Module 4 - Construction of a gravity fed system

Module 4 - Construction of a gravity fed system

Module 4 - Construction of a gravity fed system

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

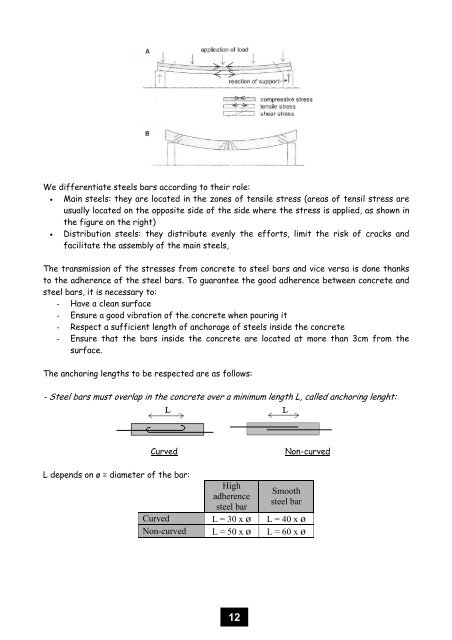

We differentiate steels bars according to their role:<br />

• Main steels: they are located in the zones <strong>of</strong> tensile stress (areas <strong>of</strong> tensil stress are<br />

usually located on the opposite side <strong>of</strong> the side where the stress is applied, as shown in<br />

the figure on the right)<br />

• Distribution steels: they distribute evenly the efforts, limit the risk <strong>of</strong> cracks and<br />

facilitate the assembly <strong>of</strong> the main steels,<br />

The transmission <strong>of</strong> the stresses from concrete to steel bars and vice versa is done thanks<br />

to the adherence <strong>of</strong> the steel bars. To guarantee the good adherence between concrete and<br />

steel bars, it is necessary to:<br />

- Have a clean surface<br />

- Ensure a good vibration <strong>of</strong> the concrete when pouring it<br />

- Respect a sufficient length <strong>of</strong> anchorage <strong>of</strong> steels inside the concrete<br />

- Ensure that the bars inside the concrete are located at more than 3cm from the<br />

surface.<br />

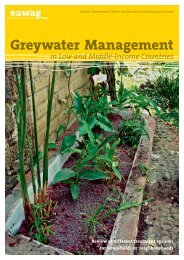

The anchoring lengths to be respected are as follows:<br />

- Steel bars must overlap in the concrete over a minimum length L, called anchoring lenght:<br />

Curved<br />

Non-curved<br />

L depends on ø = diameter <strong>of</strong> the bar:<br />

High<br />

adherence<br />

steel bar<br />

Smooth<br />

steel bar<br />

Curved L = 30 x ø L = 40 x ø<br />

Non-curved L = 50 x ø L = 60 x ø<br />

12