Dic</strong> 2004 - No.41<br />

Poste Italiane Spa-Spedizione in Abbonamento Postale-70%-DCB Milano. Reg. Trib. Milano n. 494 del 24.9.1994 – Redazione: Via G. Negri 10 Milano<br />

The 2005<br />

<strong>Pirelli</strong> Cal

CONTENTS<br />

A Responsible Business<br />

<strong>Pirelli</strong> publishes its fourth<br />

Environmental Report<br />

page 6<br />

Girls from Ipanema<br />

Rio de Janeiro hosts the launch of the<br />

2005 edition of “The Cal”<br />

page 15<br />

La Scala and Arcimboldi<br />

The role of the new Arcimboldi Theatre<br />

after the reopening of La Scala<br />

page 22<br />

Focus on Technology,<br />

Quality, Research<br />

Marco Tronchetti Provera explains the<br />

strategy of the <strong>Pirelli</strong> Group<br />

page 2<br />

Striking a Cord<br />

in Rumania<br />

<strong>Pirelli</strong> and Continental will jointly<br />

produce steel cord in Rumania<br />

page 9<br />

Tunable Light Rays<br />

The Dynamically Tunable Laser, a<br />

mayor breakthrough in photonics<br />

page 18<br />

12 November 2004. in a video message<br />

on the <strong>Pirelli</strong> Intranet, Marco Tronchetti<br />

Provera explained the future developments<br />

to all employees of the strategy<br />

announced in August 2001: the beginning<br />

of a process that will result in the transfer<br />

of Cables and Energy Systems and<br />

Cables for Telecommunications, a three<br />

year investment programme by the Tyre<br />

Sector in Brazil, China and Rumania,<br />

the birth of <strong>Pirelli</strong> Broadband Solutions<br />

and a technological centre for the environment<br />

(p. 2-3). A few days later, Mr.<br />

Tronchetti received an honorary degree<br />

in telecommunications engineering from<br />

the University of Genoa and gave a lectio<br />

magistralis (p. 7-8) – in which he talked<br />

of the “innovation company” concept<br />

and the mission of the <strong>Pirelli</strong> Group. The<br />

theme is innovation across the board, and<br />

the results are already there for all to see.<br />

In Italy, <strong>Pirelli</strong> Tyres received the<br />

Confindustria and A.T. Kearney 2004<br />

Best Innovator award for its “excellence<br />

in integrating the different dimensions<br />

of innovation” with the MIRS and<br />

CCM technologies. In Canada, <strong>Pirelli</strong><br />

was presented with the 2004 Italy-Canada<br />

Investaward and in Australia the 2004<br />

Azienda Italia Award for its contribution<br />

to the economic and commercial development<br />

of the two countries (p. 16-17).<br />

<strong>Pirelli</strong>’s participation in the Technology<br />

in Movement meeting also deserves<br />

a mention. It was an event organised<br />

by Intermonte, the investment bank,<br />

to bring the financial community up<br />

to speed on technological evolution<br />

in the European motor manufacturing<br />

industry (p. 19). A mention, too, for the<br />

winter tyre Oscar, awarded to the <strong>Pirelli</strong><br />

Sottozero by three of Germany’s top<br />

motoring magazines (p. 23).<br />

And finally, a look at the year to come<br />

with the new 2005 <strong>Pirelli</strong> Calendar, presented<br />

in Brazil for the first time, in the<br />

teeming city of Rio de Janeiro (p. 12-15).<br />

An overwhelming success for an icon<br />

now more than 40 years old … although<br />

it certainly does not look it. With this<br />

edition, <strong>Pirelli</strong> World wishes its readers a<br />

merry Christmas and a happy new year.<br />

Arrivederci until 2005!<br />

1

STRATEGY<br />

A message from the Chairman<br />

Focus on Technology,<br />

Quality, Research<br />

The re-organisation of the Group is over: <strong>Pirelli</strong> is now refocusing on its activities<br />

with greater added value and is ready to valorise the Energy Cables & Systems<br />

and the Telecom Cables Sectors, investing in tyres and broadband access products<br />

A<br />

s you<br />

will<br />

recall, in July<br />

2001, on<br />

announcing<br />

participation<br />

in the Olivetti-Telecom<br />

Group, the<br />

<strong>Pirelli</strong>’s strategy<br />

was redefined stating that “the new<br />

Telecommunications activities would be<br />

flanked by a select number of high profitability<br />

businesses, with top end market<br />

segmentation”. Tyre Sector activities and<br />

the real estate activities of <strong>Pirelli</strong> & C<br />

Real Estate SpA were indicated as being<br />

among these. As regards Cable Sector, it<br />

was announced that <strong>Pirelli</strong> would gradually<br />

divest them even though they are high<br />

cash flow generators with strong market<br />

positionings.<br />

A series of unexpected events during<br />

the months that followed, beginning<br />

with the tragedy of 11 September 2001,<br />

sparked off the biggest economic crisis<br />

since the end of the Second World War to<br />

the present day. The Group’s management<br />

timely started to implement a number of<br />

measures directed at the rationalisation<br />

and re-launch of manufacturing activities,<br />

thus reacting to falling markets through<br />

the recovery of efficiency. This re-organisation,<br />

carried out in all the industrial<br />

Sectors with the fullest commitment on<br />

the part of all the people involved, allowed<br />

<strong>Pirelli</strong> to quickly overcome the crisis and<br />

further strengthen its technological leadership<br />

and competitiveness. It should<br />

be remembered also that, despite adverse<br />

economic conditions, <strong>Pirelli</strong> has always<br />

maintained its high priority commitment<br />

to research and technological innovation,<br />

in order to safeguard the Group’s future<br />

capability to create value.<br />

This re-organisation phase – which<br />

culminated in August 2003 with the<br />

merger operations that simplified the<br />

A Mirs robot and the <strong>Pirelli</strong> Real Estate<br />

head quarter in Milan<br />

Group’s shareholding structure – is now<br />

over. Consequently <strong>Pirelli</strong> intends to<br />

continue to refocus on activities with<br />

greater added value and higher margins.<br />

So it is from this standpoint and fully consistent<br />

with the strategy outlined in 2001<br />

that, in the light of the manifestations of<br />

interest received from major institutional<br />

investors, we feel the time has come to<br />

valorise the activities of Energy Cables<br />

and Systems and Telecom Cables which<br />

<strong>Pirelli</strong> successfully re-launched and<br />

which today perform better than all major<br />

competitors.<br />

After having overcome in the last two<br />

years an unprecedented market crisis, the<br />

Energy and Telecom Cables and Systems<br />

Sector today boasts a position of international<br />

leadership in terms of market<br />

shares, technologies, profitability improvements<br />

and management quality. These<br />

strengths have made it once again of interest<br />

to primary institutional investors.<br />

The Board of Directors has decided<br />

therefore to set in motion a valorisation<br />

project for the development of these<br />

activities, through a procedure which will<br />

allow <strong>Pirelli</strong> to fully evaluate the different<br />

options before it and the different manifestations<br />

of interest, with the intention of<br />

retaining a minority share.<br />

<strong>Pirelli</strong> acknowledges the professionalism<br />

of all the people at all organisational<br />

levels who worked for the Cables and<br />

2

Systems Sector. We respect and are<br />

grateful to these people who improved<br />

its competitiveness and brought about<br />

its present results. The Group has taken<br />

this into account in defining the priorities<br />

of the valorisation project so that, while<br />

aiming to attain an appropriate valuation<br />

of the Cable activities, the Sector’s future<br />

capability to grow further will be safeguarded.<br />

For this project, <strong>Pirelli</strong> will avail itself<br />

of the assistance of primary international<br />

financial institutions. The <strong>Pirelli</strong> management,<br />

who successfully completed the<br />

rationalisation of the Cable Sector and<br />

who do not envisage further reductions in<br />

production capacity nor in the head count,<br />

represent a guarantee of continuity and<br />

further growth to the business. We are<br />

fully convinced that the Cable Sector can<br />

continue, with the new majority shareholders,<br />

along the road of development and<br />

value creation which has characterised the<br />

business during the past few years.<br />

A<br />

s regards the other business sectors,<br />

the <strong>Pirelli</strong> Group’s refocusing strategy<br />

indicated in July 2001 envisages:<br />

• in tyres, a strengthening of activities<br />

through major investments in high growth<br />

areas for products with a higher technological<br />

content, thanks to which the Group<br />

will increase manufacturing capacity<br />

significantly. In fact the Company has<br />

signed a memorandum of understanding<br />

regarding the start of an important jointventure<br />

in China (in Henan province)<br />

for the production of all steel radial<br />

truck tyres, envisaging the installation of<br />

a manufacturing capacity equal to 33%<br />

of all the capacity currently installed by<br />

<strong>Pirelli</strong> world wide in this product area.<br />

In Romania, in addition to the new steel<br />

cord plant in Slatina, a vast manufacturing<br />

base will be built up for high performance<br />

car tyres, to serve the growing demand<br />

from east European markets. As regards<br />

South America, the expansion of the<br />

recent plant in Bahia is envisaged and also<br />

the construction of a new all steel radial<br />

truck tyre facility on the Gravatai site.<br />

Furthermore, three new plants utilising<br />

MIRS manufacturing technology are<br />

currently being installed in Germany, the<br />

United States and the United Kingdom<br />

and will become operational during the<br />

first half of 2005. Overall, we are planning<br />

to make investments of more than<br />

400 million euro during the next three<br />

years, as stated in the Industrial Plan<br />

presented last may.<br />

• in telecommunications, the Group<br />

intends to accelerate the development of<br />

innovative technologies for broadband<br />

A six inches wafer and the cable-laying<br />

ship Giulio Verne<br />

access and second generation photonics,<br />

sectors in which <strong>Pirelli</strong> Labs have already<br />

<strong>file</strong>d a series of important patents which<br />

assure a position of leadership world<br />

wide. A new company, <strong>Pirelli</strong> Broadband<br />

Solutions, has also been established with<br />

the object of marketing products and<br />

applications developed by the Group’s<br />

advanced research activities.<br />

• in real estate, <strong>Pirelli</strong> & C. Real<br />

Estate SpA , which successfully launched<br />

in 2003 a series of common real<br />

estate funds, intended for retail as well as<br />

institutional investors, envisages further<br />

growth. By 30 June 2004, the portfolio<br />

managed by <strong>Pirelli</strong> RE amounted to a<br />

market value of 10 billion euro, with a<br />

corporate pro-quota of 24%. Furthermore,<br />

a Franchising Network is being set up for<br />

the distribution of real estate services and<br />

related financing and insurance products<br />

which, thanks to its diffusion over the<br />

territory, will allow significant synergies<br />

to be realised with corporate activities.<br />

• in line with the Group’s strategic<br />

approach is also the creation of a business<br />

nucleus in the environmental technologies<br />

sector, bringing together the<br />

activities in the field of energy recovery<br />

from waste carried out by <strong>Pirelli</strong> & C.<br />

Ambiente SpA and those in the field of<br />

low environmental impact fuel, such as<br />

GECAM-Il Gasolio Bianco, produced by<br />

Cam Tecnologie SpA.<br />

A<br />

s you all know, our competitive<br />

strength has always been and is<br />

founded on technological and research<br />

capabilities, on quality and on the professional<br />

competencies of our employees.<br />

Sound financial position, ongoing investments<br />

in technological innovation and the<br />

quality of the people are the three certainties<br />

which make shareholders trust in the<br />

future of <strong>Pirelli</strong>.<br />

The resources coming from the sale of<br />

Energy and Telecom Cables and Systems<br />

activities will allow us to support the<br />

development of the Group’s strategic<br />

business areas, which will undoubtedly<br />

produce greater opportunities for professional<br />

growth for all our employees<br />

engaged in creating value. These opportunities<br />

cannot be grasped without strong<br />

determination and the ability to work as a<br />

team to achieve common goals. It is our<br />

wish that with the commitment of all of us<br />

<strong>Pirelli</strong> continues along the road of growth<br />

for many more years to come.<br />

Milan, 12 November 2004<br />

3

PRODUCT<br />

Truck tyre expansion<br />

The Race of the<br />

Giant Tyres<br />

A joint venture in China, sales expansion in South-East Asia, another factory<br />

in South America – and even a crack at the Paris-Dakar: the Truck Tyre BU at work<br />

+50%<br />

overall increase<br />

of all-steel truck<br />

tyres by the end<br />

of 2007<br />

signed between <strong>Pirelli</strong> and<br />

the Aeolus Tyre Co.<br />

Ltd, one of China’s<br />

leading tyre<br />

manufacturers,<br />

for the construction<br />

of<br />

a joint venture<br />

truck<br />

factory in<br />

the province<br />

of<br />

Henan by<br />

June 2005.<br />

The unit<br />

will produce all-steel technology<br />

radial ply giants.<br />

The establishment of <strong>Pirelli</strong> Tyre<br />

in China will enable the Sector to<br />

increase overall production of its<br />

truck covers by up to 33% - (plus<br />

50% if we consider only all-steel<br />

truck tyres). Output of the Henan<br />

plant will mainly be destined for<br />

the Chinese and South-East Asia<br />

markets. As well as the manufacture<br />

of truck, a second phase of the<br />

operation also envisages the manufacture<br />

of car tyres and steel cord<br />

in China.<br />

I<br />

n the<br />

wake of the<br />

positive results achieved by the<br />

Tyre Sector, the Truck Business<br />

Unit continues to grow: and its<br />

policy of investment and expansion<br />

consolidates its strategic role within<br />

the Group. After the re-launch of<br />

the sector, which took place last<br />

April with the presentation of the<br />

new generation Amaranto truck tyre<br />

produced with the innovative SATT<br />

technology, the Truck Tyre Business<br />

Unit is preparing for a new challenge:<br />

an assault on the Chinese and<br />

South-East Asia markets.<br />

A letter of intent has just been<br />

Above left, the FH85 Amaranto tyre and above, the Iveco Eurocargo<br />

with <strong>Pirelli</strong> tyres in Tunisia during a test for the 2005 Paris-Dakar.<br />

4

“<strong>Pirelli</strong> is the leader in radial<br />

ply tyre technology in both the<br />

car and truck fields and intends to<br />

be among the protagonists in this<br />

phase of momentous growth in the<br />

radial ply tyre market in China”,<br />

said Francesco Gori, Managing<br />

Director of <strong>Pirelli</strong> Tyres.<br />

The Sector forecasts that its<br />

investment in China over the next<br />

three years will amount to 150<br />

million euros: the country is of<br />

strategic importance to the operation<br />

and is, in fact, the market<br />

with the greatest growth potential<br />

as far as transport on tyres is concerned.<br />

Radial ply tyre production<br />

in China increased by no less than<br />

28.5% during the first half of 2004<br />

against the same period in 2003,<br />

and exceeded 38 million units,<br />

equal to over 60% of the country’s<br />

overall tyre production.<br />

As well as the new factory,<br />

which will come on stream in<br />

Henan province in 2005, the Truck<br />

Tyre Business Unit will establish<br />

another plant in South America,<br />

in the Gravatai area of Brazil. The<br />

two new factories will join existing<br />

manufacturing facilities in Italy,<br />

Turkey, Brazil and Egypt. With<br />

a volume growth trend of 25%<br />

between 2002 figures and those of<br />

2004 and an expected PBIT increase<br />

for the same period of 670%, the<br />

Truck Tyre Business Unit plans to<br />

invest another 80 million euros<br />

over the next three years, independent<br />

of the resources earmarked for<br />

China. That money will be used to<br />

expand the manufacturing potential<br />

of existing factories and extend the<br />

BU’s range of products.<br />

“After the world launch of the<br />

Amaranto in April 2004, development<br />

of this high performance<br />

line will also proceed at a substantial<br />

pace in 2005”, said Alberto<br />

<strong>Pirelli</strong>, Director of the Truck Tyre<br />

Business Unit. “There will be an<br />

extension of the Amaranto range<br />

for buses and trucks, as well as an<br />

increase in production capacity not<br />

only in Europe, but also at Santo<br />

André, Brazil, and Izmit, Turkey,<br />

where our factories will begin to<br />

make this new range in 2005 and<br />

2006”.<br />

But <strong>Pirelli</strong>’s giant tyre race does<br />

not stop there. Next January, its<br />

PS 22 Pista tyres will be fitted<br />

to two Iveco Eurocargo trucks,<br />

which will compete in the 2005<br />

Paris-Dakar marathon, the most<br />

famous motoring event of its kind<br />

in the world. The rally will be run<br />

over more than 10,000 kilometres<br />

of unmade surfaces and desert,<br />

all the way to the finish on the<br />

celebrated beach in Senegal. The<br />

drivers of the <strong>Pirelli</strong>-shod Eurocargos,<br />

stars of road transport and<br />

A Iveco truck with the <strong>Pirelli</strong> FH85 Amaranto<br />

similar motor sport events, will<br />

be Miki Biasion, double world<br />

rally champion, and Markku Alen,<br />

widely believed to be one of the<br />

most outstanding rally drivers of<br />

all time.<br />

As well as with the Iveco trucks,<br />

<strong>Pirelli</strong> will take on the Paris-Dakar<br />

with a private Spanish team called<br />

Pro-Motor Les Comes, who will<br />

enter a MAN truck. The event<br />

will begin in Barcelona on New<br />

Year’s Day 2005 and will end on<br />

that famous Dakar beach on 16<br />

January. It will be a spectacular<br />

race that will also take truck tyres<br />

to a sporting pedigree that has<br />

always ennobled the <strong>Pirelli</strong> brand<br />

for almost 100 years.<br />

by Stefania Dolci, Milan<br />

5

ETHICS<br />

The fourth Environmental Report<br />

A Responsible<br />

Business<br />

The <strong>Pirelli</strong> Group publishes its fourth Environmental Report, cataloguing initiatives<br />

that improve the climate in which it conducts its business<br />

F<br />

or the fourth year, the <strong>Pirelli</strong><br />

Group has published its Environmental<br />

Report, a demonstration<br />

of its continuous commitment<br />

to the positive management of the environmental<br />

aspects of its business. It is<br />

a commitment that has not diminished,<br />

despite what is a far from rosy situation<br />

for the economy in general and, particularly,<br />

for a number of our specific<br />

areas of production in different<br />

geographical zones.<br />

Apart from a substantial<br />

confirmation of the positive<br />

progress shown by the principal<br />

environmental indices for the<br />

1999-2003 period – i.e., lower<br />

specific consumptions of water and<br />

the increase in the amount of wast<br />

recycled – last year was also the on<br />

in which the new <strong>Pirelli</strong> Policy for th<br />

Health, the Safety, the Environm<br />

and the Social Responsibility was<br />

brought together in one single do<br />

ment and adopted. And that is a fu<br />

demonstration of the Group’s integrated<br />

approach to sustainable development,<br />

which unites and adapts economic, environmental<br />

and social matters within the<br />

organisation.<br />

A fundamental step on the way to a<br />

form of continuity that began in 1995,<br />

when the first environmental and safety<br />

at work policies were adopted. In this<br />

context, the elaboration of The <strong>Pirelli</strong><br />

Group Code of Ethics was also completed<br />

in 14 different languages and was<br />

published with the objective of focusing<br />

more precisely and in a homogeneous<br />

manner on professional conduct and<br />

actions in company life.<br />

In addition, the so-called Organisational<br />

Model has been disseminated<br />

through tailor-made training initiatives<br />

within all Italian Group’s Companies,<br />

employees from which represent over<br />

25% of the Group’s total work force.<br />

Specifically, this<br />

n isational<br />

Model<br />

revises, in<br />

line with the di<br />

the above mentioned Code of Ethics,<br />

processes and instruments of work, specifying<br />

the principles of the code in an<br />

operational context.<br />

A wide-ranging initiative that should<br />

be mentioned concerns the protection<br />

of the health of the Group’s employees:<br />

the activation of an internal policy, which<br />

will make <strong>Pirelli</strong> a “No Smoking Company”,<br />

to the benefit of both smokers<br />

and especially non-smokers.<br />

It is clear that the stages of implementation<br />

of that programme will be gradual,<br />

and will include necessary local adaptations<br />

of the plan in relation to the socioeconomic<br />

and regulatory practices in the<br />

countries in which the Group operates,<br />

in full compliance with the well known<br />

principle “think globally, act locally”.<br />

Another undertaking worthy of<br />

mention is the initiative known as<br />

“Progetto Donna”, which was established<br />

with the objective of offering<br />

women working for the<br />

Group the opportunity of<br />

growing professionally in<br />

all the functions and fields<br />

f activity in which <strong>Pirelli</strong><br />

involved, through specific<br />

itive actions. This measure<br />

ot only a guarantee of equal<br />

rtunity, but also one that<br />

des management with speciruments<br />

of conduct that are<br />

and efficient.<br />

g all of these initiatives into<br />

<strong>Pirelli</strong> believes it is adding<br />

elements to the elaboration,<br />

sharing and attenuation of a business<br />

culture that unites in practical daily<br />

management terms the achievement of<br />

the economic objectives of the Group<br />

with conduct that respects the environment<br />

and is socially responsible<br />

both towards its own employees and<br />

the communities in which it operates<br />

throughout the world.<br />

by Gioacchino Verga, Milan<br />

6

HIGHLIGHT<br />

Genoa University confers a degree to Marco Tronchetti Provera<br />

The Innovation<br />

Engineer<br />

O<br />

n 29 November Marco Tronchetti<br />

Provera received from<br />

the University of Genoa a<br />

Honorary Degree in Electronics Engineering.<br />

The Chairman gave a “lectio<br />

magistralis” of which we reproduce<br />

below an ample section.<br />

If you ask historians and economists,<br />

they will spread out before you an<br />

ample offering of explanations on the<br />

structural weaknesses of the country,<br />

on the late take-off of diffuse industrialization,<br />

on certain wrong political<br />

choices, on real or presumed cultural<br />

backwardness.<br />

As far as I’m concerned, I believe<br />

there is also another far from negligible<br />

factor which made the difference<br />

between us and the other industrialized<br />

countries: it’s that far weaker community<br />

spirit which in Italy makes it much<br />

more difficult to work in team, to join<br />

forces to reach shared medium and<br />

long term objectives. Always, except in<br />

an emergency.<br />

But it’s hard to perceive innovation<br />

as a community emergency. So, we’ve<br />

never been at a loss for talents. What we<br />

lack is the other pillars of a system really<br />

oriented towards valorizing them: organization,<br />

method, managerial capability.<br />

In short, everything which makes a team<br />

strong and allows it to play the game on<br />

an even footing. But if there’s no team,<br />

it’s unthinkable to measure oneself against<br />

ever more complex technologies and<br />

with increasingly riskier investments.<br />

Of course, nobody puts in doubt that<br />

all progress in the general context of the<br />

country can give companies a hand. But<br />

however much innovation may – and<br />

should – be a mutual objective of the<br />

entire community, there is no substitute<br />

for the entrepreneur in this duty and in<br />

this responsibility. As a matter of fact, to<br />

make the company grow, to push it into<br />

coming up with something new every<br />

day, to try to keep it constantly one step<br />

ahead of the others is an incredible inner<br />

driving force for the entrepreneur; if<br />

crowned with success, it offers enormous<br />

satisfactions.<br />

Needless to say self-confidence is not<br />

enough. We need to be able to count<br />

on people with whom to talk about the<br />

future, weigh up ideas, define projects<br />

and programmes. Today you have<br />

conferred on me the title of engineer,<br />

which I certainly do not deserve for<br />

technical abilities. I confess, however,<br />

that I don’t feel it foreign to me provided<br />

I can refer it to the building up of a<br />

community of enterprise in which the<br />

people – people of quality – have all the<br />

room they deserve to put themselves to<br />

the test and demonstrate that they know<br />

how to give body to ideas. To their ideas,<br />

to their technical solutions.<br />

Mine is a different task: to act as<br />

a bridge between the creativity and<br />

competitiveness of the company,<br />

between the imagination of a possibile<br />

future and its realization, according to<br />

a long term value creation logic. This<br />

is the reason why in both <strong>Pirelli</strong> and<br />

Telecom Italia the people who attend to<br />

research and technological innovation<br />

head up directly to me and, with me,<br />

meet and, report on progress at least<br />

once a month. With a dual advantage:<br />

knowing exactly where we are going,<br />

I can better gauge and direct the march<br />

of the company; and that by being<br />

able to interact directly with me, the<br />

researchers and technologists have in<br />

me a guarantor of their work, above<br />

all when the wager seems particularly<br />

high. This is how <strong>Pirelli</strong> returned to<br />

innovation levels of absolute world<br />

excellence; and we are proceeding in<br />

the same way in Telecom Italia.<br />

Astride the end of the ‘80s and the<br />

beginning of the ‘90s, <strong>Pirelli</strong> found<br />

itself in a truly critical situation, the most<br />

critical in almost 120 years of history<br />

during which the company had grown<br />

accustomed to playing leader in and<br />

outside Italy.<br />

With the accounts very much in the<br />

red, net debt equal to almost one and<br />

half times equity and an internal climate<br />

of lack of confidence and pessimism, we<br />

had to save what we could by restoring<br />

competitiveness. What did we build the<br />

new on? On a radical choice of terrain:<br />

from that moment on we would place all<br />

7

our bets on technological innovation and<br />

focus on the higher value added products,<br />

on quality, on the speed of market<br />

service. Our objective was to turn <strong>Pirelli</strong><br />

into a knowledge company, a company<br />

which evolves and creates value through<br />

the development of new knowledge and<br />

new technologies. This was, and still is,<br />

the direction of our march.<br />

MIRS and its architect<br />

The first thing we had to do was re-launch<br />

tyres. We had the technical competencies<br />

and the right person: Renato Caretta is a<br />

name which means little or nothing to<br />

people not in the field; in world industry<br />

however he is a celebrity.<br />

When he joined <strong>Pirelli</strong> in 1953 as a<br />

mechanical draughtsman, Caretta had<br />

no academic titles, but his professional<br />

experience is a demonstration of<br />

where intelligence, passion and the<br />

determination to overcome the obstacles<br />

of life, including that of starting at the<br />

lowest rung in the ladder, can take you.<br />

In 1995, at the threshold of his sixtieth<br />

birthday Caretta, at that time head of the<br />

tyre R & D centre in Bicocca, invented<br />

the P6000, our most successful product<br />

by far with its 100 million pieces sold and<br />

still in production; an exceptional feat for<br />

a tyre at the top end of the range.<br />

But this too wasn’t enough. The<br />

break through was achieved in the<br />

Spring of 1997. It was MIRS, the<br />

Modular Integrated Robotized System,<br />

a completely robotized, modular,<br />

extremely flexible mini-factory, suitable<br />

for the manufacture of advanced<br />

products which cannot be or would<br />

not be economical to produce with<br />

traditional technologies; “run flat” tyres<br />

for example. The standard profitability<br />

values of the sector are overturned thanks<br />

to a 25% lower total product cost, a 100%<br />

improvement in quality, an 80% increase<br />

in blue-collar productivity, a reduction in<br />

tyre/day capital expenditure of roughly<br />

50%, energy savings of 30%.<br />

Compounds and molecules<br />

Having got perfect control of<br />

production, we had to start thinking<br />

about perfect control of the materials<br />

feeding the system. It meant stepping<br />

in on the compound production process.<br />

Working in team with Enrico Albizzati<br />

– the head of the Materials Innovation<br />

division of <strong>Pirelli</strong> Labs –, Caretta<br />

thought up a completely new process<br />

– the CCM, Continuous Mixing System<br />

–, which, using a two-screw extruder<br />

and a series of component dosing and<br />

feeding systems, makes it possible to<br />

produce compounds continuously, at a<br />

constant temperature and in the quantities<br />

needed to feed the MIRS modules.<br />

So two years ago we built in Bicocca<br />

the only plant in the world capable of<br />

processing elastomers (in other words<br />

any substance with elastic properties<br />

similar to those of rubber) as if they were<br />

plastomers (that is to say materials with<br />

plastic characteristics). Here too with<br />

very important benefits compared to<br />

traditional equipment.<br />

For his part, Enrico Albizzati is<br />

a demonstration of what the Italian<br />

chemical industry could have been, had it<br />

believed and invested in its talents. A man<br />

of research, who acquired experience<br />

in Giulio Natta’s group in Montedison,<br />

arrived in <strong>Pirelli</strong> just under ten years ago<br />

to attend to new polymeric materials,<br />

superconductivity, clean energy from<br />

photovoltaic cells and fuel cells. his work<br />

and that of his team of sixty people cuts<br />

across our industrial sectors.<br />

Our safety behind the steering wheel,<br />

for example, depends on him to an<br />

important extent since he works on<br />

perfecting, thanks to nanotechnologies,<br />

the chemical characteristics of the<br />

so-called “intelligent” tyres; tyres that<br />

are not only suitable for particular<br />

road conditions but are also capable of<br />

combining with special sensors which<br />

communicate pressure, temperature and,<br />

in a not too distant future, also tyre set to<br />

the vehicle and the driver.<br />

Communicating with photons<br />

If Albizzati is a relatively recent<br />

acquisition, this is not so for Giorgio<br />

Grasso, who has been with <strong>Pirelli</strong> 25<br />

years and is currently responsible for<br />

the Optical Innovation division of our<br />

laboratories. Grasso too has to do with<br />

our everyday lives. He, however, doesn’t<br />

work on macromolecules; he works<br />

on light or, better, on its elementary<br />

particles, photons.<br />

At the beginning of the ‘90s, Grasso<br />

and some of his colleagues perfected<br />

two ideas without which the Internet<br />

revolution wouldn’t have snowballed<br />

into a mass phenomenon so quickly.<br />

First and foremost it was the invention<br />

which made it possible to construct the<br />

optical amplifier, the device which, along<br />

the length of long-haul terrestrial and<br />

submarine telecommunication systems,<br />

was going to replace the more costly and<br />

complex traditional signal regenerators.<br />

Grasso and his team are also the<br />

creators of the DWDM (Dense<br />

Wavelength Division Multiplexing)<br />

system, the technique which allows a<br />

great quantity of data to be transmitted<br />

along an optical fiber by exploiting the<br />

different wave lengths. The keystone for<br />

the take-off of broadband.<br />

A recent arrival from the Optical<br />

Innovation laboratories is the modular<br />

technological solution - “Smart Gate”<br />

used by Telecom Italia for “Alice Mia”<br />

– which allows residential users to<br />

access broadband services from all the<br />

telephones and PCs in their home. It’s<br />

the first nucleus of a true and proper<br />

home networking system.<br />

At the moment Grasso is developing<br />

optical chips that integrate on a suitably<br />

modified silica surface those functions<br />

now carried out by individual and far<br />

more expensive items of equipment.<br />

Patents with method<br />

I hope that these examples of works<br />

accomplished or in progress and their<br />

authors have highlighted the way in<br />

which we face the innovation challenge:<br />

by developing technological excellence<br />

“in house” as much as possible.<br />

You will hear some people say that<br />

<strong>Pirelli</strong> has given up and taken refuge<br />

in the safer and more comfortable<br />

harbour of the telecommunications<br />

market. Not only is this not true, but<br />

the stimulus that we actually get from<br />

8

PARTNERSHIP<br />

being also in the telecommunications<br />

market is to strengthen, not to weaken,<br />

our commitment to research in the most<br />

advanced frontiers.<br />

And it is from this that the opportunity<br />

to gain a strong and long-lasting<br />

competitive advantage and a greater<br />

value creation ability derives. One should<br />

also say, however, that this value has to be<br />

protected. The management of industrial<br />

property rights is an indispensable<br />

complement of the management of<br />

research, for the protection of the<br />

business and for the protection of the<br />

shareholders.<br />

It is certainly no easy thing to put a<br />

structure in place to govern patenting:<br />

one needs specific competencies,<br />

professionalities, the ability to grasp the<br />

very essence of an innovation, something<br />

that often not even the researchers and<br />

the designers themselves can do.<br />

In <strong>Pirelli</strong> and in Telecom Italia we<br />

have entrusted the task of organizing this<br />

structure to another of our talents, Pier<br />

Giovanni Giannesi, a true and proper<br />

“patent advocate”. He is the author of<br />

a valuation method considered to be<br />

among the absolutely most advanced<br />

in the world and which allows us to<br />

establish how likely an invention is to be<br />

of interest to others, the likelihood of it<br />

being imitated and, once patented, of our<br />

winning an infringement suit.<br />

At the moment <strong>Pirelli</strong> ranks first in<br />

Italy in the number of national patents<br />

<strong>file</strong>d. During the last ten years alone<br />

these were over 7.100, 5.000 of which<br />

are “still alive”. An enormous wealth.<br />

The industrial innovation effort we are<br />

making is leading us with ever greater<br />

frequency to the frontiers of chemistry,<br />

physics, the science of communications,<br />

engineering.<br />

We need the universities and their<br />

talents, as much in terms of research as<br />

in terms of new skilled human resources.<br />

We need to establish relations of cooperation<br />

and partnership. There isn’t a<br />

country in the world that belies this selfevident<br />

truth: universities and companies<br />

are the unsubstitutable linch-pin around<br />

which any winning team revolves.<br />

<strong>Pirelli</strong>-Continental joint venture<br />

Striking<br />

a Cord<br />

in Rumania<br />

<strong>Pirelli</strong> and Continental finalise a joint venture for the production<br />

of steel cord in Slatina, Rumania<br />

T<br />

he 80% <strong>Pirelli</strong> 20% Continental<br />

joint venture will<br />

invest up to 40 million euro<br />

over the next three years in the production<br />

of 30,000 tons of steel cord a year.<br />

The factory will be located in Slatina,<br />

Rumania opposite the <strong>Pirelli</strong> facility<br />

making power and telecom cables and<br />

next to the recently announced new<br />

<strong>Pirelli</strong> tyre plant.<br />

Continental has a<br />

tyre-making operation<br />

in Timisoara,<br />

which produces<br />

about 25,000 units<br />

a day. The unit will<br />

begin deliveries to<br />

customers in mid-<br />

2005, less than<br />

nine months after<br />

the acquisition of the land on which it<br />

is to be built.<br />

The investment is the first by the<br />

<strong>Pirelli</strong> Tyre Sector in south-eastern<br />

Europe, a region in which steel cord<br />

demand is now growing fast and is<br />

almost double that of current local<br />

production.<br />

Cord Rumania is the latest start-up<br />

initiative by <strong>Pirelli</strong> Steel Cord BU,<br />

as well as the consolidation of a long<br />

standing business partnership with<br />

Continental, one of the fastest growing<br />

players in the tyre market today. <strong>Pirelli</strong><br />

began making steel reinforcement<br />

material for tyres in Figline Valdarno,<br />

Florence, in 1962. Ten years later, a<br />

joint venture was set up at Merzig in<br />

Germany, together with Dunlop and<br />

Continental, now a 50% <strong>Pirelli</strong> and<br />

50% Conti consortium.<br />

Today, the business unit is made up<br />

of four manufacturing units, with the<br />

addition of the two cornerstones, one<br />

in Sumarè, Brazil,<br />

in 1983 and the<br />

other in Izmit,<br />

Turkey, in 1987.<br />

About 50% of the<br />

Sector’s total steel<br />

cord output is now<br />

sourced from these<br />

last two plants.<br />

<strong>Pirelli</strong> Steel<br />

Cord is a business<br />

unit with a total consolidated revenue<br />

expected to total just over 220 million<br />

euros in 2004 - 10% up on the previous<br />

year - has 1,400 employees and<br />

accounts for a 7.6% share of the worldwide<br />

steel cord market: that makes it<br />

the third largest free market player in<br />

the commodity.<br />

The above average return on investment<br />

by the business unit in recent<br />

years has been built on a basis of a consistent<br />

strategy of product innovation,<br />

strong customer focus and cost management.<br />

In an industry with a moderate<br />

but relatively consistent growth rate<br />

9

of about 5% a<br />

year, the logic<br />

of self-financed<br />

growth and<br />

selective investment<br />

is the driver<br />

with which<br />

to sustain cash<br />

generation and<br />

profitability<br />

in the years to<br />

come.<br />

The new initiative is part of a fiveyear<br />

commercial agreement between<br />

<strong>Pirelli</strong> BU Steel Cord and Continental<br />

that not only covers supplies from the<br />

new joint venture, but also from the<br />

existing undertaking in Germany, as<br />

well as supplies to North and Latin<br />

America.<br />

The consumption of steel cord<br />

in south-east Europe is growing at<br />

an annual two digit rate and will be<br />

supported in the future by investment<br />

from a number of major tyre manufacturers<br />

: Michelin has<br />

also recently announced<br />

a solid investment<br />

plan to expand current<br />

operations in the city of<br />

Zalau, Rumania.<br />

Lastly, the technically<br />

qualified and highly cost<br />

competitive business<br />

environment is making<br />

it possible to accelerate<br />

investment payback and<br />

to self-finance a large<br />

portion of it from as<br />

early as the second year<br />

of operations.<br />

Among the most<br />

important factors<br />

that have to be dealt<br />

with when facing the challenge of<br />

establishing a new factory are time<br />

and financial sustainability of strong<br />

growth. The Steel Cord BU believes<br />

the translation of these considerations<br />

into results passes through the application<br />

of some basic principles, which<br />

are:<br />

• modular growth: the final configuration<br />

of the factory is not the only<br />

important point; it is fundamental to<br />

consider how to get there while making<br />

sure investments are timed as closely<br />

as possible with cash returns;<br />

• complexity minimisation: limited<br />

start-up product range and process<br />

alternatives. Limited number of transformation<br />

steps, at least in the early<br />

phases;<br />

• strong project teamwork and<br />

priority management: product and<br />

manufacturing, purchasing and engineering,<br />

all resources that will become<br />

involved in the problem solving<br />

activity. Enthusiasm and the will to<br />

achieve are key;<br />

• kernel factory team development:<br />

quality and skills of the resources in<br />

the field not only make the difference<br />

to the start up phase, they also condition<br />

the future development of the<br />

company and its ability to withstand<br />

the challenges<br />

of large, highly<br />

sophisticated<br />

industrial<br />

customers.<br />

A careful<br />

study of the<br />

A computer rendering of how the plant modular steps<br />

will look once completed. as well as leverage<br />

on conso-<br />

Below, two workers during the apprenticeship phase.<br />

lidated competences<br />

has allowed the compression of<br />

a start up time from the traditional 18<br />

to about nine months. The long- established<br />

presence of <strong>Pirelli</strong> Cables in<br />

Rumania has made a significant difference<br />

to the steel cord project, not<br />

only in terms of logistical support and<br />

knowledge of the local environment,<br />

but it has also organised the selection<br />

and hiring process. Training the<br />

labour force means taking advantage<br />

of an extremely well tuned training<br />

programme, designed to sustain the<br />

growth of the Izmit steel cord factory<br />

in earlier years.<br />

Apart from activities<br />

connected to the continuous<br />

monitoring of project<br />

development versus planned<br />

milestones, the single<br />

most important factor that<br />

minimises the risk of delay<br />

is the quality of resources,<br />

their motivation and specific<br />

technical skills.<br />

The most experienced<br />

resources in the Steel Cord<br />

BU team have enjoyed the<br />

opportunity of working on<br />

more than one green field<br />

initiative in recent years:<br />

they include Turkey, Brazil<br />

and several turnkey<br />

projects in China and Bielorussia.<br />

Blending past experience with new<br />

resources and enthusiasm will stand<br />

a good chance of proving that the<br />

promise can be delivered: certainly,<br />

nobody in the BU will be able to complain<br />

about having a boring job over<br />

the next few months!<br />

by Italo Natali, Slatina, Rumania<br />

10

EVENTS<br />

Debut of the 26-inch Scorpion Asimmetrico<br />

Legends<br />

of Las Vegas<br />

<strong>Pirelli</strong> chose the internationally renowned SEMA Show<br />

in Las Vegas to present the press with its new UHP<br />

product of 26’’ diameter<br />

Roberto Boccafogli reports from Las<br />

Vegas, USA<br />

T<br />

he car world – and to some<br />

extent motorcycles – were centre<br />

stage once more at the 2004<br />

SEMA Show in Las Vegas. “The SEMA<br />

Show does not exhibit what is ‘useful’ to<br />

the motor industry”, explained Peter Mac-<br />

Gillivray, vice-president of SEMA, “but<br />

everything that automobile technology<br />

can or could desire”. So the SEMA Show<br />

is more than just a motoring salon, more<br />

than a rich, imaginative, vast exposition<br />

of a product, varied and diversified like<br />

the car itself and will ever more be so.<br />

“Today’s consumers increasingly base<br />

their choice of car on a vehicle able to<br />

accept the most advanced new developments<br />

in terms of performance, spare<br />

parts, electronics, wheels, tyres, suspension”,<br />

added the vice-president of the<br />

organising committee.<br />

Over 100,000 staff in attendance.<br />

Almost 2,000 exhibitors scattered along<br />

the invisible line<br />

that links the major car manufacturers<br />

with the decorator of theme<br />

clothing, the producer of tail lights of any<br />

shape, size or colour. One hundred and ten<br />

thousand square metres of exhibits enclosed<br />

in stands that increase in number year<br />

after year, and which were not enough to<br />

accommodate everyone at the 2004 show.<br />

That was confirmed by the dozens of cars<br />

on display at the roadside under a Las<br />

Vegas sky, fortunately without a suggestion<br />

of rain.<br />

<strong>Pirelli</strong> also played its part in this cross<br />

between an exhibition and show business.<br />

And, given that the “Long P” logo evokes<br />

a legend that goes beyond the actual United<br />

States market, with its roots deeply<br />

embedded in an idea of all-Italian performance<br />

and competitiveness, balanced<br />

between a heroic past and a present of<br />

great Ferrari and Maserati success, that is<br />

why interest has been so extremely high.<br />

On the <strong>Pirelli</strong> stand, next to the increasingly<br />

extensive Planet Zero range, with<br />

its P Zero and Scorpion Zero for cars and<br />

SUV-light trucks respectively, but always<br />

in the spirit of Ultra-High Performance,<br />

Las Vegas marked the world debut of the<br />

new, 26-inch diameter Scorpion Zero. A<br />

true UHP, the Scorpion Zero Asimmetrico,<br />

as confirmed by the world speed record for<br />

pick-ups set by a Dodge RAM SRT10 on<br />

the tyre last winter. A tyre which, on those<br />

enormous 26-inch rims, confirms, even<br />

magnifies its performance capabilities<br />

and resistance to stress which, on the cars<br />

that fit wheels of those dimensions, can be<br />

nothing other than extremely high.<br />

The new 26-inch tyre exists to fit real<br />

rims and real vehicles, withstanding<br />

the stress imposed today<br />

on large sizes in performance<br />

and the weight of vehicles<br />

in movement. Confirmation<br />

of that will come in 2005,<br />

when the 26-inch Scorpion<br />

Asimmetrico becomes available<br />

in Europe, the first tyre<br />

of such dimensions to be sold<br />

on a regular basis for the SUVs<br />

of the old Continent.<br />

But the SEMA show also thrives<br />

on the fascination of associations: <strong>Pirelli</strong><br />

at the side of Ferrari and Maserati, for<br />

instance, has maximum appeal in the<br />

States, which will, in fact, see that synergy<br />

also reflected on the race track. But<br />

another association that achieved great<br />

success in the exhibition halls of SEMA<br />

was the one between <strong>Pirelli</strong> and Ford, who<br />

are celebrating 40 years of the legendary<br />

Mustang. Almost half a century old, but<br />

no way does the car look it: living proof<br />

that the stupendous American car has lived<br />

unscathed, in fact has been reinvigorated<br />

in terms of fascination, through dozens<br />

of re-stylings and modernisations. <strong>Pirelli</strong><br />

and Ford invited some absolutely exceptional<br />

guests to the event in honour of the<br />

Mustang: the Beach Boys, a true icon of<br />

West Coast music. Time passes for all of<br />

us: even for this legendary group, which<br />

has helped almost two generations to sing<br />

and dream. But their fascination does not<br />

diminish, quite the reverse. Ford knows<br />

that and so does <strong>Pirelli</strong>. It is the future, just<br />

around the corner.<br />

11

THE CAL<br />

“O Espirito do Brazil”<br />

The 2005<br />

<strong>Pirelli</strong> Calendar<br />

“The <strong>Pirelli</strong> Cal is the world’s<br />

most prestigious calendar.<br />

It is pure art”<br />

Patrick Demarchelier, photographer<br />

“Every image is a graphic<br />

portrait, classical but at the<br />

same time modern,<br />

exalting the beauty<br />

of the female body”<br />

Douglas Lloyd, art director<br />

12

Opposite page: Cover (Adriana Lima); from left to right: January (Julia Stegner), February (Michelle Buswell), March (Erin Wasson).<br />

Above: April (Adriana Lima), May (Marija Vujovic), June (Fillipa Hamilton). Below: July (Julia Stegner), August (Liliane Ferrarezi),<br />

September (Valentina). Next page: <strong>Oct</strong>ober (Diana Dondoe), November (Isabeli Fontana), December (Naomi Campbell).<br />

T<br />

he setting is Rio de<br />

Janeiro, Ipanema beach.<br />

The subjects are 12 of<br />

the most beautiful models of the<br />

moment. The result is the <strong>Pirelli</strong><br />

2005 Calendar, the creator Patrick<br />

Demarchelier, a world-renowned<br />

photographer. Rio de Janeiro was<br />

chosen as the metropolis that, as<br />

Naomi Campbell says (appearing in<br />

The Cal for the third time) “reflects<br />

the Brazilian people’s energetic and<br />

positive spirit”.<br />

In the calendar, Demarchelier has<br />

grasped and assimilated the spirit<br />

of Brazil (‘O espirito do Brazil’ is<br />

in fact the title chosen for the backstage<br />

film) and of Rio de Janeiro, a<br />

city dominated by strong contrasts.<br />

His black and white photographs,<br />

investigate the most mysterious<br />

aspects of the models of the “<strong>Pirelli</strong><br />

Cal 2005” seeking out the invisible<br />

source of their allure. Alongside<br />

Naomi Campbell (who made her<br />

debut at just 16 years of age in the<br />

1987 Calendar by Terence Donovan,<br />

returning in 1995 for the one<br />

by Richard Avedon) are Fillipa<br />

Hamilton and Isabeli Fontana (photographed<br />

earlier by Bruce Weber<br />

for the 2003 edition), Adriana<br />

Lima, Diana Dondoe, Erin Wasson,<br />

Euguenia Vodianova, Julia Stegner,<br />

Liliane Ferrarezi, Marija Vujovic,<br />

Michelle Buswell, “Valentina” and<br />

Valeria Bohm. This is truly an international<br />

event with three Brazilians,<br />

two Americans, one Russian, one<br />

Montenegrin, one Romanian, one<br />

Swede and one German.<br />

Demarchelier’s masterly use of<br />

13

light, strong contrasts and striking<br />

portraits are quite the opposite of<br />

Nick Knight’s imaginative and<br />

highly coloured calendar of last year.<br />

The <strong>Pirelli</strong> 2005 Calendar therefore<br />

marks a return to the traditional<br />

technique of black and white photography<br />

that also characterised the<br />

calendars by Arthur Elgort (1990),<br />

Peter Lindberg (1996), Richard<br />

Avedon (1997), Bruce Weber (1998)<br />

and Herb Ritts (1999).<br />

The French photographer uses<br />

a personal technique that ensures<br />

the immediacy of the result, taking<br />

direct positive shots on Polaroid<br />

film. His photography stands out<br />

for its capacity to apply the most<br />

sophisticated studio techniques to<br />

spectacular, luminous locations,<br />

creating images that are fluid and<br />

at the same time immersed in nature.<br />

Demarchelier has chosen two<br />

particular locations to immortalise<br />

his muses and to re-create in the<br />

open, the environment of the photographic<br />

studio: a dune on the beach<br />

and the luxuriant garden of a colonial<br />

house. The elegance and fresh<br />

spontaneity of the young models<br />

give the pictures a sense of expression<br />

and natural beauty, in line with<br />

the exuberance of Brazil.<br />

The result is a truly unique version<br />

of the <strong>Pirelli</strong> Calendar, made<br />

up for the first time of 22 pages.<br />

The Calendar closes with a lively<br />

collage of shots “stolen” by the<br />

great photographer in a famous Rio<br />

discotheque, during the party that<br />

concluded the shooting.<br />

Always attentive to detail,<br />

Demarchelier chose the model’s<br />

clothes with particular care. These,<br />

he comments, “confer elegance and<br />

an aura of mystery and emotion on<br />

women”. Intriguing and sensual, the<br />

garments were specially designed<br />

to underline contrasts and geometrical<br />

lines. Standing out amongst<br />

the clothes worn by the models<br />

is the <strong>Pirelli</strong> Pzero line, to which<br />

Demarchelier dedicates his August<br />

portrait.<br />

Patrick Demarchelier<br />

Patrick Demarchelier was born in<br />

1943 in a suburb of Paris, France. At<br />

17 years old he was given a camera,<br />

and discovered his true calling. To pay<br />

for the cost of film and developing his<br />

photos, he worked for two years in the<br />

basement of a photo shop in Le Havre,<br />

learning everything there was to know<br />

about developing techniques and photographic<br />

paper. Later he moved to Paris,<br />

where he found work as an assistant<br />

in the black and white laboratory of<br />

Publicis. The first tough impact with<br />

professional reality came a few years<br />

later, when he presented his photos to<br />

the Art Director of Elle who rejected<br />

his work out of hand. But he persevered,<br />

and three years later it was the magazine<br />

Elle that commissioned a photograph<br />

from him for the cover which, out of<br />

negligence, was published without his<br />

name. He opened his first studio 1975<br />

in New York and from 1992 to May<br />

2004 was the leading photographer<br />

for Harper’s Bazaar. Celebrated in<br />

the pages of the most important international<br />

magazines, Demarchelier is<br />

undoubtedly one of the master fashion<br />

photographers of our era. His work has<br />

been published in the American, British,<br />

French and Italian editions of Vogue, in<br />

Mademoiselle and Glamour and other<br />

magazines around the world including<br />

Premier, Life and Rolling Stone.<br />

He has been responsible for major<br />

international advertising campaigns<br />

for brands such as Chanel, Calvin<br />

Klein, Revlon and Lancôme, The Gap,<br />

Gianni Versace, Giorgio Armani, Elizabeth<br />

Arden and many others, alongside<br />

many television campaigns. His talent<br />

can also be recognised on the album<br />

covers of records by stars such as Janet<br />

Jackson, Billy Joel, Madonna and Quincy<br />

Jones.<br />

In 1989 Princess Diana asked him<br />

to portray her, becoming her official<br />

photographer and the first non-Briton<br />

to photograph the Royal Family.<br />

14

THE CAL<br />

The 2005 Cal launch in Brazil<br />

Girls from Ipanema<br />

Photographed on the boundless beaches of Ipanema and Copacabana, the <strong>Pirelli</strong> Calendar<br />

turns 40 with grace, beauty and vitality in Rio de Janeiro<br />

Salvatore Ricco reports from Rio de<br />

Janeiro, Brazil<br />

I<br />

t<br />

was just a few minutes to<br />

midnight on 18 November when<br />

fireworks erupted and lit the<br />

Brazilian night sky as if it were day.<br />

A magnificent display to mark the end<br />

of a gala dinner in Rio<br />

de Janeiro, preceded by<br />

the world premiere of<br />

the 2005 <strong>Pirelli</strong> Calendar.<br />

The pyrotechnic<br />

magic was a symbolic<br />

salute from the carioca<br />

city to “The Cal”, never<br />

more closely linked to<br />

its urban host than with<br />

its new edition.<br />

Rio, the megalopolis<br />

that never sleeps, a city<br />

that “reflects the energetic<br />

and positive spirit<br />

of its people” – words<br />

and music by Naomi<br />

Campbell, star of the<br />

month of December<br />

and, after the 1987 and 1995 editions,<br />

appearing in her third <strong>Pirelli</strong> Calendar<br />

– is practically everywhere in the 2005<br />

edition: first of all in the collection of<br />

22 black and white shots by the French<br />

photographer Patrick Demarchelier<br />

and particularly in the cover, which<br />

portrays Brazil’s own, splendid Adriana<br />

Lima in a sash of black lace on the<br />

beach at Ipanema, with the celebrated<br />

Corcovado at her back. Brazil is also<br />

the protagonist of the emotional backstage<br />

film of the creation of the 2005<br />

Cal’s pictures, entitled symbolically<br />

“O espirito do Brazil”, as well as at<br />

of the launch ceremony in the name<br />

of beauty and of a country with which<br />

<strong>Pirelli</strong> has enjoyed a happy marriage<br />

for over 75 years. “<strong>Pirelli</strong> - an Italian<br />

journalist and long time resident in<br />

Rio told us - enjoys a great reputation<br />

in Brazil. Everyone knows and<br />

thinks highly of the company here. It<br />

Patrick Demarchelier with some of the Calendar’s models at<br />

the press conference in Rio.<br />

is so well integrated with the social<br />

fabric of the country that much of the<br />

population thinks <strong>Pirelli</strong> is a Brazilianbased<br />

firm”.<br />

There is also a lot of the “Espirito<br />

do Brazil” in the stars of “The Cal”,<br />

in which Demarchelier devotes a further<br />

nine portraits for the first time, in<br />

addition to the cover and traditional<br />

12 monthly photographs. Four of the<br />

models – among them Adriana Lima<br />

and Valeria Bohm (“Garota TIM<br />

Brazil 2005”) - are Brazilian, and<br />

appear together with two American<br />

girls, two Russians, a Montenegrin, a<br />

Romanian, a Swede and a German. A<br />

stupendous gathering of international<br />

beauty, photographed by the masterly<br />

Demarchelier with his own technique<br />

that guarantees pictures of tremendous<br />

immediacy by shooting directly in<br />

positive on a Polaroid plate. The setting<br />

is extremely effective, with the elegant<br />

beauty of the models’<br />

bodies in direct contact<br />

with nature, among the<br />

dunes and on the beach<br />

of Ipanema, mythical<br />

object of the famous<br />

Joao and Astrid Gilberto<br />

song, and the luxuriant<br />

garden<br />

of a typical<br />

colonial-style<br />

house. The<br />

elegance and<br />

fresh spontaneity<br />

of the young<br />

models give the<br />

photographs a<br />

natural expressiveness<br />

completely<br />

i n<br />

character with the<br />

exuberant land of jazz samba.<br />

In fact, it was the Brazilians led by<br />

Adriana Lima and dressed by <strong>Pirelli</strong><br />

P Zero, who were the hostesses of the<br />

launch ceremony, lending their added<br />

touch of elegance to an entire Thursday<br />

18 November. After a number of days<br />

of rain, Rio awakened on the 18 th to<br />

a threatening sky, but it could not ruin<br />

the festive atmosphere created by the<br />

late spring temperature, the contagious<br />

energy of the city and the anticipation<br />

of the launch itself. An atmosphere<br />

packed with glamour, folklore, fun<br />

15

AWARDS<br />

and imagination: like the street sellers<br />

of souvenir Copacabana plaques, who<br />

extended their sales offer to tourists<br />

with a celebratory targa bearing the red<br />

<strong>Pirelli</strong> logo on a yellow background.<br />

More than 200 journalists travelled<br />

to Rio from all corners of the earth<br />

to attend the press conference for the<br />

new edition of the legendary Calendar<br />

at the Copacabana Palace, one<br />

of the most exclusive hotels on the<br />

celebrated carioca beach. The opening<br />

gambit could be nothing other than an<br />

electrifying, 13-minute backstage film<br />

portraying the beauty of the models,<br />

the art of Patrick Demarchelier and<br />

the vibrant life of Rio de Janeiro. Then<br />

came the interactive part, during which<br />

a self-effacing Demarchelier answered<br />

journalists’ questions with few well<br />

chosen, effective words. “The <strong>Pirelli</strong><br />

Cal” - he said in answer to one writer<br />

- “is the most prestigious calendar in<br />

the world: it is pure art”.<br />

After a quick brunch, the press went<br />

off to write their stories and then changed<br />

for the “gran finale”: the gala dinner<br />

at the Copacabana fort, from which the<br />

Brazilian army defended the shores of<br />

Copacabana and Ipanema - the two beaches<br />

symbolic of the 2005 Cal - from<br />

assault by foreign armadas.<br />

Over 500 people representing the<br />

leaders of business, finance and international<br />

journalism took part in the event,<br />

which was presented by the fascinating<br />

(and extremely tall….) Brazilian model<br />

Anna Hickmann. The highlight of the<br />

evening was the backstage film, which<br />

immersed all of those attending in the<br />

creation of “The Cal” during a hot and<br />

lively Rio in May.<br />

The dinner was followed by some<br />

Brazilian rhythm and then by the<br />

closing fireworks display. After the<br />

tribute to Rio, the <strong>Pirelli</strong> Calendar<br />

bid its guests goodbye until next time.<br />

But the location, names of the models<br />

and photographer of the 2006 edition<br />

are still top secret: the only certainty<br />

is that “The Cal” will continue to be<br />

the cult object it has been for the last<br />

40 years.<br />

Italy, Australia and Canada award <strong>Pirelli</strong><br />

Prizes<br />

all over<br />

the world<br />

<strong>Pirelli</strong> receives recognitions for its ability<br />

of creating value through innovation with<br />

the “Best Innovator” award and for its presence and industrial<br />

achievements with the “Italy-Canada Investaward”<br />

and the “Azienda Italia Award”<br />

W<br />

ith an industrial and<br />

commercial presence in<br />

many countries of the<br />

five continents, <strong>Pirelli</strong><br />

is a pure multinational<br />

company: at the same<br />

time, it is firmly rooted<br />

in any national market<br />

it operates, with very<br />

strong ties with local<br />

communities. This role<br />

has been for more than<br />

a century a core element<br />

of <strong>Pirelli</strong> culture,<br />

along with the ability<br />

of creating value and<br />

excellence through<br />

innovation. These two<br />

important aspects of<br />

<strong>Pirelli</strong>’s system of values have been<br />

recently awarded in three different<br />

corners of the world.<br />

Italy: “Best Innovator 2004”<br />

In Italy, <strong>Pirelli</strong> Tyres was awarded<br />

the “Best Innovator 2004” prize<br />

– organized by the consulting firm<br />

A.T.Kearney in partnership with Confindustria,<br />

the organization of Italian<br />

entrepreneurs – for “the excellence<br />

of integrating different dimensions<br />

of innovation”. The prize is a further<br />

recognition for <strong>Pirelli</strong>’s advanced<br />

technologies and in particular to<br />

MIRS (Modular<br />

Integrated Robotized<br />

System) and to innovative<br />

mixing room<br />

CCM (Continuous<br />

Compound Mixing),<br />

which allow for significant<br />

reductions both<br />

in lead time and costs’<br />

production of high<br />

performance tyres,<br />

while at the same time<br />

increasing flexibility<br />

and products quality.<br />

“The Group - Francesco<br />

Gori, Managing<br />

Director of <strong>Pirelli</strong> Tyres Sector<br />

commented - aims at excellence<br />

both in processes and products, not<br />

being satisfied of current standards.<br />

Innovation allows to create value for<br />

customers and Company, which – in<br />

order to success – must foster and stimulate<br />

creativity and speed not only<br />

in Research and Development activities”.<br />

Among the latest innovations<br />

patented by <strong>Pirelli</strong> the Tyre Sector,<br />

could be mentioned X-Pressure – the<br />

16

system which allows to monitor tyres<br />

pressure every six seconds sending<br />

data to a display on central car<br />

console – and SWS (Safety Wheel<br />

System), a solution that re-inflates a<br />

motorcycle’s tyre in the case of either<br />

a puncture of loss of air pressure.<br />

Antonio Capristo of <strong>Pirelli</strong> Power Cables and Systems Australia<br />

Pty Ltd receiving the “Azienda Italia Award 2004” in Sidney.<br />

Canada: “Italy-Canada<br />

Investaward 2004”<br />

In Canada, <strong>Pirelli</strong> received the<br />

“Italy-Canada Investaward 2004” for<br />

its commitment and its investments in<br />

the country. <strong>Pirelli</strong> has been in Canada<br />

since 1952: in the country, the Group<br />

has invested about 30 million Canadian<br />

dollars and at present employs<br />

350 persons. The Investaward – at<br />

the second edition – has been promoted<br />

by the ICE (Italian Foreign<br />

Trade Association) and Team Italia<br />

(an organization of Italian companies<br />

and managers in Canada), under the<br />

auspices of the Italian Ambassador<br />

in Canada Marco Colombo, in order<br />

to develop bilateral investments. The<br />

initiative gives each year a prize<br />

to two companies, an Italian and a<br />

Canadian one, for their investments<br />

in the other country. The award ceremony<br />

was held in the Ritz-Carlton<br />

Hotel in Montreal, with the presence<br />

of more than 120 Italian and Canadian<br />

entrepreneurs. The prize – the so-called<br />

“Team Italia Sculpture”, a bronze<br />

sculpture with a marble basis realized<br />

by the artist Silvio Mastrodascio –<br />

was delivered to Paolo Bazzoni, CFO<br />

and Vice President of <strong>Pirelli</strong> North<br />

America. For the Canadian side, the<br />

Investaward 2004 was received by<br />

Bombardier.<br />

Australia:<br />

“Azienda Italia Award 2004”<br />

<strong>Pirelli</strong>’s excellence has been also<br />

awarded in Australia, where <strong>Pirelli</strong><br />

Power Cables and Systems Australia<br />

Pty limited has received the prestigious<br />

“Azienda Italia Award 2004”,<br />

within the category “large business”,<br />

for its “incontestable contribution<br />

to Italian-Australian relations”.<br />

Organized by the Italian Chamber of<br />

Commerce and Industry in Australia<br />

(ICCI), under the auspices of the<br />

Italian Ambassador in Australia Dino<br />

Volpicelli, the award is open to Italian<br />

companies who have been in business<br />

longer than a year and recognizes<br />

companies or individuals who have<br />

substantially contributed to fostering<br />

of relations between Italy and Australia<br />

in 2004, taking in account not<br />

only the volume of business but also<br />

the image of Italy presented. Beside<br />

the high quality and excellent pro<strong>file</strong>,<br />

<strong>Pirelli</strong> Power Cables and Systems<br />

Australia has been also awarded<br />

for some successful local power<br />

cable projects such “Telfer Mine”,<br />

“Woolnorth Wind Farm” and “Anzac<br />

Frigate” Australia’s Navel ships. The<br />

26 th Gala Ball award ceremony was<br />

held in Sydney, in the presence of<br />