Life Cycle Assessment of Fiber Composites_final__rättad

Life Cycle Assessment of Fiber Composites_final__rättad

Life Cycle Assessment of Fiber Composites_final__rättad

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

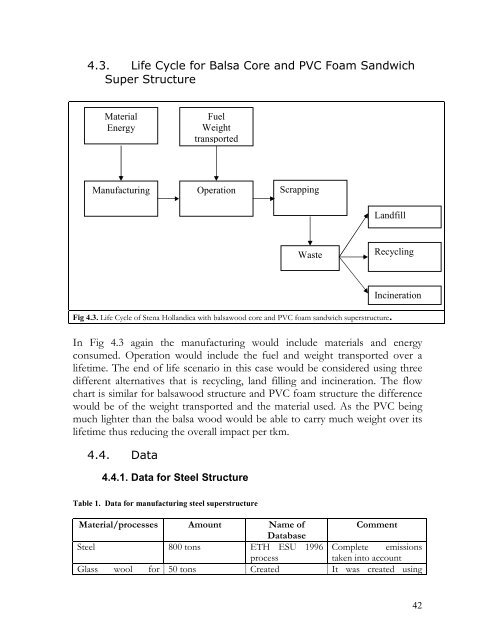

4.3. <strong>Life</strong> <strong>Cycle</strong> for Balsa Core and PVC Foam Sandwich<br />

Super Structure<br />

Material<br />

Energy<br />

Fuel<br />

Weight<br />

transported<br />

Manufacturing Operation Scrapping<br />

Landfill<br />

Waste<br />

Recycling<br />

Fig 4.3. <strong>Life</strong> <strong>Cycle</strong> <strong>of</strong> Stena Hollandica with balsawood core and PVC foam sandwich superstructure.<br />

In Fig 4.3 again the manufacturing would include materials and energy<br />

consumed. Operation would include the fuel and weight transported over a<br />

lifetime. The end <strong>of</strong> life scenario in this case would be considered using three<br />

different alternatives that is recycling, land filling and incineration. The flow<br />

chart is similar for balsawood structure and PVC foam structure the difference<br />

would be <strong>of</strong> the weight transported and the material used. As the PVC being<br />

much lighter than the balsa wood would be able to carry much weight over its<br />

lifetime thus reducing the overall impact per tkm.<br />

4.4. Data<br />

4.4.1. Data for Steel Structure<br />

Incineration<br />

Table 1. Data for manufacturing steel superstructure<br />

Material/processes Amount Name <strong>of</strong><br />

Comment<br />

Database<br />

Steel 800 tons ETH ESU 1996 Complete emissions<br />

process<br />

taken into account<br />

Glass wool for 50 tons Created It was created using<br />

42