Balloon Bomb - Smithsonian Institution Libraries

Balloon Bomb - Smithsonian Institution Libraries

Balloon Bomb - Smithsonian Institution Libraries

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

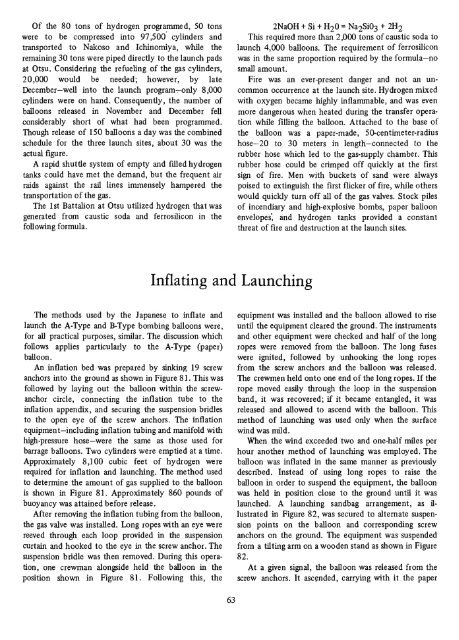

Of the 80 tons of hydrogen programmed, 50 tons<br />

were to be compressed into 97,500 cylinders and<br />

transported to Nakoso and Ichinomiya, while the<br />

remaining 30 tons were piped directly to the launch pads<br />

at Otsu. Considering the refueling of the gas cylinders,<br />

20,000 would be needed; however, by late<br />

December—well into the launch program—only 8,000<br />

cylinders were on hand. Consequently, the number of<br />

balloons released in November and December fell<br />

considerably short of what had been programmed.<br />

Though release of 150 balloons a day was the combined<br />

schedule for the three launch sites, about 30 was the<br />

actual figure.<br />

A rapid shuttle system of empty and filled hydrogen<br />

tanks could have met the demand, but the frequent air<br />

raids against the rail lines immensely hampered the<br />

transportation of the gas.<br />

The 1st Battalion at Otsu utilized hydrogen that was<br />

generated from caustic soda and ferrosilicon in the<br />

following formula.<br />

2NaOH + Si + H 2 0 = Na 2 Si0 3 + 2H 2<br />

This required more than 2,000 tons of caustic soda to<br />

launch 4,000 balloons. The requirement of ferrosilicon<br />

was in the same proportion required by the formula—no<br />

small amount.<br />

Fire was an ever-present danger and not an uncommon<br />

occurrence at the launch site. Hydrogen mixed<br />

with oxygen became highly inflammable, and was even<br />

more dangerous when heated during the transfer operation<br />

while filling the balloon. Attached to the base of<br />

the balloon was a paper-made, 50-centimeter-radius<br />

hose-20 to 30 meters in length—connected to the<br />

rubber hose which led to the gas-supply chamber. This<br />

rubber hose could be crimped off quickly at the first<br />

sign of fire. Men with buckets of sand were always<br />

poised to extinguish the first flicker of fire, while others<br />

would quickly turn off all of the gas valves. Stock piles<br />

of incendiary and high-explosive bombs, paper balloon<br />

envelopes', and hydrogen tanks provided a constant<br />

threat of fire and destruction at the launch sites.<br />

Inflating and Launching<br />

The methods used by the Japanese to inflate and<br />

launch the A-Type and B-Type bombing balloons were,<br />

for all practical purposes, similar. The discussion which<br />

follows applies particularly to the A-Type (paper)<br />

balloon.<br />

An inflation bed was prepared by sinking 19 screw<br />

anchors into the ground as shown in Figure 81. This was<br />

followed by laying out the balloon within the screwanchor<br />

circle, connecting the inflation tube to the<br />

inflation appendix, and securing the suspension bridles<br />

to the open eye of the screw anchors. The inflation<br />

equipment—including inflation tubing and manifold with<br />

high-pressure hose—were the same as those used for<br />

barrage balloons. Two cylinders were emptied at a time.<br />

Approximately 8,100 cubic feet of hydrogen were<br />

required for inflation and launching. The method used<br />

to determine the amount of gas supplied to the balloon<br />

is shown in Figure 81. Approximately 860 pounds of<br />

buoyancy was attained before release.<br />

After removing the inflation tubing from the balloon,<br />

the gas valve was installed. Long ropes with an eye were<br />

reeved through each loop provided in the suspension<br />

curtain and hooked to the eye in the screw anchor. The<br />

suspension bridle was then removed. During this operation,<br />

one crewman alongside held the balloon in the<br />

position shown in Figure 81. Following this, the<br />

equipment was installed and the balloon allowed to rise<br />

until the equipment cleared the ground. The instruments<br />

and other equipment were checked and half of the long<br />

ropes were removed from the balloon. The long fuses<br />

were ignited, followed by unhooking the long ropes<br />

from the screw anchors and the balloon was released.<br />

The crewmen held onto one end of the long ropes. If the<br />

rope moved easily through the loop in the suspension<br />

band, it was recovered; if it became entangled, it was<br />

released and allowed to ascend with the balloon. This<br />

method of launching was used only when the surface<br />

wind was mild.<br />

When the wind exceeded two and one-half miles per<br />

hour another method of launching was employed. The<br />

balloon was inflated in the same manner as previously<br />

described. Instead of using long ropes to raise the<br />

balloon in order to suspend the equipment, the balloon<br />

was held in position close to the ground until it was<br />

launched. A launching sandbag arrangement, as illustrated<br />

in Figure 82, was secured to alternate suspension<br />

points on the balloon and corresponding screw<br />

anchors on the ground. The equipment was suspended<br />

from a tilting arm on a wooden stand as shown in Figure<br />

82.<br />

At a given signal, the balloon was released from the<br />

screw anchors. It ascended, carrying with it the paper<br />

63