Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

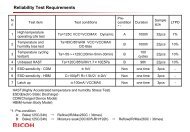

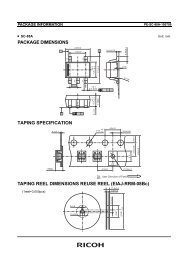

<strong>RN5T614</strong> <strong>PCB</strong> <strong>LAYOUT</strong> <strong>GUIDE</strong><br />

<strong>RN5T614</strong><br />

<strong>PCB</strong> Layout Guide<br />

Version 1.1<br />

September 28, 2012<br />

RICOH COMPANY, LTD.<br />

Electronic Devices Company<br />

©2012

<strong>RN5T614</strong> <strong>PCB</strong> <strong>LAYOUT</strong> <strong>GUIDE</strong><br />

Abstract<br />

This document describes the constraints and points when designing the <strong>PCB</strong> layout with <strong>RN5T614</strong>.<br />

This guide provides examples to explain of how it can be done.<br />

The <strong>PCB</strong> layout example is helpful to achieve optimal <strong>RN5T614</strong> performance.<br />

Contents<br />

1. Basic Policy and Examples of Board Pattern ............................................................................................. 3<br />

1.1 .................................................................................................................................... 3<br />

1.2 .................................................................................................................................. 6<br />

2. Recommended External Parts List ............................................................................................................. 7<br />

3. Example of Parts Layout............................................................................................................................. 8<br />

©2012 Page 2

<strong>RN5T614</strong> <strong>PCB</strong> <strong>LAYOUT</strong> <strong>GUIDE</strong><br />

1. Basic Policy and Examples of Board Pattern<br />

1.1 <br />

Current Loop<br />

Cin_A<br />

Analog<br />

Power<br />

Supply<br />

<strong>RN5T614</strong><br />

Buffer<br />

Power<br />

Supply<br />

Cin_B<br />

(Input capacitance)<br />

VFB<br />

Control<br />

and<br />

Analog<br />

BUF<br />

LX<br />

L<br />

Vout<br />

Cout<br />

(Output capacitance)<br />

Analog<br />

GND<br />

Buffer<br />

GND<br />

Fig. 1-1: Simplified Schematic for DCDC1 and DCDC2<br />

Analog<br />

Power<br />

Supply<br />

<strong>RN5T614</strong><br />

Buffer<br />

Power<br />

Supply<br />

Current Loop<br />

Cin_A<br />

Cin_B<br />

(Input capacitance)<br />

Control<br />

and<br />

Analog<br />

BUF<br />

LX<br />

R1<br />

L<br />

Cf<br />

Vout<br />

Cout<br />

(Output capacitance)<br />

+<br />

- VREF<br />

VFB<br />

R2<br />

Analog<br />

GND<br />

Buffer<br />

GND<br />

Fig. 1-2: Simplified Schematic for DCDC3<br />

©2012 Page 3

<strong>RN5T614</strong> <strong>PCB</strong> <strong>LAYOUT</strong> <strong>GUIDE</strong><br />

<strong>RN5T614</strong> Pin Names<br />

DCDC1 DCDC2 DCDC3<br />

Analog Power Supply<br />

VINA<br />

Buffer Power Supply VINP1 VINP2 VINP3<br />

VFB VFB1 VFB2 VFB3<br />

LX LX1 LX2 LX3<br />

Table 1-1: <strong>RN5T614</strong> Pin Names<br />

(7)<br />

(8)<br />

(3)<br />

C<br />

L<br />

(1)<br />

(4)<br />

(5)<br />

(6)<br />

(5)<br />

(1)<br />

(4)<br />

LX<br />

L<br />

C<br />

VOUT<br />

(2)<br />

(7)<br />

(3)<br />

Fig. 1-3: DCDC Block Evaluation Board Pattern (Top Layer)<br />

(1) Place the parts to minimize the switching current loop (Figure 1-1 and 1-2: blue line, Figure 1-3: red<br />

line).<br />

(2) Route the LX line between <strong>RN5T614</strong> and an inductor as short and wide as possible,<br />

and yet should not add other redundant lines on it<br />

(3) Connect the GND line of “Cout” directly to the internal GND plane with multiple vias, in order to reduce<br />

impedance as small as possible. (Target: 50mΩ or less)<br />

(4) Begin to route the VOUT line from near not “L” but “Cout”.<br />

(5) Place “Cin” as close as possible to <strong>RN5T614</strong>. (Higher priority level is “Cin” < L < “Cout” in the close<br />

distance order with <strong>RN5T614</strong>.)<br />

©2012 Page 4

<strong>RN5T614</strong> <strong>PCB</strong> <strong>LAYOUT</strong> <strong>GUIDE</strong><br />

(7)<br />

VFB3<br />

VFB1<br />

(7)<br />

Fig. 1-4: DCDC Block Evaluation Board Pattern<br />

*Top Layer (High-light: Lx and VOUT) + 3rd Layer (VFB)<br />

(6) Place inductors for DCDC1, DCDC2 and DCDC3 without becoming too close between them, in order to<br />

avoid the electromagnetic interference.<br />

(7) Route the VFB line not to go back into the chip parallel to noise source as the LX line in the same layer,<br />

and it's preferable to set the VFB line in the different layer from noise source.<br />

In addition, it should not pass under the Inductors.<br />

(8) Place R1, R2, and Cf as close as possible in the same layer, and connect GND of R2 to Cout's in<br />

DCDC3.<br />

Note:<br />

*Need to arrange the layout pattern of DCDC2 along with DCDC1's, too. (Pay attention to (6) at that time.)<br />

©2012 Page 5

<strong>RN5T614</strong> <strong>PCB</strong> <strong>LAYOUT</strong> <strong>GUIDE</strong><br />

1.2 <br />

IMONI<br />

(1)<br />

VCHG<br />

VBAT<br />

VSYS<br />

(2)<br />

Fig. 1-5: Charger Block Evaluation Board Pattern (Top Layer)<br />

(1) Place each capacitor (VCHG, VSYS*, VBAT*) as close as possible to <strong>RN5T614</strong> and route the line to<br />

<strong>RN5T614</strong> short and widely in order to minimize resistance.<br />

(2) Place IMONI resistance as close as possible to <strong>RN5T614</strong> and route the line of it to avoid the having<br />

many parasitic resistance. And Use the high-accuracy resistance (Recommended value: ±0.5% or less)<br />

in order to increase the accuracy of Charge Current.<br />

(3) The device can withstand up to 6.5V on VCHG pin. However, it can withstand high voltage by combining a<br />

high voltage protection IC (up to 28V by using BD6040 of ROHM)<br />

©2012 Page 6

<strong>RN5T614</strong> <strong>PCB</strong> <strong>LAYOUT</strong> <strong>GUIDE</strong><br />

2. Recommended External Parts List<br />

<strong>RN5T614</strong> External Parts<br />

Block Pin Name<br />

Parts Size [mm]<br />

Parts<br />

Model value Vender Num<br />

X Size Y Size Z Size [mm2]<br />

PMU - - <strong>RN5T614</strong> RICOH 1 6.00 6.00 0.90 36<br />

CHG VCHG 4.7uF GRM21BB31E475KA75B Murata 1 2.00 1.25 1.25 2.5<br />

Zener Diode RD6.8UM RENESAS 1 2.10 0.80 0.70 1.68<br />

(for OVP) OVP BD6040 ROHM 1 1.60 1.60 0.55 2.56<br />

2.2uF GRM188B31C225KE14B Murata 1 1.60 0.80 0.80 1.28<br />

VSYS1 10uF C1608JB0J106M TDK 1 1.60 0.80 0.80 1.28<br />

VSYS2<br />

VSYS3<br />

VBAT1 4.7uF GRM188B30J475KE18B Murata 1 1.60 0.80 0.80 1.28<br />

VBAT2<br />

THERMBAT Thermistor NTCG103JF103GT TDK 1 1.00 0.50 0.50 0.5<br />

10kohm - 1 1.00 0.50 0.35 0.5<br />

VTHM 1.0uF GRM155B31A105KE15 Murata 1 1.00 0.50 0.50 0.5<br />

IMONI 1kohm 1kohm +/- 0.5% - 1 1.00 0.50 0.35 0.5<br />

VCHGREG 1.0uF GRM155B31A105KE15 Murata 1 1.00 0.50 0.50 0.5<br />

DCDC VINA 2.2uF LMK107BJ225KA Taiyo Yuden 1 1.60 0.80 0.80 1.28<br />

VINP1 2.2uF LMK107BJ225KA Taiyo Yuden 1 1.60 0.80 0.80 1.28<br />

LX1 2.2uH NRH2410T2R2MN Taiyo Yuden 1 2.40 2.40 1.00 5.76<br />

VFB1 10uF C1608JB0J106M TDK 1 1.60 0.80 0.80 1.28<br />

VINP2 10uF LMK107BBJ106MALT Taiyo Yuden 1 1.60 0.80 0.80 1.28<br />

LX2 2.2uH NRH2410T2R2MN Taiyo Yuden 1 2.40 2.40 1.00 5.76<br />

VFB2 10uF C1608JB0J106M TDK 1 1.60 0.80 0.80 1.28<br />

VINP3 2.2uF LMK107BJ225KA Taiyo Yuden 1 1.60 0.80 0.80 1.28<br />

LX3 2.2uH MLP2012S2R2M TDK 1 2.00 1.25 1.00 2.5<br />

VFB3 4.7uF C1608JB1A475K TDK 1 1.60 0.80 0.80 1.28<br />

R1 (for DCDC3 Voltage set) - 1 1.00 0.50 0.35 0.5<br />

R2 (for DCDC3 Voltage set) - 1 1.00 0.50 0.35 0.5<br />

Cf (for DCDC3 Voltage set) - 1 1.00 0.50 0.50 0.5<br />

LDO VIN1 1.0uF GRM155B31A105KE15 Murata 1 1.00 0.50 0.50 0.5<br />

VREF 1.0uF GRM155B31A105KE15 Murata 1 1.00 0.50 0.50 0.5<br />

VOUT1 1.0uF GRM155B31A105KE15 Murata 1 1.00 0.50 0.50 0.5<br />

VOUT2 1.0uF GRM155B31A105KE15 Murata 1 1.00 0.50 0.50 0.5<br />

VOUT3 1.0uF GRM155B31A105KE15 Murata 1 1.00 0.50 0.50 0.5<br />

VOUT4 1.0uF GRM155B31A105KE15 Murata 1 1.00 0.50 0.50 0.5<br />

VOUTD 1.0uF GRM155B31A105KE15 Murata 1 1.00 0.50 0.50 0.5<br />

VIN2 1.0uF GRM155B31A105KE15 Murata 1 1.00 0.50 0.50 0.5<br />

VOUT5 1.0uF GRM155B31A105KE15 Murata 1 1.00 0.50 0.50 0.5<br />

VOUT6 1.0uF GRM155B31A105KE15 Murata 1 1.00 0.50 0.50 0.5<br />

VIN3 1.0uF GRM155B31A105KE15 Murata 1 1.00 0.50 0.50 0.5<br />

VOUT7 1.0uF GRM155B31A105KE15 Murata 1 1.00 0.50 0.50 0.5<br />

VOUT8 1.0uF GRM155B31A105KE15 Murata 1 1.00 0.50 0.50 0.5<br />

OTHER VDDIO 0.1uF GRM155B31A105KE15 Murata 1 1.00 0.50 0.50 0.5<br />

BATDET 330kohm for Pullup - 1 1.00 0.50 0.35 0.5<br />

ONOB 330kohm for Pullup - 1 1.00 0.50 0.35 0.5<br />

RESETO 330kohm for Pullup - 1 1.00 0.50 0.35 0.5<br />

SDA 330kohm for Pullup - 1 1.00 0.50 0.35 0.5<br />

INTB 330kohm for Pullup - 1 1.00 0.50 0.35 0.5<br />

Total Num 44 Total Parts size 83.06<br />

©2012 Page 7

<strong>RN5T614</strong> <strong>PCB</strong> <strong>LAYOUT</strong> <strong>GUIDE</strong><br />

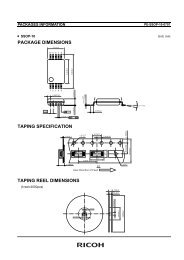

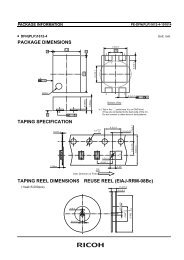

3. Example of Parts Layout<br />

8.1 mm<br />

4.5 mm<br />

R<br />

2.3 mm<br />

C<br />

C<br />

R<br />

C<br />

C<br />

R<br />

R<br />

C<br />

R<br />

R<br />

L<br />

C<br />

C<br />

8.5 mm<br />

3.2 mm<br />

C<br />

BD60<br />

40<br />

GUL<br />

D<br />

C<br />

C<br />

C<br />

<strong>RN5T614</strong><br />

C<br />

L<br />

C<br />

11.6 mm<br />

10.5 mm<br />

C C<br />

C<br />

C<br />

C<br />

C<br />

C<br />

L<br />

C<br />

R<br />

R<br />

R<br />

C<br />

C<br />

C<br />

C<br />

C<br />

C<br />

C<br />

1.6 mm<br />

Total Parts Area 158.21mm 2<br />

Fig. 3-1: Example <strong>PCB</strong> Parts Layout<br />

Note: Connect Exposed Paddle (Tab on the bottom side) to GND.<br />

©2012 Page 8