Design Guide - Solvay Plastics

Design Guide - Solvay Plastics

Design Guide - Solvay Plastics

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

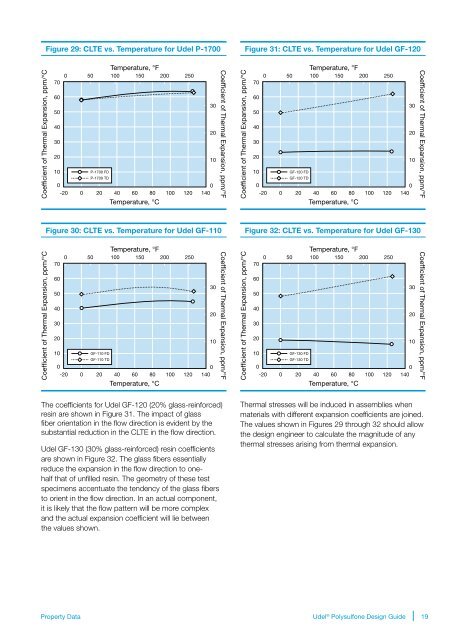

Figure 29: CLTE vs. Temperature for Udel P-1700<br />

Figure 31: CLTE vs. Temperature for Udel GF-120<br />

Coefficient of Thermal Expansion, ppm/°C<br />

Temperature, °F<br />

0 50 100 150 200 250<br />

70<br />

60<br />

30<br />

50<br />

40<br />

20<br />

30<br />

20<br />

10<br />

10<br />

P-1700 FD<br />

P-1700 TD<br />

0<br />

0<br />

-20 0 20 40 60 80 100 120 140<br />

Temperature, °C<br />

Coefficient of Thermal Expansion, ppm/°F<br />

Coefficient of Thermal Expansion, ppm/°C<br />

Temperature, °F<br />

0 50 100 150 200 250<br />

70<br />

60<br />

30<br />

50<br />

40<br />

20<br />

30<br />

20<br />

10<br />

10<br />

GF-120 FD<br />

GF-120 TD<br />

0<br />

0<br />

-20 0 20 40 60 80 100 120 140<br />

Temperature, °C<br />

Coefficient of Thermal Expansion, ppm/°F<br />

Figure 30: CLTE vs. Temperature for Udel GF-110<br />

Figure 32: CLTE vs. Temperature for Udel GF-130<br />

Coefficient of Thermal Expansion, ppm/°C<br />

Temperature, °F<br />

0 50 100 150 200 250<br />

70<br />

60<br />

30<br />

50<br />

40<br />

20<br />

30<br />

20<br />

10<br />

10<br />

GF-110 FD<br />

GF-110 TD<br />

0<br />

0<br />

-20 0 20 40 60 80 100 120 140<br />

Temperature, °C<br />

Coefficient of Thermal Expansion, ppm/°F<br />

Coefficient of Thermal Expansion, ppm/°C<br />

Temperature, °F<br />

0 50 100 150 200 250<br />

70<br />

60<br />

30<br />

50<br />

40<br />

20<br />

30<br />

20<br />

10<br />

10<br />

GF-130 FD<br />

GF-130 TD<br />

0<br />

0<br />

-20 0 20 40 60 80 100 120 140<br />

Temperature, °C<br />

Coefficient of Thermal Expansion, ppm/°F<br />

The coefficients for Udel GF-120 (20% glass-reinforced)<br />

resin are shown in Figure 31. The impact of glass<br />

fiber orientation in the flow direction is evident by the<br />

substantial reduction in the CLTE in the flow direction.<br />

Udel GF-130 (30% glass-reinforced) resin coefficients<br />

are shown in Figure 32. The glass fibers essentially<br />

reduce the expansion in the flow direction to onehalf<br />

that of unfilled resin. The geometry of these test<br />

specimens accentuate the tendency of the glass fibers<br />

to orient in the flow direction. In an actual component,<br />

it is likely that the flow pattern will be more complex<br />

and the actual expansion coefficient will lie between<br />

the values shown.<br />

Thermal stresses will be induced in assemblies when<br />

materials with different expansion coefficients are joined.<br />

The values shown in Figures 29 through 32 should allow<br />

the design engineer to calculate the magnitude of any<br />

thermal stresses arising from thermal expansion.<br />

Property Data<br />

Udel ® Polysulfone <strong>Design</strong> <strong>Guide</strong><br />

19