BBW - DBW 46 - VW-Bus-T4.de

BBW - DBW 46 - VW-Bus-T4.de

BBW - DBW 46 - VW-Bus-T4.de

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

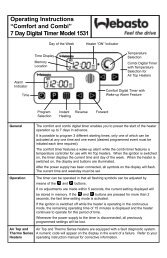

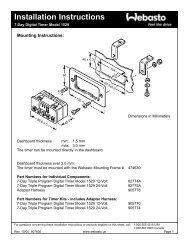

<strong>BBW</strong> <strong>46</strong> / <strong>DBW</strong> <strong>46</strong><br />

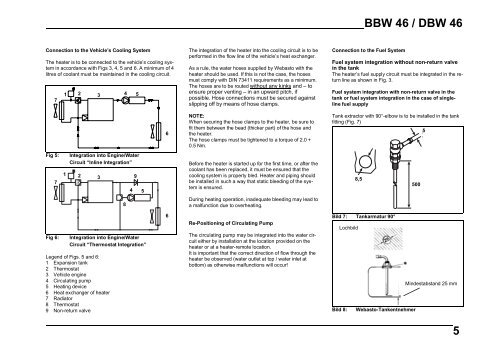

Connection to the Vehicle’s Cooling System<br />

The heater is to be connected to the vehicle’s cooling system<br />

in accordance with Figs 3, 4, 5 and 6. A minimum of 4<br />

litres of coolant must be maintained in the cooling circuit.<br />

7<br />

1 2 3 4 5<br />

6<br />

The integration of the heater into the cooling circuit is to be<br />

performed in the flow line of the vehicle’s heat exchanger.<br />

As a rule, the water hoses supplied by Webasto with the<br />

heater should be used. If this is not the case, the hoses<br />

must comply with DIN 73411 requirements as a minimum.<br />

The hoses are to be routed without any kinks and – to<br />

ensure proper venting – in an upward pitch, if<br />

possible. Hose connections must be secured against<br />

slipping off by means of hose clamps.<br />

NOTE:<br />

When securing the hose clamps to the heater, be sure to<br />

fit them between the bead (thicker part) of the hose and<br />

the heater.<br />

The hose clamps must be tightened to a torque of 2.0 +<br />

0.5 Nm.<br />

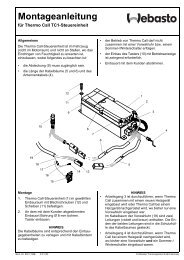

Connection to the Fuel System<br />

Fuel system integration without non-return valve<br />

in the tank<br />

The heater’s fuel supply circuit must be integrated in the return<br />

line as shown in Fig. 3.<br />

Fuel system integration with non-return valve in the<br />

tank or fuel system integration in the case of singleline<br />

fuel supply<br />

Tank extractor with 90°-elbow is to be installed in the tank<br />

fitting (Fig. 7)<br />

5<br />

Fig 5:<br />

7<br />

1<br />

Integration into Engine/Water<br />

Circuit “Inline Integration”<br />

2<br />

3<br />

8<br />

4<br />

9<br />

5<br />

Before the heater is started up for the first time, or after the<br />

coolant has been replaced, it must be ensured that the<br />

cooling system is properly bled. Heater and piping should<br />

be installed in such a way that static bleeding of the system<br />

is ensured.<br />

During heating operation, inadequate bleeding may lead to<br />

a malfunction due to overheating.<br />

8,5<br />

500<br />

Fig 6:<br />

Integration into Engine/Water<br />

Circuit “Thermostat Integration”<br />

Legend of Figs. 5 and 6:<br />

1 Expansion tank<br />

2 Thermostat<br />

3 Vehicle engine<br />

4 Circulating pump<br />

5 Heating device<br />

6 Heat exchanger of heater<br />

7 Radiator<br />

8 Thermostat<br />

9 Non-return valve<br />

6<br />

Re-Positioning of Circulating Pump<br />

The circulating pump may be integrated into the water circuit<br />

either by installation at the location provided on the<br />

heater or at a heater-remote location.<br />

It is important that the correct direction of flow through the<br />

heater be observed (water outlet at top / water inlet at<br />

bottom) as otherwise malfunctions will occur!<br />

Bild 7: Tankarmatur 90°<br />

Lochbild<br />

Mindestabstand 25 mm<br />

Bild 8: Webasto-Tankentnehmer<br />

5