Teaching Elements and Principles of Bridge Design - International ...

Teaching Elements and Principles of Bridge Design - International ...

Teaching Elements and Principles of Bridge Design - International ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

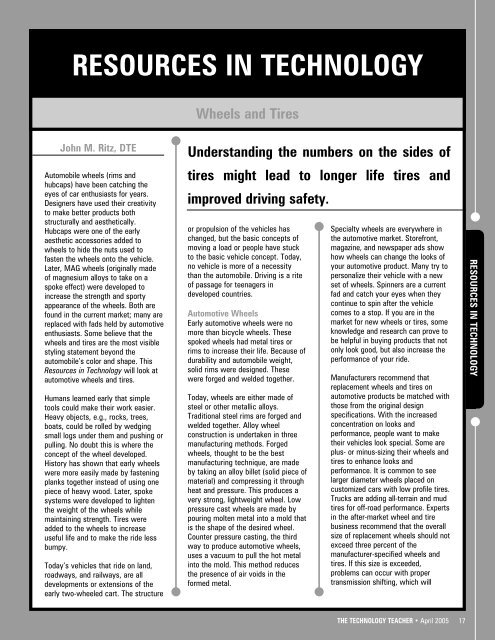

RESOURCES IN TECHNOLOGY<br />

RESOURCES IN TECHNOLOGY<br />

Wheels <strong>and</strong> Tires<br />

John M. Ritz, DTE<br />

Automobile wheels (rims <strong>and</strong><br />

hubcaps) have been catching the<br />

eyes <strong>of</strong> car enthusiasts for years.<br />

<strong>Design</strong>ers have used their creativity<br />

to make better products both<br />

structurally <strong>and</strong> aesthetically.<br />

Hubcaps were one <strong>of</strong> the early<br />

aesthetic accessories added to<br />

wheels to hide the nuts used to<br />

fasten the wheels onto the vehicle.<br />

Later, MAG wheels (originally made<br />

<strong>of</strong> magnesium alloys to take on a<br />

spoke effect) were developed to<br />

increase the strength <strong>and</strong> sporty<br />

appearance <strong>of</strong> the wheels. Both are<br />

found in the current market; many are<br />

replaced with fads held by automotive<br />

enthusiasts. Some believe that the<br />

wheels <strong>and</strong> tires are the most visible<br />

styling statement beyond the<br />

automobile’s color <strong>and</strong> shape. This<br />

Resources in Technology will look at<br />

automotive wheels <strong>and</strong> tires.<br />

Humans learned early that simple<br />

tools could make their work easier.<br />

Heavy objects, e.g., rocks, trees,<br />

boats, could be rolled by wedging<br />

small logs under them <strong>and</strong> pushing or<br />

pulling. No doubt this is where the<br />

concept <strong>of</strong> the wheel developed.<br />

History has shown that early wheels<br />

were more easily made by fastening<br />

planks together instead <strong>of</strong> using one<br />

piece <strong>of</strong> heavy wood. Later, spoke<br />

systems were developed to lighten<br />

the weight <strong>of</strong> the wheels while<br />

maintaining strength. Tires were<br />

added to the wheels to increase<br />

useful life <strong>and</strong> to make the ride less<br />

bumpy.<br />

Today’s vehicles that ride on l<strong>and</strong>,<br />

roadways, <strong>and</strong> railways, are all<br />

developments or extensions <strong>of</strong> the<br />

early two-wheeled cart. The structure<br />

Underst<strong>and</strong>ing the numbers on the sides <strong>of</strong><br />

tires might lead to longer life tires <strong>and</strong><br />

improved driving safety.<br />

or propulsion <strong>of</strong> the vehicles has<br />

changed, but the basic concepts <strong>of</strong><br />

moving a load or people have stuck<br />

to the basic vehicle concept. Today,<br />

no vehicle is more <strong>of</strong> a necessity<br />

than the automobile. Driving is a rite<br />

<strong>of</strong> passage for teenagers in<br />

developed countries.<br />

Automotive Wheels<br />

Early automotive wheels were no<br />

more than bicycle wheels. These<br />

spoked wheels had metal tires or<br />

rims to increase their life. Because <strong>of</strong><br />

durability <strong>and</strong> automobile weight,<br />

solid rims were designed. These<br />

were forged <strong>and</strong> welded together.<br />

Today, wheels are either made <strong>of</strong><br />

steel or other metallic alloys.<br />

Traditional steel rims are forged <strong>and</strong><br />

welded together. Alloy wheel<br />

construction is undertaken in three<br />

manufacturing methods. Forged<br />

wheels, thought to be the best<br />

manufacturing technique, are made<br />

by taking an alloy billet (solid piece <strong>of</strong><br />

material) <strong>and</strong> compressing it through<br />

heat <strong>and</strong> pressure. This produces a<br />

very strong, lightweight wheel. Low<br />

pressure cast wheels are made by<br />

pouring molten metal into a mold that<br />

is the shape <strong>of</strong> the desired wheel.<br />

Counter pressure casting, the third<br />

way to produce automotive wheels,<br />

uses a vacuum to pull the hot metal<br />

into the mold. This method reduces<br />

the presence <strong>of</strong> air voids in the<br />

formed metal.<br />

Specialty wheels are everywhere in<br />

the automotive market. Storefront,<br />

magazine, <strong>and</strong> newspaper ads show<br />

how wheels can change the looks <strong>of</strong><br />

your automotive product. Many try to<br />

personalize their vehicle with a new<br />

set <strong>of</strong> wheels. Spinners are a current<br />

fad <strong>and</strong> catch your eyes when they<br />

continue to spin after the vehicle<br />

comes to a stop. If you are in the<br />

market for new wheels or tires, some<br />

knowledge <strong>and</strong> research can prove to<br />

be helpful in buying products that not<br />

only look good, but also increase the<br />

performance <strong>of</strong> your ride.<br />

Manufacturers recommend that<br />

replacement wheels <strong>and</strong> tires on<br />

automotive products be matched with<br />

those from the original design<br />

specifications. With the increased<br />

concentration on looks <strong>and</strong><br />

performance, people want to make<br />

their vehicles look special. Some are<br />

plus- or minus-sizing their wheels <strong>and</strong><br />

tires to enhance looks <strong>and</strong><br />

performance. It is common to see<br />

larger diameter wheels placed on<br />

customized cars with low pr<strong>of</strong>ile tires.<br />

Trucks are adding all-terrain <strong>and</strong> mud<br />

tires for <strong>of</strong>f-road performance. Experts<br />

in the after-market wheel <strong>and</strong> tire<br />

business recommend that the overall<br />

size <strong>of</strong> replacement wheels should not<br />

exceed three percent <strong>of</strong> the<br />

manufacturer-specified wheels <strong>and</strong><br />

tires. If this size is exceeded,<br />

problems can occur with proper<br />

transmission shifting, which will<br />

THE TECHNOLOGY TEACHER • April 2005 17