TO 35-1-3 - Robins Air Force Base

TO 35-1-3 - Robins Air Force Base

TO 35-1-3 - Robins Air Force Base

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

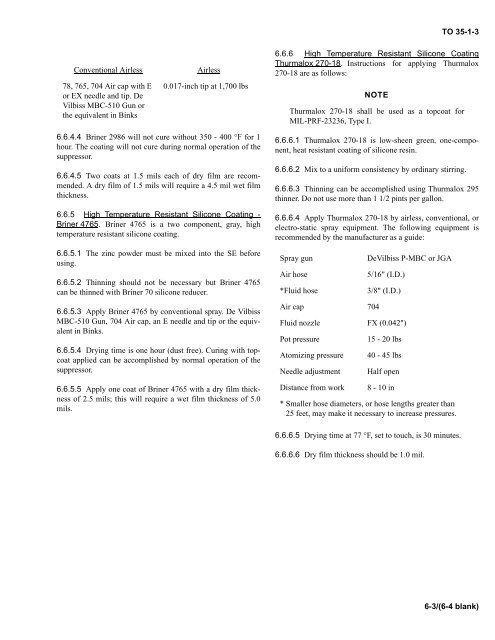

<strong>TO</strong> <strong>35</strong>-1-3<br />

Conventional <strong>Air</strong>less<br />

78, 765, 704 <strong>Air</strong> cap with E<br />

or EX needle and tip. De<br />

Vilbiss MBC-510 Gun or<br />

the equivalent in Binks<br />

<strong>Air</strong>less<br />

0.017-inch tip at 1,700 lbs<br />

6.6.6 High Temperature Resistant Silicone Coating<br />

Thurmalox 270-18. Instructions for applying Thurmalox<br />

270-18 are as follows:<br />

NOTE<br />

Thurmalox 270-18 shall be used as a topcoat for<br />

MIL-PRF-23236, Type I.<br />

6.6.4.4 Briner 2986 will not cure without <strong>35</strong>0 - 400 °F for 1<br />

hour. The coating will not cure during normal operation of the<br />

suppressor.<br />

6.6.4.5 Two coats at 1.5 mils each of dry film are recommended.<br />

A dry film of 1.5 mils will require a 4.5 mil wet film<br />

thickness.<br />

6.6.5 High Temperature Resistant Silicone Coating -<br />

Briner 4765. Briner 4765 is a two component, gray, high<br />

temperature resistant silicone coating.<br />

6.6.5.1 The zinc powder must be mixed into the SE before<br />

using.<br />

6.6.5.2 Thinning should not be necessary but Briner 4765<br />

can be thinned with Briner 70 silicone reducer.<br />

6.6.5.3 Apply Briner 4765 by conventional spray. De Vilbiss<br />

MBC-510 Gun, 704 <strong>Air</strong> cap, an E needle and tip or the equivalent<br />

in Binks.<br />

6.6.5.4 Drying time is one hour (dust free). Curing with topcoat<br />

applied can be accomplished by normal operation of the<br />

suppressor.<br />

6.6.5.5 Apply one coat of Briner 4765 with a dry film thickness<br />

of 2.5 mils; this will require a wet film thickness of 5.0<br />

mils.<br />

6.6.6.1 Thurmalox 270-18 is low-sheen green, one-component,<br />

heat resistant coating of silicone resin.<br />

6.6.6.2 Mix to a uniform consistency by ordinary stirring.<br />

6.6.6.3 Thinning can be accomplished using Thurmalox 295<br />

thinner. Do not use more than 1 1/2 pints per gallon.<br />

6.6.6.4 Apply Thurmalox 270-18 by airless, conventional, or<br />

electro-static spray equipment. The following equipment is<br />

recommended by the manufacturer as a guide:<br />

Spray gun<br />

<strong>Air</strong> hose<br />

*Fluid hose<br />

<strong>Air</strong> cap 704<br />

DeVilbiss P-MBC or JGA<br />

5/16" (I.D.)<br />

3/8" (I.D.)<br />

Fluid nozzle FX (0.042")<br />

Pot pressure<br />

Atomizing pressure<br />

Needle adjustment<br />

Distance from work<br />

15 - 20 lbs<br />

40 - 45 lbs<br />

Half open<br />

8 - 10 in<br />

* Smaller hose diameters, or hose lengths greater than<br />

25 feet, may make it necessary to increase pressures.<br />

6.6.6.5 Drying time at 77 °F, set to touch, is 30 minutes.<br />

6.6.6.6 Dry film thickness should be 1.0 mil.<br />

6-3/(6-4 blank)