Service and Parts Manual - Cummins Onan

Service and Parts Manual - Cummins Onan

Service and Parts Manual - Cummins Onan

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

FIGURE 33. MEASURING PISTON CLEARANCE<br />

1. Fitting Pistons:<br />

a. Proper piston tolerances must. be maintained<br />

for satisfactory operation.<br />

b. Measure the piston to cylinder clearance as<br />

shown in Figure 33 to be sure the total clearance<br />

follows specifications.<br />

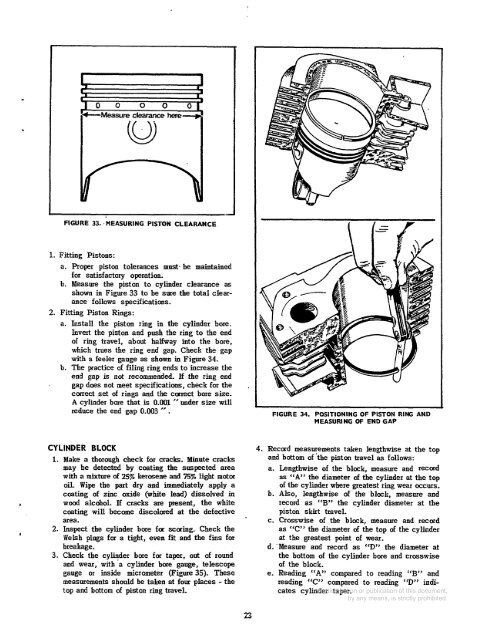

2. Fitting Piston Rings:<br />

a. Install the piston ring in the cylinder bore.<br />

Invert the piston <strong>and</strong> push the ring to the end<br />

of ring travel, about halfway into the bore,<br />

which trues the ring end gap. Check the gap<br />

with a feeler gauge as shown in Figure 34.<br />

b. The practice of filing ring ends to increase the<br />

end gap is not recommended. If the ring end<br />

gap does not meet specifications, check for the<br />

correct set of rings <strong>and</strong> the carrect bore size.<br />

A cylinder bore that is 0.001 ” under size will<br />

reduce the end gap 0.003 ” .<br />

FIGURE 34. POSITIONING OF PISTON RING AND<br />

MEASURING OF END GAP<br />

L<br />

I<br />

CYLINDER BLOCK<br />

1. Make a thorough check for cracks. Minute cracks<br />

may be detected by ccating the suspected area<br />

with a mixture of 25% kerasene <strong>and</strong> 75% light motor<br />

oil. Wipe the part dry <strong>and</strong> immediately apply a<br />

coating of zinc oxide (white lead) dissolved in<br />

wood alcohol. If cracks are present, the white<br />

coating will become discolored at the defective<br />

area.<br />

2. Inspect the cylinder bore far scaring. Check the<br />

Welsh plugs for a tight, even fit <strong>and</strong> the fins for<br />

breakage.<br />

3. Check the cylinder bore for taper, out of round<br />

<strong>and</strong> wear, with’a cylinder bore gauge, telescope<br />

gauge or inside micrometer (Figure 35). These<br />

measurements should be taken at four pIaces - the<br />

top <strong>and</strong> bottom of piston ring travel.<br />

4. Record measurements taken lengthwise at the top<br />

<strong>and</strong> bottom of ‘the piston travel as follows:<br />

a. Lengthwise of the black, measure <strong>and</strong> record<br />

as “A” the diameter of the cylinder at the top<br />

of the cylinder where greatest ring wear occurs.<br />

b. Also, lengthwise of the blak, measure <strong>and</strong><br />

record as “By’ the cylinder diameter at the<br />

piston skirt travel.<br />

c. Crosswise of the block, measure <strong>and</strong> record<br />

as “C” the diameter of the top of the cylinder<br />

at the greatest point of wear.<br />

d.’Measure <strong>and</strong> recard as “D” the diameter at<br />

the bottom of the cylinder bore <strong>and</strong> crosswise<br />

of the block.<br />

e. Reading “A” compared to reading “B” <strong>and</strong><br />

reading “C” compared to reading “D’? indicates<br />

cylinder taper.