Module 4 - Construction of a gravity fed system

Module 4 - Construction of a gravity fed system

Module 4 - Construction of a gravity fed system

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

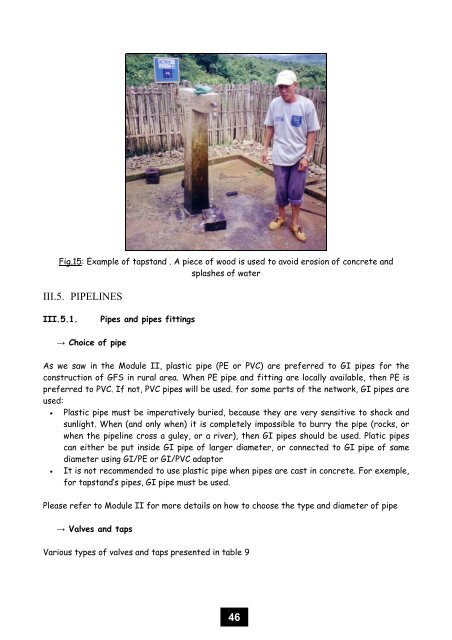

Fig.15: Example <strong>of</strong> tapstand . A piece <strong>of</strong> wood is used to avoid erosion <strong>of</strong> concrete and<br />

splashes <strong>of</strong> water<br />

III.5. PIPELINES<br />

III.5.1.<br />

Pipes and pipes fittings<br />

→ Choice <strong>of</strong> pipe<br />

As we saw in the <strong>Module</strong> II, plastic pipe (PE or PVC) are preferred to GI pipes for the<br />

construction <strong>of</strong> GFS in rural area. When PE pipe and fitting are locally available, then PE is<br />

preferred to PVC. If not, PVC pipes will be used. for some parts <strong>of</strong> the network, GI pipes are<br />

used:<br />

• Plastic pipe must be imperatively buried, because they are very sensitive to shock and<br />

sunlight. When (and only when) it is completely impossible to burry the pipe (rocks, or<br />

when the pipeline cross a guley, or a river), then GI pipes should be used. Platic pipes<br />

can either be put inside GI pipe <strong>of</strong> larger diameter, or connected to GI pipe <strong>of</strong> same<br />

diameter using GI/PE or GI/PVC adaptor<br />

• It is not recommended to use plastic pipe when pipes are cast in concrete. For exemple,<br />

for tapstand’s pipes, GI pipe must be used.<br />

Please refer to <strong>Module</strong> II for more details on how to choose the type and diameter <strong>of</strong> pipe<br />

→ Valves and taps<br />

Various types <strong>of</strong> valves and taps presented in table 9<br />

46