Design Guide - Solvay Plastics

Design Guide - Solvay Plastics

Design Guide - Solvay Plastics

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Product Data<br />

Material Selection<br />

Udel resins are amorphous sulfone polymers and offer<br />

many desirable characteristics, such as resistance to<br />

hydrolysis, thermal stability, retention of mechanical<br />

properties at elevated temperatures, clarity, and<br />

transparency.<br />

This material is available in both unfilled grades and<br />

glass-reinforced grades. The unfilled grades are<br />

available in a range of melt viscosities.<br />

Udel ® polysulfone is indicated when higher thermal<br />

capability, inherent flame resistance, better chemical<br />

resistance, and improved mechanical properties are<br />

required. The recommended maximum service<br />

temperature shown in Table 1 may help you position<br />

polysulfone among other engineering materials.<br />

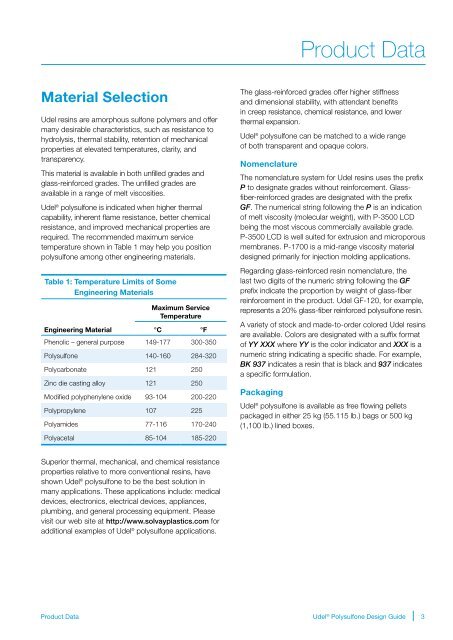

Table 1: Temperature Limits of Some<br />

Engineering Materials<br />

Engineering Material<br />

Maximum Service<br />

Temperature<br />

°C °F<br />

Phenolic – general purpose 149-177 300-350<br />

Polysulfone 140-160 284-320<br />

Polycarbonate 121 250<br />

Zinc die casting alloy 121 250<br />

Modified polyphenylene oxide 93-104 200-220<br />

Polypropylene 107 225<br />

Polyamides 77-116 170-240<br />

Polyacetal 85-104 185-220<br />

The glass-reinforced grades offer higher stiffness<br />

and dimensional stability, with attendant benefits<br />

in creep resistance, chemical resistance, and lower<br />

thermal expansion.<br />

Udel ® polysulfone can be matched to a wide range<br />

of both transparent and opaque colors.<br />

Nomenclature<br />

The nomenclature system for Udel resins uses the prefix<br />

P to designate grades without reinforcement. Glassfiber-reinforced<br />

grades are designated with the prefix<br />

GF. The numerical string following the P is an indication<br />

of melt viscosity (molecular weight), with P-3500 LCD<br />

being the most viscous commercially available grade.<br />

P-3500 LCD is well suited for extrusion and microporous<br />

membranes. P-1700 is a mid-range viscosity material<br />

designed primarily for injection molding applications.<br />

Regarding glass-reinforced resin nomenclature, the<br />

last two digits of the numeric string following the GF<br />

prefix indicate the proportion by weight of glass-fiber<br />

reinforcement in the product. Udel GF-120, for example,<br />

represents a 20% glass-fiber reinforced polysulfone resin.<br />

A variety of stock and made-to-order colored Udel resins<br />

are available. Colors are designated with a suffix format<br />

of YY XXX where YY is the color indicator and XXX is a<br />

numeric string indicating a specific shade. For example,<br />

BK 937 indicates a resin that is black and 937 indicates<br />

a specific formulation.<br />

Packaging<br />

Udel ® polysulfone is available as free flowing pellets<br />

packaged in either 25 kg (55.115 lb.) bags or 500 kg<br />

(1,100 lb.) lined boxes.<br />

Superior thermal, mechanical, and chemical resistance<br />

properties relative to more conventional resins, have<br />

shown Udel ® polysulfone to be the best solution in<br />

many applications. These applications include: medical<br />

devices, electronics, electrical devices, appliances,<br />

plumbing, and general processing equipment. Please<br />

visit our web site at http://www.solvayplastics.com for<br />

additional examples of Udel ® polysulfone applications.<br />

Product Data<br />

Udel ® Polysulfone <strong>Design</strong> <strong>Guide</strong><br />

3