Architecture for Athens 2004 - Roof & Facade

Architecture for Athens 2004 - Roof & Facade

Architecture for Athens 2004 - Roof & Facade

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Roof</strong>&<strong>Facade</strong> Asia<br />

Paints & Coatings<br />

Intumescent coating combining<br />

fire-protection with decoration<br />

FM-900 was developed to solve the problems relating to fire<br />

protection, whilst maintaining architectural freedom.<br />

Applicator of fluorocarbon coatings<br />

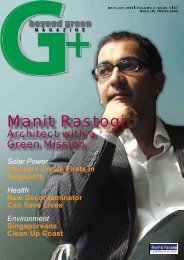

The fluorocarbon finish <strong>for</strong> the aluminium facade of Kandang Kerbau Hospital in Singapore was applied by JASMET.<br />

JAS Metal Coatings Pte Ltd (JASMET) was<br />

established in 1984 to provide high-quality metal<br />

finishing services to the aluminium industries in<br />

Singapore, Southeast Asia and the Pacific Rim.<br />

In recognition of JASMET’s advanced facility,<br />

technical knowledge and its ability to consistently<br />

provide quality coatings that comply with<br />

international standards (ASTM, AAMA, ASCA, JIS<br />

and BSS), the company has been awarded Approved<br />

Applicator Licences by practically all major<br />

producers of fluorocarbon coatings including PPG<br />

Industries Inc (USA), DeSoto Inc (USA), Taubmans<br />

(Australia), Dulux (Australia), DNT (Japan) and<br />

Nippon Paint (Japan).<br />

Further, JASMET is said to be the only coating<br />

company outside the US, to be admitted as a full<br />

member of the Architectural Spray Coaters<br />

Association of America (ASCA).<br />

In 1989, the company moved into its present<br />

factory which is equipped with two parallel,<br />

independent, multi-stage paint lines, with a<br />

coating capacity of 1,200 sq m <strong>for</strong> every eight-hour<br />

shift.<br />

JASMET’s painting services have been utilised<br />

by clients in Australia, Brunei, China including<br />

Hong Kong SAR, Guam, Indonesia, Japan,<br />

Malaysia, Philippines, Spain, Sri Lanka, Taiwan,<br />

Thailand and the UK. RnF<br />

Enquiry No: 10/110<br />

FIRE safety is of fundamental importance in the<br />

design, management and operation of buildings,<br />

industrial plants and transportation systems.<br />

Regulations there<strong>for</strong>e require certain elements of the<br />

structure to be fire-resistant.<br />

With the increasing complexity of modern design<br />

and the need <strong>for</strong> greater space utilisation, designers<br />

and architects often have to make difficult<br />

compromises between design aspirations and<br />

regulatory constraints.<br />

FIRECUT FM-900 intumescent, mastic coating<br />

was developed to solve the problems relating to fire<br />

protection, whilst maintaining architectural<br />

freedom.<br />

As part of a complete intumescent system, FM-<br />

900 provides up to 2 hours of fire-resistance to<br />

structural steel with a smooth surface.<br />

When the temperature rises to 200º C, FM-900<br />

will begin to react and gradually <strong>for</strong>ms a cake-like<br />

char layer that is 100 times the initial volume. The<br />

char layer insulates against the conduction of heat,<br />

thereby protecting the steel structure.<br />

The features of FM-900 include good fireresistance,<br />

suitability <strong>for</strong> spray-on applications, ease<br />

of application, a smooth and pleasant appearance,<br />

avoidance of asbestos in its <strong>for</strong>mulation, and<br />

con<strong>for</strong>mance to international standards.<br />

With just 0.34 mm dry film thickness, FM-900 can<br />

meet the requirements of the 1 hour fire resistance<br />

rating, on a 3-sided beam.<br />

The wet film can reach 1000 microns without<br />

sagging. It is touch-dry in half an hour and harddry<br />

in 4 hours.<br />

The coating is fully cured in 7 days. The interval<br />

between coats is 4 hours by spray and 1 hour by<br />

spray and brush.<br />

After the complete application of the FM-900<br />

coating system, the surface becomes smooth and<br />

even. Further, various colours can be incorporated<br />

in the topcoat, thus combining fire-protection with<br />

aesthetics.<br />

FM-900 has been tested at Warrington Fire<br />

Research Centre (WFRC) and Loss Prevention<br />

Centre (LPC), in the UK, and has been certified to<br />

BS476 Part 21 ‘Loaded beam and Loaded column at<br />

2 hour fire-resistance rating’. The product has also<br />

been tested and certified in Singapore by PSB.<br />

As an applicator of the FIRECUT FM-900<br />

intumescent coating, Singapore-based Industrial<br />

Contracts Marketing (2001) provides a comprehensive<br />

‘supply-apply’ system starting from initial<br />

survey and inspection, to application and after-sales<br />

service including maintenance. RnF<br />

Enquiry No: 10/109<br />

10 <strong>Roof</strong> & <strong>Facade</strong> Asia • October <strong>2004</strong>