Atomic-scale microstructures of Zr2Al3C4 and Zr3Al3C5 ceramics

Atomic-scale microstructures of Zr2Al3C4 and Zr3Al3C5 ceramics

Atomic-scale microstructures of Zr2Al3C4 and Zr3Al3C5 ceramics

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

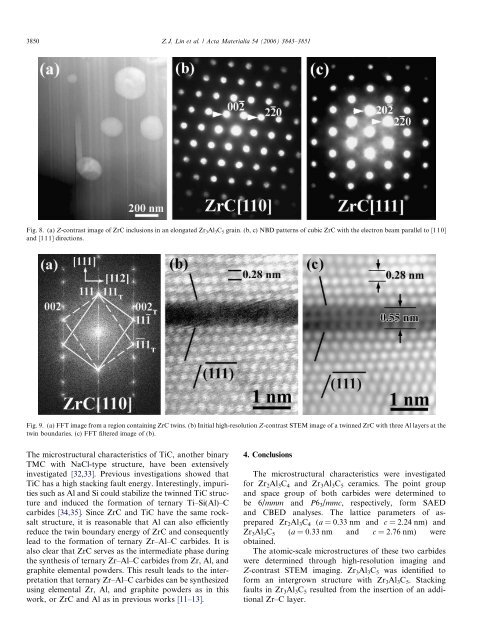

3850 Z.J. Lin et al. / Acta Materialia 54 (2006) 3843–3851<br />

Fig. 8. (a) Z-contrast image <strong>of</strong> ZrC inclusions in an elongated Zr 3 Al 3 C 5 grain. (b, c) NBD patterns <strong>of</strong> cubic ZrC with the electron beam parallel to [110]<br />

<strong>and</strong> [111] directions.<br />

Fig. 9. (a) FFT image from a region containing ZrC twins. (b) Initial high-resolution Z-contrast STEM image <strong>of</strong> a twinned ZrC with three Al layers at the<br />

twin boundaries. (c) FFT filtered image <strong>of</strong> (b).<br />

The microstructural characteristics <strong>of</strong> TiC, another binary<br />

TMC with NaCl-type structure, have been extensively<br />

investigated [32,33]. Previous investigations showed that<br />

TiC has a high stacking fault energy. Interestingly, impurities<br />

such as Al <strong>and</strong> Si could stabilize the twinned TiC structure<br />

<strong>and</strong> induced the formation <strong>of</strong> ternary Ti–Si(Al)–C<br />

carbides [34,35]. Since ZrC <strong>and</strong> TiC have the same rocksalt<br />

structure, it is reasonable that Al can also efficiently<br />

reduce the twin boundary energy <strong>of</strong> ZrC <strong>and</strong> consequently<br />

lead to the formation <strong>of</strong> ternary Zr–Al–C carbides. It is<br />

also clear that ZrC serves as the intermediate phase during<br />

the synthesis <strong>of</strong> ternary Zr–Al–C carbides from Zr, Al, <strong>and</strong><br />

graphite elemental powders. This result leads to the interpretation<br />

that ternary Zr–Al–C carbides can be synthesized<br />

using elemental Zr, Al, <strong>and</strong> graphite powders as in this<br />

work, or ZrC <strong>and</strong> Al as in previous works [11–13].<br />

4. Conclusions<br />

The microstructural characteristics were investigated<br />

for Zr 2 Al 3 C 4 <strong>and</strong> Zr 3 Al 3 C 5 <strong>ceramics</strong>. The point group<br />

<strong>and</strong> space group <strong>of</strong> both carbides were determined to<br />

be 6/mmm <strong>and</strong> P6 3 /mmc, respectively, form SAED<br />

<strong>and</strong> CBED analyses. The lattice parameters <strong>of</strong> asprepared<br />

Zr 2 Al 3 C 4 (a = 0.33 nm <strong>and</strong> c = 2.24 nm) <strong>and</strong><br />

Zr 3 Al 3 C 5 (a = 0.33 nm <strong>and</strong> c = 2.76 nm) were<br />

obtained.<br />

The atomic-<strong>scale</strong> <strong>microstructures</strong> <strong>of</strong> these two carbides<br />

were determined through high-resolution imaging <strong>and</strong><br />

Z-contrast STEM imaging. Zr 3 Al 3 C 5 was identified to<br />

form an intergrown structure with Zr 3 Al 3 C 5 . Stacking<br />

faults in Zr 3 Al 3 C 5 resulted from the insertion <strong>of</strong> an additional<br />

Zr–C layer.