Design Guide - Solvay Plastics

Design Guide - Solvay Plastics

Design Guide - Solvay Plastics

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Hot Chlorinated Water<br />

Because residual chlorine in water systems combined<br />

with elevated temperatures can produce an oxidizing<br />

environment, resistance to hot water is not always enough.<br />

Since many plastics are susceptible to oxidation and<br />

oxidizing agents, this condition can dramatically shorten<br />

the service life of components made from some plastics.<br />

Typical free chlorine levels in most US municipal water<br />

supplies at the point of use are in the range of 0.5 ppm<br />

to 2 ppm chlorine and are achieved by the addition of<br />

hypochlorites or chloramines.<br />

Several studies have demonstrated that Udel ® polysulfone<br />

based materials offer very good resistance to hot<br />

chlorinated water. Tests were conducted in static water,<br />

containing up to 30 ppm chlorine for 6 months at 60°C<br />

(140°F). As shown in Table 23, Udel ® polysulfone did not<br />

exhibit any significant weight loss.<br />

Tests were also conducted using flowing water containing<br />

5 ppm chlorine for 2 months at 90°C (194°F). As shown<br />

in Table 24, again Udel ® polysulfone did not exhibit any<br />

significant weight loss.<br />

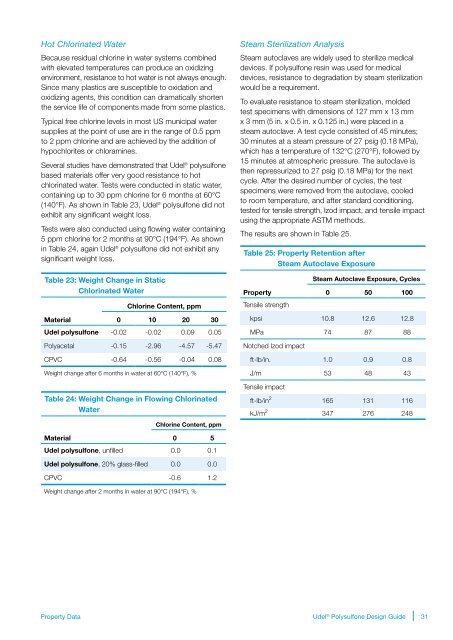

Table 23: Weight Change in Static<br />

Chlorinated Water<br />

Chlorine Content, ppm<br />

Material 0 10 20 30<br />

Udel polysulfone -0.02 -0.02 0.09 0.05<br />

Polyacetal -0.15 -2.96 -4.57 -5.47<br />

CPVC -0.64 -0.56 -0.04 0.08<br />

Weight change after 6 months in water at 60°C (140°F), %<br />

Table 24: Weight Change in Flowing Chlorinated<br />

Water<br />

Chlorine Content, ppm<br />

Steam Sterilization Analysis<br />

Steam autoclaves are widely used to sterilize medical<br />

devices. If polysulfone resin was used for medical<br />

devices, resistance to degradation by steam sterilization<br />

would be a requirement.<br />

To evaluate resistance to steam sterilization, molded<br />

test specimens with dimensions of 127 mm x 13 mm<br />

x 3 mm (5 in. x 0.5 in. x 0.125 in.) were placed in a<br />

steam autoclave. A test cycle consisted of 45 minutes;<br />

30 minutes at a steam pressure of 27 psig (0.18 MPa),<br />

which has a temperature of 132°C (270°F), followed by<br />

15 minutes at atmospheric pressure. The autoclave is<br />

then repressurized to 27 psig (0.18 MPa) for the next<br />

cycle. After the desired number of cycles, the test<br />

specimens were removed from the autoclave, cooled<br />

to room temperature, and after standard conditioning,<br />

tested for tensile strength, Izod impact, and tensile impact<br />

using the appropriate ASTM methods.<br />

The results are shown in Table 25.<br />

Table 25: Property Retention after<br />

Steam Autoclave Exposure<br />

Steam Autoclave Exposure, Cycles<br />

Property 0 50 100<br />

Tensile strength<br />

kpsi 10.8 12.6 12.8<br />

MPa 74 87 88<br />

Notched Izod impact<br />

ft-lb/in. 1.0 0.9 0.8<br />

J/m 53 48 43<br />

Tensile impact<br />

ft-lb/in 2 165 131 116<br />

kJ/m 2 347 276 248<br />

Material 0 5<br />

Udel polysulfone, unfilled 0.0 0.1<br />

Udel polysulfone, 20% glass-filled 0.0 0.0<br />

CPVC -0.6 1.2<br />

Weight change after 2 months in water at 90°C (194°F), %<br />

Property Data<br />

Udel ® Polysulfone <strong>Design</strong> <strong>Guide</strong><br />

31