08 71 00 Door Hardware.pdf - Milestone Construction Services, Inc

08 71 00 Door Hardware.pdf - Milestone Construction Services, Inc

08 71 00 Door Hardware.pdf - Milestone Construction Services, Inc

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

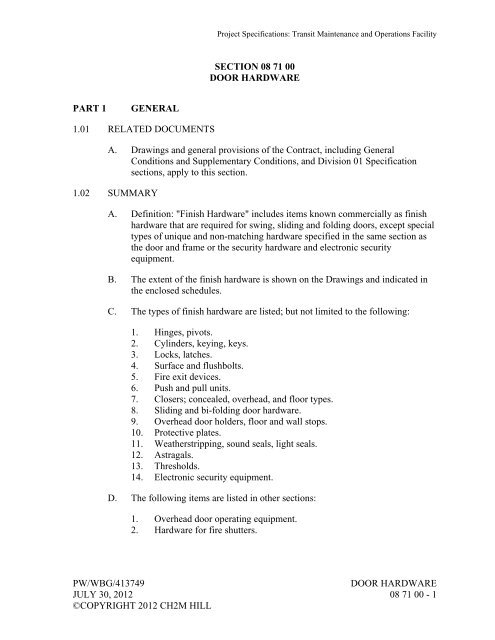

Project Specifications: Transit Maintenance and Operations Facility<br />

SECTION <strong>08</strong> <strong>71</strong> <strong>00</strong><br />

DOOR HARDWARE<br />

PART 1<br />

GENERAL<br />

1.01 RELATED DOCUMENTS<br />

A. Drawings and general provisions of the Contract, including General<br />

Conditions and Supplementary Conditions, and Division 01 Specification<br />

sections, apply to this section.<br />

1.02 SUMMARY<br />

A. Definition: "Finish <strong>Hardware</strong>" includes items known commercially as finish<br />

hardware that are required for swing, sliding and folding doors, except special<br />

types of unique and non-matching hardware specified in the same section as<br />

the door and frame or the security hardware and electronic security<br />

equipment.<br />

B. The extent of the finish hardware is shown on the Drawings and indicated in<br />

the enclosed schedules.<br />

C. The types of finish hardware are listed; but not limited to the following:<br />

1. Hinges, pivots.<br />

2. Cylinders, keying, keys.<br />

3. Locks, latches.<br />

4. Surface and flushbolts.<br />

5. Fire exit devices.<br />

6. Push and pull units.<br />

7. Closers; concealed, overhead, and floor types.<br />

8. Sliding and bi-folding door hardware.<br />

9. Overhead door holders, floor and wall stops.<br />

10. Protective plates.<br />

11. Weatherstripping, sound seals, light seals.<br />

12. Astragals.<br />

13. Thresholds.<br />

14. Electronic security equipment.<br />

D. The following items are listed in other sections:<br />

1. Overhead door operating equipment.<br />

2. <strong>Hardware</strong> for fire shutters.<br />

PW/WBG/413749<br />

DOOR HARDWARE<br />

JULY 30, 2012 <strong>08</strong> <strong>71</strong> <strong>00</strong> - 1<br />

©COPYRIGHT 2012 CH2M HILL

Project Specifications: Transit Maintenance and Operations Facility<br />

1.03 QUALITY ASSURANCE<br />

A. Obtain each type of hardware (hinges, locks and latches, closers, overhead<br />

holders) from a single manufacturer, although several may be indicated as<br />

offering products complying with the requirements.<br />

B. Supplier shall be a recognized architectural finish hardware contractor with<br />

warehousing facilities, who has been furnishing finish hardware in the<br />

projects vicinity for a period of not less than 2 years and who is, or who<br />

employs an experienced architectural hardware consultant, who is available at<br />

reasonable times during the course of the Work for consultation about the<br />

project's hardware requirements, to the architect, Owner and general<br />

contractor.<br />

C. Fire Rated Openings: Provide hardware for fire rated openings in compliance<br />

with NFPA 80 and local code requirements. Provide only hardware that has<br />

been tested and is listed by Underwriter's Laboratories <strong>Inc</strong>. for the types and<br />

sizes of doors required and complies with the requirements of the door and<br />

frame labels. Where the emergency exit devices are required on fire rated<br />

doors, provide UL label on exit device indicating "FIRE EXIT<br />

HARDWARE". Provide door seals for smoke/draft-control doors and door<br />

assemblies in corridors and smoke barriers.<br />

1.04 SUBMITTALS<br />

A. Action Submittals:<br />

1. Shop Drawings:<br />

a. Product Data: Submit manufacturer's technical product data for<br />

each item of hardware in accordance with Section 01 33 <strong>00</strong>,<br />

Submittal Procedures. <strong>Inc</strong>lude whatever information may be<br />

necessary to show compliance with the requirements, and include<br />

instructions for the installation and for the maintenance of the<br />

operating parts and finishes.<br />

b. <strong>Hardware</strong> Schedule Submit a final hardware schedule in the<br />

manner indicated below. Coordinate hardware with the doors,<br />

frames and related work to ensure proper size, thickness, hand,<br />

function and finish of hardware. Based on finish hardware<br />

indicated, organize the hardware schedule into sets indicating<br />

complete designations of every item of hardware required for each<br />

door or opening. <strong>Inc</strong>lude the following information.<br />

1) Type, style, function, size and finish of the item of<br />

hardware.<br />

2) Name and manufacturer of each item.<br />

3) Fastenings and other pertinent information.<br />

DOOR HARDWARE<br />

PW/WBG/413749<br />

<strong>08</strong> <strong>71</strong> <strong>00</strong> - 2 JULY 30, 2012<br />

©COPYRIGHT 2012 CH2M HILL

Project Specifications: Transit Maintenance and Operations Facility<br />

4) Location of hardware set, cross-referenced to the door<br />

number on the drawings and the hardware group in the<br />

Specifications.<br />

5) Explanations of all abbreviations symbol and codes on the<br />

schedule.<br />

6) <strong>Door</strong> and frame sizes and materials.<br />

7) Mounting information: Location on door, degree of opening<br />

and co-ordination with other items.<br />

8) Keying.<br />

9) Wiring diagrams for all openings using electrically operated<br />

hardware.<br />

10) MDPA/NOA, ITS approval and pressure ratings.<br />

11) LEED’s V.30 credits and information, End of Useful Life<br />

Recycle Program.<br />

c. Submit hardware schedule at the earliest possible date, as<br />

hardware schedule acceptance must precede fabrication of other<br />

work (i.e., hollow metal frames), which are critical in the project<br />

construction schedule.<br />

d. Wiring Diagram: Openings using electrically operated hardware<br />

will require a detailed, color coded, wiring diagram showing all<br />

components used in the opening. The hardware supplier will<br />

provide this diagram at the time of the hardware submittals.<br />

Factory installation instructions from the various elements will not<br />

be accepted as meeting this requirement.<br />

1) Diagram will include an elevation showing the location of<br />

various elements and power sources, a written description of<br />

the function of the opening and a custom diagram showing<br />

all runs and terminations for all the equipment used.<br />

e. Submit templates for each fabricator of doors, frames and other<br />

related work to be factory prepared for the installation of<br />

hardware. Upon request, check shop drawings of other such work<br />

to confirm that adequate provisions are made for the proper<br />

location and installation of hardware.<br />

B. Informational Submittals:<br />

1. Product Test Reports: Based on evaluation of comprehensive tests<br />

performed by manufacturer and witnessed by a qualified testing agency,<br />

indicating current products comply with requirements.<br />

1.05 PRODUCT HANDLING<br />

A. Tag each item or package separately with the identification related to the final<br />

hardware schedule; include basic installation instructions with each item or<br />

package.<br />

PW/WBG/413749<br />

DOOR HARDWARE<br />

JULY 30, 2012 <strong>08</strong> <strong>71</strong> <strong>00</strong> - 3<br />

©COPYRIGHT 2012 CH2M HILL

Project Specifications: Transit Maintenance and Operations Facility<br />

B. Provide a secure lock-up for the hardware delivered to the jobsite but not<br />

installed. Control handling and installation of hardware items that are not<br />

immediately replaceable, so that completion of the work will not be delayed<br />

by hardware losses, both before and after installation.<br />

C. Deliver individually packaged hardware items at the proper time and locations<br />

(jobsite or shop) for installation.<br />

D. Inventory hardware jointly with the representative of the general contractor<br />

and the hardware supplier until each is satisfied that count is correct.<br />

PART 2<br />

PRODUCTS<br />

2.01 SCHEDULE HARDWARE<br />

A. Requirements for the design, grade, function, finish, size and other distinctive<br />

qualities of each type of hardware are indicated in the hardware groups at the<br />

end of this section. The catalog numbers used in the hardware groups attached<br />

are from the manufacturer listed in the first column of the material section.<br />

Items considered equal and approved for substitution are listed in the adjacent<br />

tables.<br />

B. All other substitutions must be submitted to the architect with the catalog<br />

information, supporting data and samples, at least 7 working days prior to the<br />

bid date. Approvals will be given in writing or by addendum only.<br />

C. Supporting data must include BHMA listing and performance testing data,<br />

certified by an independent third party, showing required life cycle and other<br />

performance tests successfully completed.<br />

2.02 FINISHES<br />

A. General: Match finish of every hardware unit at each door opening except as<br />

noted or as otherwise indicated in the attached hardware groups. In general,<br />

match all items to the manufacturer's standard finish for the latch or lockset<br />

(or push and pull units) for the color and texture. All door hardware to be<br />

brushed stainless steel, US32D, 630 at exterior openings and brushed chrome,<br />

US26D, 652 at interior openings except as noted in the schedule attached.<br />

Contractors will co-ordinate finish of hardware to be applied to aluminum<br />

doors with the storefront contractor.<br />

B. At locations where tactile warnings are needed to meet the requirements of<br />

ADA, ANSI 117 or state and local codes; knobs, levers or crossbars will be<br />

"knurled" at the factory before finishing is applied to the base metal. Liquid<br />

abrasive or other field applied substances are NOT acceptable.<br />

DOOR HARDWARE<br />

PW/WBG/413749<br />

<strong>08</strong> <strong>71</strong> <strong>00</strong> - 4 JULY 30, 2012<br />

©COPYRIGHT 2012 CH2M HILL

Project Specifications: Transit Maintenance and Operations Facility<br />

2.03 HINGES<br />

A. All hinges will be manufactured to the standard template (ANSI 156.1) and<br />

supplied with Phillips, flat head, machine, or wood screws as appropriate.<br />

Finish screw head to match exposed surface of hinges.<br />

B. Except as otherwise indicated; provide hinge pins as follows:<br />

1. Steel Hinges: Steel hinge pins.<br />

2. Non-ferrous Hinges: Stainless steel hinge pins.<br />

3. Exterior and Locking Out-swinging <strong>Door</strong>s: Non-removable pins.<br />

4. Interior <strong>Door</strong>s: Non-rising pins.<br />

5. Tips: Flush button and plugs, finished to match the leaf except where<br />

HT (hospital tip) is indicated.<br />

C. Number of Hinges: Provide the number of hinges indicated but not less than<br />

3 hinges for each door leaf up to 90 inches in height and one additional hinge<br />

for each 30 inches of height. One center pivot will be supplied on all door<br />

leaves. <strong>Door</strong> leaves up to 86 inches in height. Additional center pivot will be<br />

provided for each 30 inches of height. <strong>Door</strong>s that are oversized will be<br />

supplied with additional hinges or pivots as indicated in the schedule attached.<br />

D. Hinges will be a minimum of 4-1/2 inches in height and .134 inch thick.<br />

Width of hinge shall be sufficient to provide clearance for trim, applied door<br />

panels, frame moldings and door thickness.<br />

E. Life of building warranty for all hinges. Full replacement will be made for<br />

failure of mechanical operation or finish.<br />

F. Models and Functions:<br />

BOMMER PBB STANLEY<br />

5<strong>00</strong>0 PB81 F179<br />

BB5<strong>00</strong>0 BB81 FBB179<br />

5<strong>00</strong>2 PB51 F191<br />

BB5<strong>00</strong>2 BB51 FBB191<br />

BB5<strong>00</strong>4 4B81 FBB168<br />

BB5<strong>00</strong>6 4B51 FBB199<br />

2.04 CYLINDERS AND KEYING<br />

A. The hardware manufacturer will meet with the Owner to finalize keying<br />

requirements and to obtain keying instructions in writing.<br />

PW/WBG/413749<br />

DOOR HARDWARE<br />

JULY 30, 2012 <strong>08</strong> <strong>71</strong> <strong>00</strong> - 5<br />

©COPYRIGHT 2012 CH2M HILL

Project Specifications: Transit Maintenance and Operations Facility<br />

B. All cylinders will be SFIC, 7-pin interchangeable core type. All cylinders<br />

shall be keyed to the Dorma, Best, Schlage or Yale small format<br />

interchangable core key system.<br />

C. All cylinders will be supplied with temporary construction cores. <strong>Construction</strong><br />

cores and keys will be a different keyway (key section) than the Owner’s final<br />

cores.<br />

D. The following will be provided by the Contractor.<br />

1. 3 change keys each cylinder.<br />

2. 10 construction keys.<br />

3. 2 each construction core removal keys.<br />

4. 10 each of all GGMK, GMK and MKs used in system.<br />

5. 3 each control keys.<br />

E. All keys shall be stamped DO NOT DUPLICATE.<br />

F. All keys and cylinders will be stamped with the keying symbol (e.g., AA1,<br />

AC27) for visual key control.<br />

2.05 KEY CONTROL SYSTEM<br />

A. Provide a key control system, including envelopes, tags, labels, receipt forms,<br />

3-way visible card index, temporary markers and standard metal cabinet with<br />

a capacity of 150 percent of the number of cylinders required for this project.<br />

B. Models and Functions:<br />

TELKEE LUND MMF<br />

RWC-75S 12<strong>00</strong> 201-6<strong>08</strong>0<br />

C. Representative of the distributor will deliver the key cabinet with all the<br />

building keys, all tagged, entered in the index and marked with the<br />

corresponding door numbers, installed in the cabinet. Representative will<br />

accompany building owner during turnover of the building; while construction<br />

cores are removed and each individual key is tested on the door indicated.<br />

2.06 LOCKS AND LATCHES<br />

A. Provide standard wrought box strike for each latch or lock; with a curved lip,<br />

extended to protect the frame without interfering with the opening. On pairs of<br />

doors, adjust LTC dimensions to clear the astragals.<br />

B. Provide a 3/4 inch minimum throw latchbolt when used on pairs of doors.<br />

Provide the manufacturer's standard latchbolt on all other units.<br />

DOOR HARDWARE<br />

PW/WBG/413749<br />

<strong>08</strong> <strong>71</strong> <strong>00</strong> - 6 JULY 30, 2012<br />

©COPYRIGHT 2012 CH2M HILL

Project Specifications: Transit Maintenance and Operations Facility<br />

C. Provide a knurled lever on the public side of all openings to mechanical and<br />

electrical rooms, stairwells or other areas that are a danger to persons with<br />

limited visual ability. Refer to ANSI 117 and current ADA standards for<br />

requirements.<br />

D. Locksets will have a written 5-year warranty issued by the manufacturer.<br />

E. Models and Functions:<br />

COR/RUS DORMA<br />

NZD<br />

LRB<br />

33<strong>00</strong> CL8<strong>00</strong>A<br />

2.07 FIRE EXIT DEVICES<br />

A. Except on fire rated openings, wherever closers are used with exit devices;<br />

equip units with a cylinder operated dogging device to hold the push bar<br />

depressed and the latchbolt in a retracted position.<br />

B. All exit devices, delayed egress units and electronically controlled exit<br />

operators are to be by one manufacturer. Electronically operated units to be<br />

applied to fire rated openings cannot be modified in the field or shop after the<br />

manufacturer has applied label.<br />

C. All exit devices on exterior openings will have a deadlocking latchbolt<br />

feature, preventing manipulation of the latchbolt when the door is closed.<br />

D. Exit devices will have a written 10-year warranty issued by the manufacturer.<br />

E. All exit devices will have a stainless steel push bar. Chassis and baseplate will<br />

be extra heavy-duty double walled stainless steel.<br />

F. Contractor will provide factory prepared spacers to allow exit devices to clear<br />

applied moldings, window trims and decorative appliqué on doors. Spacers<br />

will be from the exit device manufacturer and finished to match devices.<br />

G. Models and Functions:<br />

2.<strong>08</strong> DOOR CLOSERS<br />

VonDUPRIN DORMA<br />

XP-98/99 9<strong>00</strong>0<br />

A. Unless otherwise specified, comply with the manufacturer's recommendations<br />

for the size of the closers and door control devices, depending on the size of<br />

the door, exposure to the weather, and the anticipated frequency of use.<br />

PW/WBG/413749<br />

DOOR HARDWARE<br />

JULY 30, 2012 <strong>08</strong> <strong>71</strong> <strong>00</strong> - 7<br />

©COPYRIGHT 2012 CH2M HILL

Project Specifications: Transit Maintenance and Operations Facility<br />

B. The opening force required to operate a door must be in compliance with the<br />

current ADA guidelines for the interior and exterior openings.<br />

C. Use the regular arm, parallel arm or top jamb mounted position to locate the<br />

closer for the maximum degree of efficiency and to place the closer out of<br />

sight wherever possible. Closers will be located on the interior side of the<br />

opening where possible.<br />

D. Closers will have a written 25-year warranty issued by the manufacturer.<br />

E. Models and Functions<br />

LCN<br />

DORMA<br />

4040XP 89<strong>00</strong><br />

4040-18 8980<br />

EDA<br />

SPA<br />

CUSH-S<br />

S-DS<br />

CUSH-H<br />

S-DST<br />

2.09 ELECTRONIC HARDWARE AND EQUIPMENT<br />

A. All electronically controlled or operated hardware will be by one<br />

manufacturer. Every component will have been tested and certified by UL and<br />

will bear a label showing its approval, rating and parameters. All power<br />

supplies will be listed as UL Class 2 access control, fire, burglary, releasing<br />

devices. Electronically operated units to be applied to fire rated openings<br />

cannot be modified in the field or shop after the manufacturer has applied<br />

label.<br />

B. Power Supplies:<br />

VonDUPRIN DORMA SDC<br />

873 x 8<strong>71</strong>-2 502RF 602RF<br />

JB7T 501JP-20TS 601JP-20TS<br />

MS764 MC4 MC-4<br />

EPT ES105 PT-5<br />

R2(24Vdc coil/120V ac-12 amp contacts) RLY24<br />

24-RY<br />

2.10 DOOR TRIM AND ACCESSORIES<br />

A. All kickplates will be 8 inches high and 1-1/2 inches less than the door width,<br />

with all exposed edges beveled. Mop plates will be 4 inches high and 1 inch<br />

less than the door width, with all exposed edges beveled. Armor plates and<br />

edge guards will be 34 inches high. All kickplates, mop plates, edge guards<br />

and armor plates will be stainless steel, .051 inch or thicker.<br />

DOOR HARDWARE<br />

PW/WBG/413749<br />

<strong>08</strong> <strong>71</strong> <strong>00</strong> - 8 JULY 30, 2012<br />

©COPYRIGHT 2012 CH2M HILL

Project Specifications: Transit Maintenance and Operations Facility<br />

B. Push and Pull Units - Models and Functions<br />

BURNS HAGER TRIMCO<br />

M36D X23L 1191-4J<br />

M422 136S-V 1745<br />

5425-C 39J 1018-3B<br />

57 30S-8X16 1<strong>00</strong>1-11<br />

C. Wall and Floor Stops - Models and Functions<br />

BURNS TRIMCO IVES<br />

570 W1270WVCP WS406CCV<br />

510 W1210ES FS436<br />

529 1234 FS451<br />

542 1209HA FS18S<br />

D. Flushbolts and Co-coordinators - Models and Functions<br />

BURNS TRIMCO IVES<br />

590 3915 FB258N<br />

591 3913 FB258NW<br />

E. Overhead Stops and Holders - Models and Functions<br />

GLYNN JOHNSON ABH Brookline<br />

90 9<strong>00</strong>0 1599<br />

1<strong>00</strong> 1<strong>00</strong>0 1511<br />

7<strong>00</strong> 33<strong>00</strong> 1555<br />

450 4<strong>00</strong>0 1505<br />

F. Weatherstrip and Thresholds: Provide weatherstrip and thresholds at all<br />

exterior openings.<br />

REESE NATL GUARD PEMKO<br />

S205A 425E 1<strong>71</strong>A<br />

S257AS 950S 2<strong>00</strong>1AS<br />

S487AS 884S 177AS<br />

S405A 513 2<strong>71</strong>G<br />

S488AV 803V 181AV<br />

330C 420NA 4301CRL<br />

430A 422N 434ARL<br />

757A 7<strong>00</strong>SA 2891AS<br />

93C 109NA 375CR<br />

599CS 107SA 350CSR<br />

797 2525 S88D<br />

967C C627A 3452C<br />

PW/WBG/413749<br />

DOOR HARDWARE<br />

JULY 30, 2012 <strong>08</strong> <strong>71</strong> <strong>00</strong> - 9<br />

©COPYRIGHT 2012 CH2M HILL

Project Specifications: Transit Maintenance and Operations Facility<br />

REESE NATL GUARD PEMKO<br />

195C 140MA 51CM<br />

R201A 16A 346C<br />

964C 6<strong>00</strong>A 18061CP<br />

970C A626A 45061CP<br />

Note: Changes in materials (e.g., stainless steel) may change the equivalent<br />

manufacturer’s model number. Contractor is to use material shown in<br />

schedule and change model number as required to obtain same style in<br />

specified material.<br />

PART 3<br />

EXECUTION<br />

3.01 INSTALLATION<br />

A. Factory representatives of the lock, exit device and closer manufacturers will<br />

each provide one hour of installation training on the job Site to the installation<br />

crew for this project.<br />

B. Representatives will return to the jobsite after 40 percent of the hardware has<br />

been installed to check for problems and answer questions from the<br />

installation crew. Representative will inform the Architect, General<br />

Contractor and Owner, in writing, of any serious problems encountered during<br />

this inspection.<br />

C. Mount hardware units at the height indicated in the Recommended Locations<br />

for Builder's <strong>Hardware</strong> for Standard Steel <strong>Door</strong>s and Frames by the <strong>Door</strong> and<br />

<strong>Hardware</strong> Institute; except as specifically indicated or required to comply with<br />

the governing regulations or as otherwise directed by the architect.<br />

D. Install each hardware item in compliance with the manufacturer's<br />

recommendations and instructions. Whenever cutting or fitting is required to<br />

install hardware on or into surfaces which are later to be painted, or finished<br />

another way; co-ordinate removal, storage and the re-installation of hardware<br />

with the finishing work specified in Division 9 sections. Do not install surface<br />

mounted hardware until finishes have been completed on the substrate.<br />

E. Drill and counter sink units that are not factory prepared for anchorage<br />

fasteners. Space anchors and fasteners in accordance with industry standards.<br />

F. Set thresholds for exterior openings in full bed of butyl rubber or<br />

polyisobutylene mastic sealant.<br />

G. Adjust and clean each operating item of hardware and each door to ensure the<br />

proper operation or function of each unit. Replace units that cannot be<br />

adjusted to operate freely and smoothly as intended for the application made.<br />

DOOR HARDWARE<br />

PW/WBG/413749<br />

<strong>08</strong> <strong>71</strong> <strong>00</strong> - 10 JULY 30, 2012<br />

©COPYRIGHT 2012 CH2M HILL

Project Specifications: Transit Maintenance and Operations Facility<br />

H. Instruct Owner's personnel in the proper adjustment and maintenance of the<br />

hardware and finishes during the final adjustment of the hardware.<br />

3.02 CONTINUED SERVICE AND WARRANTY<br />

A. Representatives of the lock, exit device and closer manufacturers will inspect<br />

the hardware and installation in the 7 days prior to the turnover of the<br />

building. Each opening will be examined for problems with materials and<br />

installation. A written report of their findings will be included with the<br />

warranty documents submitted to the owner at the turnover/occupancy of the<br />

building.<br />

B. Approximately 6 months after the acceptance of the building, the installers,<br />

and representatives of the lock, exit device, closer and card reader<br />

manufacturers will return to the project. At that time they will re-adjust every<br />

item of hardware to restore proper function of doors and hardware. They will<br />

consult with the Owner’s personnel in recommended changes to the<br />

maintenance procedures and will replace items that have failed under the<br />

warranty period. A written report will be submitted to the architect describing<br />

current or predictable problems (of a substantial nature) in the performance of<br />

the hardware.<br />

3.03 HARDWARE GROUP SETS<br />

A. This project may contain doors that are oversized, non-standard thickness and<br />

have applied trims. See the plans and schedules for the hinge widths and<br />

clearance requirements. <strong>Door</strong>s with glass lites and moldings will require spacers<br />

to allow fire exit device installation.<br />

B. Thru-bolts are to be used only where specifically indicated. No bolts, heads or<br />

retainers are to show through the door from surface applied hardware.<br />

Reinforce hollow metal or specialty doors to provide a minimum 12GA. steel<br />

for drilling and tapping to install hardware. Install hardwood blocking in wood<br />

doors to hold wood screws where hardware is installed.<br />

C. Furnish a detailed, color coded, wiring diagram showing all components used in<br />

openings where electrified hardware is specified. The hardware supplier will<br />

provide this diagram at the time of the hardware submittals. Factory installation<br />

instructions from the various elements will not be accepted as meeting this<br />

requirement.<br />

PW/WBG/413749<br />

DOOR HARDWARE<br />

JULY 30, 2012 <strong>08</strong> <strong>71</strong> <strong>00</strong> - 11<br />

©COPYRIGHT 2012 CH2M HILL

Project Specifications: Transit Maintenance and Operations Facility<br />

Administration Building<br />

<strong>Hardware</strong> Group 1-A<br />

ALUMINUM & GLASS ENTRANCES WITH POWER OPERATOR, LATCH RETRACTION<br />

AND CARD READER<br />

ETH:<br />

8ea Butts BB5<strong>00</strong>6 NRP 630 Bommer<br />

2ea Power Transfer EPT 10 689 Von Duprin<br />

1ea Exit Device EL-SS-3547EO 630 Von Duprin<br />

1ea Exit Device EL-SS-3547NL-OP-370T-L/C 630 Von Duprin<br />

1ea Mortise Cylinder 1070-114-AXX-6-CT6 (TMP)* 630 COR/RUS<br />

2ea Permanent Core 8<strong>00</strong>0-59D2-MKD 626 COR/RUS<br />

2ea Auto Operator/Closer EDA (Concealed) x RS 689 Stanley<br />

2ea Actuator 630 Stanley<br />

2ea Pulls M39-1G x 6HD 630 Burns<br />

2ea Auto Operator/Closer EDA x RS 689 Stanley<br />

2ea Actuator 630 Stanley<br />

1ea Key Switch 643-04-HDP-L2 628 Locknetics<br />

1ea Mortise Cylinder 1070-114-AXX-6-CT6 (TMP)* 630 COR/RUS<br />

1ea Power Supply 873 x 8<strong>71</strong>-2 6<strong>00</strong> Von Duprin<br />

1ea Junction Box JB7 6<strong>00</strong> Von Duprin<br />

1ea <strong>Door</strong> Position Switch MS764 <strong>71</strong>9 Von Duprin<br />

1ea Wiring Diagram WD-X - Von Duprin<br />

2ea <strong>Door</strong> Bottom 967C (ext side of door) 628 Reese<br />

1ea Threshold S257AS x ¼-20SS-MSA <strong>71</strong>9 Reese<br />

* Supplier to determine and confirm tailpiece and cylinder length for devices on submittals.<br />

Notes: <strong>Door</strong> seals and brush astragals by Al. door manufacturer.<br />

Card reader, conduit, back boxes, wire and additional relays by card reader supplier.<br />

<strong>Hardware</strong> Group 2-A<br />

ETH:<br />

8ea Butts BB5<strong>00</strong>6 NRP 630 Bommer<br />

1ea Exit Device CD-3547EO 630 Von Duprin<br />

1ea Exit Device CD-3547NL-OP-370T-L/C 630 Von Duprin<br />

3ea Mortise Cylinder 1070-114-AXX-6-CT6 (TMP)* 630 COR/RUS<br />

3ea Permanent Core 8<strong>00</strong>0-59D2-MKD 626 COR/RUS<br />

2ea Pulls M39-1G x 6HD 630 Burns<br />

2ea Concealed Closer 2030-3038B 689 LCN<br />

2ea <strong>Door</strong> Position Switch MS764 <strong>71</strong>9 Von Duprin<br />

2ea <strong>Door</strong> Bottom 967C (ext side of door) 628 Reese<br />

1ea Threshold S257AS x ¼-20SS-MSA <strong>71</strong>9 Reese<br />

* Supplier to determine and confirm tailpiece and cylinder length for devices on submittals.<br />

Notes: <strong>Door</strong> seals and brush astragals by Al. door manufacturer.<br />

DOOR HARDWARE<br />

PW/WBG/413749<br />

<strong>08</strong> <strong>71</strong> <strong>00</strong> - 12 JULY 30, 2012<br />

©COPYRIGHT 2012 CH2M HILL

Project Specifications: Transit Maintenance and Operations Facility<br />

<strong>Hardware</strong> Group 3-A<br />

ETH:<br />

4ea Butts BB5<strong>00</strong>6 NRP 630 Bommer<br />

1ea Exit Device 33L-370L06 630 Von Duprin<br />

1ea Mortise Cylinder 1070-114-AXX-6-CT6 (TMP)* 630 COR/RUS<br />

1ea Permanent Core 8<strong>00</strong>0-59D2-MKD 626 COR/RUS<br />

1ea Closer 4040S-CUSH (3077SC) 689 LCN<br />

1ea <strong>Door</strong> Position Switch MS764 <strong>71</strong>9 Von Duprin<br />

2ea <strong>Door</strong> Bottom 967C (ext side of door) 628 Reese<br />

1ea Threshold S257AS x ¼-20SS-MSA <strong>71</strong>9 Reese<br />

* Supplier to determine and confirm tailpiece and cylinder length for devices on submittals.<br />

Notes: <strong>Door</strong> seals by Al. door manufacturer.<br />

<strong>Hardware</strong> Group 4-A<br />

ETH:<br />

8ea Butts BB5<strong>00</strong>6 NRP 630 Bommer<br />

2ea Flush Bolts 590 652 Burns<br />

1ea Exit Device XP-98L-F- 994L06-L/C-1609 630 Von Duprin<br />

1ea Rim Cylinder 3070-178-6-CT6 (TMP) 630 COR/RUS<br />

1ea Permanent Core 8<strong>00</strong>0-59D2-MKD 626 COR/RUS<br />

1ea Closer 4040S-CUSH-H (3049SC) (act. leaf) 689 LCN<br />

1ea O.H. Stop/Holder 1<strong>00</strong>H (inact leaf) 651 Glynn Johnson<br />

2ea <strong>Door</strong> Position Switch MS764 <strong>71</strong>9 Von Duprin<br />

1ea Drip Cap R201A 4”ODW 628 Reese<br />

1set <strong>Door</strong> Seals 970C 628 Reese<br />

1ea <strong>Door</strong> Seals 797C (applied to astragal) Gray Reese<br />

2ea <strong>Door</strong> Bottom 967C (ext side of door) 628 Reese<br />

1ea Threshold S487AS x ¼-20SS-MSA <strong>71</strong>9 Reese<br />

Full-height overlapping steel astragal on active leaf pull side provided by door manufacturer.<br />

<strong>Hardware</strong> Group 5-A<br />

ETH:<br />

8ea Butts BB5<strong>00</strong>2 NRP 630 Bommer<br />

2ea Flush Bolts 590 652 Burns<br />

1ea StoreRm Lock CL3357-NZD-134-234-SC118-M21-CT6 (TMP) 630 COR/RUS<br />

1ea Permanent Core 8<strong>00</strong>0-59D2-MKD 626 COR/RUS<br />

1ea Closer 4040S-CUSH-H (3049SC) (act. leaf) 689 LCN<br />

1ea O.H. Stop 1<strong>00</strong>S (inact leaf) 651 Glynn Johnson<br />

2ea <strong>Door</strong> Position Switch MS764 <strong>71</strong>9 Von Duprin<br />

1set <strong>Door</strong> Seals 797C Gray Reese<br />

1ea <strong>Door</strong> Seals 797C (applied to astragal) Gray Reese<br />

1ea Threshold S488AV x ¼-20SS-MSA <strong>71</strong>9 Reese<br />

Full-height overlapping steel astragal on active leaf pull side provided by door manufacturer.<br />

Special LTC to avoid cutting astragal.<br />

PW/WBG/413749<br />

DOOR HARDWARE<br />

JULY 30, 2012 <strong>08</strong> <strong>71</strong> <strong>00</strong> - 13<br />

©COPYRIGHT 2012 CH2M HILL

Project Specifications: Transit Maintenance and Operations Facility<br />

<strong>Hardware</strong> Group 6-A<br />

ETH:<br />

6ea Butts BB5<strong>00</strong>6 NRP 630 Bommer<br />

2ea Pulls M36D x 6HD 630 Burns<br />

2ea Pushbar M422 x 6HD 630 Burns<br />

2ea Concealed Closer 2030-3038B 689 LCN<br />

Notes: <strong>Door</strong> Seals and brush astragals by Al. Dr. Mfg.<br />

<strong>Hardware</strong> Group 7-A<br />

ETH:<br />

3ea Butts 5<strong>00</strong>0 652 Bommer<br />

1ea Office Lock CL3351-NZD-134-234-SC118-CT6 (TMP) 626 COR/RUS<br />

1ea Permanent Core 8<strong>00</strong>0-59D2-MKD 626 COR/RUS<br />

1ea Wall/Floor Stop 570/510 626 Burns<br />

3ea Silencers 5<strong>00</strong> Gray Burns<br />

<strong>Hardware</strong> Group 8-A<br />

ETH:<br />

4ea Butts BB5<strong>00</strong>0 652 Bommer<br />

1ea Office Lock CL3351-NZD-134-234-SC118-CT6 (TMP) 626 COR/RUS<br />

1ea Permanent Core 8<strong>00</strong>0-59D2-MKD 626 COR/RUS<br />

1ea Closer 4040-TB (TBSRT) 689 LCN<br />

1ea Kickplates J102 x .050 x CSK x 3BE x 8 x 2LDW 630 Burns<br />

1ea Wall/Floor Stop 570/510 626 Burns<br />

1ea Sill 273D 273D Pemko<br />

3ea Silencers 5<strong>00</strong> Gray Burns<br />

<strong>Hardware</strong> Group 9-A<br />

ETH:<br />

4ea Butts BB5<strong>00</strong>4 NRP 652 Bommer<br />

1ea Classroom Lock CL3355-NZD-134-234-SC118-CT6 (TMP) 626 COR/RUS<br />

1ea Permanent Core 8<strong>00</strong>0-59D2-MKD 626 COR/RUS<br />

1ea Closer 4040EDA (3077EDA)-TB (TBSRT) 689 LCN<br />

1ea Kickplates J102 x .050 x CSK x 3BE x 8 x 2LDW 630 Burns<br />

1ea Wall/Floor Stop 570/510 626 Burns<br />

1ea Sill 273D 273D Pemko<br />

2ea Silencers 5<strong>00</strong> Gray Burns<br />

At door 124, provide in addition to the above the following:<br />

1ea Power Transfer EPT 10 689 Von Duprin<br />

1ea Power Supply 873 x 8<strong>71</strong>-2 6<strong>00</strong> Von Duprin<br />

1ea Junction Box JB7 6<strong>00</strong> Von Duprin<br />

1ea <strong>Door</strong> Positioning Switch MS764 <strong>71</strong>9 Von Duprin<br />

1ea Wiring Diagram WD –X - Von Duprin<br />

Card reader, conduit, back boxes, wire and additional relays by card reader supplier.<br />

DOOR HARDWARE<br />

PW/WBG/413749<br />

<strong>08</strong> <strong>71</strong> <strong>00</strong> - 14 JULY 30, 2012<br />

©COPYRIGHT 2012 CH2M HILL

Project Specifications: Transit Maintenance and Operations Facility<br />

<strong>Hardware</strong> Group 10-A<br />

ETH:<br />

4ea Butts BB5<strong>00</strong>4 SH & NRP 652 Bommer<br />

1ea StoreRm Lock CL3357-NZD-134-234-SC118-M21-CT6 (TMP) 630 COR/RUS<br />

1ea Permanent Core 8<strong>00</strong>0-59D2-MKD 626 COR/RUS<br />

1ea Closer 4040S-CUSH-H (3049SC) 689 LCN<br />

1ea Kickplates J102 x .050 x CSK x 3BE x 8 x 2LDW 630 Burns<br />

1set <strong>Door</strong> Seals 797B x 588CH* BLK Reese<br />

<strong>Hardware</strong> Group 11-A<br />

ETH:<br />

4ea Butts BB5<strong>00</strong>0 652 Bommer<br />

1ea Classroom Lock CL3355-NZD-134-234-SC118-CT6 (TMP) 626 COR/RUS<br />

1ea Permanent Core 8<strong>00</strong>0-59D2-MKD 626 COR/RUS<br />

1ea Closer 4040-TB (TBSRT) 689 LCN<br />

3ea Silencers 5<strong>00</strong> Gray Burns<br />

1ea Sill 273D 273D Pemko<br />

<strong>Hardware</strong> Group 12-A<br />

ETH:<br />

4ea Butts BB5024 4.5 x 4.5 652 Bommer<br />

1ea StoreRm Lock CL3357-NZD-134-234-SC118-CT6 (TMP) 630 COR/RUS<br />

1ea Permanent Core 8<strong>00</strong>0-59D2-MKD 626 COR/RUS<br />

1ea Lever Guard DNP-10 (Inside) Gray Burns<br />

1ea O.H. Stop & Holder 1<strong>00</strong>H 652 Glynn Johnson<br />

1ea Armor Plate J101 x .050 x CSK x 3BE x 34”H x 2LDW 630 Burns<br />

1ea Edge Guards 307 x CFH c 34” 630 Burns<br />

3ea Silencers Gray Burns<br />

1ea Sill PGBAP18 x 5 x SS¼-20MSES (Heavy Duty CAST ) Gray Reese<br />

<strong>Hardware</strong> Group 13-A<br />

ETH:<br />

3ea Butts BB5<strong>00</strong>0 652 Bommer<br />

1ea StoreRm Lock CL3357-NZD-134-234-SC118-M21-CT6 (TMP) 630 COR/RUS<br />

1ea Permanent Core 8<strong>00</strong>0-59D2-MKD 626 COR/RUS<br />

1ea Closer 4040-TB (TBSRT) 689 LCN<br />

1ea Wall/Floor Stop 570/510 626 Burns<br />

1set <strong>Door</strong> Seals 797B x 588CH* BLK Reese<br />

1ea Power Transfer EPT 10 689 Von Duprin<br />

1ea Power Supply 873 x 8<strong>71</strong>-2 6<strong>00</strong> Von Duprin<br />

1ea Junction Box JB7 6<strong>00</strong> Von Duprin<br />

1ea <strong>Door</strong> Positioning Switch MS764 <strong>71</strong>9 Von Duprin<br />

1ea Wiring Diagram WD –X - Von Duprin<br />

Card reader, conduit, back boxes, wire and additional relays by card reader supplier.<br />

PW/WBG/413749<br />

DOOR HARDWARE<br />

JULY 30, 2012 <strong>08</strong> <strong>71</strong> <strong>00</strong> - 15<br />

©COPYRIGHT 2012 CH2M HILL

Project Specifications: Transit Maintenance and Operations Facility<br />

<strong>Hardware</strong> Group 14-A<br />

ETH:<br />

4ea Butts BB5<strong>00</strong>0 NRP 652 Bommer<br />

1ea StoreRm Lock CL3357-NZD-134-234-SC118-M21-CT6 (TMP) 630 COR/RUS<br />

1ea Permanent Core 8<strong>00</strong>0-59D2-MKD 626 COR/RUS<br />

1ea Closer 4040S-CUSH-H (3049SC) 689 LCN<br />

1ea Wall/Floor Stop 570/510 626 Burns<br />

1set <strong>Door</strong> Seals 797C Gray Reese<br />

1ea Sill 252D 252D Pemko<br />

*Note: Delete HO at fire rated openings.<br />

<strong>Hardware</strong> Group 15-A<br />

ETH:<br />

4ea Butts BB5<strong>00</strong>0 652 Bommer<br />

1ea Passage Set CL3310-NZD-134-234-SC118 626 COR/RUS<br />

1ea Closer 4040-TB (TBSRT) 689 LCN<br />

1ea Kickplates J102 x .050 x CSK x 3BE x 8 x 2LDW 630 Burns<br />

1ea Wall/Floor Stop 570/510 626 Burns<br />

1set Sound Seals 599CS 628 Reese<br />

1ea <strong>Door</strong> Bottom 330C <strong>71</strong>9 Reese<br />

<strong>Hardware</strong> Group 16-A<br />

ETH:<br />

4ea Butts BB5<strong>00</strong>6 NRP 630 Bommer<br />

1ea Deadbolt 45<strong>00</strong>-COR/RUS 626 ILCO<br />

1ea Permanent Core 8<strong>00</strong>0-59D2-MKD 626 COR/RUS<br />

1ea Pushplate 57 8x16 x C/C (CFC) 630 Burns<br />

1ea Pull 5425-C x TB* 630 Burns<br />

1ea Closer 4040-TB (TBSRT) 689 LCN<br />

1ea Kickplates J102 x .050 x CSK x 3BE x 8 x 2LDW 630 Burns<br />

1ea Mop Plate J103 x .038 x CSK x 3BE x 4 x 1LDW 630 Burns<br />

1ea Wall/Floor Stop 570/510 626 Burns<br />

1ea Sill 252D 252D Pemko<br />

3ea Silencers Gray Burns<br />

Note: Sill and signage by others.<br />

* Install pull with TB’s. Cover TBs with pushplate. Locate cylinder hole so plate edge is<br />

1/8 inch from the frame stop when door is closed.<br />

DOOR HARDWARE<br />

PW/WBG/413749<br />

<strong>08</strong> <strong>71</strong> <strong>00</strong> - 16 JULY 30, 2012<br />

©COPYRIGHT 2012 CH2M HILL

Project Specifications: Transit Maintenance and Operations Facility<br />

<strong>Hardware</strong> Group 17-A<br />

Provide the following:<br />

1 ea. Key Cabinet (see Article Key Control System)<br />

10 ea. Const. Master Keys (see Article Cylinders and Keying)<br />

X Cut keys: GMK, MKs, and 3 keys each cylinder (see Article Cylinders and Keying)<br />

5 ea. Extra permanent cores keyed to Owner’s directions<br />

1 ea. Written warranty for each lock and cylinder, closer, and exit device<br />

(See Articles Locksets and Latches, Fire Exit Devices, and <strong>Door</strong> Closers)<br />

1 set Catalog cuts and parts manuals for locks, closers and exit devices<br />

4 ea. Job Site instruction, inspection and consultations<br />

(See Article Installation, and Article Continued Service and Warranty)<br />

1 ea. Installation of permanent cores by core manufacturer’s representative<br />

Maintanence Building<br />

<strong>Hardware</strong> Group 1-M<br />

ETH:<br />

3ea Butts BB5<strong>00</strong>6 NRP 630 Bommer<br />

1ea Exit Device XP-98EO 630 Von Duprin<br />

1ea Closer 4040S-CUSH (3077SC) 689 LCN<br />

1ea Kickplates J102 x .050 x CSK x 3BE x 8 x 2LDW 630 Burns<br />

1ea <strong>Door</strong> Position Switch MS764 6<strong>00</strong> Von Duprin<br />

1ea Drip Cap R201A 4”ODW 628 Reese<br />

1set <strong>Door</strong> Seals 757A 628 Reese<br />

1ea <strong>Door</strong> Bottom 967C (ext side of door) 628 Reese<br />

1ea Threshold S257AS x ¼-20SS-MSA <strong>71</strong>9 Reese<br />

<strong>Hardware</strong> Group 2-M<br />

ETH:<br />

3ea Butts BB5<strong>00</strong>6 NRP 630 Bommer<br />

1ea Exit Device XP-98L-994L06-Less Cyl 630 Von Duprin<br />

1ea Rim Cylinder 3070-178-6-CT6 (TMP) 630 COR/RUS<br />

1ea Permanent Core 8<strong>00</strong>0-59D2-MKD 626 COR/RUS<br />

1ea Closer 4040S-CUSH-H (3049SC) 689 LCN<br />

1ea Kickplates J102 x .050 x CSK x 3BE x 8 x 2LDW 630 Burns<br />

1ea <strong>Door</strong> Position Switch MS764 6<strong>00</strong> Von Duprin<br />

1ea Drip Cap R201A 4”ODW 628 Reese<br />

1set <strong>Door</strong> Seals 757A 628 Reese<br />

1ea <strong>Door</strong> Bottom 967C (ext side of door) 628 Reese<br />

1ea Threshold S257AS x ¼-20SS-MSA <strong>71</strong>9 Reese<br />

PW/WBG/413749<br />

DOOR HARDWARE<br />

JULY 30, 2012 <strong>08</strong> <strong>71</strong> <strong>00</strong> - 17<br />

©COPYRIGHT 2012 CH2M HILL

Project Specifications: Transit Maintenance and Operations Facility<br />

<strong>Hardware</strong> Group 3-M<br />

ETH:<br />

3ea Butts BB5<strong>00</strong>6 NRP 630 Bommer<br />

1ea Power Transfer EPT-10 689 Von Duprin<br />

1ea Exit Device EL-SS-XP-98L-994L06-Less Cyl 630 Von Duprin<br />

1ea Rim Cylinder 3070-178-6-CT6 (TMP) 630 COR/RUS<br />

1ea Permanent Core 8<strong>00</strong>0-59D2-MKD 626 COR/RUS<br />

1ea Closer 4040S-CUSH (3077SC) 689 LCN<br />

1ea Kickplates J102 x .050 x CSK x 3BE x 8 x 2LDW 630 Burns<br />

1ea Power Supply 873 x 8<strong>71</strong>-2 6<strong>00</strong> Von Duprin<br />

1ea Junction Box JB7 6<strong>00</strong> Von Duprin<br />

1ea <strong>Door</strong> Position Switch MS764 6<strong>00</strong> Von Duprin<br />

1ea Wiring Diagram WD-X - Von Duprin<br />

1ea Drip Cap R201A 4”ODW 628 Reese<br />

1set <strong>Door</strong> Seals 757A 628 Reese<br />

1ea <strong>Door</strong> Bottom 967C (ext side of door) 628 Reese<br />

1ea Threshold S257AS x ¼-20SS-MSA <strong>71</strong>9 Reese<br />

Note: Card reader, relays, cable, conduit, connectors, and terminations by security<br />

contractor.<br />

<strong>Hardware</strong> Group 4-M<br />

ETH:<br />

3ea Butts BB5<strong>00</strong>6 NRP 630 Bommer<br />

1ea StoreRm Lock CL3357-NZD-134-234-SC118-M21-CT6 (TMP) 630 COR/RUS<br />

1ea Permanent Core 8<strong>00</strong>0-59D2-MKD 626 COR/RUS<br />

1ea Latch Guard 621 630 Burns<br />

1ea Closer 4040S-CUSH-H (3049SC) 689 LCN<br />

1ea Kickplates J102 x .050 x CSK x 3BE x 8 x 2LDW 630 Burns<br />

1ea <strong>Door</strong> Position Switch MS764 6<strong>00</strong> Von Duprin<br />

1ea Drip Cap R201A 4”ODW 628 Reese<br />

1set <strong>Door</strong> Seals 970C 628 Reese<br />

1ea <strong>Door</strong> Bottom 967C (ext side of door) 628 Reese<br />

1ea Threshold S257AS x ¼-20SS-MSA <strong>71</strong>9 Reese<br />

DOOR HARDWARE<br />

PW/WBG/413749<br />

<strong>08</strong> <strong>71</strong> <strong>00</strong> - 18 JULY 30, 2012<br />

©COPYRIGHT 2012 CH2M HILL

Project Specifications: Transit Maintenance and Operations Facility<br />

<strong>Hardware</strong> Group 5-M<br />

ETH:<br />

6ea Butts BB5<strong>00</strong>2 NRP 630 Bommer<br />

2ea Surface Bolts 598 652 Burns<br />

1ea StoreRm Lock CL3357-NZD-134-234-SC118-M21-CT6 (TMP) 630 COR/RUS<br />

1ea Permanent Core 8<strong>00</strong>0-59D2-MKD 626 COR/RUS<br />

1ea Closer 4040S-CUSH (3077SC) 689 LCN<br />

1ea O.H. Stop 790S (inact leaf) 651 Glynn Johnson<br />

2ea <strong>Door</strong> Position Switch MS764 6<strong>00</strong> Von Duprin<br />

1set <strong>Door</strong> Seals 797C Gray Reese<br />

1ea <strong>Door</strong> Seals 797C (applied to astragal) Gray Reese<br />

1ea Threshold S488AV x ¼-20SS-MSA <strong>71</strong>9 Reese<br />

*Note: Flat steel astragal, on pull side of active leaf, by door manufacturer.<br />

Special LTC to avoid cutting astragal.<br />

<strong>Hardware</strong> Group 6-M<br />

ETH:<br />

1ea Lockset 1<strong>00</strong>-HBX-STR 628 Multi Lock<br />

1ea Mortise Cylinder 1070-114-AXX-6-CT6 (TMP)* 630 COR/RUS<br />

1ea Permanent Core 8<strong>00</strong>0-59D2-MKD 626 COR/RUS<br />

All other hardware by partition manufacturer.<br />

*Gate lock to be equipped with COR/RUS mortise cylinder shells; installed by lock manufacturer.<br />

<strong>Hardware</strong> Group 7-M<br />

ETH:<br />

1ea Rim Cylinder 3070-178-6-CT6 (TMP)* 630 COR/RUS<br />

2ea Permanent Core 8<strong>00</strong>0-59D2-MKD 626 COR/RUS<br />

1ea <strong>Construction</strong> Core CT6 626 COR/RUS<br />

1ea Padlock 35<strong>00</strong> Less Core (HD Exterior Grade, 2” steel shackle) 626 American<br />

2ea DPS 2209 630 Sentrol<br />

All other hardware shall be provided by door manufacturer or security contractor.<br />

* <strong>Hardware</strong> supplier must confirm cylinder type, size and tailpiece or cam with equipment<br />

manufacturer when shop drawings are submitted.<br />

<strong>Hardware</strong> Group 8-M<br />

ETH:<br />

3ea Butts 5<strong>00</strong>0 NRP 652 Bommer<br />

1ea Office Lock CL3351-NZD-134-234-SC118-CT6 (TMP) 626 COR/RUS<br />

1ea Permanent Core 8<strong>00</strong>0-59D2-MKD 626 COR/RUS<br />

1ea O.H Stop 410H 689 Glynn Johnson<br />

3ea Silencers 5<strong>00</strong> Gray Burns<br />

PW/WBG/413749<br />

DOOR HARDWARE<br />

JULY 30, 2012 <strong>08</strong> <strong>71</strong> <strong>00</strong> - 19<br />

©COPYRIGHT 2012 CH2M HILL

Project Specifications: Transit Maintenance and Operations Facility<br />

<strong>Hardware</strong> Group 9-M<br />

ETH:<br />

3ea Butts BB5<strong>00</strong>0 652 Bommer<br />

1ea Office Lock CL3351-NZD-134-234-SC118-CT6 (TMP) 626 COR/RUS<br />

1ea Permanent Core 77-BB-626-MKD 626 Dorma<br />

1ea Closer 4040-TB (TBSRT) 689 LCN<br />

1ea Kickplates J102 x .050 x CSK x 3BE x 8 x 2LDW 630 Burns<br />

1ea Floor Stop 510 626 Burns<br />

1ea Sill S405A x ¼-20SS-MSA <strong>71</strong>9 Reese<br />

3ea Silencers 5<strong>00</strong> Gray Burns<br />

<strong>Hardware</strong> Group 10-M<br />

ETH:<br />

3ea Butts BB5<strong>00</strong>0 652 Bommer<br />

1ea Classroom Lock CL3355-NZD-134-234-SC118-CT6 (TMP) 626 COR/RUS<br />

1ea Permanent Core 8<strong>00</strong>0-59D2-MKD 626 COR/RUS<br />

1ea Closer 4040-TB (TBSRT) 689 LCN<br />

1ea Kickplates J102 x .050 x CSK x 3BE x 8 x 2LDW 630 Burns<br />

1ea Wall Stop 570 626 Burns<br />

3ea Silencers 5<strong>00</strong> Gray Burns<br />

<strong>Hardware</strong> Group 11-M<br />

ETH:<br />

3ea Butts BB5<strong>00</strong>6 NRP 630 Bommer<br />

1ea Classroom Lock CL3355-NZD-134-234-SC118-CT6 (TMP) 626 COR/RUS<br />

1ea Permanent Core 8<strong>00</strong>0-59D2-MKD 626 COR/RUS<br />

1ea Closer 4040S-CUSH-H (3049SC) 689 LCN<br />

1ea Kickplates J102 x .050 x CSK x 3BE x 8 x 2LDW 630 Burns<br />

3ea Silencers 5<strong>00</strong> Gray Burns<br />

<strong>Hardware</strong> Group 12-M<br />

ETH:<br />

3ea Butts BB5<strong>00</strong>6 NRP & SH 630 Bommer<br />

1ea Deadbolt 45<strong>00</strong>-COR/RUS 626 ILCO<br />

1ea StoreRm Lock CL3357-NZD-134-234-SC118-CT6 (TMP) 630 COR/RUS<br />

2ea Permanent Core 8<strong>00</strong>0-59D2-MKD 626 COR/RUS<br />

1ea Closer TJ4040-18G-TB (TBSRT) 689 LCN<br />

1ea O.H. Stop 1<strong>00</strong>S 652 Glynn Johnson<br />

1ea Kickplates J102 x .050 x CSK x 3BE x 8 x 2LDW 630 Burns<br />

1set <strong>Door</strong> Seals 797B BLK Reese<br />

1ea Threshold S257AS x ¼-20SS-MSA <strong>71</strong>9 Reese<br />

DOOR HARDWARE<br />

PW/WBG/413749<br />

<strong>08</strong> <strong>71</strong> <strong>00</strong> - 20 JULY 30, 2012<br />

©COPYRIGHT 2012 CH2M HILL

Project Specifications: Transit Maintenance and Operations Facility<br />

<strong>Hardware</strong> Group 13-M<br />

ETH:<br />

3ea Butts BB5<strong>00</strong>6 NRP & SH 630 Bommer<br />

1ea Deadbolt 45<strong>00</strong>-COR/RUS 626 ILCO<br />

1ea StoreRm Lock CL3357-NZD-134-234-SC118-CT6 (TMP) 630 COR/RUS<br />

2ea Permanent Core 8<strong>00</strong>0-59D2-MKD 626 COR/RUS<br />

1ea Closer 4040-TB (TBSRT) 689 LCN<br />

1ea Viewer 856 626 Burns<br />

1ea Kickplates J102 x .050 x CSK x 3BE x 8 x 2LDW 630 Burns<br />

1ea Floor Stop 542 626 Burns<br />

1set <strong>Door</strong> Seals 797B BLK Reese<br />

1ea Threshold S257AS x ¼-20SS-MSA <strong>71</strong>9 Reese<br />

<strong>Hardware</strong> Group 14-M<br />

ETH:<br />

3ea Butts BB5<strong>00</strong>0 652 Bommer<br />

1ea StoreRm Lock CL3357-NZD-134-234-SC118-CT6 (TMP) 630 COR/RUS<br />

1ea Permanent Core 8<strong>00</strong>0-59D2-MKD 626 COR/RUS<br />

1ea Closer 4040-TB (TBSRT) 689 LCN<br />

1ea Kickplates J102 x .050 x CSK x 3BE x 8 x 2LDW 630 Burns<br />

1ea Wall Stop 570 626 Burns<br />

3ea Silencers 5<strong>00</strong> Gray Burns<br />

<strong>Hardware</strong> Group 15-M<br />

ETH:<br />

3ea Butts BB5<strong>00</strong>6 630 Bommer<br />

1ea Passage Set CL3310-NZD-134-234-SC118 626 COR/RUS<br />

1ea Closer 4040S-CUSH-H (3049SC) 689 LCN<br />

1ea Kickplates J102 x .050 x CSK x 3BE x 8 x 2LDW 630 Burns<br />

1ea Wall Stop 570 626 Burns<br />

3ea Silencers 5<strong>00</strong> Gray Burns<br />

PW/WBG/413749<br />

DOOR HARDWARE<br />

JULY 30, 2012 <strong>08</strong> <strong>71</strong> <strong>00</strong> - 21<br />

©COPYRIGHT 2012 CH2M HILL

Project Specifications: Transit Maintenance and Operations Facility<br />

<strong>Hardware</strong> Group 16-M<br />

ETH:<br />

6ea Butts BB5026 4.5 x 4.5 NRP 630 Bommer<br />

2ea Flushbolts 590 626 Burns<br />

1ea StoreRm Lock CL3357-NZD-134-234-SC118-CT6 (TMP) 630 COR/RUS<br />

1ea Permanent Core 8<strong>00</strong>0-59D2-MKD 626 COR/RUS<br />

2ea Lever Guards DNP-10 Gray Burns<br />

1ea Closer 4040S-CUSH-H (3049SC) active leaf 689 LCN<br />

1ea O.H. Stop & Holder 79H (inactive leaf) 652 Glynn Johnson<br />

2ea Armor Plate J101 x .050 x CSK x 3BE x 34”H x 2LDW 630 Burns<br />

2ea Edge Guards 307 x CFH c 34” 630 Burns<br />

1ea Edge Guard 307 x CF FB’s x 34” 630 Burns<br />

1ea Edge Guard 307 x CF Mort Lock front (Gov’t 86) x 34” 630 Burns<br />

1ea <strong>Door</strong> Seals 797C (applied to astragal) Gray Reese<br />

1set <strong>Door</strong> Seals 797C Gray Reese<br />

1ea Sill PGBAP18 x 5 x SS¼-20MSES (Heavy Duty CAST ) Gray Reese<br />

X FACTORY PREP FOR STRIKE.<br />

<strong>Hardware</strong> Group 17-M<br />

ETH:<br />

3ea Butts BB5<strong>00</strong>0 652 Bommer<br />

1ea StoreRm Lock CL3357-NZD-134-234-SC118-M21-CT6 (TMP) 630 COR/RUS<br />

1ea Permanent Core 8<strong>00</strong>0-59D2-MKD 626 COR/RUS<br />

1ea Closer 4040-TB (TBSRT) 689 LCN<br />

1ea Kickplates J102 x .050 x CSK x 3BE x 8 x 2LDW 630 Burns<br />

1ea Floor Stop/Holder *529 626 Burns<br />

1set <strong>Door</strong> Seals 797C Gray Reese<br />

1ea Sill S205A x ¼-20MS/LA <strong>71</strong>9 Reese<br />

* Note: Delete HO at fire rated openings.<br />

<strong>Hardware</strong> Group 18-M<br />

ETH:<br />

3ea Butts BB5<strong>00</strong>0 652 Bommer<br />

1ea StoreRm Lock CL3357-NZD-134-234-SC118-M21-CT6 (TMP) 630 COR/RUS<br />

1ea Permanent Core 8<strong>00</strong>0-59D2-MKD 626 COR/RUS<br />

1ea Closer 4040-TB (TBSRT) 689 LCN<br />

1ea Floor Stop 510 626 Burns<br />

1set <strong>Door</strong> Seals 797B x 588CH* BLK Reese<br />

1ea Threshold S257AS x ¼-20SS-MSA <strong>71</strong>9 Reese<br />

DOOR HARDWARE<br />

PW/WBG/413749<br />

<strong>08</strong> <strong>71</strong> <strong>00</strong> - 22 JULY 30, 2012<br />

©COPYRIGHT 2012 CH2M HILL

Project Specifications: Transit Maintenance and Operations Facility<br />

<strong>Hardware</strong> Group 19-M<br />

ETH:<br />

3ea Butts BB5<strong>00</strong>6 630 Bommer<br />

1ea Classroom Deadbolt 45<strong>00</strong>-COR/RUS 626 ILCO<br />

1ea Permanent Core 8<strong>00</strong>0-59D2-MKD 626 COR/RUS<br />

1ea Pushplate 57 8x16 x C/C (CFC) 630 Burns<br />

1ea Pull 5425-C x TB* 630 Burns<br />

1ea Closer 4040-TB (TBSRT) 689 LCN<br />

1ea Kickplates J102 x .050 x CSK x 3BE x 8 x 2LDW 630 Burns<br />

1ea Mop Plate J103 x .038 x CSK x 3BE x 4 x 1LDW 630 Burns<br />

1ea Floor Stop 510 626 Burns<br />

3ea Silencers Gray Burns<br />

Note: Sill & Signage by others.<br />

* Install pull with TB’s. Cover TB’s with pushplate. Locate cylinder hole so plate<br />

edge is 1/8” from the frame stop when door is closed.<br />

<strong>Hardware</strong> Group 20-M<br />

ETH:<br />

3ea Butts BB5<strong>00</strong>0 652 Bommer<br />

1ea Privacy Lock CL3320-NZD-134-234-SC118 626 COR/RUS<br />

1ea Closer 4040-TB (TBSRT) 689 LCN<br />

1ea Kickplates J102 x .050 x CSK x 3BE x 8 x 2LDW 630 Burns<br />

1ea Wall Stop 570 626 Burns<br />

3ea Silencers 5<strong>00</strong> Gray Burns<br />

<strong>Hardware</strong> Group 21-M<br />

ETH:<br />

3ea Butts BB5<strong>00</strong>4 652 Bommer<br />

1ea Pushplate 57 8x16 630 Burns<br />

1ea Pull 5425-C x TB* 630 Burns<br />

1ea Closer 4040-TB (TBSRT) 689 LCN<br />

1ea Kickplates J102 x .050 x CSK x 3BE x 8 x 2LDW 630 Burns<br />

1ea Mop Plate J103 x .038 x CSK x 3BE x 4 x 1LDW 630 Burns<br />

1ea Wall Stop 570 626 Burns<br />

3ea Silencers 5<strong>00</strong> Gray Burns<br />

Note: Sill by others.<br />

Install pull with TB’s. Cover TB’s with pushplate.<br />

PW/WBG/413749<br />

DOOR HARDWARE<br />

JULY 30, 2012 <strong>08</strong> <strong>71</strong> <strong>00</strong> - 23<br />

©COPYRIGHT 2012 CH2M HILL

Project Specifications: Transit Maintenance and Operations Facility<br />

<strong>Hardware</strong> Group - Miscellaneous<br />

Provide the following:<br />

1 ea. Key Cabinet (see Article Key Control System)<br />

10 ea. Const. Master Keys (see Article Cylinders and Keying)<br />

X Cut keys: GMK, MKs, and 3 keys each cylinder (see Article Cylinders and Keying)<br />

10 ea. Extra permanent cores keyed to Owner’s directions<br />

1 ea. Written warranty for each lock and cylinder, closer, and exit device<br />

(See Articles Locksets and Latches, Fire Exit Devices, and <strong>Door</strong> Closers)<br />

1 set Catalog cuts and parts manuals for locks, closers and exit devices<br />

4 ea. Job Site instruction, inspection and consultations<br />

(See Article Installation, and Article Continued Service and Warranty)<br />

1 ea. Installation of permanent cores by hardware distributor representative<br />

END OF SECTION<br />

DOOR HARDWARE<br />

PW/WBG/413749<br />

<strong>08</strong> <strong>71</strong> <strong>00</strong> - 24 JULY 30, 2012<br />

©COPYRIGHT 2012 CH2M HILL