eco-ATWB Engineering Bulletin - Evapco

eco-ATWB Engineering Bulletin - Evapco

eco-ATWB Engineering Bulletin - Evapco

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

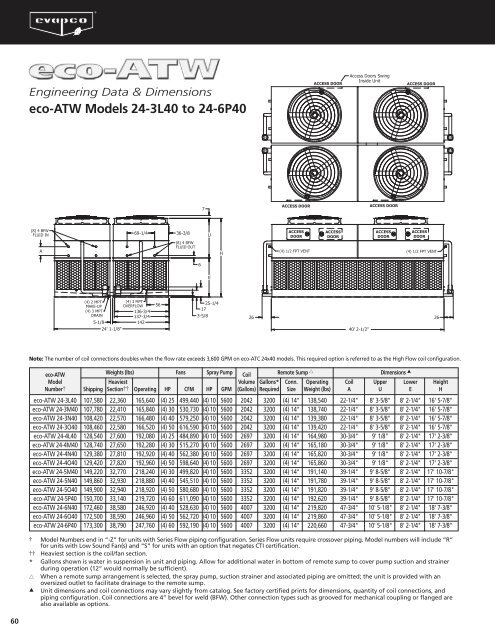

<strong>Engineering</strong> Data & Dimensions<br />

<strong>eco</strong>-ATW Models 24-3L40 to 24-6P40<br />

ACCESS DOOR<br />

Access Doors Swing<br />

Inside Unit<br />

ACCESS DOOR<br />

P<br />

P<br />

P<br />

P<br />

7<br />

ACCESS DOOR<br />

ACCESS DOOR<br />

(8) 4 BFW<br />

FLUID IN<br />

A<br />

69-1/4 36-3/8<br />

(8) 4 BFW<br />

FLUID OUT<br />

U<br />

H<br />

ACCESS<br />

DOOR<br />

ACCESS<br />

DOOR<br />

ACCESS<br />

DOOR<br />

ACCESS<br />

DOOR<br />

(4) 1/2 FPT VENT (4) 1/2 FPT VENT<br />

6<br />

E<br />

(4) 2 MPT<br />

(4) 3 MPT<br />

56<br />

25-1/4<br />

MAKE-UP<br />

OVERFLOW<br />

(4) 3 MPT<br />

17<br />

136-3/4<br />

DRAIN<br />

137-3/4<br />

3-5/8<br />

26 26<br />

5-1/8<br />

142<br />

24' 1-1/8" 40' 2-1/2"<br />

Note: The number of coil connections doubles when the flow rate exceeds 3,600 GPM on <strong>eco</strong>-ATC 24x40 models. This required option is referred to as the High Flow coil configuration.<br />

<strong>eco</strong>-ATW<br />

Weights (lbs)<br />

Fans Spray Pump Coil<br />

Remote Sump Dimensions <br />

Model Heaviest Volume Gallons* Conn. Operating Coil Upper Lower Height<br />

Number† Shipping Section†† Operating HP CFM HP GPM (Gallons) Required Size Weight (lbs) A U E H<br />

<strong>eco</strong>-ATW 24-3L40 107,580 22,360 165,640 (4) 25 499,440 (4) 10 5600 2042 3200 (4) 14" 138,540 22-1/4" 8' 3-5/8" 8' 2-1/4" 16' 5-7/8"<br />

<strong>eco</strong>-ATW 24-3M40 107,780 22,410 165,840 (4) 30 530,730 (4) 10 5600 2042 3200 (4) 14" 138,740 22-1/4" 8' 3-5/8" 8' 2-1/4" 16' 5-7/8"<br />

<strong>eco</strong>-ATW 24-3N40 108,420 22,570 166,480 (4) 40 579,250 (4) 10 5600 2042 3200 (4) 14" 139,380 22-1/4" 8' 3-5/8" 8' 2-1/4" 16' 5-7/8"<br />

<strong>eco</strong>-ATW 24-3O40 108,460 22,580 166,520 (4) 50 616,590 (4) 10 5600 2042 3200 (4) 14" 139,420 22-1/4" 8' 3-5/8" 8' 2-1/4" 16' 5-7/8"<br />

<strong>eco</strong>-ATW 24-4L40 128,540 27,600 192,080 (4) 25 484,890 (4) 10 5600 2697 3200 (4) 14" 164,980 30-3/4" 9' 1/8" 8' 2-1/4" 17' 2-3/8"<br />

<strong>eco</strong>-ATW 24-4M40 128,740 27,650 192,280 (4) 30 515,270 (4) 10 5600 2697 3200 (4) 14" 165,180 30-3/4" 9' 1/8" 8' 2-1/4" 17' 2-3/8"<br />

<strong>eco</strong>-ATW 24-4N40 129,380 27,810 192,920 (4) 40 562,380 (4) 10 5600 2697 3200 (4) 14" 165,820 30-3/4" 9' 1/8" 8' 2-1/4" 17' 2-3/8"<br />

<strong>eco</strong>-ATW 24-4O40 129,420 27,820 192,960 (4) 50 598,640 (4) 10 5600 2697 3200 (4) 14" 165,860 30-3/4" 9' 1/8" 8' 2-1/4" 17' 2-3/8"<br />

<strong>eco</strong>-ATW 24-5M40 149,220 32,770 218,240 (4) 30 499,820 (4) 10 5600 3352 3200 (4) 14" 191,140 39-1/4" 9' 8-5/8" 8' 2-1/4" 17' 10-7/8"<br />

<strong>eco</strong>-ATW 24-5N40 149,860 32,930 218,880 (4) 40 545,510 (4) 10 5600 3352 3200 (4) 14" 191,780 39-1/4" 9' 8-5/8" 8' 2-1/4" 17' 10-7/8"<br />

<strong>eco</strong>-ATW 24-5O40 149,900 32,940 218,920 (4) 50 580,680 (4) 10 5600 3352 3200 (4) 14" 191,820 39-1/4" 9' 8-5/8" 8' 2-1/4" 17' 10-7/8"<br />

<strong>eco</strong>-ATW 24-5P40 150,700 33,140 219,720 (4) 60 611,090 (4) 10 5600 3352 3200 (4) 14" 192,620 39-1/4" 9' 8-5/8" 8' 2-1/4" 17' 10-7/8"<br />

<strong>eco</strong>-ATW 24-6N40 172,460 38,580 246,920 (4) 40 528,630 (4) 10 5600 4007 3200 (4) 14" 219,820 47-3/4" 10' 5-1/8" 8' 2-1/4" 18' 7-3/8"<br />

<strong>eco</strong>-ATW 24-6O40 172,500 38,590 246,960 (4) 50 562,720 (4) 10 5600 4007 3200 (4) 14" 219,860 47-3/4" 10' 5-1/8" 8' 2-1/4" 18' 7-3/8"<br />

<strong>eco</strong>-ATW 24-6P40 173,300 38,790 247,760 (4) 60 592,190 (4) 10 5600 4007 3200 (4) 14" 220,660 47-3/4" 10' 5-1/8" 8' 2-1/4" 18' 7-3/8"<br />

† Model Numbers end in “-Z” for units with Series Flow piping configuration. Series Flow units require crossover piping. Model numbers will include “R”<br />

for units with Low Sound Fan(s) and “S” for units with an option that negates CTI certification.<br />

†† Heaviest section is the coil/fan section.<br />

* Gallons shown is water in suspension in unit and piping. Allow for additional water in bottom of remote sump to cover pump suction and strainer<br />

during operation (12” would normally be sufficient).<br />

When a remote sump arrangement is selected, the spray pump, suction strainer and associated piping are omitted; the unit is provided with an<br />

oversized outlet to facilitate drainage to the remote sump.<br />

Unit dimensions and coil connections may vary slightly from catalog. See factory certified prints for dimensions, quantity of coil connections, and<br />

piping configuration. Coil connections are 4” bevel for weld (BFW). Other connection types such as grooved for mechanical coupling or flanged are<br />

also available as options.<br />

60