collet type - Floyd Automatic Tooling Ltd

collet type - Floyd Automatic Tooling Ltd

collet type - Floyd Automatic Tooling Ltd

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Tooling</strong> Systems for CNC Turning machines 2010<br />

BACKWORKING HOLDERS ........................................................................................................................... 2<br />

MILLING ARBORS......................................................................................................................................... 8<br />

QUICK CHANGE .......................................................................................................................................... 9<br />

COLLET HOLDERS WITH COMPACT DIMENSIONS ..................................................................................... 13<br />

EXTENDED LENGTH COLLET HOLDERS ...................................................................................................... 15<br />

COLLET CHUCK-DRILL EXTENSION ............................................................................................................ 16<br />

THRO’ COOLANT COLLET HOLDER ............................................................................................................ 17<br />

ER/ESX COLLETS ........................................................................................................................................ 18<br />

ER/ESX SEALED COLLETS FOR THRO’ COOLANT ......................................................................................... 19<br />

DOUBLE ENDED COLLET HOLDERS ............................................................................................................ 20<br />

ESX COLLET REDUCTION SLEEVES ............................................................................................................. 22<br />

DOUBLE ENDED TAP HOLDERS .................................................................................................................. 23<br />

DOUBLE ENDED TAP-COLLET HOLDERS ..................................................................................................... 24<br />

TAP HOLDERS ............................................................................................................................................ 25<br />

BUTTON DIE HOLDER ................................................................................................................................ 29<br />

BUTTON DIE HOLDER WITH SHANK ........................................................................................................... 30<br />

FLOATING REAMER HOLDERS .................................................................................................................... 31<br />

ADJUSTABLE REAMER HOLDER ................................................................................................................... 33<br />

THROUGH COOLANT REAMER HOLDER ..................................................................................................... 34<br />

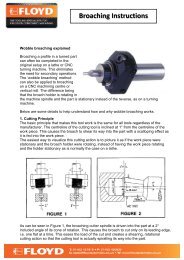

BROACHING HEAD – ADJUSTABLE .............................................................................................................. 35<br />

BROACHING HEAD – FIXED – SMALL DIAMETER ......................................................................................... 36<br />

BROACHES ................................................................................................................................................ 37<br />

BROACHING HEAD EXTERNAL – ADJUSTABLE ............................................................................................. 38<br />

BROACHING HEAD EXTERNAL – FIXED ....................................................................................................... 38<br />

BROACHING HEAD – FIXED........................................................................................................................ 41<br />

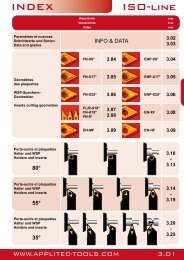

ISO HOLDERS ............................................................................................................................................ 42<br />

THREADING HOLDERS ............................................................................................................................... 46<br />

DIAMOND CUT KNURLING HOLDER .......................................................................................................... 47<br />

STRAIGHT CUT KNURLING HOLDER ........................................................................................................... 47<br />

AXIAL KNURL HOLDERS ............................................................................................................................. 48<br />

AXIAL KNURL HOLDERS - 3 WHEEL TYPE RTH ............................................................................................. 49<br />

BORING BAR BUSHES ................................................................................................................................. 51<br />

BORING BAR SLEEVE WITH THROUGH COOLANT INLETS ........................................................................... 52<br />

REVOLVING CENTRES - SPRUNG ................................................................................................................ 53<br />

MULTI-DRILL HOLDERS .............................................................................................................................. 54<br />

ER MINI NUT TUBE SPANNER ..................................................................................................................... 55<br />

ER11 COLLET HOLDER REDUCTION/EXTENSION ........................................................................................ 56<br />

SPECIAL COLLETS DATA SHEETS<br />

R <strong>Floyd</strong> <strong>Automatic</strong> <strong>Tooling</strong> <strong>Ltd</strong> Tel: 01462 491919 Fax: 01462 490835<br />

www.floydautomatic.co.uk e: sales@floydautomatic.co.uk<br />

Index

<strong>Tooling</strong> Systems for CNC Turning machines<br />

BACKWORKING HOLDERS<br />

Height Adjustable<br />

Counter Spindle Toolholders to provide a back working turning station for sub-spindle<br />

operations<br />

For Citizen, Star, Tornos & all Sliding Head machines with back working capability<br />

R <strong>Floyd</strong> <strong>Automatic</strong> <strong>Tooling</strong> <strong>Ltd</strong> Tel: 01462 491919 Fax: 01462 490835<br />

www.floydautomatic.co.uk e: sales@floydautomatic.co.uk<br />

Page 2

<strong>Tooling</strong> Systems for CNC Turning machines<br />

Shanks for back working holders<br />

Fig. 1 Fig. 2<br />

Fig. 3 Fig. 4<br />

Cat. No. D L Fig. Machine<br />

HVD1620 16 20 4 Star SR16/SST16<br />

HVD1660 16 60 1<br />

HVD1960 3/4” 60 1 Citizen L20/C16<br />

HVD2060 20 60 1 Citizen B12<br />

HVD2080 20 80 1<br />

HVD2012 20 125 1 Tornos Deco<br />

HVD2225 22 25 2 Star SR20R/ECAS12/20<br />

HVD2230 22 30 3 Star SR32<br />

HVD2270 22 70 1 Star<br />

HVD2299 22 100 1 Star<br />

HVD1620 16 20 4 Star SR16 SST16<br />

HVD2560 25 60 1<br />

HVD2510 25 100 1 Manurhin Swing<br />

HVD2512 25 125 1 Tornos Deco<br />

HVD2670 1” 70 1 Citizen M32/C32<br />

HVD2885 28 85 1 Traub TNL 12/16<br />

HVD2885IK 28 85 1 Traub TNL 12/16 with<br />

through coolant<br />

HVD3419 34 19,5 Maier<br />

HVD3444 34 44 Maier/Star ECAS<br />

HVD3444S 34 44 For Star SR/SV in driven tool<br />

position<br />

HVD3045 30 45 Maier<br />

Shorter shanks available on request. Spacer plates 10-15-20-25-30mm thick available.<br />

R <strong>Floyd</strong> <strong>Automatic</strong> <strong>Tooling</strong> <strong>Ltd</strong> Tel: 01462 491919 Fax: 01462 490835<br />

www.floydautomatic.co.uk e: sales@floydautomatic.co.uk<br />

Page 3

<strong>Tooling</strong> Systems for CNC Turning machines<br />

Insert Holder for 16ER threading inserts<br />

Fig. 1 Fig. 2<br />

Right hand shown<br />

Calculation of Helix angle: 20*pitch/dia.<br />

Cat. No. Hand Helix Angle L Fig. Insert Screw<br />

HVWP-ER-16-0 right 0° 31 1 16 ER ISO A02-30100<br />

HVWP-ER-16-15 right 1.5° 31 1 16 ER ISO A02-30100<br />

HVWP-ER-16-3 right 3° 31 1 16 ER ISO A02-30100<br />

HVWPL-ER-16-0 right 0° 40 1 16 ER ISO A02-30100<br />

HVWPL-ER-16-15 right 1.5° 40 1 16 ER ISO A02-30100<br />

HVWPL-ER-16-3 right 3° 40 1 16 ER ISO A02-30100<br />

HVWPA-ER-16-0 right 0° 31 2 16 ER ISO A02-30100<br />

HVWPA-ER-16-15 right 1.5° 31 2 16 ER ISO A02-30100<br />

HVWPA-ER-16-3 right 3° 31 2 16 ER ISO A02-30100<br />

Insert Holder for CC--06 & CC--09 inserts<br />

Fig. 1 Fig. 2<br />

Left hand shown<br />

Cat. No. Hand L Fig. Insert Screw<br />

HVWP-SCJCR06 right 23 1 CCMT/CCGT 0602 A02-25059<br />

HVWP-SCJCL06 left 23 1 CCMT/CCGT 0602 A02-25059<br />

HVWP-SCJCR09 right 23 2 CCMT/CCGT 09T3 A02-40105<br />

HVWP-SCJCL09 left 23 2 CCMT/CCGT 09T3 A02-40105<br />

R <strong>Floyd</strong> <strong>Automatic</strong> <strong>Tooling</strong> <strong>Ltd</strong> Tel: 01462 491919 Fax: 01462 490835<br />

www.floydautomatic.co.uk e: sales@floydautomatic.co.uk<br />

Page 4

<strong>Tooling</strong> Systems for CNC Turning machines<br />

Insert Holder for DC—07& DC--11 inserts<br />

Fig. 1 Left hand shown Fig. 2<br />

Cat. No. Hand L Fig. Insert Screw<br />

HVWP-SDJCR07 right 23 1 DCMT/DCGT 0702 A02-25059<br />

HVWP-SDJCL07 left 23 1 DCMT/DCGT 0702 A02-25059<br />

HVWP-SDJCR11 right 23 2 DCMT/DCGT 11T3 A02-40105<br />

HVWP-SDJCL11 left 23 2 DCMT/DCGT 11T3 A02-40105<br />

HVWPL-SDJCR11 right 40 2 DCMT/DCGT 11T3 A02-40105<br />

HVWPL-SDJCL11 left 40 2 DCMT/DCGT 11T3 A02-40105<br />

Insert Holders for DC--11 inserts<br />

Fig. 1<br />

Fig. 2 Right hand shown<br />

Cat. No. Hand L Fig. Insert Screw<br />

HVWP-SDNCN11 right 23 1 DCMT/DCGT 11T3 A02-40105<br />

HVWP-SDNCR11 right 23 2 DCMT/DCGT 11T3 A02-40105<br />

HVWP-SDNLR11 left 23 2 DCMT/DCGT 11T3 A02-40105<br />

Insert Holders for 10 & 12mm sq. tool holders<br />

Fig. 1<br />

Fig.2<br />

Cat. No. Hand Fig. Tool Holder<br />

HVWP-1010 Right + left 1 10mm square<br />

HVWP-1212 Right + left 2 12mm square<br />

R <strong>Floyd</strong> <strong>Automatic</strong> <strong>Tooling</strong> <strong>Ltd</strong> Tel: 01462 491919 Fax: 01462 490835<br />

www.floydautomatic.co.uk e: sales@floydautomatic.co.uk<br />

Page 5

<strong>Tooling</strong> Systems for CNC Turning machines<br />

Insert Holder for VC--11 inserts<br />

Fig. 1 Fig. 2<br />

Left hand shown<br />

Cat. No. Hand L Fig. Insert Screw<br />

HVWP-SVJCR11 right 23 1 VCMT/VCGT 1103 A02-25059<br />

HVWP-SVJCL11 left 23 1 VCMT/VCGT 1103 A02-25059<br />

HVWP-SVQCR11 right 23 2 VCMT/VCGT 1103 A02-25059<br />

HVWP-SVQCL11 left 23 2 VCMT/VCGT 1103 A02-25059<br />

Insert Holder for VC--11 inserts<br />

Fig. 1 Fig. 2<br />

Left hand shown<br />

Cat. No. Hand L Fig. Insert Screw<br />

HVWP-SVUCR11 right 23 1 VCMT/VCGT 1103 A02-25059<br />

HVWP-SVUCL11 left 23 1 VCMT/VCGT 1103 A02-25059<br />

HVWP-SVVCN11 neutral 31 2 VCMT/VCGT 1103 A02-25059<br />

Insert Holder Spacer<br />

Cat. No.<br />

d<br />

HVD10S 10<br />

HVD15S 15<br />

HVD20S 20<br />

HVD25S 25<br />

HVD30S 30<br />

Delivery includes longer<br />

mounting screws and<br />

extended screw for<br />

centre height adjuster<br />

R <strong>Floyd</strong> <strong>Automatic</strong> <strong>Tooling</strong> <strong>Ltd</strong> Tel: 01462 491919 Fax: 01462 490835<br />

www.floydautomatic.co.uk e: sales@floydautomatic.co.uk<br />

Page 6

<strong>Tooling</strong> Systems for CNC Turning machines<br />

Height Adjustable Double & Triple Collet Holders<br />

R <strong>Floyd</strong> <strong>Automatic</strong> <strong>Tooling</strong> <strong>Ltd</strong> Tel: 01462 491919 Fax: 01462 490835<br />

www.floydautomatic.co.uk e: sales@floydautomatic.co.uk<br />

Page 7

<strong>Tooling</strong> Systems for CNC Turning machines<br />

MILLING ARBORS<br />

to fit into ESX/ER11 & ESX16 tapers for Driven Tool Stations<br />

Supplied complete with mounting nut – please specify thread size on Driven Spindle when ordering<br />

Cat. No. Taper Thread M Ø Arbor Ø H Ø Spacer L1 L2 Mounting Nut<br />

FD/ER8-5 ER8 5 5 12 10 25 29 M10x0,75<br />

FD/ER8-8 ER8 8 8 16 16 25 29 M10x0,75<br />

FD/ER11-5M ER11 ESX12 5 5 16 10 24 30 M13x0,75<br />

FD/ER11-5MK ER11 ESX12 5 5 16 16 17 23 M13x0,75<br />

FD/ER11-8M ER11 ESX12 8x0,75 8 16 16 24 32 M13x0,75<br />

FD/ER11-8MK ER11 ESX12 8x0,75 8 16 16 21 29 M13x0,75<br />

FD/ER11-8ML ER11 ESX12 8x0,75 8 16 16 35 40 M13x0,75<br />

FD/ER11-10M ER11 ESX12 10x0,75 10 16 16 24 32 M13x0,75<br />

FD/ER11-10MK ER11 ESX12 10x0,75 10 16 16 21 29 M13x0,75<br />

FD/ER11-5 ER11 ESX12 5 5 16 10 24 30 M14x0,75<br />

FD/ER11-5K ER11 ESX12 5 5 16 10 17 23 M14x0,75<br />

FD/ER11-8 ER11 ESX12 8x0,75 8 16 16 32 24 M14x0,75<br />

FD/ER11-8K ER11 ESX12 8x0,75 8 16 16 21 29 M14x0,75<br />

FD/ER11-8L ER11 ESX12 8x0,75 8 16 16 35 40 M14x0,75<br />

FD/ER11-10 ER11 ESX12 10x0,75 10 16 16 24 32 M14x0,75<br />

FD/ER11-10K ER11 ESX12 10x0,75 10 16 16 21 29 M14x0,75<br />

FD/ER16-5M ER16 ESX16 5 5 12 10 15 42 M19x1<br />

FD/ER16-5MK ER16 ESX16 5 5 12 10 12,5 33 M19x1<br />

FD/ER16-8M ER16 ESX16 8x0,75 8 16 16 26 42 M19x1<br />

FD/ER16-10M ER16 ESX16 10x0,75 10 16 16 26 42 M19x1<br />

FD/ER16-5 ER16 ESX16 5 5 12 10 15 42 M22x1,5<br />

FD/ER16-5K ER16 ESX16 5 5 12 10 12,5 33 M22x1,5<br />

FD/ER16-8 ER16 ESX16 8x0,75 8 16 16 26 42 M22x1,5<br />

FD/ER16-8L ER16 ESX16 8x0,75 8 16 16 35 50 M22x1,5<br />

FD/ER16-10 ER16 ESX16 10x0,75 10 16 16 26 42 M22x1,5<br />

FD/ER16-10L ER16 ESX16 10x0,75 10 16 16 35 50 M22x1,5<br />

FD/ER16-13 ER16 ESX16 6x1 int. 13 16 16 15 25 M22x1,5<br />

FD/ER16-13L ER16 ESX16 6x1 int. 13 16 16 35 50 M22x1,5<br />

Fig. 1 Extra short version<br />

Fig. 2 short version<br />

Cat. No. Taper Ød Ø Spacer L1 Mounting Nut Fig.<br />

FD/ER16M 8 S ER16 8 16 1-13 M19x1 1<br />

FD/ER16M 10 S ER16 10 16 1-13 M19x1 1<br />

FD/ER16 8 S ER16 8 16 1-13 M22x1,5 1<br />

FD/ER16 10 S ER16 10 16 1-13 M22x1,5 1<br />

FD/ER16SML 8 ER16 8 16 14-26 M19x1 2<br />

FD/ER16SML 10 ER16 10 16 14-26 M19x1 2<br />

FD/ER16SRL 8 ER16 8 16 14-26 M22x1,5 2<br />

FD/ER16SRL 10 ER16 10 16 14-26 M22x1,5 2<br />

R <strong>Floyd</strong> <strong>Automatic</strong> <strong>Tooling</strong> <strong>Ltd</strong> Tel: 01462 491919 Fax: 01462 490835<br />

www.floydautomatic.co.uk e: sales@floydautomatic.co.uk<br />

Page 8

<strong>Tooling</strong> Systems for CNC Turning machines<br />

QUICK CHANGE<br />

Quick Change tool system for ESX25 taper<br />

fits directly into Driven Tool Spindles on Cross Milling/Drilling & Counter<br />

Operations using SM25M Quick Change Nut.<br />

Repeatability 0,01mm. One turn of the Nut to release.<br />

Collet Holder Quick Change Nut SM25M SM25<br />

M30 x 1 thread<br />

M32x1,5 thread<br />

Cat No. D L Collet Collet Nut Spanner Q.C.Nut Spanner<br />

E25/ER16M 22 31 ESX16 61-16772 61-16812 HAB-SP-R32<br />

E25/ER16 28 32 ESX16 61-16773 62-20905 HAB-SP-R32<br />

E25/ER20 34 33 ESX20 61-20773 61-20811 HAB-SP-R32<br />

E25/ER25M 35 42 ESX25 61-25772 61-25812 HAB-SP-R32<br />

Extended Length Collet Holder<br />

Cat No. D L Collet Nut Spanner Q.C.Nut Spanner<br />

E25/ER16M 22 58 ESX16 61-16772 61-16812 HAB-SP-R32<br />

Milling Arbor<br />

Cat No. D L1 L2<br />

FD/ER25-8 8 25 60<br />

FD/ER25-10 10 25 47<br />

FD/ER25-10L 13 30 60<br />

FD/ER25-13 13 25 47<br />

FD/ER25-13L 13 40 62<br />

FD/ER25-16 16 25 47<br />

FD/ER25-16L 16 50 62<br />

FD/ER25-22 22 19 35<br />

FD/ER25-22L 22 50 60<br />

Supplied complete with lock-nut<br />

(Ø8, 10) or lock-screw (Ø13, 16, 22)<br />

Set of spacer rings<br />

Drive key on Ø 13, 16, 22<br />

R <strong>Floyd</strong> <strong>Automatic</strong> <strong>Tooling</strong> <strong>Ltd</strong> Tel: 01462 491919 Fax: 01462 490835<br />

www.floydautomatic.co.uk e: sales@floydautomatic.co.uk<br />

Page 9

<strong>Tooling</strong> Systems for CNC Turning machines<br />

<br />

Quick Change tool system for ESX25 taper<br />

fits directly into Driven Tool Spindles on Cross Milling/Drilling & Counter<br />

Operations using SM25M Quick Change Nut.<br />

Repeatability 0,01mm. One turn of the Nut to release.<br />

Weldon Holder<br />

Cat No. D d L A<br />

E25/WD6 27 6 30 M6<br />

E25/WD8 27 8 30 M8<br />

E25/WD10 33 10 30 M10<br />

E25/WD12 36 12 30 M10<br />

Blank<br />

Cat No. ØB L Taper hardened<br />

ER25/R32 32 67 & ground<br />

ER25/R25 25 67 Shank soft for<br />

finishing<br />

R <strong>Floyd</strong> <strong>Automatic</strong> <strong>Tooling</strong> <strong>Ltd</strong> Tel: 01462 491919 Fax: 01462 490835<br />

www.floydautomatic.co.uk e: sales@floydautomatic.co.uk<br />

Page 10

<strong>Tooling</strong> Systems for CNC Turning machines<br />

Quick Change tool system for ESX20 taper<br />

fits directly into Driven Tool Spindles on Cross Milling/Drilling & Counter<br />

Operations using SM20M Quick Change Nut.<br />

Repeatability 0,01mm. One turn of the Nut to release.<br />

Collet Holder Quick Change Nut SM20M SM20<br />

M24x1 thread<br />

M25x1,5<br />

Cat No. D L Collet Collet Nut Spanner Q.C.Nut Spanner<br />

E20/ER11M 16 26 ER11 61-11772 61-11812 HAB-SP-R25<br />

E20/ER16M 22 31 ESX16 61-16772 61-16812 HAB-SP-R25<br />

E20/ER16 28 32 ESX16 61-16773 62-20905 HAB-SP-R25<br />

E20/ER20 34 33 ESX20 61-20773 61-20811 HAB-SP-R25<br />

E20/ER20M 28 42 ESX20 61-25772 61-25812 HAB-SP-R25<br />

Extended Length Collet Holder<br />

Cat No. D L Collet Nut Spanner Q.C.Nut Spanner<br />

E20/ER16M 22 35 ESX16 61-16772 61-16812 HAB-SP-R25<br />

R <strong>Floyd</strong> <strong>Automatic</strong> <strong>Tooling</strong> <strong>Ltd</strong> Tel: 01462 491919 Fax: 01462 490835<br />

www.floydautomatic.co.uk e: sales@floydautomatic.co.uk<br />

Page 11

<strong>Tooling</strong> Systems for CNC Turning machines<br />

Quick Change tool system for ESX20 taper<br />

fits directly into Driven Tool Spindles on Cross Milling/Drilling & Counter<br />

Operations using SM20M Quick Change Nut.<br />

Repeatability 0,01mm. One turn of the Nut to release.<br />

<br />

Milling Arbor<br />

Cat No. D L1 L2<br />

FD/ER20-5 5 9 43<br />

FD/ER20-5c 5 5 30<br />

FD/ER20-5L 5 16 35<br />

FD/ER20-8c 8 5 27<br />

FD/ER20-8L 8 17 33<br />

FD/ER20-10 10 17 44<br />

FD/ER20-10a 10 5 38<br />

FD/ER20-10c 10 5 27<br />

FD/ER20-10L 10 17 33<br />

FD/ER20-13 13 17 34<br />

FD/ER20-13a 13 14 35<br />

FD/ER20-13b 13 25 50<br />

FD/ER20-13c 13 5 27<br />

FD/ER20-13L 13 17 33<br />

FD/ER20-16 16 18 49<br />

FD/ER20-16c 16 5 27<br />

FD/ER20-16L 16 17 33<br />

Supplied complete with lock-nut<br />

(Ø8, 10) or lock-screw (Ø13, 16)<br />

Set of spacer rings<br />

Drive key on Ø 13, 16<br />

Blank<br />

Cat No. ØB L Taper hardened<br />

ER20/R32 32 40 & ground<br />

ER20/R20 25 40 Shank soft for<br />

finishing<br />

R <strong>Floyd</strong> <strong>Automatic</strong> <strong>Tooling</strong> <strong>Ltd</strong> Tel: 01462 491919 Fax: 01462 490835<br />

www.floydautomatic.co.uk e: sales@floydautomatic.co.uk<br />

Page 12

<strong>Tooling</strong> Systems for CNC Turning machines<br />

COLLET HOLDERS with compact dimensions<br />

1 2<br />

3 4<br />

Cat. No. D A L1 L2 M/G1 N SW Range Collet Nut Spanner Fig.<br />

EM085830 5/8” 12 30 14 - 5,5 13 0,5-5 ER8 E08M E08M 1<br />

EM085845 5/8” 12 45 14 - 5,5 13 0,5-5 ER8 E08M E08M 1<br />

EM081645 16 12 45 14 - 5,5 13 0,5-5 ER8 E08M E08M 1<br />

EM111240 12 16 40 29 M6 12 0,5-7* ER11 ER11M E11M 4<br />

EM111418# 14 16 18 19 M6 7,5 - 0,5-7* ER11 ER11M E11M 4<br />

EM115850# 5/8” 16 50 19 M7 7,5 14 0,5-7* ER11 ER11M E11M 4<br />

EM111680# 16 16 80 19 M7 7,5 14 0,5-7* ER11 ER11M E11M 1/2<br />

EM111630# 16 16 30 19 M7 7,5 - 0,5-7* ER11 ER11M E11M 1/2<br />

EM111620 16 16 20 19 - 7,5 - 0,5-7* ER11 ER11M E11M 2<br />

EM111831 18 16 285 19 - 7,5 15 0,5-7* ER11 ER11M E11M 1<br />

EM112060 20 16 60 19 M7,5 - 17 0,5-7* ER11 ER11M E11M 2/3<br />

EM112099 20 16 100 19 M7,5 - 17 0,5-7* ER11 ER11M E11M 2/3<br />

EM113450# 3/4" 16 50 19 M7,5 - 17 0,5-7* ER11 ER11M E11M 2/3<br />

EM113460# 3/4" 16 60 19 M7,5 - 17 0,5-7* ER11 ER11M E11M 2/3<br />

EM113470# 3/4" 16 70 19 M7,5 - 17 0,5-7* ER11 ER11M E11M 2/3<br />

EM112290 22 16 90 19 M7,5 - 17 0,5-7* ER11 ER11M E11M 2/3<br />

EM112212 22 16 120 19 M7,5 - 17 0,5-7* ER11 ER11M E11M 2/3<br />

* Range up to Ø8mm with FLO-TOOL oversize <strong>collet</strong>s # Also available with thro’ bore ‘N’ dia<br />

EM161418 14 22 18 36 M8 - 17 1-10* ER16 ER16M E16M 4<br />

EM165835 5/8” 22 35 36 M8 - 17 1-10* ER16 ER16M E16M 4<br />

EM161620 16 22 20 36 M8 - 17 1-10* ER16 ER16M E16M 4<br />

EM161630 16 22 30 36 M8 - 17 1-10* ER16 ER16M E16M 4<br />

EM161635 16 22 35 36 M8 - 17 1-10* ER16 ER16M E16M 4<br />

EM161670 16 22 70 36 M8 - 17 1-10* ER16 ER16M E16M 4<br />

EM161600 16 22 100 36 M8 - 17 1-10* ER16 ER16M E16M 4<br />

EM161831 16 22 280 30 - - 17 1-10* ER16 ER16M E16M 1<br />

EM162038 20 22 30 23 M11 - 17 1-10* ER16 ER16M E16M 2/3<br />

EM162050 20 22 50 23 M11 - 17 1-10* ER16 ER16M E16M 2/3<br />

EM162070 20 22 70 23 M11 12# 17 1-10* ER16 ER16M E16M 2/3<br />

EM162012 20 22 120 23 M11 - 17 1-10* ER16 ER16M E16M 2/3<br />

EM163438 3/4" 22 38 23 M11 - 17 1-10* ER16 ER16M E16M 2/3<br />

EM163450 3/4" 22 50 23 M11 12# 17 1-10* ER16 ER16M E16M 2/3<br />

EM163470 3/4" 22 70 23 M11 12# 17 1-10* ER16 ER16M E16M 2/3<br />

EM163499 3/4" 22 100 23 M11 - 17 1-10* ER16 ER16M E16M 4<br />

EM163412 3/4" 22 120 23 M11 - 17 1-10* ER16 ER16M E16M 4<br />

EM162238 22 22 38 23 M11 12# 19 1-10* ER16 ER16M E16M 2/3<br />

EM162270 22 22 70 23 M11 12# 19 1-10* ER16 ER16M E16M 2/3<br />

EM162290 22 22 90 23 M11 12# 19 1-10* ER16 ER16M E16M 2/3<br />

* Range up to Ø12mm with FLO-TOOL oversize <strong>collet</strong>s #Also available with thro’ bore ‘N’ dia<br />

R <strong>Floyd</strong> <strong>Automatic</strong> <strong>Tooling</strong> <strong>Ltd</strong> Tel: 01462 491919 Fax: 01462 490835<br />

www.floydautomatic.co.uk e: sales@floydautomatic.co.uk<br />

Page 13

<strong>Tooling</strong> Systems for CNC Turning machines<br />

COLLET HOLDERS with compact dimensions<br />

2<br />

1<br />

3 4<br />

Cat. No. D A L1 L2 M/G1 N/G2 SW Range Collet Nut Spanner Fig.<br />

EM1622105 22 22 105 23 M11 12# 19 1-10* ER16 ER16M E16M 2/3<br />

EM162212 22 22 120 23 M11 12# 19 1-10* ER16 ER16M E16M 2/3<br />

EM162558 25 22 60 23 M11 - 22 1-10* ER16 ER16M E16M 2/3<br />

EM162574 25 22 75 23 M11 - 22 1-10* ER16 ER16M E16M 2/3<br />

EM162599 25 22 100 23 M11 - 22 1-10* ER16 ER16M E16M 2/3<br />

EM161058 1” 22 60 23 M11 - 22 1-10* ER16 ER16M E16M 2/3<br />

EM161074 1” 22 75 23 M11 - 22 1-10* ER16 ER16M E16M 2/3<br />

EM161099 1” 22 100 23 M11 - 22 1-10* ER16 ER16M E16M 2/3<br />

EM161015 1” 22 150 23 M11 - 22 1-10* ER16 ER16M E16M 2/3<br />

EM162890** 28 22 90 23 - M12x1,5 24 1-10* ER16 ER16M E16M 3<br />

* Range up to Ø12 with FLO-TOOL oversize <strong>collet</strong>s<br />

EM203450 ¾” 28 50 31 M12 - - 1-13* ER20 ER20M E20M 2/3<br />

EM202050 20 28 50 31 M12 - - 1-13* ER20 ER20M E20M 2/3<br />

EM202085 20 28 85 31 M12 - - 1-13* ER20 ER20M E20M 2/3<br />

EM202270 22 28 70 31 M12 14 19 1-13* ER20 ER20M E20M 2/3<br />

EM202550 25 28 50 25 M14 14# 22 1-13* ER20 ER20M E20M 2/3<br />

EM202575 25 28 75 25 M14 14# 22 1-13* ER20 ER20M E20M 2/3<br />

EM202599 25 28 100 27 M14 14# 22 1-13* ER20 ER20M E20M 2/3<br />

EM201038 1" 28 38 27 M14 14# 22 1-13* ER20 ER20M E20M 2/3<br />

EM201099 1" 28 100 27 M14 14# 22 1-13* ER20 ER20M E20M 2/3<br />

EM203280 32 28 80 27 M14 - 22 1-13* ER20 ER20M E20M 2/3<br />

EM2032105 32 28 105 25 M14 ¼”BSP 22 1-13* ER20 ER20M E20M 2/3<br />

EM202890** 28 28 90 25 - - 24 1-13* ER20 ER20M E20M 3<br />

* Range up to Ø15 with FLO-TOOL oversize <strong>collet</strong>s # Also available with thro’ bore Ø14mm<br />

EM252074 20 35 75 44 M12 - 27 1-16* ER25 ER25M E25M 2<br />

EM253474 ¾” 35 75 44 M12 - 27 1-16* ER25 ER25M E25M 2<br />

EM253450 ¾” 35 50 44 M12 - 27 1-16* ER25 ER25M E25M 2<br />

EM252274 22 35 75 44 M14 - 27 1-16* ER25 ER25M E25M 2<br />

EM252574 25 35 75 38 M18 - 27 1-16* ER25 ER25M E25M 2/3<br />

EM252510 25 35 100 38 M18 - 27 1-16* ER25 ER25M E25M 2/3<br />

EM252515 25 35 150 38 M18 M14x1,5 27 1-16* ER25 ER25M E25M 3<br />

EM251074 1” 35 75 38 M18 - 27 1-16* ER25 ER25M E25M 2/3<br />

EM251099 1” 35 99 38 M18 - 27 1-16* ER25 ER25M E25M 2/3<br />

EM251015 1” 35 150 38 M18 - 27 1-16* ER25 ER25M E25M 2/3<br />

EM252890** 28 35 90 25 - M12x1,5 24 1-16* ER25 ER25M E25M 3<br />

* Range up to Ø20 with FLO-TOOL oversize <strong>collet</strong>s ** For Traub TNL with thro’ coolant inlet M12x1,5<br />

All <strong>collet</strong> holders are available (at extra cost) with high pressure coolant inlet in back of shank add IK to pt.no.<br />

R <strong>Floyd</strong> <strong>Automatic</strong> <strong>Tooling</strong> <strong>Ltd</strong> Tel: 01462 491919 Fax: 01462 490835<br />

www.floydautomatic.co.uk e: sales@floydautomatic.co.uk<br />

Page 14

<strong>Tooling</strong> Systems for CNC Turning machines<br />

EXTENDED LENGTH COLLET HOLDERS<br />

with clamping flat<br />

(cylindrical shank on request)<br />

Cat. No. D A L1 L2 M Range Collet Nut Spanner<br />

RF508996 6 12 70 16 - 0,3-5 ER8 ER8M E8M<br />

RF508808 8 12 125 16 - 0,3-5 ER8 ER8M E8M<br />

RF508810 10 12 120 16 - 0,3-5 ER8 ER8M E8M<br />

RF508710 10 12 80 16 - 0,3-5 ER8 ER8M E8M<br />

RF508812 12 12 125 16 - 0,3-5 ER8 ER8M E8M<br />

RF508999 12 12 80 16 - 0,3-5 ER8 ER8M E8M<br />

RF511878 5/8” 16 125 19 M8 0,5-7* ER11 ER11M E11M<br />

RF511910 10 16 80 19 - 0,5-7* ER11 ER11M E11M<br />

RF511812 12 16 125 19 - 0,5-7* ER11 ER11M E11M<br />

RF511868 16 16 125 19 - 0,5-7* ER11 ER11M E11M<br />

RF511968 16 16 150 19 - 0,5-7* ER11 ER11M E11M<br />

RF516862 16 22 150 36 - 1-10* ER16 ER16M E16M<br />

RF516852 16 22 100 36 - 1-10* ER16 ER16M E16M<br />

RF516882 3/4" 22 125 23 M10 1-10* ER16 ER16M E16M<br />

RF516872 20 22 140 23 M10 1-10* ER16 ER16M E16M<br />

EU162599 25 28 100 22 M10 1-10* ER16 D16S S25<br />

EU162512 25 28 125 22 M10 1-10* ER16 D16S S25<br />

EM162017 20 22 170 22 M10 1-10* ER16 ER16M E16M<br />

EM162020 20 22 200 22 M10 1-10* ER16 ER16M E16M<br />

EM162515 25 22 150 22 M10 1-10* ER16 ER16M E16M<br />

RF520890 1" 28 140 24 M14 1-13* ER20 ER20M E20M<br />

RF520880 25 28 140 24 M14 1-13* ER20 ER20M E20M<br />

RF520881 25 28 140 24 M14 1-13* ER20 ER20M E20M<br />

EM202015 20 28 150 24 M14 1-13* ER20 ER20M E20M<br />

RF525820 20 35 150 45 - 1-16* ER25 ER25M E25M<br />

RF525825 25 35 150 36 M16 1-16* ER25 ER25M E25M<br />

EM252500 25 35 100 36 M16 1-16* ER25 ER25M E25M<br />

RF525830 30 35 180 28 M18 1-16* ER25 ER25M E25M<br />

RF525832 32 35 180 28 M18 1-16* ER25 UM/ER25 E25M<br />

EM253218 32 35 180 28 M18 1-16* ER25 ER25M E25M<br />

* Increased range available using FLO-TOOL oversize <strong>collet</strong>s:-<br />

ER11 Ø8mm<br />

ESX16 Ø12mm<br />

ESX20 Ø15mm<br />

ESX25 Ø20mm<br />

R <strong>Floyd</strong> <strong>Automatic</strong> <strong>Tooling</strong> <strong>Ltd</strong> Tel: 01462 491919 Fax: 01462 490835<br />

www.floydautomatic.co.uk e: sales@floydautomatic.co.uk<br />

Page 15

<strong>Tooling</strong> Systems for CNC Turning machines<br />

COLLET CHUCK-DRILL EXTENSION<br />

All Holders are supplied complete with mini-nut<br />

Cat. No. Type D A L1 L2 Range Collet Nut Spanner<br />

RF508996 CYL 6 ER 8M 6 12 70 25 0,3 - 5 ER 8 ER 8 M E 8 M<br />

RF508998 CYL 8 ER 8M 8 12 70 25 0,3 - 5 ER 8 ER 8 M E 8 M<br />

RF508990 CYL 10 ER 8M 10 12 80 25 0,3 - 5 ER 8 ER 8 M E 8 M<br />

RF508999 CYL 12 ER 8 M 12 12 80 16 0,3 - 5 ER 8 ER 8 M E 8 M<br />

RF511805 CYL 5 ER11 M 5 16 56 32 0,5 - 7 ER11 ER11 M E11 M<br />

RF511801 CYL 6 ER11 M 6 16 56 29 0,5 - 7 ER11 ER11 M E11 M<br />

RF511800 CYL 7 ER11 M 7 16 56 26 0,5 - 7 ER11 ER11 M E11 M<br />

RF511810 CYL 8 ER11 M 8 16 56 26 0,5 - 7 ER11 ER11 M E11 M<br />

RF516808 CYL 8 ER16 M 8 22 60 37 1 - 10 ER16 ER16 M E16 M<br />

RF516800 CYL10 ER16 M 10 22 60 37 1 - 10 ER16 ER16 M E16 M<br />

RF516810 CYL12 ER16 M 12 22 80 37 1 - 10 ER16 ER16 M E16 M<br />

RF520800 CYL15 ER20 M 15 28 100 38 1 - 13 ER20 ER20 M E20 M<br />

RF520810 CYL16 ER20 M 16 28 100 38 1 - 13 ER20 ER20 M E20 M<br />

RF520820 CYL18 ER20 M 18 28 70 38 1 - 13 ER20 ER20 M E20 M<br />

22mm SHANK COLLET HOLDERS FOR THRO’ COOLANT<br />

Rear coolant inlet<br />

Cat. No. D A L1 L2 G SW Collet Nut<br />

EM 162260 AKS 22 22 60 23 1/8” BSP 19 ER16 ER16M (Std)<br />

EM 162270 AKS 22 22 70 23 1/8” BSP 19 ER16 ER16M (Std)<br />

EM 162280 AKS 22 22 80 23 1/8” BSP 19 ER16 ER16M (Std)<br />

R <strong>Floyd</strong> <strong>Automatic</strong> <strong>Tooling</strong> <strong>Ltd</strong> Tel: 01462 491919 Fax: 01462 490835<br />

www.floydautomatic.co.uk e: sales@floydautomatic.co.uk<br />

Page 16

<strong>Tooling</strong> Systems for CNC Turning machines<br />

THRO’ COOLANT COLLET HOLDER<br />

Coolant inlet possible from side or rear<br />

All Holders are supplied complete with nut and have clamping flat.<br />

ER16AK<br />

Cat. No. D D1 L1 L2 G L Collet Nut<br />

EM 163450 AK1<br />

EM 163450 AK2<br />

EM 163450 AK3<br />

EM 163470 AK1<br />

EM 163470 AK2<br />

EM 163470 AK3<br />

EM 162050 AK1<br />

EM 162050 AK2<br />

EM 162050 AK3<br />

EM 162070 AK1<br />

EM 162070 AK2<br />

EM 162070 AK3<br />

EM 162250 AK1<br />

EM 162250 AK2<br />

EM 162250 AK3<br />

EM 162270 AK1<br />

EM 162270 AK2<br />

EM 162270 AK3<br />

EM 162550 AK1<br />

EM 162550 AK2<br />

EM 162550 AK3<br />

EM 162570 AK1<br />

EM 162570 AK2<br />

EM 162570 AK3<br />

EM 161050 AK1<br />

EM 161050 AK2<br />

EM 161050 AK3<br />

EM 161070 AK1<br />

EM 161070 AK2<br />

EM 161070 AK3<br />

3/4" 22 50 27<br />

3/4" 22 70 27<br />

20 22 50 27<br />

20 22 70 27<br />

22 22 50 27<br />

22 22 70 27<br />

25 22 50 27<br />

25 22 70 27<br />

1” 22 50 27<br />

1” 22 50 27<br />

1/8” BSP<br />

M8x1<br />

M10x1<br />

1/8” BSP<br />

M8x1<br />

M10x1<br />

1/8” BSP<br />

M8x1<br />

M10x1<br />

1/8” BSP<br />

M8x1<br />

M10x1<br />

1/8” BSP<br />

M8x1<br />

M10x1<br />

1/8” BSP<br />

M8x1<br />

M10x1<br />

1/8” BSP<br />

M8x1<br />

M10x1<br />

1/8” BSP<br />

M8x1<br />

M10x1<br />

1/8” BSP<br />

M8x1<br />

M10x1<br />

1/8” BSP<br />

M8x1<br />

M10x1<br />

90 ER16<br />

110 ER16<br />

90 ER16<br />

110 ER16<br />

90 ER16<br />

110 ER16<br />

90 ER16<br />

90 ER16<br />

90 ER16<br />

90 ER16<br />

ER16M (Std)<br />

ER16 Sealed (option)<br />

ER16M (Std)<br />

ER16 Sealed (option)<br />

ER16M (Std)<br />

ER16 Sealed (option)<br />

ER16M (Std)<br />

ER16 Sealed (option)<br />

ER16M (Std)<br />

ER16 Sealed (option)<br />

ER16M (Std)<br />

ER16 Sealed (option)<br />

ER16M (Std)<br />

ER16 Sealed (option)<br />

ER16M (Std)<br />

ER16 Sealed (option)<br />

ER16M (Std)<br />

ER16 Sealed (option)<br />

ER16M (Std)<br />

ER16 Sealed (option)<br />

EM 202515 AK<br />

28<br />

30<br />

180 ER20 ER20 Sealed/ER20M(O}<br />

25<br />

150<br />

1/4” BSP<br />

EM 252515 AK 35 32 182 ER25 ER25 Sealed/ER20M(O}<br />

R <strong>Floyd</strong> <strong>Automatic</strong> <strong>Tooling</strong> <strong>Ltd</strong> Tel: 01462 491919 Fax: 01462 490835<br />

www.floydautomatic.co.uk e: sales@floydautomatic.co.uk<br />

Page 17

<strong>Tooling</strong> Systems for CNC Turning machines<br />

8° 30°<br />

ER/ESX COLLETS<br />

Flo-Tool Eco ER <strong>collet</strong>s – Low cost option & oversize range<br />

D2<br />

D1<br />

L<br />

Cat. No. L D1 D2 Std. Range Step *O/size Range D2 Step<br />

ER8 13.5 8.5 0.5-5 Ø1-5 0.5 - -<br />

ER11 18 11.5 0.5-7 Ø1-7 0.5 Ø7.5-8 0.5<br />

ER16 27.5 17 1-10 Ø1-10 0.5 Ø10.5-12 0.5<br />

ER20 31.5 21 1-13 Ø1-13 0.5 Ø14-15 0.5<br />

ER25 34 26 1-16 Ø1-16 0.5 Ø17-20 0.5<br />

ER32 40 33 2-20 Ø2-20 0.5 Ø21-22 1.0<br />

ER/ESX SEALED COLLET NUTS & SEALING DISCS<br />

FOR THRO’ COOLANT<br />

Sealed Collet Nuts<br />

ER <strong>type</strong><br />

The shortest sealed nut system available<br />

Collet Nut Cat. No. Thread Sealing Disc Diameter range<br />

ER16-FDS M22x1.5 DSF16 Ø2-10 x 0.5mm<br />

ER16M-FDS M19x1 DSF16 Ø2-10 x 0.5mm<br />

ER20-FDS M25x1.5 DSF20 Ø2-13 x 0.5mm<br />

ER20M-FDS M24x1 DSF20 Ø2-13 x 0.5mm<br />

ER25-FDS M32x1.5 DSF25 Ø2-16 x 0.5mm<br />

ER25M-FDS M30x1 DSF25 Ø2-16 x 0.5mm<br />

ER32-FDS M40x1.5 DSF32 Ø2-20 x 0.5mm<br />

ER40-FDS M50x1.5 DSF40 Ø3-26 x 0.5mm<br />

R <strong>Floyd</strong> <strong>Automatic</strong> <strong>Tooling</strong> <strong>Ltd</strong> Tel: 01462 491919 Fax: 01462 490835<br />

www.floydautomatic.co.uk e: sales@floydautomatic.co.uk<br />

Page 18

<strong>Tooling</strong> Systems for CNC Turning machines<br />

ER/ESX SEALED COLLETS FOR THRO’ COOLANT<br />

Sealed Collets - for thro’ coolant<br />

ER<br />

New sealing technology tested to 130 bar<br />

Cat. No.<br />

Diameter<br />

ER11S 3,0-7,0 x 0,5<br />

ER16S 3,0 – 10,0 x 0,5<br />

ER20S 3,0 – 13,0 x 1,0<br />

ER25S 3,0 – 16,0 x 1,0<br />

ER32S 3,0 - 20,0 x 1,0<br />

ER40S 6,0/8,0/10,0/12,0/14,0/16,0/18,0/20,0<br />

Solid Tapping Collets – with internal driver square<br />

ER<br />

Cat. No.<br />

ERG16<br />

ERG20<br />

ERG25<br />

ERG32<br />

ERG40<br />

Diameter x square<br />

2,8x2,1/3,5x2,7/4,0x3,0/4,5x3,4/6,0x4,9/7,0x5,5/8,0x6,3/9,0x7,0<br />

3,5x2,7/4,0x3,0/4,5x3,4/6,0x4,9/7,0x5,5/8,0x6,3/9,0x7,1/10,0x8,0/11x9<br />

3,5x2,7/4,0x3,0/4,5x3,4/6,0x4,9/7,0x5,5/8,0x6,3/9,0x7,1/10,0x8,0<br />

3,5x2,7/4,0x3,0/4,5x3,4/6,0x4,9/7,0x5,5/8,0x6,3/9,0x7,1/10,0x8,0<br />

11,0x9,0/12,0x9,0/14,0x11,0/16,0x12,0/18,0x14,5/20,0x16,0<br />

3,5x2,7/4,0x3,0/4,5x3,4/6,0x4,9/7,0x5,5/8,0x6,3/9,0x7,1/10,0x8,0<br />

11,0x9,0/12,0x9,0/14,0x11,0/16,0x12,0/18,0x14,5/20,0x16,0/22,0x18,0<br />

Floating Reamer Collets<br />

ERP<br />

Cat. No.<br />

Diameter d<br />

ERP IM-CBA-16 2, 3, 4, 5, 6, 7<br />

ERP IM-CBA-20 3, 4, 5, 6, 7, 8<br />

ERP IM-CBA-25 3, 4, 5, 6, 7, 8, 9, 10<br />

ERP IM-CBA-32 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14<br />

ERP IM-CBA-40 5, 6, 7, 8, 9, 10, 11, 12, 13, 14,15 ,16<br />

R <strong>Floyd</strong> <strong>Automatic</strong> <strong>Tooling</strong> <strong>Ltd</strong> Tel: 01462 491919 Fax: 01462 490835<br />

www.floydautomatic.co.uk e: sales@floydautomatic.co.uk<br />

Page 19

<strong>Tooling</strong> Systems for CNC Turning machines<br />

DOUBLE ENDED COLLET HOLDERS<br />

For machines with sub-spindle with compact dimensions & clamping flat<br />

Cat. No. D A L1 L2 N SW Range Collet Nut Spanner<br />

ED085818 5/8” 12 18 14 5,5 13 0,3-5 ER8 ER8 E8M<br />

ED085830 5/8” 12 29 14 5,5 13 0,3-5 ER8 ER8 E8M<br />

ED085835 5/8” 12 35 14 5,5 13 0,3-5 ER8 ER8 E8M<br />

ED085840 5/8” 12 40 14 5,5 13 0,3-5 ER8 ER8 E8M<br />

ED111632 16 16 32 19 7.5 13 0,5-7* ER11 ER11M E11M<br />

ED111650 16 16 50 19 7,5 13 0,5-7* ER11 ER11M E11M<br />

ED111670 16 16 70 19 7,5 13 0,5-7* ER11 ER11M E11M<br />

ED113432 3/4" 16 32 19 7,5 13 0,5-7* ER11 ER11M E11M<br />

ED113440 3/4" 16 40 19 7,5 13 0,5-7* ER11 ER11M E11M<br />

ED113450 3/4" 16 52 19 7,5 13 0,5-7* ER11 ER11M E11M<br />

ED113465 3/4" 16 65 19 7,5 13 0,5-7* ER11 ER11M E11M<br />

ED113472 3/4" 16 72 19 7,5 13 0,5-7* ER11 ER11M E11M<br />

ED113495 3/4" 16 95 19 7,5 13 0,5-7* ER11 ER11M E11M<br />

ED112032 20 16 32 19 7,5 13 0,5-7* ER11 ER11M E11M<br />

ED112040 20 16 40 19 7,5 13 0,5-7* ER11 ER11M E11M<br />

ED112050 20 16 52 19 7,5 13 0,5-7* ER11 ER11M E11M<br />

ED112065 20 16 65 19 7,5 13 0,5-7* ER11 ER11M E11M<br />

ED112080 20 16 80 19 7,5 13 0,5-7* ER11 ER11M E11M<br />

ED112295 22 16 94 19 7,5 13 0,5-7* ER11 ER11M E11M<br />

ED112299 22 16 100 19 7,5 13 0,5-7* ER11 ER11M E11M<br />

* Range up to Ø8 with FLO-TOOL oversize <strong>collet</strong>s<br />

ED163455 3/4" 22 55 23 11 16 1-10* ESX16 ER16M E16M<br />

ED163432 3/4" 22 32 23 11 16 1-10* ESX16 ER16M E16M<br />

ED163495 3/4" 22 95 23 11 16 1-10* ESX16 ER16M E16M<br />

ED163499 3/4" 22 99 23 11 16 1-10* ESX16 ER16M E16M<br />

ED162032 20 22 32 23 11 16 1-10* ESX16 ER16M E16M<br />

ED162050 20 22 50 23 11 16 1-10* ESX16 ER16M E16M<br />

ED162062 20 22 62 23 11 16 1-10* ESX16 ER16M E16M<br />

ED162075 20 22 75 23 11 16 1-10* ESX16 ER16M E16M<br />

ED162240 22 22 40 23 11 22 1-10* ESX16 ER16M E16M<br />

ED162255 22 22 55 23 11 19 1-10* ESX16 ER16M E16M<br />

ED162262 22 22 62 23 11 19 1-10* ESX16 ER16M E16M<br />

ED162267 22 22 67 23 11 19 1-10* ESX16 ER16M E16M<br />

ED162275 22 22 75 23 11 19 1-10* ESX16 ER16M E16M<br />

ED162295 22 22 94 23 11 19 1-10* ESX16 ER16M E16M<br />

ED162299 22 22 100 23 11 19 1-10* ESX16 ER16M E16M<br />

ED162212 22 22 120 23 11 19 1-10* ESX16 ER16M E16M<br />

ED161021 1" 22 21 23 11 22 1-10* ESX16 ER16M E16M<br />

ED161035 1" 22 35 23 11 22 1-10* ESX16 ER16M E16M<br />

ED161045 1" 22 45 23 11 22 1-10* ESX16 ER16M E16M<br />

ED161062 1" 22 62 23 11 22 1-10* ESX16 ER16M E16M<br />

ED162562 25 22 62 23 11 22 1-10* ESX16 ER16M E16M<br />

* Range up to Ø12 with FLO-TOOL oversize <strong>collet</strong>s<br />

ED201045 1” 28 45 25 14 22 1-13* ESX20 ER20M E20M<br />

ED201075 1” 28 75 25 14 22 1-13* ESX20 ER20M E20M<br />

ED202555 25 28 55 25 14 22 1-13* ESX20 ER20M E20M<br />

ED202599 25 28 100 25 14 22 1-13* ESX20 ER20M E20M<br />

ED203220 32 28 20 25 14 - 1-13* ESX20 ER20M E20M<br />

ED203235 32 28 35 25 14 - 1-13* ESX20 ER20M E20M<br />

ED203242 32 28 42 25 14 - 1-13* ESX20 ER20M E20M<br />

ED203250 32 28 50 25 14 - 1-13* ESX20 ER20M E20M<br />

ED203255 32 28 55 25 14 - 1-13* ESX20 ER20M E20M<br />

ED203285 32 28 85 25 14 - 1-13* ESX20 ER20M E20M<br />

* Range up to Ø15 with FLO-TOOL oversize <strong>collet</strong>s<br />

R <strong>Floyd</strong> <strong>Automatic</strong> <strong>Tooling</strong> <strong>Ltd</strong> Tel: 01462 491919 Fax: 01462 490835<br />

www.floydautomatic.co.uk e: sales@floydautomatic.co.uk<br />

Page 20

<strong>Tooling</strong> Systems for CNC Turning machines<br />

DOUBLE ENDED COLLET HOLDERS<br />

For machines with sub-spindle with compact dimensions & clamping flat<br />

Cat. No. D A1/A2 L1/L3 L2 N SW Collet Nut Spanner<br />

ED11/163432 3/4" 16/22 19/23 32 7,5 17 ER11/ESX16 ER11/ER16M E11/16M<br />

ED11/163450 3/4” 16/22 19/23 55 7,5 17 ER11/ESX16 ER11/ER16M E11/16M<br />

ED11/163465 3/4” 16/22 19/23 65 7,5 17 ER11/ESX16 ER11/ER16M E11/16M<br />

ED11/163480 3/4” 16/22 19/23 80 7,5 17 ER11/ESX16 ER11/ER16M E11/16M<br />

ED11/163495 3/4” 16/22 19/23 95 7,5 17 ER11/ESX16 ER11/ER16M E11/16M<br />

ED11/162032 20 16/22 19/23 32 7,5 17 ER11/ESX16 ER11/ER16M E11/16M<br />

ED11/162050 20 16/22 19/23 55 7,5 17 ER11/ESX16 ER11/ER16M E11/16M<br />

ED11/162075 20 16/22 19/23 75 7,5 17 ER11/ESX16 ER11/ER16M E11/16M<br />

ED11/162265 22 19/22 19/23 90 7,5 19 ER11/ESX16 ER11/ER16M E11/16M<br />

ED11/162290 22 19/22 19/23 90 7,5 19 ER11/ESX16 ER11/ER16M E11/16M<br />

ED11/162292 22 19/22 19/23 92 7,5 19 ER11/ESX16 ER11/ER16M E11/16M<br />

ED20/251062 1” 28/35 25/34 62 13 27 ESX20/ESX25 ER20/ER25M E20/25M<br />

ED20/252562 25 28/35 25/34 62 13 27 ESX20/ESX25 ER20/ER25M E20/25M<br />

ED20/253250 32 28/35 25/34 62 11 17 ESX20/ESX25 ER20/ER25M E20/25M<br />

COLLET HOLDER STOP RINGS FOR PRE-SETTING<br />

Cat. No. A B<br />

EM-PA16 20 16<br />

EM-PA19 23 19,05<br />

EM-PA20 23 20<br />

EM-PA22 25 22<br />

EM-PA22B 34 22<br />

EM-PA28* 32 28<br />

EM-PA32** 39,8 32<br />

*For Traub TNL<br />

**For Star<br />

Stop ring<br />

shown in<br />

situ.<br />

R <strong>Floyd</strong> <strong>Automatic</strong> <strong>Tooling</strong> <strong>Ltd</strong> Tel: 01462 491919 Fax: 01462 490835<br />

www.floydautomatic.co.uk e: sales@floydautomatic.co.uk<br />

Page 21

<strong>Tooling</strong> Systems for CNC Turning machines<br />

ESX COLLET REDUCTION SLEEVES<br />

Cat. No. Type Thread D1 L1 L2 L G D<br />

D2<br />

EQ11M/ER08 ER11M/ER8 M13x0.75 20 15 33 18 M4 12<br />

EQ11/ER08 ER11/ER8 M14x0.75 20 15 33 18 M4 12<br />

EQ11M/ER16# ER11M/ER16M M13x0.75 20 38 56 41 - 22<br />

EQ11/ER16# ER11/ER16M M14x0.75 20 38 56 41 - 22<br />

EQ16M/F8 ER16M/F8 M19x1 22a/f 30 60 39 M8 20<br />

EQ16M/F8L ER16M/F8 M19x1 22a/f 47 81 60 M8 20<br />

EQ16/F8 ER16M/F8 M22x1,5 28 30 60 39 M8 20<br />

EQ16/F8L ER16M/F8 M22x1,5 28 47 81 60 M8 20<br />

EQ16M/ER08M ER16M/ER8M M19x1 22a/f 40 45 50 M8 16<br />

EQ16/ER08ML ER16/ER8M M22x1,5 28 40 70 50 M8 16<br />

EQ16M/ER11M ER16M/ER11M M19x1 22a/f 15 70 24 M8 16<br />

EQ16M/ER11ML ER16M/ER11M M19x1 22a/f 30 60 39 M8 16<br />

EQ16M/ER11MxL ER16M/ER11M M19x1 22a/f 51 81 60 M8 16<br />

EQ16/ER11M ER16/ER11M M22x1,5 28 15 45 24 M8 16<br />

EQ16/ER11ML ER16/ER11M M22x1,5 28 30 60 39 M8 16<br />

EQ16/ER11MxL ER16/ER11M M22x1,5 28 51 81 60 M8 16<br />

EQ20M/ER16M ER20M/ER16M M24x1 28 23 52,5 30 M10 22<br />

EQ20/ER16M ER20/ER16M M25x1,5 34 23 52,5 30 M10 22<br />

EQ25M/ER16M ER25M/ER16M M30x1 35 25 61,5 34 M12 22<br />

EQ25M/ER16ML ER25M/ER16M M30x1 35 33 69 42 M12 22<br />

EQ25/ER16M ER25/ER16M M32x1,5 42 25 61,5 34 M12 22<br />

EQ25/ER16ML ER25/ER16M M32x1,5 42 33 69 42 M12 22<br />

EQ25/ER20 ER25/ER20 M32x1,5 42 20 58 28 M12 34<br />

# Increases ER11 to ER16<br />

R <strong>Floyd</strong> <strong>Automatic</strong> <strong>Tooling</strong> <strong>Ltd</strong> Tel: 01462 491919 Fax: 01462 490835<br />

www.floydautomatic.co.uk e: sales@floydautomatic.co.uk<br />

Page 22

<strong>Tooling</strong> Systems for CNC Turning machines<br />

DOUBLE ENDED TAP HOLDERS<br />

Non-reversing tap holder both ends<br />

For machines with sub-spindle i.e. Citizen, Star, Manurhin, Miyano, Traub<br />

1 2<br />

Cat. No. D A1/A2 L1 L2/L3 Fig. SW Collet Nut Spanner<br />

EGD113440M 3/4" 16 48 15 1 - ER11 ER11M E11M<br />

EGD113440 3/4" 16 48 15 1 - ER11 D11 S17<br />

EGD11/163440 3/4" 16/22 48 15/25 2 - ER11/ESX16 ER11/16M E11/16M<br />

EGD113455 3/4" 16 57 15 1 - ER11 ER11M E11M<br />

EGD113460 3/4" 16 60 15 1 - ER11 ER11M E11M<br />

EGD11/163460 3/4" 19/22 60 15/25 2 17 ER11/ESX16 D11/ER16M S17/E16M<br />

EGD163455 3/4" 22 57 25/35 1 17 ESX16 ER16M E16M<br />

EGD112040M 20 16 48 15 1 - ER11 ER11M E11M<br />

EGD112040 20 19 48 15 1 - ER11 D11 E11M<br />

EGD11/162040 20 19/22 48 15/25 2 - ER11/ESX16 D11/ER16M S17/E16M<br />

EGD112055 20 16 57 15/25 1 - ER11 ER11M E11M<br />

EGD112060 20 16 60 15 1 - ER11 ER11M E11M<br />

EGD11/162060 20 19/22 60 15/25 2 17 ER11/ESX16 D11/ER11M S17/E11M<br />

EGD162055 20 22 57 25/35 1 17 ESX16 ER16M E16M<br />

EGD112240M 22 16 48 15 1 - ER11 ER11M E11M<br />

EGD112240 22 19 48 15 1 - ER11 D11 S17<br />

EGD11/162240 22 19/22 48 15/25 2 - ER11/ESX16 D11/ER16M S17/E16M<br />

EGD112255 22 16 57 25/35 1 - ER11 ER11M S17<br />

EGD112260 22 16 60 15 1 - ER11 D11 S17<br />

EGD11/162260 22 19/22 60 15/25 2 17 ER11/ESX16 D11/ER16M S17/E16M<br />

EGD112275 22 22 75 15 1 - ER11 ER11M E11M<br />

EGD112285 22 22 85 15 1 - ER11 ER11M E11M<br />

EGD112295 22 22 95 15 1 - ER11 ER11M E11M<br />

EGD162255 22 22 57 25/35 1 17 ER16 ER16M E16M<br />

EGD162275 22 22 75 25 1 17 ER16 ER16M E16M<br />

EGD162285 22 22 85 25 1 17 ER16 ER16M E16M<br />

EGD162295 22 22 95 25 1 17 ER16 ER16M E16M<br />

EGD162570 25 22 69 35 1 17 ER16 ER16M E16M<br />

EGD162560 25 22 60 35/26 1 17 ER16 ER16M E16M<br />

EGD161070 1” 22 69 35 1 17 ER16 ER16M E16M<br />

EGD161060 1” 22 69 35/26 1 17 ER16 ER16M E16M<br />

Use Button Die Holders Type ER11/ER16 S16/20 & SMK16/20 in place of <strong>collet</strong> nut to convert to Double Die<br />

Holder<br />

R <strong>Floyd</strong> <strong>Automatic</strong> <strong>Tooling</strong> <strong>Ltd</strong> Tel: 01462 491919 Fax: 01462 490835<br />

www.floydautomatic.co.uk e: sales@floydautomatic.co.uk<br />

Page 23

<strong>Tooling</strong> Systems for CNC Turning machines<br />

DOUBLE ENDED TAP-COLLET HOLDERS<br />

Drill holder one end, non-reversing tap holder the other<br />

For machines with sub-spindle i.e. Citizen, Star, Manurhin, Miyano, Traub<br />

1 2<br />

Cat. No. D A1/A2 L1 L2/L3 Fig. Collet Collet Nut<br />

Drill end Tap end<br />

EMG163470 3/4" 22 70 23 1 ESX16 ESX16 E16M<br />

EMG162070 20 22 70 23 1 ESX16 ESX16 E16M<br />

EMG162270 22 22 70 23 1 ESX16 ESX16 E16M<br />

EMG162299 22 22 100 23 1 ESX16 ESX16 E16M<br />

EMG162212 22 22 120 23 1 ESX16 ESX16 E16M<br />

EMG112032 20 16 32 15 1 ER11 ER11 E11M<br />

EUG112032 20 19 32 15 1 ER11 ER11 D11<br />

EMG112055 20 16 55 15 1 ER11 ER11 E11M<br />

EUG112055 20 19 55 15 1 ER11 ER11 D11<br />

EMG11/162055 20 16/22 52 15/23 1 ER11 ESX16 E11M/E16M<br />

EUG11/162055 20 19/22 52 15/23 1 ER11 ESX16 D11/E16M<br />

EUG112255 22 19 52 15 1 ER11 ER11 E11M<br />

R <strong>Floyd</strong> <strong>Automatic</strong> <strong>Tooling</strong> <strong>Ltd</strong> Tel: 01462 491919 Fax: 01462 490835<br />

www.floydautomatic.co.uk e: sales@floydautomatic.co.uk<br />

Page 24

<strong>Tooling</strong> Systems for CNC Turning machines<br />

TAP HOLDERS<br />

Non-reversing <strong>type</strong> EG - Hexagon Drive<br />

For ER11 & ER16 <strong>collet</strong>s – fitted with mini-nut to give compact size<br />

Pull-out approx. 10mm<br />

Cat. No. D A Range L1 L2 Cat. No. D A Range L1 L2<br />

EG111430 14 16 M1-8 20 19 EG161430 14 22 M1-8 20 36<br />

EG111620 16 16 M1-8 20 19 EG161620 16 22 M1-8 20 36<br />

EG111630 16 16 M1-8 30 19 EG161630 16 22 M1-8 30 36<br />

EG111670 16 16 M1-8 70 19 EG161670 16 22 M1-8 70 36<br />

EG113438 3/4" 16 M1-8 38 19 EG163438 3/4" 22 M1-8 38 36<br />

EG113450 3/4" 16 M1-8 50 19 EG163450 3/4" 22 M1-8 50 36<br />

EG113470 3/4" 16 M1-8 70 19 EG163470 3/4" 22 M1-8 70 36<br />

EG113412 3/4" 16 M1-8 120 19 EG163412 3/4" 22 M1-8 120 36<br />

EG112038 20 16 M1-8 38 19 EG162038 20 22 M1-8 38 36<br />

EG112050 20 16 M1-8 50 19 EG162050 20 22 M1-8 50 36<br />

EG112070 20 16 M1-8 70 19 EG162070 20 22 M1-8 70 36<br />

EG112012 20 16 M1-8 120 19 EG162012 20 22 M1-8 120 36<br />

EG112238 22 16 M1-8 38 19 EG162238 22 22 M1-8 38 36<br />

EG112270 22 16 M1-8 70 19 EG162270 22 22 M1-8 70 36<br />

EG112212 22 16 M1-8 120 19 EG162212 22 22 M1-8 120 36<br />

EG111038 1” 16 M1-8 38 19 EG161038 1” 22 M1-8 38 36<br />

EG111080 1” 16 M1-8 80 19 EG161080 1” 22 M1-8 80 36<br />

EG112538 25 16 M1-8 38 19 EG162538 25 22 M1-8 38 36<br />

EG112580 25 16 M1-8 80 19 EG162580 25 22 M1-8 80 36<br />

R <strong>Floyd</strong> <strong>Automatic</strong> <strong>Tooling</strong> <strong>Ltd</strong> Tel: 01462 491919 Fax: 01462 490835<br />

www.floydautomatic.co.uk e: sales@floydautomatic.co.uk<br />

Page 25

<strong>Tooling</strong> Systems for CNC Turning machines<br />

TAP HOLDER FOR FINE TAPPING<br />

Tap holder for sensitive tapping applications<br />

Guide diameters ground & polished<br />

Almost Zero Free Play<br />

Extremely small dimensions<br />

Cat. No. Ød ØD L1 L2 Nut Pull out Collet Range<br />

EGF081450 14 12 50 15 ER08M 7mm ER8 M1-M6<br />

EGF081550 5/8” 12 50 15 ER08M 7mm ER8 M1-M6<br />

EGF081650 16 12 50 15 ER08M 7mm ER8 M1-M6<br />

EGF081540 5/8” 12 40 15 ER08M 7mm ER8 M1-M6<br />

EGF081640 16 12 40 15 ER08M 7mm ER8 M1-M6<br />

EGF 11 16 45 16 16 45 36 ER11M 7mm ER11 M1-M6<br />

EGF 11 34 50 3/4" 16 50 15 ER11M 7mm ER11 M1-M6<br />

EGF 11 20 50 20 16 50 15 ER11M 7mm ER11 M1-M6<br />

EGF 11 22 70 22 16 70 15 ER11M 7mm ER11 M1-M6<br />

EGF 11 25 70 25 16 70 15 ER11M 7mm ER11 M1-M6<br />

EGF 11 10 70 1” 16 70 15 ER11M 7mm ER11 M1-M6<br />

EGF 16 16 45 16 22 45 50 ER16M 7mm ER16 M1-M8<br />

EGF 16 34 50 3/4" 22 50 29 ER16M 7mm ER16 M1-M8<br />

EGF 16 20 50 20 22 50 29 ER16M 7mm ER16 M1-M8<br />

EGF 16 20 70 20 22 70 29 ER16M 7mm ER16 M1-M8<br />

EGF 16 22 70 22 22 70 29 ER16M 7mm ER16 M1-M8<br />

EGF 16 25 70 25 22 70 29 ER16M 7mm ER16 M1-M8<br />

EGF 20 32 50 32 16 50 31 ER20M 10mm ER20 M1-M10<br />

EGF 20 32 80 32 16 80 31 ER20M 10mm ER20 M1-M10<br />

Also available with hex <strong>collet</strong> nut <strong>type</strong> EKF<br />

R <strong>Floyd</strong> <strong>Automatic</strong> <strong>Tooling</strong> <strong>Ltd</strong> Tel: 01462 491919 Fax: 01462 490835<br />

www.floydautomatic.co.uk e: sales@floydautomatic.co.uk<br />

Page 26

<strong>Tooling</strong> Systems for CNC Turning machines<br />

Non-reversing Tap Holders Type EG<br />

For ER20 & ER25 <strong>collet</strong>s – fitted with mini-nut to give compact size<br />

Tapping head is ball bearing guided<br />

EG20 <strong>type</strong> Pull-out approx. 10mm - EG25 <strong>type</strong> Pull-out approx. 12mm<br />

Cat. No. D A ØG - Range L1 L2<br />

EG20S16 16 34 M2-16 32 55<br />

EG20S34 3/4 34 M2-16 50 55<br />

EG20S20 20 34 M2-16 50 55<br />

EG20S25 25 34 M2-16 45 55<br />

EG20S25L 25 34 M2-16 100 55<br />

EG20S25XL 25 34 M2-16 125 55<br />

EG20MS25XL 25 28* M2-16 125 55<br />

EG20S10 1” 34 M2-16 45 55<br />

EG20S10L 1” 34 M2-16 100 55<br />

EG20S32 32 34 M2-16 55 55<br />

*Fitted with mini-nut<br />

Cat. No. D A ØG - Range L1 L2<br />

EG25S16 16 42 M3-16 32 55<br />

EG25S34 3/4 42 M3-16 50 55<br />

EG25S20 20 42 M3-16 50 55<br />

EG25S25 25 42 M3-16 45 55<br />

EG25S25L 25 42 M3-16 100 55<br />

EG25S25XL 25 42 M3-16 125 55<br />

EG25MS25XL 25 38* M3-16 125 55<br />

EG25S10 1” 42 M3-16 45 55<br />

EG25S11 1” 42 M3-16 55 55<br />

EG25S10L 1” 42 M3-16 100 55<br />

EG25S32 32 42 M3-16 55 55<br />

EG25S40 40 42 M3-16 85 55<br />

*Fitted with mini-nut<br />

R <strong>Floyd</strong> <strong>Automatic</strong> <strong>Tooling</strong> <strong>Ltd</strong> Tel: 01462 491919 Fax: 01462 490835<br />

www.floydautomatic.co.uk e: sales@floydautomatic.co.uk<br />

Page 27

<strong>Tooling</strong> Systems for CNC Turning machines<br />

Non-reversing Tap Holders Type EK – Hexagon drive<br />

For ER16 & ER11 <strong>collet</strong>s – fitted with standard hexagon nut<br />

*For ER11 version – A=16mm L2=19mm Cat. No. EK11 .. ..<br />

Pull-out approx. 12mm<br />

Cat. No.* D A Range L1 L2<br />

EK161630 16 28 M1-8 34 36<br />

EK161670 16 28 M1-8 70 36<br />

EK163438 3/4" 28 M1-8 38 36<br />

EK163450 3/4" 28 M1-8 50 36<br />

EK163470 3/4" 28 M1-8 70 36<br />

EK163412 3/4" 28 M1-8 120 36<br />

28<br />

EK162038 20 28 M1-8 38 36<br />

EK162050 20 28 M1-8 50 36<br />

EK162070 20 28 M1-8 70 36<br />

EK162012 20 28 M1-8 120 36<br />

28<br />

EK162238 22 28 M1-8 38 36<br />

EK162270 22 28 M1-8 70 36<br />

28<br />

EK161038 1” 28 M1-8 38 36<br />

EK161080 1” 28 M1-8 80 36<br />

28<br />

EK162538 25 28 M1-8 38 36<br />

EK162580 25 28 M1-8 80 36<br />

R <strong>Floyd</strong> <strong>Automatic</strong> <strong>Tooling</strong> <strong>Ltd</strong> Tel: 01462 491919 Fax: 01462 490835<br />

www.floydautomatic.co.uk e: sales@floydautomatic.co.uk<br />

Page 28

<strong>Tooling</strong> Systems for CNC Turning machines<br />

BUTTON DIE HOLDER<br />

Fits to EG11 EG16 & EG20 Tap Holders in place of <strong>collet</strong> nut<br />

Converts Tap holder into floating button die holder<br />

Lock nut required for ER16 & 20 <strong>type</strong>. ER11 <strong>type</strong> locks with brass screws to thread<br />

SK – <strong>type</strong> with 3 screw die clamping<br />

SKS – <strong>type</strong> with split clamping<br />

Cat. No. ØA B ØD L Thread GEW Max Thread Lock nut<br />

Length<br />

SK11MK-1 16 5 22 23 M13x0.75 32 N/R<br />

SK11MK-2 20 7 27 25 M13x0.75 34 N/R<br />

SK11K-16 16 5 22 23 M14x0.75 32 N/R<br />

SK11K-20 20 7 27 25 M14x0.75 34 N/R<br />

SK11K-20 25 9 32 39 M14x0.75 32 N/R<br />

SK16MK-1 16 5 22 23 M19x1 37 ESM16M<br />

SK16MK-2 20 7 27 25 M19x1 39 ESM16M<br />

SK16MK-25 25 9 32 30 M19x1 42 ESM16M<br />

SKS16M-16 16 5 25 45 M19x1 56 ESM16M<br />

SKS16M-20 20 7 27 45 M19x1 56 ESM16M<br />

SK16M-16 16 5 25 45 M19x1 56 ESM16M<br />

SK16M-20 20 7 27 45 M19x1 56 ESM16M<br />

SK16M-25 25 9 33 45 M19x1 56 ESM16M<br />

SK20-16B 16 5 23 45 M25x1.5 70 ESM20<br />

SK20-20B 20 7 29 45 M25x1.5 66 ESM20<br />

SK20-25 25 9 34 45 M25x1.5 65 ESM20<br />

SK20-30B 30 11 40 45 M25x1.5 60 ESM20<br />

R <strong>Floyd</strong> <strong>Automatic</strong> <strong>Tooling</strong> <strong>Ltd</strong> Tel: 01462 491919 Fax: 01462 490835<br />

www.floydautomatic.co.uk e: sales@floydautomatic.co.uk<br />

Page 29

<strong>Tooling</strong> Systems for CNC Turning machines<br />

BUTTON DIE HOLDER WITH SHANK<br />

SH – <strong>type</strong> with 3 screw die clamping<br />

Cat. No. ØA B d D L1 L Max Thread Length<br />

SH16-6 16 5 6 22 28 80 21<br />

SH16-6L 16 5 6 22 46 95 35<br />

SH16-7 16 5 7 22 27 80 21<br />

SH16-7L 16 5 7 22 46 95 35<br />

SH16-8 16 5 8 22 27 80 21<br />

SH16-8L 16 5 8 22 46 95 35<br />

SH20-7 20 7 7 27 28 80 21<br />

SH20-7L 20 7 7 27 46 95 35<br />

SH20-8 20 7 8 27 28 80 21<br />

SH20-8L 20 7 8 27 46 95 35<br />

SH25-7 25 9 7 32 36 85 29<br />

SH25-7L 25 9 7 32 46 95 35<br />

SH25-8 25 9 8 32 36 85 29<br />

SH25-8L 25 9 8 32 46 95 35<br />

SH25-10 25 9 10 32 36 85 29<br />

BUTTON DIE HOLDER<br />

For 2 hole front fixing dies (Manigley <strong>type</strong> 503)<br />

Cat. No. ØD ØD2 L L1 L5<br />

PFC120570 12 5 70 54.5 15.5<br />

PFC160570 16 5 70 53.5 16.5<br />

PFC200678 20 6 78 51 27<br />

R <strong>Floyd</strong> <strong>Automatic</strong> <strong>Tooling</strong> <strong>Ltd</strong> Tel: 01462 491919 Fax: 01462 490835<br />

www.floydautomatic.co.uk e: sales@floydautomatic.co.uk<br />

Page 30

<strong>Tooling</strong> Systems for CNC Turning machines<br />

FLOATING REAMER HOLDERS<br />

non-adjustable <strong>type</strong> EP<br />

For ER16 & ER11 <strong>collet</strong>s – fitted with mini-nut to give compact size<br />

For ER11 version – A=16mm L2=19mm Cat. No. EG11 .. ..<br />

Cat. No. D A Ø G Range L1 L2<br />

EP111620 16 22 1-7mm 20 20<br />

EP111630 16 22 1-7mm 34 20<br />

EP111670 16 22 1-7mm 70 20<br />

EP113450 3/4" 22 1-7mm 50 20<br />

EP113470 3/4" 22 1-7mm 70 20<br />

EP113412 3/4" 22 1-7mm 120 20<br />

EP112050 20 22 1-7mm 50 20<br />

EP112070 20 22 1-7mm 70 20<br />

EP112012 20 22 1-7mm 120 20<br />

EP112250 22 22 1-7mm 50 20<br />

EP112270 22 22 1-7mm 70 20<br />

EP112212 22 22 1-7mm 120 20<br />

EP161620 16 22 1-7mm 20 36<br />

EP161630 16 22 1-7mm 34 36<br />

EP161670 16 22 1-7mm 70 36<br />

EP163450 3/4" 22 1-8mm 50 36<br />

EP163470 3/4" 22 1-8mm 70 36<br />

EP163412 3/4" 22 1-8mm 120 36<br />

EP162050 20 22 1-8mm 50 36<br />

EP162070 20 22 1-8mm 70 36<br />

EP162012 20 22 1-8mm 120 36<br />

EP162250 22 22 1-8mm 50 36<br />

EP162270 22 22 1-8mm 70 36<br />

EP162212 22 22 1-8mm 120 36<br />

EP161038 1” 22 1-8mm 50 36<br />

EP161080 1” 22 1-8mm 80 36<br />

EP162538 25 22 1-8mm 50 36<br />

EP162580 25 22 1-8mm 80 36<br />

R <strong>Floyd</strong> <strong>Automatic</strong> <strong>Tooling</strong> <strong>Ltd</strong> Tel: 01462 491919 Fax: 01462 490835<br />

www.floydautomatic.co.uk e: sales@floydautomatic.co.uk<br />

Page 31

<strong>Tooling</strong> Systems for CNC Turning machines<br />

Floating Reamer Holders, non-adjustable <strong>type</strong> EKP<br />

For ER16 <strong>collet</strong>s – fitted with standard hexagon nut<br />

Cat. No. D A Ø G Range L1 L2<br />

EP161630 16 28 1-7mm 34 36<br />

EP161670 16 28 1-7mm 70 36<br />

EP163450 3/4" 28 2-10mm 50 36<br />

EP163470 3/4" 28 2-10mm 70 36<br />

EP163412 3/4" 28 2-10mm 120 36<br />

EP162050 20 28 2-10mm 50 36<br />

EP162070 20 28 2-10mm 70 36<br />

EP162012 20 28 2-10mm 120 36<br />

EP162250 22 28 2-10mm 50 36<br />

EP162270 22 28 2-10mm 70 36<br />

EP162550 25 28 2-10mm 50 36<br />

EP162580 25 28 2-10mm 80 36<br />

EP161050 1” 28 2-10mm 50 36<br />

R <strong>Floyd</strong> <strong>Automatic</strong> <strong>Tooling</strong> <strong>Ltd</strong> Tel: 01462 491919 Fax: 01462 490835<br />

www.floydautomatic.co.uk e: sales@floydautomatic.co.uk<br />

Page 32

<strong>Tooling</strong> Systems for CNC Turning machines<br />

ADJUSTABLE REAMER HOLDER<br />

Adjustable for parallel & axial float & centre alignment<br />

Screw No. 2 adjusts spring pressure (No. 1) giving parallel float adjustment (R). Slacken<br />

grub screw in shank then turn screw No. 2 in to reduce float and out to increase float<br />

Cap No. 3 adjusts axial float (Bild2). Through coolant feed possible from direction of arrow.<br />

Cat. No. d D H L R Collet<br />

V155.517 5/8” 39 31 35 1 ER/ESX11<br />

V155.716 16 39 31 35 1 ER/ESX11<br />

V155.719 3/4” 39 31 35 1 ER/ESX11<br />

V155.720 20 39 31 35 1 ER/ESX11<br />

V155.015 5/8” 42 38 46 1 ESX16<br />

V155.016 16 42 38 46 1 ESX16<br />

V155.019 3/4” 42 38 46 1 ESX16<br />

V155.020 20 42 38 46 1 ESX16<br />

V155.022 22 42 38 46 1 ESX16<br />

V155.025 25 42 38 46 1 ESX16<br />

V155.026 1” 42 38 46 1 ESX16<br />

V155.119 3/4” 48 45 46 1 ESX20<br />

V155.120 20 48 45 46 1 ESX20<br />

V155.125 25 48 45 46 1 ESX20<br />

V155.126 1” 48 45 46 1 ESX20<br />

V155.219 3/4” 57 47 46 1 ESX25<br />

V155.220 20 57 47 46 1 ESX25<br />

V155.222 22 57 47 46 1 ESX25<br />

V155.225 25 57 47 46 1 ESX25<br />

V155.226 1” 57 47 46 1 ESX25<br />

V155.325 25 68 57 50 1,5 ESX32<br />

V155.326 1” 68 57 50 1,5 ESX32<br />

V155.330 30 68 57 50 1,5 ESX32<br />

V155.331 1 1/4” 68 57 50 1,5 ESX32<br />

V155.332 32 68 57 50 1,5 ESX32<br />

R <strong>Floyd</strong> <strong>Automatic</strong> <strong>Tooling</strong> <strong>Ltd</strong> Tel: 01462 491919 Fax: 01462 490835<br />

www.floydautomatic.co.uk e: sales@floydautomatic.co.uk<br />

Page 33

<strong>Tooling</strong> Systems for CNC Turning machines<br />

THROUGH COOLANT REAMER<br />

HOLDER<br />

with parallel float<br />

1mm Float in all directions<br />

• Exact parallel float Also available with flange for Star**<br />

• Self-centreing SR16/20: PH1616SR IK SR20R: PH1622SRR IK<br />

• Non-tilting action ECAS20: PH1622SRR IK SR32: PH1622SR IK<br />

• Compact dimensions<br />

• For ER11 <strong>collet</strong><br />

Cat. No. D D1 L1 L2 A B L G Nut<br />

PH 11 10 40 IK 10<br />

PH 11 12 40 IK 12<br />

40<br />

77 M8x1<br />

PH 11 14 40 IK 14<br />

PH 11 16 50 IK 16<br />

PH 11 34 50 IK 3/4"<br />

PH 11 20 50 IK 20<br />

PH 11 22 50 IK 22<br />

PH 11 25 50 IK 25<br />

19<br />

22 24 45<br />

50 87<br />

PH 11 10 50 IK 1”<br />

1/4” BSP<br />

PH 11 16 50 IK 16 1/8” BSP<br />

PH 11 16 70 IK 16<br />

PH 11 34 70 IK 3/4"<br />

PH 11 20 70 IK 20<br />

PH 11 22 70 IK 22<br />

PH 11 25 70 IK 25<br />

19<br />

70<br />

22 24<br />

45 107<br />

PH 11 10 70 IK 1”<br />

1/4” BSP<br />

PH 11 22 SRR IK** 22 25 49 60 1/8” BSP<br />

• For ER16 <strong>collet</strong><br />

19 50 20 24 45 87<br />

ER11M<br />

Sealed<br />

(see P46 for<br />

sealing discs)<br />

1/8” BSP ER11M<br />

Sealed<br />

(see P46 for<br />

sealing discs)<br />

Cat. No. D D1 L1 L2 A B L G Nut<br />

PH 16 16 50 IK 16<br />

PH 16 34 50 IK ¾”<br />

1/8” BSP ER16M<br />

PH 16 20 50 IK 20<br />

sealed<br />

PH 16 22 50 IK 22<br />

PH 16 25 50 IK 25<br />

PH 16 10 50 IK 1”<br />

PH 16 16 70 IK 16<br />

PH 16 34 70 IK ¾”<br />

PH 16 20 70 IK 20<br />

PH 16 22 70 IK 22<br />

PH 16 25 70 IK 25<br />

PH 16 10 70 IK 1”<br />

19<br />

70<br />

20 24 45<br />

107<br />

¼” BSP<br />

1/8” BSP<br />

¼” BSP<br />

PH 16 25 15AK* 25 140 199 1/8”-1/4”BSP<br />

*with coolant inlet at front & back<br />

(see P46 for<br />

sealing discs)<br />

ER16M<br />

Sealed<br />

(see P46 for<br />

sealing discs)<br />

R <strong>Floyd</strong> <strong>Automatic</strong> <strong>Tooling</strong> <strong>Ltd</strong> Tel: 01462 491919 Fax: 01462 490835<br />

www.floydautomatic.co.uk e: sales@floydautomatic.co.uk<br />

Page 34

<strong>Tooling</strong> Systems for CNC Turning machines<br />

BROACHING HEAD – ADJUSTABLE<br />

See P37 for broaches U175.1**uses Ø8 x 30mm version U175.2** uses Ø12x40mm version<br />

Cat. No. d D H L S F<br />

U175.112 12 50 34 35 30 8<br />

U175.114 14 50 34 35 30 8<br />

U175.115 5/8” 50 34 35 30 8<br />

U175.116 16 50 34 35 30 8<br />

U175.119 3/4” 50 34 46 30 8<br />

U175.120 20 50 34 46 30 8<br />

U175.125 25 50 34 46 30 8<br />

U175.125a 25 50 34 80 30 8<br />

U175.125b 25 50 34 150 30 8<br />

U175.126 1” 50 34 46 30 8<br />

U175.122c 22 50 34 30 30 8<br />

U175.122 22 50 34 80 30 8<br />

U175.122SRR 22 50 34 30 30 8 Star SR20R/SR32J<br />

U175.122SRJ 22 50 34 30 28 8 Star SR10J<br />

U175.219 3/4” 62 52 50 40,5 12<br />

U175.220 20 62 52 50 40.5 12<br />

U175.222 22 62 52 50 40,5 12<br />

U175.225 25 62 52 50 40,5 12<br />

U175.226 1” 62 52 50 40,5 12<br />

U175.230 30 62 52 50 40,5 12<br />

U175.231 31,75 62 52 50 40,5 12<br />

U175.232 32 62 52 50 40,5 12<br />

Broaches available:<br />

1-6mm hexagon with d = Ø8mm shank & 2-32mm hexagon with d = Ø12mm shank<br />

Torx from T6-T55 with 12mm shank. Other profiles & sizes on request<br />

R <strong>Floyd</strong> <strong>Automatic</strong> <strong>Tooling</strong> <strong>Ltd</strong> Tel: 01462 491919 Fax: 01462 490835<br />

www.floydautomatic.co.uk e: sales@floydautomatic.co.uk<br />

Page 35

<strong>Tooling</strong> Systems for CNC Turning machines<br />

BROACHING HEAD – FIXED – SMALL DIAMETER<br />

For Ø8 x 28mm Broaches<br />

Cat. No. d L I D H F<br />

U175.610 10 35 38 32 18 8<br />

U175.612 12 35 38 32 18 8<br />

U175.614 14 35 38 32 18 8<br />

U175.616 16 35 38 32 18 8<br />

U175.619 3/4” 50 38 32 18 8<br />

U175.620 20 50 38 32 18 8<br />

U175.622 22 50 38 32 18 8<br />

U175.625 25 50 38 32 18 8<br />

U175.126 1” 50 38 32 18 8<br />

For Ø5 x 17mm Broaches (please see table below)<br />

Cat. No. d L I D H F<br />

U175.508 8 35 34 22 10 5<br />

U175.510 10 35 34 22 10 5<br />

U175.512 12 35 34 22 10 5<br />

U175.514 14 35 34 22 10 5<br />

U175.515 5/8” 35 34 22 10 5<br />

U175.516 16 35 34 22 10 5<br />

U175.519 3/4” 50 34 22 10 5<br />

U175.520 20 50 34 22 10 5<br />

U175.522 22 50 34 22 10 5<br />

U175.525 25 50 34 22 10 5<br />

U175.526 1” 50 34 22 10 5<br />

Cat No.<br />

Hex<br />

V805.020S 2<br />

V805.025S 2,5<br />

V805.030S 3<br />

V805.035S 3,5<br />

V805.040S 4<br />

V805.050S 5<br />

Other sizes available to order<br />

R <strong>Floyd</strong> <strong>Automatic</strong> <strong>Tooling</strong> <strong>Ltd</strong> Tel: 01462 491919 Fax: 01462 490835<br />

www.floydautomatic.co.uk e: sales@floydautomatic.co.uk<br />

Page 36

<strong>Tooling</strong> Systems for CNC Turning machines<br />

BROACHES<br />

Cat. No. d l l1 l2 S Cat. No. d l l1 L2 S<br />

V808.010S 8 30 12 18 1 V812.020S 12 40 15 25 2<br />

V808.013S 8 30 12 18 1,3 V812.025S 12 40 15 25 2,5<br />

V808.015S 8 30 12 18 1,5 V812.030S 12 40 15 25 3<br />

V808.020S 8 30 12 18 2 V812.040S 12 40 15 25 4<br />

V808.025S 8 30 12 18 2,5 V812.050S 12 40 18 22 5<br />

V808.030S 8 30 12 18 3 V812.060S 12 40 18 22 6<br />

V808.032S 8 30 12 18 3,175 V812.070S 12 40 18 22 7<br />

V808.040S 8 30 15 15 4 V812.080S 12 40 18 22 8<br />

V808.0476S 8 30 15 15 4,76 V812.095S 12 40 18 22 9,5<br />

V808.050S 8 30 15 15 5 V812.100S 12 40 18 22 10<br />

V808.060S 8 30 15 15 6 V812.110S 12 40 18 22 11<br />

V808.063S 8 30 15 15 6,35 V812.120S 12 40 18 22 12<br />

V812.130S 12 40 18 22 13<br />

V808.06T 8 30 10 20 T6 V812.140S 12 40 18 22 14<br />

V808.07T 8 30 10 20 T7 V812.150S 12 40 18 22 15<br />

V808.08T 8 30 10 20 T8 V812.170S 12 40 18 22 17<br />

V808.10T 8 30 15 15 T10 V812.190S 12 40 18 22 19<br />

V808.15T 8 30 15 15 T15 V812.200S 12 40 18 22 20<br />

V812.220S 12 40 18 22 22<br />

V812.06T 12 40 12 22 T6 V812.270S 12 40 18 22 27<br />

V812.07T 12 40 12 22 T7 V812.320S 12 40 18 22 32<br />

V812.08T 12 40 12 22 T8<br />

V812.10T 12 40 12 22 T10 V805.020S 5 17 2<br />

V812.15T 12 40 12 22 T15 V805.025S 5 17 2,5<br />

V812.20T 12 40 12 22 T20 V805.030S 5 17 3<br />

V812.25T 12 40 12 22 T25 V805.035S 5 17 3,5<br />

V812.30T 12 40 12 22 T30 V805.040S 5 17 4<br />

V812.40T 12 40 12 22 T40 V805.050S 5 17 5<br />

V812.45T 12 40 12 22 T45<br />

V812.50T 12 40 12 22 T50<br />

V812.55T 12 40 12 22 T55<br />

S = Hexagon T = Torx<br />

Other dimensions and profiles to order<br />

R <strong>Floyd</strong> <strong>Automatic</strong> <strong>Tooling</strong> <strong>Ltd</strong> Tel: 01462 491919 Fax: 01462 490835<br />

www.floydautomatic.co.uk e: sales@floydautomatic.co.uk<br />

Page 37

<strong>Tooling</strong> Systems for CNC Turning machines<br />

BROACHING HEAD EXTERNAL – ADJUSTABLE<br />

Cat. No. d D H L S F<br />

U175.A216 16 62 77 50 40,5 32<br />

U175.A219 3/4” 62 77 50 40,5 32<br />

U175.A220 20 62 77 50 40,5 32<br />

U175.A225 25 62 77 50 40,5 32<br />

U175.A225b 25 62 77 50 40,5 32<br />

U175.A226 1” 62 77 50 40,5 32<br />

U175.A222 22 62 77 50 40,5 32<br />

U175.A222a 22 62 77 50 40,5 32<br />

U175.230 30 62 77 50 40,5 32<br />

U175.231 31,75 62 77 50 40,5 32<br />

U175.232 32 62 77 50 40,5 32<br />

BROACHING HEAD EXTERNAL – FIXED<br />

Cat. No. d D H L F<br />

U175.A716 16 44 63 50 32<br />

U175.A719 3/4” 44 63 50 32<br />

U175.A720 20 44 63 50 32<br />

U175.A722 22 44 63 50 32<br />

U175.A225 25 44 63 50 32<br />

U175.A726 1” 44 63 50 32<br />

R <strong>Floyd</strong> <strong>Automatic</strong> <strong>Tooling</strong> <strong>Ltd</strong> Tel: 01462 491919 Fax: 01462 490835<br />

www.floydautomatic.co.uk e: sales@floydautomatic.co.uk<br />

Page 38

<strong>Tooling</strong> Systems for CNC Turning machines<br />

EXTERNAL BROACH ADAPTOR<br />

For adapting U175.2 & U175.8 series heads<br />

Cat. No. d D H L l F<br />

U175.790 12 44 17 15 12 32<br />

U175.890 16 44 32 19 12 32<br />

EXTERNAL BROACH BLANKS<br />

Cat. No. F D H Range Profile<br />

U175.R1 32 25,3 20,5 3 to 13 square<br />

U175.R2 32 30 20,5 14 to 18 square<br />

U175.R3 32 25,3 20,5 3 to 15 hexagon<br />

U175.R4 32 30 20,5 16 to 20 hexagon<br />

R <strong>Floyd</strong> <strong>Automatic</strong> <strong>Tooling</strong> <strong>Ltd</strong> Tel: 01462 491919 Fax: 01462 490835<br />

www.floydautomatic.co.uk e: sales@floydautomatic.co.uk<br />

Page 39

<strong>Tooling</strong> Systems for CNC Turning machines<br />

EXTERNAL BROACH DIES - Hexagon<br />

For U175.790 / U175.890<br />

Cat. No. F D H Hexagon<br />

U806.003 32 25,3 20,5 3<br />

U806.004 32 25,3 20,5 4<br />

U806.005 32 25,3 20,5 5<br />

U806.006 32 25,3 20,5 6<br />

U806.007 32 25,3 20,5 7<br />

U806.008 32 25,3 20,5 8<br />

U806.009 32 25,3 20,5 9<br />

U806.010 32 25,3 20,5 10<br />

U806.011 32 25,3 20,5 11<br />

U806.012 32 25,3 20,5 12<br />

U806.013 32 25,3 20,5 13<br />

U806.014 32 25,3 20,5 14<br />

U806.015 32 25,3 20,5 15<br />

U806.016 32 30 20,5 16<br />

U806.017 32 30 20,5 17<br />

U806.018 32 30 20,5 18<br />

U806.019 32 30 20,5 19<br />

U806.020 32 30 20,5 20<br />

EXTERNAL BROACH DIES – Square For U175.790 / U175.890<br />

Cat. No. F D H Square<br />

U806.103 32 25,3 20,5 3<br />

U806.104 32 25,3 20,5 4<br />

U806.105 32 25,3 20,5 5<br />

U806.106 32 25,3 20,5 6<br />

U806.107 32 25,3 20,5 7<br />

U806.108 32 25,3 20,5 8<br />

U806.109 32 25,3 20,5 9<br />

U806.110 32 25,3 20,5 10<br />

U806.111 32 25,3 20,5 11<br />

U806.112 32 25,3 20,5 12<br />

U806.113 32 25,3 20,5 13<br />

U806.114 32 30 20,5 14<br />

U806.115 32 30 20,5 15<br />

U806.116 32 30 20,5 16<br />

U806.117 32 30 20,5 17<br />

U806.118 32 30 20,5 18<br />

R <strong>Floyd</strong> <strong>Automatic</strong> <strong>Tooling</strong> <strong>Ltd</strong> Tel: 01462 491919 Fax: 01462 490835<br />

www.floydautomatic.co.uk e: sales@floydautomatic.co.uk<br />

Page 40

<strong>Tooling</strong> Systems for CNC Turning machines<br />

BROACHING HEAD – FIXED<br />

For Ø12 x 40mm Broaches (please see page 33)<br />

Cat. No. d L I D H F<br />

U175.716 16 50 49 41 25 12<br />

U175.719 3/4” 50 49 41 25 12<br />

U175.720 20 50 49 41 25 12<br />

U175.722 22 50 49 41 25 12<br />

U175.725 25 50 49 41 25 12<br />

U175.726 1” 50 49 41 25 12<br />

BROACHING HEAD WITH VDI SHANK<br />

Cat. No. D D1 D2 L H Broach Ø<br />

U175.V20-12 20 44 50 57 25 12<br />

U175.V30-12 30 58 68 83 25 12<br />

U175.V40-12 40 58 83 83 25 12<br />

R <strong>Floyd</strong> <strong>Automatic</strong> <strong>Tooling</strong> <strong>Ltd</strong> Tel: 01462 491919 Fax: 01462 490835<br />

www.floydautomatic.co.uk e: sales@floydautomatic.co.uk<br />

Page 41

<strong>Tooling</strong> Systems for CNC Turning machines<br />

ISO HOLDERS<br />

without crank for CNC sliding head machines<br />

Type SDACR/L – SDNCN – SDNCR/L<br />

Top picture right hand version,<br />

Set Back Version<br />

Bottom picture MX left hand version<br />

Front clearance angle 7°<br />

Cat. No. B L S Insert Key Screw<br />

SDACR/L 0808K07 8 x 8 130 7 DCMT 0702--<br />

SDACR/L 1010M07 10 x 10 150 7 DCGT 0702-- T8 A02-25059<br />

SDACR/L 1212M07 12 x 12 150 7<br />

SDACR/L 1010MX11 10 x 10 150 11<br />

A02-40085<br />

SDACR/L 1212M11 12 x 12 150 11 DCMT 11T3-- T15<br />

SDACR/L 1212MX11 12 x 12 150 11 DCGT 11T3--<br />

SDACR/L 1616H11 16 x 16 100 11<br />

A02-40105<br />

Set Back Version<br />

A<br />

SDACR 1010MV11 10 x 10 150 11<br />

SDACR 1212MV11 12 x 12 150 11<br />

SDACR 1616HV11 16 x 16 100 11<br />

SDACR 1616KV11 16 x 16 125 11<br />

8<br />

DCMT 11T3--<br />

DCGT 11T3-- T15 A02-40105<br />

Front clearance angle 7°<br />

Cat. No. B L S Insert Key Screw<br />

SDNCN 0808K07 8 x 8 130 7 DCMT 0702--<br />

SDNCN 1010M07 10 x 10 150 7 DCGT 0702-- T8 A02-25059<br />

SDNCN 1212M07 12 x 12 150 7<br />

SDNCN 1010MX11 10 x 10 150 11 DCMT 11T3--<br />

A02-40085<br />

SDNCN 1212MX11 12 x 12 150 11 DCGT 11T3-- T15<br />

SDNCN 1616H11 16 x 16 100 11<br />

A02-40105<br />

Cat. No. B L S Insert Key Screw<br />

SDNCR/L 1010MX11 10 x 10 150 11 DCMT 11T3--<br />

A02-35085<br />

SDNCR/L 1212M11 12 x 12 150 11 DCGT11T3-- T15<br />

SDNCR/L 1616H11 16 x 16 100 11<br />

A02-35096<br />

R <strong>Floyd</strong> <strong>Automatic</strong> <strong>Tooling</strong> <strong>Ltd</strong> Tel: 01462 491919 Fax: 01462 490835<br />

www.floydautomatic.co.uk e: sales@floydautomatic.co.uk<br />

Page 42

<strong>Tooling</strong> Systems for CNC Turning machines<br />

ISO Holders without crank for CNC sliding head machines<br />

Type SVACR/L<br />

SVACR set back version<br />

Front clearance angle 7°<br />

Cat. No. B L S Insert Key Screw<br />

SVACR/L 1010M11 10 x 10 150 11 VCMT 1103--<br />

SVACR/L 1212M11 12 x 12 150 11 VCGT 1103-- T9 A02-25059<br />

SVACR/L 1616H11 16 x 16 100 11<br />

SVACR/L 1010M13 10 x 10 150 11<br />

SVACR/L 1212M13 12 x 12 150 11 VCMT 1303-- T9<br />

A02-W3082<br />

SVACR/L 1616M13 16 x 16 150 11 VCGT 1303--<br />

SVACR/L 1616H11 16 x 16 100 11<br />

SVACR/L 1212MX16<br />

SVACR/L 1616H16<br />

12 x 12<br />

16 x 16<br />

150<br />

160<br />

16<br />

16<br />

VCMT 1604--<br />

VCGT 1604--<br />

SVACR/L 1212MX16 12 x 12 150 16<br />

Set Back Version A Insert<br />

SVACR 1010MV11 10 x 10 150 11<br />

VCMT<br />

SVACR 1212MV11 12 x 12 150 11<br />

8 VCGT<br />

SVACR 1616HV11 16 x 16 100 11<br />

1103--<br />

SVACR 1616KV11 16 x 16 125 11<br />

Type SVVCN<br />

T15<br />

A02-40085<br />

A02-35096<br />

A02-40105<br />

T9 A02-25059<br />

Front clearance angle 7°<br />

Cat. No. B L S Insert Key Screw<br />

SVVCN 1010M11 10 x 10 150 11 VCMT 1103--<br />

SVVCN 1212M11 12 x 12 150 11 VCGT 1103-- T9 A02-25059<br />

SVVCN 1616H11 16 x 16 150 11<br />

SVVCN 1010M13 10 x 10 150 13<br />

SVVCN 1212M13 12 x 12 150 13<br />

SVVCN 1616M13 16 x 16 150 13<br />

SVVCN 1616H13 16 x 16 100 13<br />

VCMT 1303--<br />