Features: - Tanker Operator

Features: - Tanker Operator

Features: - Tanker Operator

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

TECHNOLOGY - TANK CLEANING<br />

manufacturers were used, but as can be seen,<br />

the names of the manufacturers and the<br />

specific product names are not disclosed for<br />

reasons of confidentiality and also because the<br />

objective of the project was not to say that one<br />

cleaning chemical manufacturer was better<br />

than another, rather that different cleaning<br />

chemicals do not behave the same way under<br />

the same conditions.<br />

Consideration should also be given to the<br />

concentration of use of the respective cleaning<br />

chemicals, as this will have a direct impact on<br />

the total cost of tank cleaning, assuming it<br />

was carried out on board a vessel.<br />

Results<br />

The following results were noted:<br />

The results are extremely interesting and very<br />

clearly show that not all cleaning chemicals<br />

are as efficient as each other under the same<br />

conditions.<br />

The first and most noticeable observation is<br />

that even the best cleaning materials still<br />

result in a hydrocarbon failure, which<br />

confirms the fact that cleaning zinc silicate<br />

from persistent hydrocarbons is indeed very<br />

challenging.<br />

It is also interesting to note that five out of<br />

the top eight performing cleaning chemicals are<br />

used at a concentration of less than 1% and<br />

four out of the top eight are actually used at a<br />

concentration of 0.5% or less. This does not<br />

particularly justify the fact that most effective<br />

detergents are effective at low concentrations,<br />

but it does suggest the same. With this in mind<br />

it would be interesting to note whether the<br />

products 1, 2 and 3 from Company E<br />

performed equally as well at lower<br />

concentrations, which would of course make<br />

them far more cost effective to the vessel.<br />

If one considers that re-circulating a cargo<br />

tank with a solution of tank cleaning<br />

chemicals will usually require a minimum<br />

volume of 10 cu m of liquid to maintain<br />

suction on the pump, it is clear that a product<br />

used at an active concentration of 0.5% will<br />

utilise 50 litres of pure cleaning chemical,<br />

whereas a product used at an active<br />

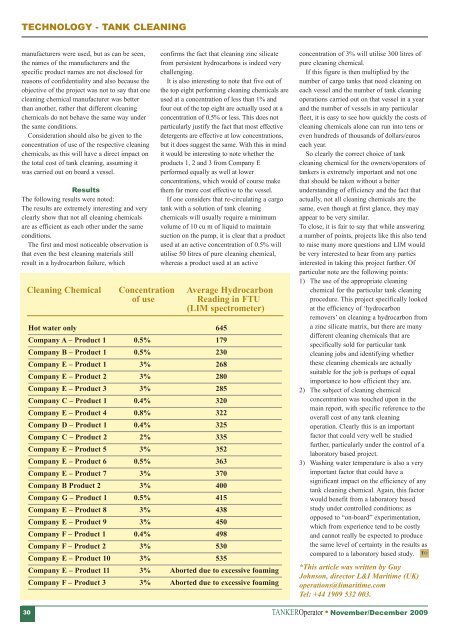

Cleaning Chemical Concentration Average Hydrocarbon<br />

of use Reading in FTU<br />

(LIM spectrometer)<br />

Hot water only 645<br />

Company A – Product 1 0.5% 179<br />

Company B – Product 1 0.5% 230<br />

Company E – Product 1 3% 268<br />

Company E – Product 2 3% 280<br />

Company E – Product 3 3% 285<br />

Company C – Product 1 0.4% 320<br />

Company E – Product 4 0.8% 322<br />

Company D – Product 1 0.4% 325<br />

Company C – Product 2 2% 335<br />

Company E – Product 5 3% 352<br />

Company E – Product 6 0.5% 363<br />

Company E – Product 7 3% 370<br />

Company B Product 2 3% 400<br />

Company G – Product 1 0.5% 415<br />

Company E – Product 8 3% 438<br />

Company E – Product 9 3% 450<br />

Company F – Product 1 0.4% 498<br />

Company F – Product 2 3% 530<br />

Company E – Product 10 3% 535<br />

Company E – Product 11 3% Aborted due to excessive foaming<br />

Company F – Product 3 3% Aborted due to excessive foaming<br />

concentration of 3% will utilise 300 litres of<br />

pure cleaning chemical.<br />

If this figure is then multiplied by the<br />

number of cargo tanks that need cleaning on<br />

each vessel and the number of tank cleaning<br />

operations carried out on that vessel in a year<br />

and the number of vessels in any particular<br />

fleet, it is easy to see how quickly the costs of<br />

cleaning chemicals alone can run into tens or<br />

even hundreds of thousands of dollars/euros<br />

each year.<br />

So clearly the correct choice of tank<br />

cleaning chemical for the owners/operators of<br />

tankers is extremely important and not one<br />

that should be taken without a better<br />

understanding of efficiency and the fact that<br />

actually, not all cleaning chemicals are the<br />

same, even though at first glance, they may<br />

appear to be very similar.<br />

To close, it is fair to say that while answering<br />

a number of points, projects like this also tend<br />

to raise many more questions and LIM would<br />

be very interested to hear from any parties<br />

interested in taking this project further. Of<br />

particular note are the following points:<br />

1) The use of the appropriate cleaning<br />

chemical for the particular tank cleaning<br />

procedure. This project specifically looked<br />

at the efficiency of ‘hydrocarbon<br />

removers’ on cleaning a hydrocarbon from<br />

a zinc silicate matrix, but there are many<br />

different cleaning chemicals that are<br />

specifically sold for particular tank<br />

cleaning jobs and identifying whether<br />

these cleaning chemicals are actually<br />

suitable for the job is perhaps of equal<br />

importance to how efficient they are.<br />

2) The subject of cleaning chemical<br />

concentration was touched upon in the<br />

main report, with specific reference to the<br />

overall cost of any tank cleaning<br />

operation. Clearly this is an important<br />

factor that could very well be studied<br />

further, particularly under the control of a<br />

laboratory based project.<br />

3) Washing water temperature is also a very<br />

important factor that could have a<br />

significant impact on the efficiency of any<br />

tank cleaning chemical. Again, this factor<br />

would benefit from a laboratory based<br />

study under controlled conditions; as<br />

opposed to “on-board” experimentation,<br />

which from experience tend to be costly<br />

and cannot really be expected to produce<br />

the same level of certainty in the results as<br />

compared to a laboratory based study. TO<br />

*This article was written by Guy<br />

Johnson, director L&I Maritime (UK)<br />

operations@limaritime.com<br />

Tel: +44 1909 532 003.<br />

30<br />

TANKER<strong>Operator</strong> November/December 2009