TO 35-1-3 - Robins Air Force Base

TO 35-1-3 - Robins Air Force Base

TO 35-1-3 - Robins Air Force Base

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>TO</strong> <strong>35</strong>-1-3<br />

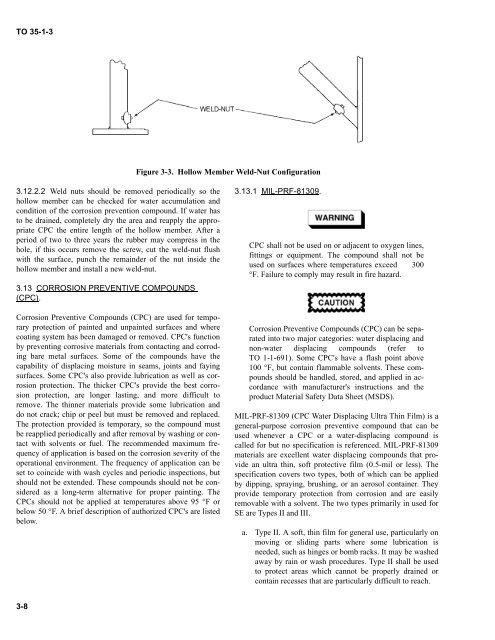

Figure 3-3. Hollow Member Weld-Nut Configuration<br />

3.12.2.2 Weld nuts should be removed periodically so the<br />

hollow member can be checked for water accumulation and<br />

condition of the corrosion prevention compound. If water has<br />

to be drained, completely dry the area and reapply the appropriate<br />

CPC the entire length of the hollow member. After a<br />

period of two to three years the rubber may compress in the<br />

hole, if this occurs remove the screw, cut the weld-nut flush<br />

with the surface, punch the remainder of the nut inside the<br />

hollow member and install a new weld-nut.<br />

3.13 CORROSION PREVENTIVE COMPOUNDS<br />

(CPC).<br />

Corrosion Preventive Compounds (CPC) are used for temporary<br />

protection of painted and unpainted surfaces and where<br />

coating system has been damaged or removed. CPC's function<br />

by preventing corrosive materials from contacting and corroding<br />

bare metal surfaces. Some of the compounds have the<br />

capability of displacing moisture in seams, joints and faying<br />

surfaces. Some CPC's also provide lubrication as well as corrosion<br />

protection. The thicker CPC's provide the best corrosion<br />

protection, are longer lasting, and more difficult to<br />

remove. The thinner materials provide some lubrication and<br />

do not crack; chip or peel but must be removed and replaced.<br />

The protection provided is temporary, so the compound must<br />

be reapplied periodically and after removal by washing or contact<br />

with solvents or fuel. The recommended maximum frequency<br />

of application is based on the corrosion severity of the<br />

operational environment. The frequency of application can be<br />

set to coincide with wash cycles and periodic inspections, but<br />

should not be extended. These compounds should not be considered<br />

as a long-term alternative for proper painting. The<br />

CPCs should not be applied at temperatures above 95 °F or<br />

below 50 °F. A brief description of authorized CPC's are listed<br />

below.<br />

3.13.1 MIL-PRF-81309.<br />

CPC shall not be used on or adjacent to oxygen lines,<br />

fittings or equipment. The compound shall not be<br />

used on surfaces where temperatures exceed 300<br />

°F. Failure to comply may result in fire hazard.<br />

Corrosion Preventive Compounds (CPC) can be separated<br />

into two major categories: water displacing and<br />

non-water displacing compounds (refer to<br />

<strong>TO</strong> 1-1-691). Some CPC's have a flash point above<br />

100 °F, but contain flammable solvents. These compounds<br />

should be handled, stored, and applied in accordance<br />

with manufacturer's instructions and the<br />

product Material Safety Data Sheet (MSDS).<br />

MIL-PRF-81309 (CPC Water Displacing Ultra Thin Film) is a<br />

general-purpose corrosion preventive compound that can be<br />

used whenever a CPC or a water-displacing compound is<br />

called for but no specification is referenced. MIL-PRF-81309<br />

materials are excellent water displacing compounds that provide<br />

an ultra thin, soft protective film (0.5-mil or less). The<br />

specification covers two types, both of which can be applied<br />

by dipping, spraying, brushing, or an aerosol container. They<br />

provide temporary protection from corrosion and are easily<br />

removable with a solvent. The two types primarily in used for<br />

SE are Types II and III.<br />

a. Type II. A soft, thin film for general use, particularly on<br />

moving or sliding parts where some lubrication is<br />

needed, such as hinges or bomb racks. It may be washed<br />

away by rain or wash procedures. Type II shall be used<br />

to protect areas which cannot be properly drained or<br />

contain recesses that are particularly difficult to reach.<br />

3-8