- Page 1 and 2: 3 rd International Conference on Co

- Page 3 and 4: Patrick Hupe, Uwe Langbecker, Mubas

- Page 5 and 6: Towards Intelligent Simulation-Base

- Page 7 and 8: ectly damage in terms of greenhouse

- Page 9 and 10: Fig.7: FEA of a catamaran made of c

- Page 11 and 12: Set the small parts fixing the part

- Page 13 and 14: main benefit of 3-d design lies in

- Page 15 and 16: Applic. Mar. Industries, COMPIT, Ha

- Page 17 and 18: Use of Genetic Algorithms in Propel

- Page 19 and 20: 3. Fitness Function Formulation The

- Page 21 and 22: where µ α and µ θ are the chose

- Page 23 and 24: From another point of view and unde

- Page 25 and 26: Y X Benchmark First Optimum Fig.8:

- Page 27 and 28: A Systematic Study on Posing and So

- Page 29 and 30: expressed as functions of the wave

- Page 31 and 32: 4.4. Optimization with modeFRONTIER

- Page 33 and 34: Fig.5: SIMPLEX optimization and Par

- Page 35: References HOFFSCHILDT, M.; BIDLOT,

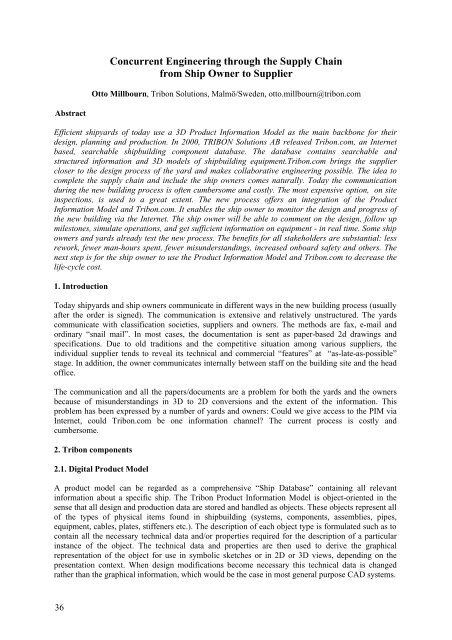

- Page 39 and 40: 3. New Process The new process is b

- Page 41 and 42: 4. Conclusions and next step The ne

- Page 43 and 44: 2. E-Commerce of goods versus servi

- Page 45 and 46: Main steps on ePING’s road-map ar

- Page 47 and 48: anon. client new client registered

- Page 49 and 50: Preparing an offer can be hierarchi

- Page 51 and 52: Acknowledgment This work was partia

- Page 53 and 54: The focus within this paper is the

- Page 55 and 56: conditions have to be prevented. Fo

- Page 57 and 58: Ship 2 LPP 182.390 m B 26.00 m T D

- Page 59 and 60: Fig.9: Ship 1; Simulated Crash stop

- Page 61 and 62: Using Simulation in Evaluating Bert

- Page 63 and 64: ship. To shorten the time spent by

- Page 65 and 66: travelled by each SC are totalled t

- Page 67 and 68: around time is the highest against

- Page 69 and 70: to alternative berths instead of pl

- Page 71 and 72: Appendix 1: Data Collected from Con

- Page 73 and 74: Abstract Introduction to BALTPORTS-

- Page 75 and 76: - at the level of operational plann

- Page 77 and 78: - External interoperability - In ad

- Page 79 and 80: 5. Setting up of the Baltic Sub-Reg

- Page 81 and 82: Robot Applications in the Field of

- Page 83 and 84: Fig.3: The main components of the D

- Page 85 and 86: The precision of the process depend

- Page 87 and 88:

The frame is further divided into 2

- Page 89 and 90:

1. Periodicity on the time line, pe

- Page 91 and 92:

Quality measures. Let J be the inst

- Page 93 and 94:

6.2 Mutation A random number out of

- Page 95 and 96:

7.1 Adaptation of Theorem 2 in our

- Page 97 and 98:

8. Conclusions and scope for future

- Page 99 and 100:

meet the needs of the user. Typical

- Page 101 and 102:

2-digit level (e.g., 220 - Engineer

- Page 103 and 104:

eviewed in dialogue boxes and on Ex

- Page 105 and 106:

Fig.3: Example tanker (HMI BRENTON

- Page 107 and 108:

Fig.7: Assigned material tabular en

- Page 109 and 110:

Fig.11: Design ship 2-digit SWBS Re

- Page 111 and 112:

Communication in Ship Design Networ

- Page 113 and 114:

number and volume of communicated i

- Page 115 and 116:

The investigated collaborations are

- Page 117 and 118:

The four principle communication pa

- Page 119 and 120:

6. Information content In design cl

- Page 121 and 122:

References ERIKSTAD, S.O., HAGEN, A

- Page 123 and 124:

intensive. The terminal's own drive

- Page 125 and 126:

A distribution of decision competen

- Page 127 and 128:

the order for planning the task to

- Page 129 and 130:

3.400.000 Total costs 3.200.000 3.0

- Page 131 and 132:

Visualisation of Ship Motions in Wa

- Page 133 and 134:

3.3. Panelisation and information e

- Page 135 and 136:

5.2. 3D visualisation Fig.4: Refere

- Page 137 and 138:

6.2. Examples of the visualisations

- Page 139 and 140:

7. Conclusions The presented toolki

- Page 141 and 142:

Fig.2: Possibilities for robotic in

- Page 143 and 144:

Experiments with the underwater cam

- Page 145 and 146:

Fig.13. and 14: Cleaning of the cha

- Page 147 and 148:

Acknowledgements The authors want t

- Page 149 and 150:

Fig.2: Result of Industrial Enginee

- Page 151 and 152:

2. Industrial engineering system fo

- Page 153 and 154:

4. Next steps In the next phase, th

- Page 155 and 156:

organizations and organizational un

- Page 157 and 158:

artifact’s context and extend the

- Page 159 and 160:

We take the ship survey process, wh

- Page 161 and 162:

device multimedia capabilities: Sur

- Page 163 and 164:

4. Future Work The mobile services

- Page 165 and 166:

FEM Supported Alignment of Power Tr

- Page 167 and 168:

2.2. Causes First researches result

- Page 169 and 170:

Fig.5: Sufficient tooth grip patter

- Page 171 and 172:

4. Alignment of a RoRo vessel’s p

- Page 173 and 174:

4.3. Calibration/Validation of the

- Page 175 and 176:

Optimisation of the Survivability o

- Page 177 and 178:

Table I: Current UK & US Damage Sta

- Page 179 and 180:

Fig.2: Damage Density Distribution,

- Page 181 and 182:

An Air-to-Surface Missile (ASM) is

- Page 183 and 184:

length according to the existing re

- Page 185 and 186:

the use of a stochastic optimizatio

- Page 187 and 188:

Each MOGA loop requires approximate

- Page 189 and 190:

JIASIONOWSKI, A. (2002), An integra

- Page 191 and 192:

Design problems are typically chara

- Page 193 and 194:

o planned: systematic; o ad-hoc: op

- Page 195 and 196:

o Provide justification for decisio

- Page 197 and 198:

o o o o o o Guide the user through

- Page 199 and 200:

- for some systems, the initial com

- Page 201 and 202:

feasible. The practical implementat

- Page 203 and 204:

PARK, J.H.; STORCH, R.L. (2002), "O

- Page 205 and 206:

where: a, b - coefficients (weights

- Page 207 and 208:

C Fig.2: The fuzzy domain of the bu

- Page 209 and 210:

5.2. Ship fuzzy domain in an open a

- Page 211 and 212:

PIETRZYKOWSKI, Z. (2003a), Modellin

- Page 213 and 214:

means that the number of intersecti

- Page 215 and 216:

4. Manipulation of Sets of Data Poi

- Page 217 and 218:

Fig.2: The selection function defin

- Page 219 and 220:

Let us define the root node of a se

- Page 221 and 222:

Fig.4 took up to several minutes on

- Page 223 and 224:

Applying Meta-Models to the Probabi

- Page 225 and 226:

The assessment of the damage stabil

- Page 227 and 228:

Fig.1 shows clearly an important ch

- Page 229 and 230:

one is willing to do, the smaller t

- Page 231 and 232:

Depending on the number of simulati

- Page 233 and 234:

Since none of the points of the lat

- Page 235 and 236:

CHEN, S.; WANG, L.; WU, X.; WANG, X

- Page 237 and 238:

alance between ship resistance and

- Page 239 and 240:

frequent movements of the pitch tha

- Page 241 and 242:

"commanding" by itself since a vari

- Page 243 and 244:

The numbers shown in the 3 rd row o

- Page 245 and 246:

angle of attack of the water flow o

- Page 247 and 248:

stationary, i.e. all variables rema

- Page 249 and 250:

the engine map runs through the ove

- Page 251 and 252:

References GRIMMELIUS, H.T.; STAPER

- Page 253 and 254:

their output to be random too. Runn

- Page 255 and 256:

simulation runs. It typically takes

- Page 257 and 258:

When the system initiates, the star

- Page 259 and 260:

The user is guided through various

- Page 261 and 262:

• Port Planning & Development •

- Page 263 and 264:

Knowledge-based Concurrent Engineer

- Page 265 and 266:

or puts components aside to make mo

- Page 267 and 268:

Technical specs Make preliminary ca

- Page 269 and 270:

ios, and knowledge about the design

- Page 271 and 272:

are applied afterwards, they can be

- Page 273 and 274:

calculations etc.) The product rela

- Page 275 and 276:

For finding the dependency of reque

- Page 277 and 278:

GIASSI, A. (2003), Multidisciplinar

- Page 279 and 280:

already mentioned. It is based on t

- Page 281 and 282:

2.2.2 Geometry Geometry covers the

- Page 283 and 284:

2.3 Simulation The simulation engin

- Page 285 and 286:

As far as the simulation engine inc

- Page 287 and 288:

time results. Table I: Mustering ti

- Page 289 and 290:

simulation means. The required time

- Page 291 and 292:

design consultants. Starting from a

- Page 293 and 294:

different severity, e.g. warning or

- Page 295 and 296:

• Execute calculation (including

- Page 297 and 298:

and ghostscript, Gnuplot, Ghostscri

- Page 299 and 300:

References CASTOR; An open source d

- Page 301 and 302:

an accurate description of a densit

- Page 303 and 304:

(a) UDS and CDS Schemes (b) Gamma S

- Page 305 and 306:

Figure 3: Typical unstructured grid

- Page 307 and 308:

(a) 0 degree (b) 5 degrees - Port s

- Page 309 and 310:

(a) Computations (b) Experiments Fi

- Page 311 and 312:

(a) X/L = +0.10 (b) X/L = +0.20 (c)

- Page 313 and 314:

4 Conclusion This paper has describ

- Page 315 and 316:

State of the art in climbing and wa

- Page 317 and 318:

2.1 REST 1 and REST 2 climbing robo

- Page 319 and 320:

Figure 5: ROWER 1 system. The full

- Page 321 and 322:

Acknowledgements The REST climbing

- Page 323 and 324:

t²Ùvl uwmhÐu \]9|>CUW>¢Hh9|>@

- Page 325 and 326:

á©ÎetÖJu‚ÓuwØ$t²o"t²Ó(

- Page 327 and 328:

ð qwÓ¸tvuwÑÎzs¤×eÕÐhlxÚNl

- Page 329 and 330:

ÖJu‚ÓuwØ›t²o"t²Ós²^hÔ

- Page 331 and 332:

X X X X X X X X Z Z Z Z Z Z Z Z Y Y

- Page 333 and 334:

30 25 20 Conjugate gradient 30 25 2

- Page 335 and 336:

CARENA is a naval architectural sof

- Page 337 and 338:

Fig.6: Cargo vessel carrying “spe

- Page 339 and 340:

used especially for shape optimizat

- Page 341 and 342:

easily given as simple auto-update

- Page 343 and 344:

and mutation concepts for evolving

- Page 345 and 346:

govern agents’ interaction with t

- Page 347 and 348:

Create generation behaviour Sequent

- Page 349 and 350:

Side Casing Hoister Deck Car Deck C

- Page 351 and 352:

The selection of the best individua

- Page 353 and 354:

Appendix A Table A-I: Optimisation

- Page 355 and 356:

2. Project Management tools in ship

- Page 357 and 358:

Fig.1: Example of document properti

- Page 359 and 360:

Fig.4: Example of query view on doc

- Page 361 and 362:

The Product Data Management is comp

- Page 363 and 364:

Abstract Applications of Self-Organ

- Page 365 and 366:

EMERGENT GLOBAL STRUCTURE LOCAL INT

- Page 367 and 368:

dynamically structured, the system

- Page 369 and 370:

After a leakage has been detected,

- Page 371 and 372:

EXIT door door corridor exit device

- Page 373 and 374:

adaptive. Furthermore, from a imple

- Page 375 and 376:

The main objective for our approach

- Page 377 and 378:

LUCAS, C. (2003), Self-organizing s

- Page 379 and 380:

• As a result of the above-mentio

- Page 381 and 382:

Table I: Exemplary matching of Refe

- Page 383 and 384:

Yard Program time Mile-stone Plan d

- Page 385 and 386:

In the following we start with a di

- Page 387 and 388:

Material Information Machines Proje

- Page 389 and 390:

module (SpaceMan) supports the allo

- Page 391 and 392:

ÖجРÆÙÖÐ ÆØÛÓÖ× ÓÖ

- Page 393 and 394:

ÙÖ ½ ÌÝÔÐ ÙÐÐÓÖÑ Ø×

- Page 395 and 396:

³× ÖØÖÓÒ Ñ×ÙÖ Ó Ø Ö

- Page 397 and 398:

ÑÓÖ ÙÖØÐݸ Ö Ó ÓÚÖ

- Page 399 and 400:

10 10 Exp ANN Exp ANN 7.5 7.5 Cr [x

- Page 401 and 402:

7 Cr [x 1000] 6 5 4 3 2 0.2 0.4 0.6

- Page 403 and 404:

Automation Tools in the Design Proc

- Page 405 and 406:

Fig.1: Visual LISP integrated devel

- Page 407 and 408:

• Bentley’s adoption of VBA •

- Page 409 and 410:

To these outstanding features, it h

- Page 411 and 412:

4.2.1. Automation The objective of

- Page 413 and 414:

• Direction of the start of the c

- Page 415 and 416:

• The FDE program processes the p

- Page 417 and 418:

Database access The FORAN System us

- Page 419 and 420:

A Heuristic for the Container Pre-M

- Page 421 and 422:

When they arrive in the terminal ya

- Page 423 and 424:

(3) The number of all badly placed

- Page 425 and 426:

still greater than zero, the minimu

- Page 427 and 428:

• For each dirty stack s exactly

- Page 429 and 430:

in the remaining 7 instances no mor

- Page 431 and 432:

DOF motion. Then, alter the input f

- Page 433 and 434:

learn of any delay that can occur b

- Page 435 and 436:

40 20 30 10 x-x0 (m) 20 roll (deg)

- Page 437 and 438:

Since, among the velocity component

- Page 439 and 440:

Y (m) -1700 -1500 -1300 -1100 -900

- Page 441 and 442:

system framework, the details of it

- Page 443 and 444:

Real-time Nonlinear Simulation (RNS

- Page 445 and 446:

design modifications are made, and

- Page 447 and 448:

Evacuation Notation - a New Concept

- Page 449 and 450:

• r(t): response time, which acco

- Page 451 and 452:

• The time tk: the time correspon

- Page 453 and 454:

5.1. Quantitative assessment Quanti

- Page 455 and 456:

Table 2: Summary of total and model

- Page 457 and 458:

notation: besides an objective asse

- Page 459 and 460:

Neural Networks Model for Ship Mane

- Page 461 and 462:

&r V G • • r = a = ( uî & & +

- Page 463 and 464:

V a Estimating Forces F Calculating

- Page 465 and 466:

Fig. 5: Error variation for the net

- Page 467 and 468:

Fig 8: Ship's path in Zigzag test 3

- Page 469 and 470:

[4] ALMAN, P.R., BERTSCHE, W.R., BO

- Page 471 and 472:

2 Numerical Methods RANSE methods l

- Page 473 and 474:

As a conclusion of these parameter

- Page 475 and 476:

For correlation of propeller data t

- Page 477 and 478:

quadratic functions result in littl

- Page 479 and 480:

Index by authors Abels 470 Akinfiev