POLYMIN - University of Waterloo

POLYMIN - University of Waterloo

POLYMIN - University of Waterloo

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

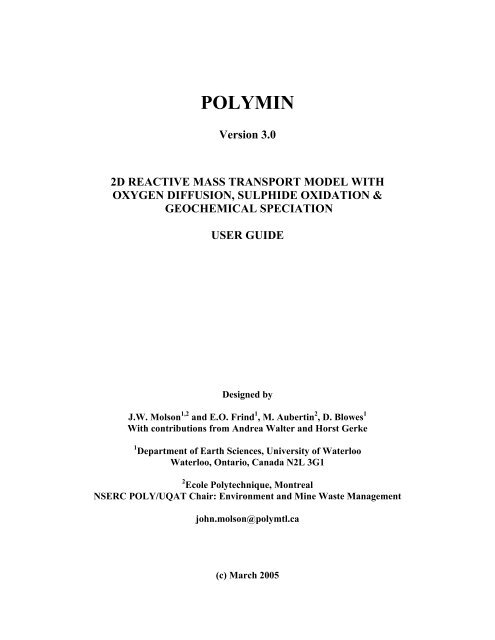

<strong>POLYMIN</strong><br />

Version 3.0<br />

2D REACTIVE MASS TRANSPORT MODEL WITH<br />

OXYGEN DIFFUSION, SULPHIDE OXIDATION &<br />

GEOCHEMICAL SPECIATION<br />

USER GUIDE<br />

Designed by<br />

J.W. Molson 1,2 and E.O. Frind 1 , M. Aubertin 2 , D. Blowes 1<br />

With contributions from Andrea Walter and Horst Gerke<br />

1 Department <strong>of</strong> Earth Sciences, <strong>University</strong> <strong>of</strong> <strong>Waterloo</strong><br />

<strong>Waterloo</strong>, Ontario, Canada N2L 3G1<br />

2 Ecole Polytechnique, Montreal<br />

NSERC POLY/UQAT Chair: Environment and Mine Waste Management<br />

john.molson@polymtl.ca<br />

(c) March 2005

<strong>POLYMIN</strong> 2005<br />

License Agreement<br />

I. Copyright Notice<br />

This s<strong>of</strong>tware is protected by both Canadian copyright law and international treaty<br />

provisions. Therefore, you must treat this s<strong>of</strong>tware just like a book, with the following single<br />

exception. The <strong>University</strong> <strong>of</strong> <strong>Waterloo</strong> (UW) and Ecole Polytechnique (EP) authorize you to make<br />

archive copies <strong>of</strong> the s<strong>of</strong>tware for the sole purpose <strong>of</strong> backing-up our s<strong>of</strong>tware and protecting your<br />

investment from loss.<br />

By saying "just like a book", it is meant for example, that this s<strong>of</strong>tware may be used by any<br />

number <strong>of</strong> people and may be freely moved from one computer location to another, so long as there<br />

is no possibility <strong>of</strong> it being used at one location while it is being used at another. This restriction is<br />

similar to that in publishing where a book for example, can't be read by two different people in two<br />

different places at the same time.<br />

II. Warranty<br />

UW and EP warrant the physical disks and documentation enclosed herein to be free <strong>of</strong><br />

defects in materials and workmanship for a period <strong>of</strong> 30 days from the date <strong>of</strong> purchase. In the event<br />

<strong>of</strong> notification <strong>of</strong> defects in material or workmanship, UW or EP will replace the defective disks or<br />

documentation. The remedy for breach <strong>of</strong> this warranty shall be limited to replacement and shall not<br />

encompass any other damages, including but not limited to loss <strong>of</strong> pr<strong>of</strong>it, and special, incidental,<br />

consequential, or other similar claims.<br />

III. Disclaimer<br />

Neither the developers <strong>of</strong> this s<strong>of</strong>tware, nor any person or organization acting on behalf <strong>of</strong><br />

them makes any warranty, express or implied, with respect to this s<strong>of</strong>tware; or assumes any<br />

liabilities with respect to the use, or misuse, <strong>of</strong> this s<strong>of</strong>tware, or the interpretation, or<br />

misinterpretation, <strong>of</strong> any results obtained from this s<strong>of</strong>tware, or for damages resulting from the use<br />

<strong>of</strong> this s<strong>of</strong>tware.<br />

IV. Governing Law<br />

This license agreement shall be construed, interpreted, and governed by the laws <strong>of</strong> the<br />

Province <strong>of</strong> Ontario, Canada.<br />

2

<strong>POLYMIN</strong> 2005<br />

TABLE OF CONTENTS<br />

page<br />

LIST OF FIGURES....................................................................................................................... 4<br />

LIST OF TABLES ......................................................................................................................... 4<br />

1. INTRODUCTION...................................................................................................................... 5<br />

1.1 Overview............................................................................................................................................5<br />

1.2 Capabilities, Assumptions and Limitations....................................................................................6<br />

1.3 S<strong>of</strong>tware Support..............................................................................................................................7<br />

2. THEORETICAL DEVELOPMENT ......................................................................................... 8<br />

2.1 Background .......................................................................................................................................8<br />

2.2 Mass Transport.................................................................................................................................8<br />

2.3 Primary Variables and their Dimensions .....................................................................................19<br />

2.4 Geochemical Database ...................................................................................................................20<br />

2.5 Input/Output File Definition..........................................................................................................21<br />

3. DESIGNING A MODEL ......................................................................................................... 22<br />

Grid Definition & Boundary Conditions.......................................................................................................22<br />

4. SAMPLE DATA SET............................................................................................................... 25<br />

Input options .................................................................................................................................................27<br />

Grid parameters.............................................................................................................................................28<br />

Data Block 1..................................................................................................................................................29<br />

Print output <strong>of</strong> components ...........................................................................................................................30<br />

Tolerance and relative values........................................................................................................................31<br />

Oxidation Parameters ....................................................................................................................................31<br />

Breakthrough points......................................................................................................................................32<br />

Time Step Data..............................................................................................................................................32<br />

Background aqueous chemistry ....................................................................................................................33<br />

Background solid chemistry..........................................................................................................................34<br />

5. STEP BY STEP INSTRUCTIONS.......................................................................................... 37<br />

6. TIPS AND TECHNIQUES ..................................................................................................... 39<br />

7. PROBLEM DIAGNOSIS AND SOLUTIONS........................................................................ 40<br />

8. REFERENCES ........................................................................................................................ 41<br />

3

<strong>POLYMIN</strong> 2005<br />

LIST OF FIGURES<br />

Figure<br />

page<br />

1. Conceptual domain for <strong>POLYMIN</strong> model applications ................................ 6<br />

2. Simplified <strong>POLYMIN</strong> flowchart .............................................. 16<br />

3. Typical boundary condition configuration. .............................................. 24<br />

4. Typical node and element numbering convention .............................................................. 24<br />

LIST OF TABLES<br />

Table<br />

page<br />

1. Capabilities, assumptions and limitations ................................................... 5<br />

2. Input/Output file definition ........................................................ 21<br />

3. Boundary condition identification ............................................................... 23<br />

4. Problem Diagnosis ...................................................................... 40<br />

4

<strong>POLYMIN</strong> 2005<br />

1. INTRODUCTION<br />

1.1 Overview<br />

<strong>POLYMIN</strong> is an advanced numerical model for solving reactive mass transport problems. The<br />

model can be used to solve one or two-dimensional mass transport problems within a variety <strong>of</strong><br />

hydrogeological systems. <strong>POLYMIN</strong> was originally developed as a research tool to study the<br />

behaviour <strong>of</strong> acid mine drainage or reactive contaminant plumes within porous media (see Figure 1).<br />

recharge<br />

waste lagoon<br />

monitor well<br />

flow<br />

2000 ppm Cl<br />

shrinking core model<br />

R<br />

r c<br />

C L<br />

recharge<br />

q=0.365m/yr<br />

O 2<br />

Diffusion<br />

sulphurcontining<br />

grain<br />

sand (SBL)<br />

gravel (GRV)<br />

10m<br />

free drainage<br />

Figure 1. Conceptual model domains for the <strong>POLYMIN</strong> model; top: contaminant plume, bottom:<br />

oxidizing rock waste pile (after Molson et al., 2005).<br />

<strong>POLYMIN</strong> will run on any computer although it is recommended that the model be run on at least a<br />

Pentium III/500 MHz machine. The memory requirements depend on your application. 2D<br />

simulations may require on the order <strong>of</strong> 64-128 Mbytes.<br />

5

<strong>POLYMIN</strong> 2005<br />

<strong>POLYMIN</strong> has been developed with some <strong>of</strong> the most efficient and powerful numerical algorithms<br />

available. Finite elements are employed for high accuracy and to allow deformable domain<br />

geometry, and the Leismann time-weighting scheme (Leismann and Frind, 1989) has been<br />

incorporated to maintain matrix symmetry which saves memory and execution time. The model<br />

includes one <strong>of</strong> the most efficient preconditioned conjugate gradient solvers available to solve the<br />

matrix equations.<br />

Custom versions, and executables are available to suit individual needs. Please contact the authors<br />

for available updates. A more recent model, BIONAPL/3D, can also simulate density flow along<br />

with multiple-component NAPL dissolution and reactive transport (Molson, 2001). The <strong>POLYMIN</strong><br />

model has most recently been applied by Molson et al. (2005) to waste rock piles, based on flow<br />

systems developed by Fala et al. (2005).<br />

1.2 Capabilities, Assumptions and Limitations<br />

The capabilities <strong>of</strong> <strong>POLYMIN</strong>, and its major assumptions and limitations are summarized in Table<br />

1.<br />

Table 1. Summary <strong>of</strong> the capabilities, assumptions and limitations <strong>of</strong> <strong>POLYMIN</strong>.<br />

Capabilities<br />

- 2D or 1D domains.<br />

- fully coupled oxygen diffusion, geochemical<br />

speciation and advective-dispersive mass<br />

transport.<br />

- domain can be heterogeneous and<br />

anisotropic.<br />

- deformable elements can conform to<br />

complex geometry.<br />

- versatile boundary condition options.<br />

- computes concentration breakthrough data<br />

(conc. vs time) at selected points.<br />

Assumptions and Limitations<br />

- non-deforming, isothermal aquifer<br />

- fluid is incompressible.<br />

- chemical reactions are assumed at equilibrium<br />

- flow system read separately<br />

- non-fractured or equivalent porous media (2)<br />

(2)<br />

Research versions also available with 1D and 2D fractures (Yang et al, 1996a,b).<br />

6

<strong>POLYMIN</strong> 2005<br />

1.3 S<strong>of</strong>tware Support<br />

If you have questions or comments concerning <strong>POLYMIN</strong>, or this manual, please contact the<br />

authors at the following address:<br />

John Molson / Dr. E.O. Frind<br />

Department <strong>of</strong> Earth Sciences<br />

<strong>University</strong> <strong>of</strong> <strong>Waterloo</strong><br />

<strong>Waterloo</strong>, Ontario, Canada<br />

N2L 3G1<br />

phone: (519) 888-4567 x3959<br />

fax: (519) 746-7484<br />

email: molson@uwaterloo.ca<br />

www: http://sciborg.uwaterloo.ca/~molson/<br />

Montreal address:<br />

J.W. Molson Ph.D. P.Eng.<br />

Dept. <strong>of</strong> Civil, Geological and Mining Engineering<br />

Ecole Polytechnique, Montreal<br />

john.molson@polymtl.ca<br />

http://www.enviro-geremi.polymtl.ca/<br />

Office: (514) 340-4711 x5189<br />

Home: (514) 935-0610<br />

Adjunct Pr<strong>of</strong>essor, <strong>University</strong> <strong>of</strong> <strong>Waterloo</strong><br />

molson@uwaterloo.ca<br />

http://sciborg.uwaterloo.ca/~molson/<br />

John.Molson@polymtl.ca<br />

We would also appreciate hearing about your particular model application and suggestions for<br />

improvement.<br />

7

<strong>POLYMIN</strong> 2005<br />

2. THEORETICAL DEVELOPMENT<br />

2.1 Background<br />

<strong>POLYMIN</strong> is based on the solutions to the 2D advective-dispersive mass transport equation.<br />

The flow field must be generated by a separate program such as FLONET (Molson & Frind,<br />

2004), however other codes can be used as well, provided the grid is compatible. This version <strong>of</strong><br />

the <strong>POLYMIN</strong> model can read the flow system from either the 2D flow model HYDRUS<br />

(Simunek et al., 1999), or from the 2D saturated flow model FLONET (Molson & Frind, 2004).<br />

(see section 4 for a step-by-step list <strong>of</strong> how to run the code)<br />

2.2 Mass Transport<br />

Mass transport is governed by the advection-dispersion equation which includes a source/sink<br />

term for equilibrium reactions. The transport equation in <strong>POLYMIN</strong> for aqueous component k (k<br />

= 1, ..., N c , where N c is the number <strong>of</strong> components) is <strong>of</strong> the form:<br />

∂ θ w C<br />

∂ t<br />

k<br />

∂ ⎛<br />

= ⎜<br />

w D<br />

x<br />

θ<br />

∂ i ⎝<br />

ij<br />

∂ C<br />

∂ x<br />

k<br />

j<br />

⎞<br />

⎟<br />

⎠<br />

-<br />

∂<br />

∂ x<br />

i<br />

( q Ck) + R<br />

i<br />

k<br />

(1)<br />

where C k is the concentration <strong>of</strong> the k th component in the pore water [ML -3 ], q i is the i th<br />

component <strong>of</strong> the volumetric water flux [LT -1 ], D ij is the dispersion coefficient tensor [L 2 T -1 ],<br />

and R k is the source/sink term for the k th component resulting from geochemical equilibrium<br />

reactions [ML -3 T -1 ]. The components <strong>of</strong> the dispersion tensor, D ij , are given by:<br />

θ w Dij<br />

= αT<br />

|q| δ ij + ( α L -α<br />

T<br />

q<br />

j<br />

qi<br />

) + θ Dd<br />

τ δ ij<br />

|q|<br />

(2)<br />

where D d is the molecular diffusion coefficient in water [L 2 T -1 ], ⏐q⏐ is the absolute value <strong>of</strong> the<br />

Darcy fluid flux [LT -1 ], δ ij is the Kronecker delta function, α L is the longitudinal and α T the<br />

transverse dispersivity [L], and τ = θ 7/3 /θ s 2 is a tortuosity factor according to Millington and<br />

Quirk (1961). The tortuosity factor was incorporated into the transport equation to account for<br />

solute diffusion with a spatially variable water content.<br />

Changes to the solid phase due to precipitation-dissolution and sorption-desorption reactions are<br />

represented in <strong>POLYMIN</strong> by the mass conservation equation:<br />

∂ S<br />

∂t<br />

k<br />

= R<br />

S<br />

k<br />

(3)<br />

8

<strong>POLYMIN</strong> 2005<br />

where S k is the solid phase concentration <strong>of</strong> the k th solid component, [ML -3 ], and R k S represents<br />

the change in the k th solid component concentration [ML -3 T -1 ]. Further details are provided by<br />

Walter et al. (1994a).<br />

Oxygen Diffusion<br />

Assuming an immobile air phase (convection is neglected), oxygen transport through the<br />

unsaturated porous medium is governed by the 2D equation for oxygen diffusion, expressed as:<br />

θ<br />

eq<br />

2 2<br />

∂ [ O2 ]<br />

a<br />

⎛ ∂ [ O2 ]<br />

a ∂ [ O2<br />

]<br />

a<br />

⎞<br />

= D e ⎜ + - Q<br />

2 2 ⎟<br />

∂t ⎝ ∂ x ∂ z ⎠<br />

O 2<br />

(4)<br />

where θ eq (x,z,t) is the spatially and temporally-variable water phase corrected volumetric air<br />

content [-], D e (x,z,t) is the effective oxygen diffusion coefficient [L 2 T -1 ], and Q O2 (x,z,t) is the<br />

sink term for oxygen consumption due to sulphide mineral oxidation (M O2 /L 3 /T) (see below).<br />

The equivalent air content θ eq in Equation (4) is defined here as θ eq = θ a + Hθ w where θ a is the<br />

air-filled porosity and H is Henry’s Law coefficient for equilibrium oxygen partitioning between<br />

air and water (-). The oxygen diffusion coefficient D e is represented in <strong>POLYMIN</strong> by the Aachib<br />

et al. (2002) model:<br />

D<br />

e<br />

1 ⎡ p D<br />

a w pw<br />

= ⎢Daθ<br />

a<br />

+ θ<br />

w<br />

θ 2<br />

⎣ H<br />

s<br />

⎤<br />

⎥<br />

⎦<br />

(5)<br />

where D a and D w are the diffusion coefficients in air and water, respectively, and p a and p w are<br />

fitting coefficients; here p a = p w = 3.3 is assumed, as suggested by Aachib et al. (2002).<br />

The coefficient D e , representing diffusion within the air-filled porosity <strong>of</strong> the unsaturated spoil,<br />

can be represented using models presented by Elberling & Nicholson (1993), Millington &<br />

Quirk (1961), or Aachib et al. (2002).<br />

Sulphide Oxidation<br />

Acid mine drainage is controlled by the oxidation <strong>of</strong> sulphide minerals, mostly pyrite and<br />

pyrrhotite, within the waste rock. The oxidation <strong>of</strong> pyrite, for example, can be described in<br />

simplified form by the following stoichiometric equations (Wunderly et al, 1996):<br />

2+<br />

2- +<br />

Fe S 2 + H 2 O +7/2 O2<br />

⇒ Fe + 2 SO4<br />

+ 2 H<br />

9

<strong>POLYMIN</strong> 2005<br />

2+<br />

+ 3+<br />

Fe +1/4 O2<br />

+ H ⇒ Fe +1/2 H 2 O<br />

3+ 2- +<br />

Fe S 2 +1/2 H 2 O +15/4 O2<br />

⇒ Fe + 2 SO4<br />

+ H<br />

The rate <strong>of</strong> these oxidation reactions, however, is controlled by the availability <strong>of</strong> oxygen at, and<br />

within the mineral grains. A common approach for modeling this process, and that adopted here,<br />

is the shrinking core model (Levenspiel, 1972) which assumes the sulphide mineral is<br />

uniformally distributed within each spherical grain. Derivations for this model have been<br />

presented by Davis and Ritchie (1986; 1987), Wunderly et al. (1996), and Gerke et al. (1998),<br />

and are not repeated here.<br />

The shrinking core model provides the oxygen sink term Q o in equation (4), defined by<br />

3 ( 1 - θ ) ⎛ r ⎞ [ O 2 ]<br />

R ⎝ r ⎠ H<br />

c<br />

o<br />

= 2 2 ⎜<br />

R -<br />

⎟<br />

c<br />

Q D<br />

a<br />

(6)<br />

where D 2 is the effective diffusion coefficient incorporating the characteristic diffusion<br />

properties <strong>of</strong> both the water film and the oxidized shell <strong>of</strong> the pyrite particle, R is the average<br />

radius <strong>of</strong> the soil particles, r c is the average radius <strong>of</strong> the unreacted core, and [O 2 ] a is the oxygen<br />

concentration in the air phase in contact with the particle.<br />

From the computed change in the oxidized grain radius (r c ), and knowing the fraction <strong>of</strong> sulfide<br />

minerals in the grain f s , (M Su /M solids ), the bulk density ρ b [ML -3 ], and ε, the mass ratio <strong>of</strong> oxygen<br />

to sulphur consumed on the basis <strong>of</strong> the reaction stoichiometry, the mass <strong>of</strong> each oxidation<br />

product can be determined for each oxidation time step ∆t oxid (Gerke et al., 1998).<br />

Geochemical Equilibrium Equations<br />

The chemical equilibrium reactions are those provided in the geochemical equilibrium model<br />

MINTEQA2 (Felmy et al., 1983; Allison et al., 1990). MINTEQA2 was derived from combining<br />

the geochemical equilibrium model MINEQL (Westall et al., 1976) with the data base <strong>of</strong> the<br />

WATEQ2 model (Ball et al., 1979).<br />

The reactions considered are chemical speciation, acid-base reactions, mineral precipitationdissolution,<br />

oxidation-reduction, and adsorption. The chemical model uses the general<br />

transformation-<strong>of</strong>-the-bases mathematical approach to solve the chemical equilibrium problem<br />

for all <strong>of</strong> the chemical reaction types (Felmy et al., 1983). The ion-association equilibriumconstant<br />

approach is used to represent the geochemical reactions. The ion-association aqueous<br />

10

<strong>POLYMIN</strong> 2005<br />

model involves three separate constituents; the masses <strong>of</strong> aqueous species and complexes,<br />

equilibrium constants which relate these complexes in solution, and the individual ion-activity<br />

coefficients for each species. These constituents are related through a system <strong>of</strong> algebraic<br />

equations that solve for the individual ion activities in a solution, which are in turn used to<br />

predict chemical reaction equilibrium.<br />

Chemical Speciation, Acid-Base Reactions and Redox Reactions<br />

In a solution, there exists a set <strong>of</strong> chemical components and species. The set <strong>of</strong> chemical<br />

components is the minimum number <strong>of</strong> species that uniquely describe a solution and that is<br />

required to be reaction invariant (Mangold and Tsang, 1991). The component mass remains<br />

constant, regardless <strong>of</strong> the distribution between chemical species in both the aqueous and solid<br />

phases. This mass conservation principle yields a set <strong>of</strong> linear algebraic equations, with one<br />

equation for each component (Cederberg, 1985).<br />

The total component concentration T k (moles/1000g H 2 O) is the sum <strong>of</strong> the aqueous-phase<br />

concentration C k and the solid-phase concentration S k , <strong>of</strong> component k:<br />

T k = Ck<br />

+ S k<br />

(7)<br />

where<br />

C<br />

S<br />

k<br />

k<br />

naq<br />

alk<br />

∑ cl<br />

(8)<br />

l=1<br />

= k = 1, ... N<br />

=<br />

naq<br />

blk<br />

∑ s<br />

k = 1,...<br />

l<br />

N<br />

(9)<br />

l=1<br />

and where c l is the concentration <strong>of</strong> species l in the aqueous phase (moles/1000g H 2 0), s l is the<br />

concentration <strong>of</strong> species l in the solid phase (moles/1000g H 2 O), a lk is the stoichiometric<br />

coefficient <strong>of</strong> component k in species c l , b lk is the stoichiometric coefficient <strong>of</strong> component k in<br />

species s l , n aq is the number <strong>of</strong> species in the aqueous phase, and n s is the number <strong>of</strong> species in<br />

the solid phase.<br />

The total mass <strong>of</strong> each chemical component must be known to describe a solution. The<br />

distribution <strong>of</strong> the species included in the component concentrations is estimated by mass-action<br />

equations that form a set <strong>of</strong> nonlinear algebraic equations, with one equation for each chemical<br />

species. For the aqueous-phase species, these equations are:<br />

N c<br />

alk<br />

χ = K ∏ χ<br />

naq<br />

(10)<br />

l<br />

cl<br />

k=1<br />

k<br />

while for the solid-phase species, they are:<br />

l = 1,...<br />

11

<strong>POLYMIN</strong> 2005<br />

sl<br />

= K<br />

N<br />

c<br />

blk<br />

∏ χ k<br />

ns<br />

(11)<br />

sl<br />

k=1<br />

l = 1,...<br />

where K cl is the equilibrium formation constant for species c l , K sl is the equilibrium formation<br />

constant for species s l in the solid phase, χ k is the activity <strong>of</strong> component k (moles/1000g H 2 0),<br />

and χ l is the activity <strong>of</strong> species l (moles/1000g H 2 0).<br />

The stoichiometric mass-balance equations for the components are written in terms <strong>of</strong><br />

component concentrations, while the mass action equations are expressed in terms <strong>of</strong> activities.<br />

The activities, χ l , are related to concentrations, c l , through the individual ionic activity<br />

coefficients, γ l , using the approximation<br />

χ = cl<br />

(12)<br />

l<br />

γ l<br />

The activity coefficients are calculated using the WATEQ, extended Debye-Hückel or Davies<br />

equations (Felmy et al. 1983). The specific equation used is dependent on the availability <strong>of</strong><br />

specific solute parameters.<br />

These equations form a set <strong>of</strong> algebraic equations which are used in the ion-association model to<br />

solve for the individual ion activities given the total component concentrations in solution. The<br />

interrelationships between the species concentrations and activities and the ionic strength cannot<br />

be solved for explicitly but require an iterative solution. MINTEQ uses the Newton-Raphson<br />

iterative technique.<br />

Chemical reactions involving the hydrogen and hydroxide ion are simulated in the chemical<br />

model using the proton condition (Westall et al., 1976; Felmy et al., 1983; Allison et al., 1990).<br />

The proton condition, representing the total analytical component concentration <strong>of</strong> H + , is the<br />

primary variable used in the transport solution. The H + -value may theoretically be negative<br />

because it does not have the physical interpretation <strong>of</strong> a total mass <strong>of</strong> hydrogen but is the change<br />

in H + activity from the reference condition. Similarly, the total calculated mass <strong>of</strong> H 2 O can also<br />

be negative.<br />

Oxidation-reduction reactions are calculated with MINTEQ using the external redox couple<br />

approach. This approach requires that the initial distribution <strong>of</strong> the specified redox couples is<br />

known before the chemical equilibrium problem can be solved. This distribution can be<br />

determined from the initial solution component chemistry and the solution pe. MINTEQ permits<br />

selection <strong>of</strong> redox couples that are set in equilibrium with the solution pe. Other electroactive<br />

species may be considered independent <strong>of</strong> the pe. Thus, the multivalent species can be reacted<br />

with their respective solid mineral phases without requiring interactions with other multivalent<br />

species. In the present transport model, the total dissolved concentration <strong>of</strong> each redox state is<br />

transported separately, and the new solution pe is calculated using the activities calculated for<br />

the specified redox couples at the new location. The electron activity, therefore, is not transported<br />

independently.<br />

Sorption<br />

12

<strong>POLYMIN</strong> 2005<br />

The three basic mathematical forms <strong>of</strong> sorption reaction models, namely isothermal, massaction/ion-exchange,<br />

and surface complexation/electrostatic models, have been incorporated into<br />

MINTEQ (Allison et al., 1990). The isothermal models included are the activity K d adsorption<br />

model, the activity Langmuir adsorption model, and the Freundlich model. The electrostatic<br />

adsorption models available are the constant-capacitance model, the diffuse-layer model, and the<br />

triple-layer model. To date only the ion-exchange model has been verified in the combined<br />

mass-transport chemical-equilibrium model.<br />

Ion-exchange sorption reactions are simulated using the Gaines and Thomas model for ion<br />

exchange (Allison et al., 1990). This model assumes that the surface site is initially occupied by<br />

an exchangeable ion that is released into solution during the exchange process, that the charge on<br />

the surface <strong>of</strong> the solid remains constant, and that the number <strong>of</strong> surface sites available for<br />

sorption, expressed as the cation exchange capacity (C.E.C.), is fixed. The ion-exchange<br />

reaction is written as:<br />

vA<br />

vB<br />

B + AB(ad) ⇔ B A(ad) + A<br />

(13)<br />

v A v v v<br />

B<br />

where v A and v B are the change on components A and B respectively, A(ad) and B(ad) are the<br />

adsorbed mass <strong>of</strong> components A and B. The mass action equation for the above expression is<br />

K<br />

AB<br />

⎛ A(ad)<br />

= ⎜<br />

vA<br />

⎝ [A ]<br />

⎞<br />

⎟<br />

⎠<br />

vB<br />

vB<br />

⎛ [B ]<br />

⎜<br />

⎝ B(ad)<br />

⎞<br />

⎟<br />

⎠<br />

vA<br />

(14)<br />

where the square brackets represent solution activity, and K AB is the selectivity coefficient <strong>of</strong><br />

species A with respect to species B.<br />

Mineral Precipitation and Dissolution<br />

Mass-action equations, which relate ion activities and a solid specific solubility product, describe<br />

mineral precipitation and dissolution reactions. These reactions can be written as follows (Walter<br />

et al., 1994a):<br />

A a<br />

B b(s)<br />

⇔ aA (aq)<br />

+ bB (aq)<br />

(15)<br />

The subscripts (s) and (aq) refer to solid and aqueous phases respectively. The thermodynamic<br />

solubility product for a given solid is described by:<br />

K<br />

sp<br />

a<br />

A B<br />

= [ ] [ ]<br />

[ AB]<br />

a<br />

b<br />

b<br />

(16)<br />

where K sp<br />

is the solubility product for the solid.<br />

13

<strong>POLYMIN</strong> 2005<br />

⎛ I.A.P. ⎞<br />

S.I.= log ⎜ ⎟<br />

(17)<br />

⎝ K sp ⎠<br />

If the saturation index is greater than zero, representing supersaturation, there is a tendency for<br />

the mineral to precipitate. When the S.I. is zero, the mineral and the solution are in equilibrium.<br />

If the S.I. is less than zero the mineral is undersaturated, and the tendency is for the mineral to<br />

dissolve. In real geochemical situations, minerals which are super-saturated or undersaturated<br />

may not precipitate or dissolve due to kinetic limitations. These limitations are not addressed in<br />

the current model.<br />

The solid phases incorporated in the data base may be designated as one <strong>of</strong> three types:<br />

1. A solid which is in infinite supply (reacted to equilibrium),<br />

2. A solid with a finite supply where the initial amount <strong>of</strong> solid must be specified (moles <strong>of</strong><br />

solid per litre <strong>of</strong> pore water), and<br />

3. A dissolved solid which may precipitate if it becomes supersaturated.<br />

Within an individual chemical simulation, the designation may switch between the last two solid<br />

types. This occurs when a finite-mass solid is completely dissolved, becoming a dissolved solid.<br />

The solid type change is accounted for in the combined chemical-transport model to allow<br />

complete mineral dissolution at an individual node within the spatial domain at any point in time.<br />

Switching solid types is well suited to the coupled geochemical-reaction, solute-transport<br />

problems where sharp changes in solid-phase concentrations may be observed.<br />

The determination <strong>of</strong> solids that are thermodynamically stable from the array <strong>of</strong> solids allowed to<br />

precipitate or dissolve is calculated by treating the S.I. (eq. 14) as an inequality. Each solid is<br />

ranked for its tendency to precipitate by dividing the S.I. by the number <strong>of</strong> ions in the solid<br />

formation reaction. After ranking, the solid with the highest value is allowed to precipitate. All<br />

<strong>of</strong> the remaining solids are then ranked again and sequentially precipitated or dissolved until all<br />

<strong>of</strong> the solids considered are undersaturated. A provision is made to insure that if the mass <strong>of</strong> the<br />

previously precipitated solid becomes negative, that solid will redissolve and the solution<br />

procedure will continue.<br />

Limitations <strong>of</strong> Geochemical Model<br />

The ion-association model used in MINTEQ to account from deviations from chemical ideality<br />

is valid only for low ionic strengths <strong>of</strong> 0 - 0.5. The previously-described chemical reactions are<br />

all based on the L.E.A. This assumption means that the reactions modelled are sufficiently rapid<br />

relative to the contaminant travel times through the reacting medium, or that a reaction will go to<br />

equilibrium before a component is transported to another point in space. On a purely<br />

geochemical basis, the majority <strong>of</strong> the reactions considered in this study adhere to the L.E.A.,<br />

with the possible exception <strong>of</strong> some solid and redox reactions which are <strong>of</strong>ten rate-dependent.<br />

The field results presented by Morin (1983) suggest that both the use <strong>of</strong> the ion-association<br />

model and the L.E.A. are reasonable at the Nordic Site.<br />

14

<strong>POLYMIN</strong> 2005<br />

Solution Strategy<br />

<strong>POLYMIN</strong> uses two-step sequential physical-chemical coupling (Walter et al, 1994a) to solve<br />

the reactive transport equations. In this approach, the transport equation is split into a physical<br />

step, and a chemical step:<br />

Step 1 (physical)<br />

n+1 phys<br />

equil<br />

( C k - Ck<br />

) δ(t + ∆t)= Rk<br />

δ(t + ∆t)<br />

k = 1,...,N c<br />

(18)<br />

Step 2 (chemical)<br />

( C<br />

- C<br />

∆t<br />

phys<br />

k<br />

n<br />

k<br />

)<br />

= L( C<br />

k<br />

)<br />

n+1/2<br />

k = 1,...,N<br />

c<br />

(19)<br />

where C k phys is the concentration <strong>of</strong> component k at the end <strong>of</strong> the physical step, L represents the<br />

transport operator, δ is the Dirac delta, and n, n+1/2, n+1 relate to the beginning, midpoint, and<br />

end <strong>of</strong> the time step ∆t, respectively.<br />

The transport model is coupled to the oxygen diffusion and pyrite oxidation modules following<br />

the sequence shown in Figure 1. The simulation over a transport time step ∆t begins with an<br />

iterative solution to the oxygen diffusion and reactive core equations which liberates H + , SO 4 2+ ,<br />

Fe 2+ and Fe 3+ . Because <strong>of</strong> the nonlinearity for these coupled reactions, the solution is performed<br />

over a smaller sub-time step ∆t oxid , typically 1/10 th - 1/50 th <strong>of</strong> the transport time step ∆t. These<br />

calculations are very rapid and do not significantly affect the total execution time. The reactive<br />

products are accumulated over each sub-time interval and are added to the existing nodal<br />

concentrations just before the chemical equilibration step.<br />

Following convergence <strong>of</strong> the diffusion and reactive core equations, a second iterative sequence<br />

begins for the physical/chemical steps. The accumulated oxidation products are added to C k<br />

phys<br />

following the transport step. The equilibrium chemical step is completed independently for each<br />

grid node. An option is available for automatically bypassing this step if the changes in<br />

concentration from the transport and oxidation steps are below a threshold. Typically, the<br />

transport and chemical steps account for approximately 1/3 rd and 2/3 rd <strong>of</strong> the total execution<br />

time, respectively. Execution times for a 50-year, 13,657-node simulation using a Pentium IV,<br />

3.3Ghz machine were on the order <strong>of</strong> 40 hours.<br />

15

<strong>POLYMIN</strong> 2005<br />

Transport/Reaction time step ∆t<br />

Oxidation time step (∆t oxid =∆t/20)<br />

Solve oxygen diffusion (O 2<br />

)<br />

Solve core oxidation (r c<br />

)<br />

[O 2<br />

] Converged?<br />

no<br />

yes<br />

Accumulate reaction products (SO 4 2+ , Fe 2+ , Fe 3+ , H + )<br />

Solve physical transport step<br />

Solve chemical step<br />

Components Converged?<br />

no<br />

yes<br />

Figure 2. Flowchart <strong>of</strong> the Polymin model.<br />

16

<strong>POLYMIN</strong> 2005<br />

Discretization Criteria<br />

Accuracy and stability criteria for the numerical solution <strong>of</strong> multi-component reactive<br />

transport problems are not yet well defined. The basic requirements, which apply to linear<br />

transport <strong>of</strong> nonreactive solutes with linear retardation are the Peclet and Courant criteria (Daus<br />

et al., 1985):<br />

Pe=<br />

Co=<br />

v ∆L<br />

≤ 2<br />

D<br />

v ∆t<br />

≤<br />

∆x<br />

Pe<br />

2<br />

(20)<br />

(21)<br />

where v and D are the velocity and dispersion coefficient in the principal (flow) direction,<br />

respectively, ∆L is the effective element length in the flow direction, and ∆t is the time step. In<br />

order to control numerical dispersion and oscillations, eq. (18) is used to constrain the spatial<br />

discretization, while eq. (19) is used to constrain the time step.<br />

In nonreactive transport applications, the Peclet and Courant constraints are <strong>of</strong>ten exceeded by a<br />

factor <strong>of</strong> 2 to 4 since the resulting small oscillations are generally harmless. In reactive<br />

transport, on the other hand, numerical oscillations are more problematic since negative concentrations<br />

can be fatal for the chemical equilibrium model. Some authors eliminate oscillations at<br />

the cost <strong>of</strong> smearing by using upwinding; we do not recommend this procedure because the<br />

smearing causes fictitious reactions ahead <strong>of</strong> the actual concentration front. Instead, we seek to<br />

maintain second-order accuracy (or equivalent) in time through time-centred weighting throughout.<br />

Numerical oscillations are controlled by satisfying criteria (19) and (20) everywhere.<br />

For reactive transport, constraints arise out <strong>of</strong> the basic requirement that the mass reacted per<br />

time step should be in some reasonable relationship to the mass present. In the case <strong>of</strong> decay or<br />

biodegradation, this requirement leads to a relationship between the time step and the decay<br />

coefficient (Luckner and Schestakov, 1991). For general reactive transport, a useful quantity is<br />

the elemental Damköhler number, defined by Zysset and Stauffer (1992) as the ratio <strong>of</strong> the<br />

advective time t a = ∆L/v to the reactive time t r = C k B /S k , with C k B being some representative<br />

concentration such as the boundary input or the background concentration <strong>of</strong> k, and S k being the<br />

reaction rate.<br />

In the case <strong>of</strong> equilibrium reactions, the reaction rate has no theoretical meaning. We therefore<br />

define the reactive time as:<br />

t<br />

r<br />

=<br />

t+ ∆t<br />

∫<br />

t<br />

t+ ∆t<br />

R<br />

∫ C k dt<br />

t<br />

=<br />

k δ(t+<br />

∆t)<br />

C<br />

k<br />

R<br />

∆t<br />

k<br />

(22)<br />

where C k represents the elemental average concentration over the time step. The Damköhler<br />

17

<strong>POLYMIN</strong> 2005<br />

number is then defined as:<br />

ta<br />

Dak<br />

=<br />

tr<br />

∆L<br />

Rk<br />

=<br />

v C k<br />

∆t<br />

(23)<br />

The product <strong>of</strong> the Courant number and the Damköhler number is used by Zysset and<br />

Stauffer (1992) to express the relationship between the reaction rate and the characteristic<br />

concentration <strong>of</strong> a component. In the case <strong>of</strong> equilibrium reactions, the equivalent quantity is the<br />

reactive mass ratio ρ k , which can be defined relative to the characteristic (background or input)<br />

concentration C k B , as:<br />

B<br />

B<br />

= Co =<br />

Rk<br />

ρ<br />

k<br />

• Dak<br />

(24)<br />

B<br />

C k<br />

Alternatively, the reactive mass ratio can be defined relative to the actual point concentration<br />

at the end <strong>of</strong> the physical step C k phys , as:<br />

C<br />

=<br />

Rk<br />

ρ<br />

k<br />

= Co • Dak<br />

(25)<br />

phys<br />

Ck<br />

Since the reactive mass depends on the time step ∆t, either <strong>of</strong> these relationships can be<br />

used to define a time step constraint. The value <strong>of</strong> such a constraint will depend on the nature <strong>of</strong><br />

the chemical reactions as well as the characteristics <strong>of</strong> the particular chemical reaction routine<br />

used. For fast reversible reactions, Zysset and Stauffer (1992) recommend ρ k B ≤ 0.01. The<br />

MINTEQ-based model generally reached much higher values (see applications below), for the<br />

scenarios investigated.<br />

The reactive mass ratio ρ k C defined by eq. (23) represents the mass generated or consumed<br />

relative to the mass present at the end <strong>of</strong> the physical step. Since the mass consumed (R k ≤ 0)<br />

cannot exceed the mass present, ρ k C ≥ - 1. Upper limits on ρ k B and ρ k C have not yet been defined;<br />

it is to be expected that any such limits will depend on the ability <strong>of</strong> the geochemical model to<br />

equilibrate a perturbed system. By monitoring the performance <strong>of</strong> the model for various<br />

scenarios under different chemical environments, we expect eventually to be able to define<br />

appropriate constraints.<br />

18

<strong>POLYMIN</strong> 2005<br />

2.3 Primary Variables and their Dimensions<br />

The following variables must be dimensioned large enough to accommodate the chosen grid size.<br />

These values are set in the PARAMETER statement within the main program.<br />

Array dimension limits: (see parm.inc, parmt.inc, mintran.inc, minteq.inc)<br />

maxne ....<br />

maxnn ....<br />

maxn ....<br />

maxna ....<br />

laa ....<br />

Nxdim …<br />

Nydim …<br />

Nrdim …<br />

maxbt ....<br />

maxtim ....<br />

maxpt …<br />

Maximum number <strong>of</strong> elements in the transport grid.<br />

Maximum number <strong>of</strong> nodes in the transport grid.<br />

Maximum number <strong>of</strong> degrees <strong>of</strong> freedom (= maxnn - # <strong>of</strong> fixed nodes).<br />

Total number <strong>of</strong> non-zero matrix entries in condensed matrix.<br />

(As a conservative approximation, use maxna = 14 * maxn).<br />

PCG solver matrix dimension.<br />

(As a conservative approximation, use laa = 3*maxn+maxna).<br />

maximum number <strong>of</strong> components<br />

maximum number <strong>of</strong> aqueous species<br />

maximum number <strong>of</strong> solid species<br />

Maximum number <strong>of</strong> "wells" at which breakthrough curves are generated<br />

Maximum number <strong>of</strong> time steps<br />

maximum number <strong>of</strong> print times<br />

Note these values all represent maximum limits, they can be equal to, or greater than, the actual<br />

number required.<br />

A conservative estimate for maxna is 14 x maxn, and since this parameter reserves memory for one<br />

<strong>of</strong> the largest real arrays, it should be minimized if available computer RAM is limited. <strong>POLYMIN</strong><br />

computes the minimum vector length (maxna) required by the flow and transport problems and<br />

writes this information to the listing file (look for "vector length"). For more efficient memory use,<br />

these values can be substituted into the PARAMETER statement. To do this, the model must first be<br />

run using an initial estimate for maxna (and hence laa), at least until the correct vector lengths are<br />

computed. The minimum vector length and new value for laa is then entered into the program,<br />

which is then recompiled and rerun for the full simulation. The code will detect if the given array<br />

limits are too small, in which case the execution will terminate with an error message.<br />

19

<strong>POLYMIN</strong> 2005<br />

Other important variables:<br />

nn<br />

ne<br />

x,y,z<br />

vx,vy,vz<br />

u0,u1,u2<br />

in<br />

........... total number <strong>of</strong> nodes in the finite element grid<br />

........... total number <strong>of</strong> elements in finite element grid<br />

........... nodal grid coordinates<br />

........... elemental average linear groundwater flow velocities<br />

........... nodal concentration arrays (at last time step, most recent iteration, and new<br />

solution respectively)<br />

........... element incidence array<br />

2.4 Geochemical Database<br />

The database files used by <strong>POLYMIN</strong> and their analogous MINTEQA2 files are:<br />

<strong>POLYMIN</strong><br />

alk.dbm<br />

analy.dbm<br />

error.dbm<br />

compcp.dbm<br />

type6cp.dbm<br />

thermcp.dbm<br />

MINTEQA2<br />

alk.dbs<br />

analyt.dbs<br />

error.dbs<br />

comp.dbs<br />

type6.dbs<br />

thermo.dbs<br />

Redox and gas reactions can be included in type6cp.dbm and thermcp.dbm database files<br />

within MINTOX and thus do not have their own database files. Modifications to these database<br />

files can be made relatively easily. They are in ascii format and the format/unformat routine<br />

necessary when modifying MINTEQA2 database files is not needed.<br />

To add a component to the databases edit the compcp.dbm file and insert the new<br />

component in the same format as in the comp.dbs MINTEQA2 file. To add reactions, add the<br />

reaction to both the type6cp.dbm and the thermcp.dbm files in the same format as the reaction<br />

occurs in the MINTEQA2 database files. The <strong>POLYMIN</strong> program does not need to be<br />

recompiled when changes are made to the database files.<br />

20

<strong>POLYMIN</strong> 2005<br />

2.5 Input/Output File Definition<br />

Table 2. Input/Output files used in <strong>POLYMIN</strong>.<br />

Unit # Filename: I/O Contents:<br />

5 polymin.dat I primary input data<br />

5 Polymin.in I name <strong>of</strong> input data file<br />

16 Polymin0.gen O Echoes the input data, prints info while running<br />

various Polymino.aq_ O 2D concentration data for all aqueous components<br />

various Polymino.so_ O 2D concentration data for all solid components<br />

various Brkaq_.out O Breakthrough data (time, concentration) - aqueous<br />

various Brks_.out O Breakthrough data (time, concentration) - aqueous<br />

88 Debug.out O Debug information<br />

2 Thermcp.dbm I Thermodynamic database<br />

3 Compcp.dbm I database<br />

4 Type6cp.dbm I database<br />

10 Alk.dbm I database<br />

7 Analy.dbm I database<br />

13 Error.dbm I database<br />

99 Bckgrndpoly,min I Background concentration data<br />

100 Meshtria.txt I Finite element triangular mesh coordinates, incidences<br />

110 th.txt I Water content<br />

120 Bdy.txt I Boundary nodes<br />

99 Nodeprop.txt I Initial nodal properties (grain radius, porosity, sulphur fraction)<br />

99 v.txt I Element velocities<br />

50 Polymin.ur1 O 2D plotting file for Tecplot (x,z,c k ) – aqueous components<br />

51 Polymin.ur2 O 2D plotting file for Tecplot (x,z,c k ) – solid components<br />

21

<strong>POLYMIN</strong> 2005<br />

3. DESIGNING A MODEL<br />

Grid Definition & Boundary Conditions<br />

<strong>POLYMIN</strong> currently supports a 1D or 2D domain discretized using triangular elements. With<br />

triangular elements, the grid can be unstructured, the connectivity (incidence) information is<br />

provided in the meshtria.txt file.<br />

The grid is generated either with the Flonet (Fnpcg) model, or by Hydrus. In either case, the grid is<br />

imported into <strong>POLYMIN</strong> using the meshtria.txt file.<br />

The element incidence array, which defines the global node numbers connected to each element, is<br />

stored in the array in(l,i) where l is the global element number, and i (=1,2,3) is the local element<br />

node number.<br />

Two examples are provided here to clarify the grid generation procedure. Note these examples are<br />

for demonstration purposes only, and would not be <strong>of</strong> sufficient resolution for a practical application<br />

since the Peclet and Courant criteria would be violated under most situations.<br />

Transport boundary conditions can be 1 st , 2 nd or 3 rd type (Table 3, Fig. 3.). The default is 2 nd type,<br />

zero-gradient. The bdy.txt file is divided into 2 sections: top and bottom boundary nodes. Currently,<br />

the model is restricted to a fixed oxygen concentration across the top, and a zero-gradient oxygen<br />

boundary at the bottom (the O2 conc. Can also be fixed to zero across the bottom boundary nodes<br />

using lo2fix=.true.. For the aqueous components, the top boundary nodes can be either first or thirdtype,<br />

depending on the value <strong>of</strong> kcauchy.<br />

The grid numbering is shown in Fig. 4 (for the case <strong>of</strong> a rectangular grid subdivided into triangles, as<br />

created by FLONET).<br />

22

<strong>POLYMIN</strong> 2005<br />

Table 3.<br />

Summary <strong>of</strong> transport boundary conditions available in <strong>POLYMIN</strong>.<br />

Boundary<br />

Type<br />

Definition<br />

First / Dirichlet c = c 0<br />

Fixed concentration boundary (e.g. a large, wellmixed<br />

source)<br />

Second /<br />

Neumann<br />

∂c = 0<br />

∂n<br />

Zero-concentration gradient (e.g. outflow or<br />

impermeable boundary).<br />

Third / Cauchy q0<br />

0 ∂c<br />

= vc - D<br />

θc<br />

∂ x i<br />

Dispersive flux boundary<br />

(e.g. source with known influx q 0 and<br />

concentration c 0 ).<br />

23

<strong>POLYMIN</strong> 2005<br />

C=1 0<br />

C=0<br />

or<br />

dc/dx=0<br />

C=0 0<br />

dc/dx=0<br />

Dc/dz=0<br />

Z<br />

X<br />

Figure 3. Typical boundary condition configuration.<br />

4<br />

8<br />

12<br />

3<br />

2<br />

1<br />

18<br />

17<br />

2<br />

1<br />

3<br />

4<br />

16<br />

1<br />

1<br />

Element number<br />

Node number<br />

Figure 4. Typical node and element numbering convention for rectangular-based triangle grid.<br />

24

<strong>POLYMIN</strong> 2005<br />

4. SAMPLE DATA SET<br />

The example below is used to illustrate the format <strong>of</strong> the input files polymin.dat and<br />

bckgrndpoly.min. The example is a source <strong>of</strong> low pH water at the watertable <strong>of</strong> an unconfined<br />

aquifer.<br />

We begin with the data file for the FLONET model, which is explained further in the FLONET<br />

manual. The polymin.dat file is explained line-by-line below.<br />

FLONET model datafile:<br />

(refer to Molson & Frind (2004) for the FLONET User Guide.<br />

FLONET: HEAD / STREAM FUNCTION MODEL:<br />

FLOW.DATA - SAMPLE DATA FILE -<br />

November, 2000<br />

0 0 -999. ;SSINK<br />

1 1 0 0 1 0 ;kp,kv,kg,kread,ksolv,khk<br />

101 21 200. 10. 1 1 ;NX,NY,XL,YL,NGX,NGY<br />

0 20 0.01 0. ;maxit,nwtl,tol,datum<br />

0 ;WATERTABLE CODE(KW)<br />

1. 0.0 .00 0.0 -0.05 ;watertable shape<br />

1 1 999 1 10.7 ;BOUNDARY CONDITIONS - left side<br />

2 1 999 0 1.000e-8 ;boundary conditions - top<br />

3 1 999 1 10.0 ;boundary conditions - right side<br />

4 1 999 0 0. ;boundary conditions - bottom<br />

-1 ;END BOUNDARY CONDITIONS<br />

-1 ;END INTERNAL DIR NODES<br />

1 4000 0.5e-4 0.5e-4 0.0 0.35 -1 ;hydraulic K triangle elements!<br />

100. 150. 2. 5. 1.e-3 1.e-3 0. .35 -1 ;high-K lense<br />

0 0 0 0 0.e-4 0.e-4 0. 0.35 -1 ;indexed<br />

25

<strong>POLYMIN</strong> 2005<br />

Sample <strong>POLYMIN</strong> Input Data File (polymin.dat)<br />

Poly triangle version<br />

1.0 0.5 0.0 ;WP,WA,WB,Leissman terms<br />

0 50.0 0 0 1 0 0 ;KMAS,PTIME,KTS,kiter,kbypass,kint,kdim=1 axisymmetric<br />

0 7 2 0 0 ;KPRT,NPRT,LPRT,N1,N2<br />

0.1 0.5 1. 5. 10. 20. 50. ;(PRNTT(I),I=1,NPRT)<br />

200 20 2 9 ;NEX,NEZ,NVTYP,NGTYP<br />

40. 50. 1000. ;XL,ZL,CONF<br />

0.06 0.35 10. 1836. .0003 0.9 ;core: fs2i,por2i,temp2i,rhob2i,ox1i,uradius1i<br />

0 0 0 ;IS1,IS2,NCHS<br />

0. 0. false ;vx,vz,ln<strong>of</strong>lx(t: zero water velocity)<br />

0.5 0.05 0.005046 ;Al,At,DD<br />

10.0 0.0 14 8 0 ;TEMP,FIONS,NNN,NR,NAS<br />

0 0 3 0 4 0 0 0 0 0 0 ;IFL(11)<br />

0 0 0 ;IADS,NUMADS,IABG<br />

0 ;ntsn<br />

1 1 2 2 3 3 4 4 5 5 6 6 7 0 0 0 ;KPLT(I),I=1,NNN<br />

0 1 2 3 4 5 6 7 0 0 0 0 ;KPLTS(I),I=1,NR<br />

1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 0 ;KPNT(I),I=1,NNN<br />

1 1 1 1 1 1 1 1 1 1 1 0 ;KPNTS(I),I=1,NR<br />

2.000E-03 1.375E-02 ;CA TOLERANCE AND RELATIVE VALUES<br />

2.000E-03 2.490E-02 ;MG FROM NICKEL3<br />

2.000E-03 1.093E-02 ;NA "<br />

2.000E-03 5.140E-03 ;K "<br />

2.000E-03 4.252E-04 ;CL "<br />

2.000E-03 1.380E-02 ;CO3 "<br />

2.000E-03 3.390E-02 ;SO4 "<br />

2.000e-03 1.000e-06<br />

;MN<br />

2.000E-03 2.468E-05 ;FE2 "<br />

2.000E-03 1.249e-04 ;FE3 "<br />

2.000e-03 1.000e-04 ;h4sio4 new 03/09<br />

2.000E-03 5.711E-03 ;AL new 03/09<br />

2.000E-03 1.309E-02 ;H "<br />

2.000E-03 1.000E+00 ;E "<br />

t f 2<br />

;loxy(t=oxidation), ldonly(t=diff.only), 2=Aachib<br />

f<br />

;lo2fix(t=o2-conc,bottom=0)<br />

0.050 50 0.001 30 1.e-6 0.265 ;gradius,no2step,oxtol,maxo2it,d2,o2atm<br />

4970 5746 4993 3902 2948 ;breakthrough node numbers<br />

5032 5903 3255 1377 5280 ; "<br />

0.0 5.0 .005 5 50 -1 ;t0,t1,dt,maxit(trans,chem),kprint<br />

0.265 ;O2 atm conc.<br />

26

<strong>POLYMIN</strong> 2005<br />

Input options<br />

1.0 0.5 0.0 ;WP,WA,WB,Leissman terms<br />

0 50.0 0 0 1 0 0 ;KMAS,PTIME,KTS,kiter,kbypass,kint,kdim<br />

0 7 2 0 0 ;KPRT,NPRT,LPRT,N1,N2<br />

0.1 0.5 1. 5. 10. 20. 50. ;(PRNTT(I),I=1,NPRT)<br />

where:<br />

wp,wa,wb are the Leisman weighting terms (leave these as is)<br />

kmas - mass weighting<br />

= 0 for lumped mass matrix<br />

= 1 for consistent mass matrix<br />

ptime - time to save solution to restart file<br />

kts - restart option<br />

= 0 for normal start<br />

= to use restart option, read initial conditions from file<br />

kiter = 0 for sequential physical-chemical coupling,<br />

= 1 for iterative coupling<br />

kbypass= 0 for minteq solution everywhere,<br />

= 1 for minteq bypass when calculated changes from transport solution are small<br />

kint = 0 for direct integration<br />

= 1 for numerical integration (added 1995 by jwhm)<br />

kdim = 0 for 2D<br />

= 1 for axisymmetric<br />

kprt - flag to print intermediate solutions<br />

nprt - number <strong>of</strong> print times<br />

lprt - flag for printout type for plotting<br />

= 1 for id simulations, conc vs time at exit boundary<br />

= 2 for 2d simulation<br />

= 3 for 1d conc vs distance pr<strong>of</strong>iles<br />

= 4 for 1d simulations,conc vs time at two distance ( nodes n1 and n2)<br />

= 5 for 1d vertical simulations conc. vs depth<br />

n1,n2 - nodes on 1d simulation distance pr<strong>of</strong>iles to print out<br />

prntt - print/plot flag, print out at nprt times<br />

27

<strong>POLYMIN</strong> 2005<br />

Grid parameters<br />

200 20 2 9 ;NEX,NEZ,NVTYP,NGTYP<br />

40. 50. 1000. ;XL,ZL,CONF<br />

c<br />

c<br />

c<br />

c<br />

c<br />

c<br />

c<br />

c<br />

c<br />

c<br />

c<br />

c<br />

nex,nez = number <strong>of</strong> elements in respective directions<br />

nx,nz = number <strong>of</strong> nodes in respective directions<br />

nvtyp = type <strong>of</strong> velocity field<br />

1 - unidirectional flow<br />

2 - velocities read from flonet<br />

ngtyp = type <strong>of</strong> grid<br />

1 - constant element length and/or widths<br />

2 - variable element length and/or widths<br />

3 - read in grid coordinates<br />

xl,zl = x and z lengths <strong>of</strong> rectangular grid<br />

conf = conversion factor to account for the unit<br />

conversion between concentrations and flux rates<br />

Note: the grid parameters nex,nez,xl,zl are read but not used (they originated from a previous<br />

version using rectangles). The grid information is instead provided in the input file <strong>of</strong><br />

meshtria.txt.<br />

Default material properties<br />

(some <strong>of</strong> these parameters are over-written by data in nodeprop.txt)<br />

0.06 0.35 10. 1836. .0003 0.9 ;core: fs2i,por2i,temp2i,rhob2i,ox1i,uradius1i<br />

fs2i = fraction <strong>of</strong> sulphur<br />

por2i = porosity<br />

temp2i = temperature<br />

rhob2 = bulk density<br />

ox1i = initial oxygen concentration<br />

uradius1i = initial fraction <strong>of</strong> unoxidized code<br />

28

<strong>POLYMIN</strong> 2005<br />

Data Block 1<br />

0 0 0 ;IS1,IS2,NCHS<br />

0. 0. false ;vx,vz,ln<strong>of</strong>lx(t: zero water velocity)<br />

0.5 0.05 0.005046 ;Al,At,DD<br />

10.0 0.0 14 8 0 ;TEMP,FIONS,NNN,NR,NAS<br />

0 0 3 0 4 0 0 0 0 0 0 ;IFL(11)<br />

0 0 0 ;IADS,NUMADS,IABQ<br />

0 ;ntsn<br />

is1, is2 = source nodes (only used if ntsn>0)<br />

nchs = skip factor for source nodes<br />

vz, vz = fixed velocities (only used if nvtyp=1)<br />

ln<strong>of</strong>lx … not used<br />

al, at,dd = longitudinal, transverse dispersivities (m), dd = coefficient <strong>of</strong> diffusion (m 2 /day)<br />

c temp = solution temperature, isothermal<br />

c fions = ionic strength variation flag<br />

c nnn = number <strong>of</strong> components (original number does not include<br />

c water or sulphur, but is added after minteq call)<br />

c nns = value to keep track <strong>of</strong> the original value for nnn<br />

c nr = number <strong>of</strong> chemical reactions<br />

c nas = number <strong>of</strong> adsorbing components (not used in minteq)<br />

c<br />

c<br />

c<br />

c<br />

c<br />

c<br />

c<br />

c<br />

c<br />

c<br />

c<br />

c<br />

ifl(11) = list <strong>of</strong> minteq chemistry flags<br />

1 = coralk<br />

2 = idebug<br />

3 = icharge<br />

4 = iprint<br />

5 = niter<br />

6 = iphvry<br />

7 = isorp<br />

8 = iprdct<br />

9 = kkdav<br />

10 = kkthr<br />

11 = iact<br />

ntsn = number <strong>of</strong> source nodes<br />

temp [R], temperature in o C, fions [R], the ionic strength variation option (see Felmy et al.<br />

1984),nnn [R], number <strong>of</strong> chemical components not including water or elemental sulphur, nr [R],<br />

number <strong>of</strong> chemical reactions, nas [R], number <strong>of</strong> adsorbed components (these are also included<br />

29

<strong>POLYMIN</strong> 2005<br />

in the nnn value).<br />

ifl(11) [I], an array <strong>of</strong> 11 values which are equal to the MINTEQA2 input options. A thorough<br />

description <strong>of</strong> these options (except for ifl(11)) is given in Felmy et al. 1984. ifl(11) = IACT,<br />

activity correction option, =0 use activity corrections, =1 don’t use any activity corrections (i.e.<br />

γ‘s =1).<br />

iads [I], adsorption model flag, =0 for no adsorption, =1 for ion exchange (the only adsorption<br />

model tested in MINTRAN), numads [I], number <strong>of</strong> adsorbing surfaces, iabq [I] a number (1-7)<br />

indicating the type <strong>of</strong> adsorption model used in MINTEQA2 (use 4 = ion exchange).<br />

Print output <strong>of</strong> components<br />

1 1 2 2 3 3 4 4 5 5 6 6 7 0 0 0 ;KPLT(I),I=1,NNN<br />

0 1 2 3 4 5 6 7 0 0 0 0 ;KPLTS(I),I=1,NR<br />

1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 0 ;KPNT(I),I=1,NNN<br />

1 1 1 1 1 1 1 1 1 1 1 0 ;KPNTS(I),I=1,NR<br />

c plot options<br />

c<br />

c kplt = plot counter,for aqueous phases<br />

c greater than 0 - plot to file o.aq* 0 - no plot<br />

c kplts = plot counter for solid phases<br />

c greater than 0 - plot to file o.so* 0 - no plot<br />

c print options<br />

c<br />

c kpnt = print counter,for aqueous phases<br />

c greater than 0 - plot to file o.gen 0 - no plot<br />

c kpnts = print counter for solid phases<br />

c greater than 0 - plot to file o.gen 0 - no plot<br />

c similarly for printing kpnt, kpnts<br />

30

<strong>POLYMIN</strong> 2005<br />

Tolerance and relative values<br />

2.000E-03 1.375E-02 ;CA TOLERANCE AND RELATIVE VALUES<br />

2.000E-03 2.490E-02 ;MG FROM NICKEL3<br />

2.000E-03 1.093E-02 ;NA "<br />

2.000E-03 5.140E-03 ;K "<br />

2.000E-03 4.252E-04 ;CL "<br />

2.000E-03 1.380E-02 ;CO3 "<br />

2.000E-03 3.390E-02 ;SO4 "<br />

2.000e-03 1.000e-06<br />

;MN<br />

2.000E-03 2.468E-05 ;FE2 "<br />

2.000E-03 1.249e-04 ;FE3 "<br />

2.000e-03 1.000e-04 ;h4sio4 new 03/09<br />

2.000E-03 5.711E-03 ;AL new 03/09<br />

2.000E-03 1.309E-02 ;H "<br />

2.000E-03 1.000E+00 ;E "<br />

tol - component tolerance values as a fraction <strong>of</strong> the representative component concentration<br />

relative value - the component representative concentration, either the component background<br />

value <strong>of</strong> the cauchy source concentration, whichever is highest<br />

Oxidation Parameters<br />

t f 2<br />

;loxy(t=oxidation), ldonly(t=diff.only), 2=Aachib<br />

f<br />

;lo2fix(t=o2-conc,bottom=0)<br />

0.050 50 0.001 30 1.e-6 0.265 ;gradius,no2step,oxtol,maxo2it,d2,o2atm<br />

where<br />

loxy = true to include pyrite oxidation<br />

ldonly = true to simulate oxygen diffusion only<br />

idmodel : diffusion model =0 Millington & Quirk; =1 for Elberling =2 for Aachib<br />

lo2fix = true if O2 concentration at bottom boundary is to be fixed at zero<br />

= false to leave O2 conc free<br />

gradius = initial grain radius (m)<br />

no2step = number <strong>of</strong> oxidation time steps within each transport time step<br />

oxtol = oxygen concentration tolerance<br />

maxo2it = maximum iterations for oxygen convergence<br />

d2 = diffusion coefficient within grains (m2/year)<br />

o2atm = oxygen concentration at boundary<br />

31

<strong>POLYMIN</strong> 2005<br />

Breakthrough points<br />

4970 5746 4993 3902 2948 ;breakthrough node numbers<br />

5032 5903 3255 1377 5280 ; "<br />

each number represents a node at which breakthrough curves will be assembled (time vs.<br />

concentration – into files brkaq_.out and brks_.out)<br />

Time Step Data<br />

0.0 5.0 .005 5 50 -1 ;t0,t1,dt,maxit(trans,chem),kprint<br />

0.265 ;O2 atm conc.<br />

T0 = initial time (years)<br />

T1 = final time (years)<br />

Dt = time step (years)<br />

Maxit = maximum iterations for oxidation/reaction/transport<br />

Kprint = print frequency (output files polymin.ur1, polymin.ur2 updated every kprint th time step)<br />

32

<strong>POLYMIN</strong> 2005<br />

Background aqueous chemistry<br />

The background (initial) aqueous chemistry data for <strong>POLYMIN</strong> is contained in the file<br />

bckgrndpoly.min. An example <strong>of</strong> this file is included at the end <strong>of</strong> this section.<br />

There is one line for the each <strong>of</strong> the background component values. The first variable on these<br />

lines is idx(nnn) [I] , the component I.D. number (see the comp.dbm data file or Felmy et al.<br />

1984), the second variable is T(nnn) [R], the total analytical component concentration in<br />

moles/kg, or for the case <strong>of</strong> an adsorbed component the concentration <strong>of</strong> the surface sites in eq/l.<br />

The third variable is gx(nnn) [R], the guess for the log <strong>of</strong> the activity for the component , use<br />

zero if a good initial guess is not known and for H + and e - components use the pH and pe values<br />

respectively. The final variable <strong>of</strong> these lines is stad(nnn) [R], the reaction stoichiometry for the<br />

adsorbed phase components (i.e. Na-S); for dissolved components, enter zero.<br />

The total component concentrations (T(nnn)) are determined from the chemical analysis <strong>of</strong> the<br />

solutions <strong>of</strong> interest. Often the chemistry will have to be modified to be used in MINTRAN or<br />

<strong>POLYMIN</strong> by MINTEQA2. This would have to be done for one <strong>of</strong> the following reasons: for a<br />

solution <strong>of</strong> known pH, the initial proton condition must be determined by fixing the pH to give<br />

the initial value for the total analytical concentration <strong>of</strong> H + component, for the simulation <strong>of</strong><br />

redox reactions, the distribution <strong>of</strong> the multi-valence elements must be predetermined from the<br />

solution pe (same procedure as fixing the pH) and e- (idx=1) must be included as a component<br />

(T=0.0), and a type 6 reaction, and for ion-exchange reactions the dissolved and adsorbed phases<br />

must both be included as components with the initial surface site concentration <strong>of</strong> the adsorbed<br />

phase determined from the cation exchange capacity (CEC) and the individual selectivity<br />

coefficients <strong>of</strong> the ion-exchange reactions (K s ). For ion-exchange reactions, the thermodynamic<br />

data base (file thermo.dbm) must be modified. Finally, chemical analyses are generally not<br />

perfectly charge balanced and it is advised that the initial background chemistry be charge<br />

balanced with a non reactive anion or cation. In summary, run the chemical data through<br />

MINTEQA2 and use the equilibrated results as input into MINTRAN or <strong>POLYMIN</strong>.<br />

33

<strong>POLYMIN</strong> 2005<br />

Background solid chemistry<br />

The background (initial) solid chemistry data for <strong>POLYMIN</strong> is also contained in the file<br />

bckgrndpoly.min. An example <strong>of</strong> this file is included at the end <strong>of</strong> this section.<br />

The following lines are for the background reaction values, three lines for each reaction.<br />

lty(nr) [I], MINTEQA2 designated reaction type 2-6 (see Felmy, 1984). lrx(nr) [I], is the<br />

MINTEQA2 reaction type, = 1 for gas, = 2 for solid, =3 for redox reaction.<br />

idys(nr) [I], reaction identification number (see type6.dbm file), gks(nr) [R], the new log K <strong>of</strong><br />

the reaction, dhs(nr) [R], the new enthalpy <strong>of</strong> the reaction (use 0.0 for the last two values and<br />

they will default to the value in the thermodynamic data base), cons(nr) [R], the initial total<br />

mass <strong>of</strong> a type 4 solid (use 0.0 for all other reaction types in moles <strong>of</strong> solid per litre <strong>of</strong> pore<br />

water.<br />

nc [I], number <strong>of</strong> components in the reaction , (idd(nc) [I], stoc(nc) [R])×nc. where idd is the<br />

identification number (as in idx) and stoc is the stoichiometry <strong>of</strong> the component in the reaction<br />

(+ or -)<br />

idnrx [I], is the reaction identification number for a reaction which will be taken out <strong>of</strong> the<br />

reaction sequence once the background chemistry has been equilibrated. This option has been<br />

used to initially set the CO 2 for an open system then remove this reaction to represent a closed<br />

system. This option has not been well used and it is recommended to leave this value as 0.<br />

ntsn [I], is the number <strong>of</strong> source nodes which have a chemical composition different then the<br />

background nodes. If this value is zero then the subroutine SRCHEM is not called and the<br />

following Source Chemistry Section inputs are not required.<br />

34

<strong>POLYMIN</strong> 2005<br />

Input File: Bkgrndpoly.min<br />

(refer to MINTEQ User Guide for further information, see Felmy et al., 1983; Allison et al.,<br />

1990)<br />

This file defines the initial background aqueous and solid chemistry. The chemistry is applied<br />

from nodes ix1-ix2 in the x-direction, and from iy1-iy2 in the y-direction. The values urmin and<br />

urmax were used in a previous version to restrict application <strong>of</strong> the background chemistry to<br />

only certain ranges <strong>of</strong> grain radii (see Gerke et al., 1998). This feature is no longer supported but<br />

these values must still be entered. The initial chemistry is assumed uniform throughout the<br />

domain.<br />

1 101 1 21 0.0 1.0 -1 ;ix1,ix2,iy1,iy2, urmin,urmax background,-1 to end<br />

150 4.000E-03 -1.86 0.0 ;CA b/g main tailings IDX,T,GX,STAD<br />

460 3.200E-03 -1.68 0.0 ;MG "<br />

500 1.100E-03 -1.96 0.0 ;NA "<br />

410 5.140E-04 -2.29 0.0 ;K "<br />

180 0.500E-03 -3.37 0.0 ;CL "<br />

140 0.200E-03 -1.93 0.0 ;CO3 "<br />

732 1.000E-02 -1.53 0.0 ;SO4 "<br />

470 3.000E-04 0.0 0.0 ;MN "<br />

280 2.468E-05 -3.61 0.0 ;FE2 "<br />

281 1.000e-04 -7.90 0.0 ;FE3 "<br />

770 1.000e-04 0.0 0.0 ;H4SIO4 "<br />

030 1.000E-03 -8.24 0.0 ;AL "<br />

330 1.000E-03 0.0 0.0 ;H "<br />

001 0.000E+00 0.0 0.0 ;E "<br />

3 3 ;LTY,LRX SOLID & REACTION VALUES<br />

2812800 0.0 0.0 0.0 ;FE2/FE3 IDYS,GKS,DHS,CONS<br />

0 ;NC,(IDD,STOC)*NC<br />

4 2 ;LTY,LRX<br />

5015001 0.0 0.0 .1 ;CALCITE IDYS,GKS,DHS,CONS [mol/l(solid)]<br />

2 150 1.00 140 0.0 ;NC,(IDD,STOC)*NC<br />

4 2 ;<br />

2077004 0.0 0.0 1.0 ;AMORPHous SILICATE<br />

1 770 1.00 ;<br />

4 2 ;<br />

2003003 0.0 0.0 1.0 ;GIBBSITE<br />

2 30 1.00 330 -3.00 ;<br />

5 2 ;<br />

5028000 0.0 0.0 0.0 ;SIDERITE<br />

2 280 1.00 140 1.00 ;<br />

5 2 ;<br />

2028100 0.0 0.0 0.0 ;FERRIHYDRITE<br />

2 281 1.00 330 -3.00 ;<br />

4 2 ;<br />

6015001 0.0 0.0 1.0 ;GYPSUM<br />

2 150 1.00 732 1.00 ;<br />

6 4 ;<br />

001 0.0 0.0 0.0 ;e-<br />

0 ;<br />

0 ;idnrx<br />

35

<strong>POLYMIN</strong> 2005<br />

y y<br />

10<br />

5<br />

0<br />

10<br />

5<br />

0<br />

10<br />

flow system<br />

O 2<br />

pH<br />

y<br />

5<br />

y<br />

y<br />

0<br />

10 SO 4<br />

5<br />

0<br />

10 Fe(III)<br />

5<br />

0<br />

0 50 100 150 200<br />

Distance (m)<br />

<strong>POLYMIN</strong> simulation results for example data set (provided in previous section), after 10 years.<br />

36

<strong>POLYMIN</strong> 2005<br />

5. STEP BY STEP INSTRUCTIONS<br />

<strong>POLYMIN</strong> is a mass transport model which assumes a steady state velocity field. The velocity<br />

field can be obtained either from the FLONET model for saturated systems (Molson & Frind,<br />

2004), or from the HYDRUS2D model (Simunek et al., 1999). In either case, the output files<br />

must converted to <strong>POLYMIN</strong> input format by running a “processing” code (process_flonetpoly.exe,<br />

or process_hydrus-poly.exe).<br />

Steps 1 & 2 below assume the flow field will be derived from the FLONET model. If running<br />

directly from a HYDRUS flow simulation, steps 1 & 2 can be skipped and replaced with steps 1b<br />

& 2b which follow.<br />

1. Simulate the flow system (refer to the FLONET user guide)<br />

• edit the fnpcg.data file<br />

• make sure kp=1 to get required output files<br />

• run fnpcg.exe<br />

• transfer these file to your transport directory: flow.vxyst, flow.incid, flow.nodes<br />

2. Convert flow system file formats for transport:<br />

• edit process_flonet-poly.in to adjust gradius, fs2, and source nodes for oxidation<br />

• run process_flonet-poly.exe<br />