Features: - Tanker Operator

Features: - Tanker Operator

Features: - Tanker Operator

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

TECHNOLOGY - EMISSIONS<br />

measuring the effects of low sulphur content<br />

on pumps, it has developed new technology<br />

and techniques to ensure high pump<br />

performance to meet current and future<br />

demands with innovative solutions.<br />

Dr Michael Matros, Allweiler CEO and vice<br />

president of Colfax Corporation, confirmed<br />

that close customer relationships enable firstclass<br />

solutions: “A very important factor for<br />

the success of our company is to reflect the<br />

voice of the customer. We are focusing on<br />

specific smart technologies to help the<br />

customer lower life cycle costs and to meet<br />

environmental standards.<br />

“Our claim ‘All fluids-o limits’<br />

implements not only our wide range of<br />

products and our global service capacity, but<br />

also our unfailing ambitions to assist the most<br />

cost-effective usage of our high-quality<br />

pumps. With our comprehensive selection of<br />

screw, centrifugal, and progressing cavity<br />

pumps, Allweiler is always able to offer an<br />

optimised solution regardless of the<br />

customer’s liquid or application,” he claimed.<br />

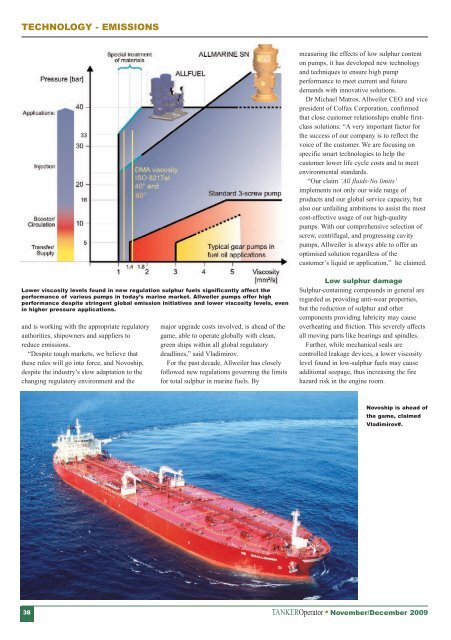

Lower viscosity levels found in new regulation sulphur fuels significantly affect the<br />

performance of various pumps in today’s marine market. Allweiler pumps offer high<br />

performance despite stringent global emission initiatives and lower viscosity levels, even<br />

in higher pressure applications.<br />

and is working with the appropriate regulatory<br />

authorities, shipowners and suppliers to<br />

reduce emissions.<br />

“Despite tough markets, we believe that<br />

these rules will go into force, and Novoship,<br />

despite the industry’s slow adaptation to the<br />

changing regulatory environment and the<br />

major upgrade costs involved, is ahead of the<br />

game, able to operate globally with clean,<br />

green ships within all global regulatory<br />

deadlines,” said Vladimirov.<br />

For the past decade, Allweiler has closely<br />

followed new regulations governing the limits<br />

for total sulphur in marine fuels. By<br />

Low sulphur damage<br />

Sulphur-containing compounds in general are<br />

regarded as providing anti-wear properties,<br />

but the reduction of sulphur and other<br />

components providing lubricity may cause<br />

overheating and friction. This severely affects<br />

all moving parts like bearings and spindles.<br />

Further, while mechanical seals are<br />

controlled leakage devices, a lower viscosity<br />

level found in low-sulphur fuels may cause<br />

additional seepage, thus increasing the fire<br />

hazard risk in the engine room.<br />

Novoship is ahead of<br />

the game, claimed<br />

Vladimirov#.<br />

38<br />

TANKER<strong>Operator</strong> November/December 2009