Eco-friendly Product Development at SNR Roulements - NTN

Eco-friendly Product Development at SNR Roulements - NTN

Eco-friendly Product Development at SNR Roulements - NTN

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Eco</strong>-<strong>friendly</strong> <strong>Product</strong> <strong>Development</strong> <strong>at</strong> <strong>SNR</strong> <strong>Roulements</strong><br />

3.3 Low torque tapered roller bearings<br />

Tapered roller bearings are often used as<br />

transmission bearings because they can carry a<br />

gre<strong>at</strong>er combined axial and radial load compared with<br />

other bearing types of similar size. However, reduction<br />

in frictional torque occurring on this bearing type poses<br />

a challenge.<br />

The <strong>SNR</strong> tapered roller bearings for automotive<br />

transmissions boasts decreased frictional torque<br />

through adoption of <strong>NTN</strong>’s design and production<br />

technologies for low torque tapered roller bearings.<br />

The advantages of these <strong>SNR</strong> products can be defined<br />

as follows:<br />

(1) Special he<strong>at</strong> tre<strong>at</strong>ment process helps improve<br />

f<strong>at</strong>igue strength and resistance against dent mark<br />

th<strong>at</strong> can result from foreign m<strong>at</strong>ter in lubricant.<br />

(2) Adoption of polyamide cage in which shear friction<br />

with oil is lower, compared with th<strong>at</strong> in standard<br />

steel sheet cages<br />

(3) Improved design for bearing interior in order to<br />

improve load carrying capacity and rigidity and<br />

mitig<strong>at</strong>e misalignment and frictional torque<br />

(optimized number and size of rollers, and special<br />

crowning on raceway surface and rolling surface)<br />

(4) Optimiz<strong>at</strong>ion of contact loc<strong>at</strong>ions between inner ring<br />

flange surface, rollers, and raceway surface<br />

(5) Reduction in surface roughness of inner ring flange<br />

surface and roller end faces to reduce frictional<br />

torque on roller end faces<br />

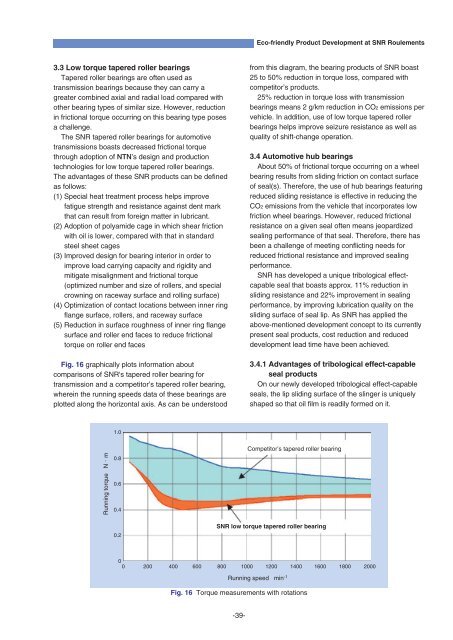

Fig. 16 graphically plots inform<strong>at</strong>ion about<br />

comparisons of <strong>SNR</strong>'s tapered roller bearing for<br />

transmission and a competitor’s tapered roller bearing,<br />

wherein the running speeds d<strong>at</strong>a of these bearings are<br />

plotted along the horizontal axis. As can be understood<br />

from this diagram, the bearing products of <strong>SNR</strong> boast<br />

25 to 50% reduction in torque loss, compared with<br />

competitor’s products.<br />

25% reduction in torque loss with transmission<br />

bearings means 2 g/km reduction in CO2 emissions per<br />

vehicle. In addition, use of low torque tapered roller<br />

bearings helps improve seizure resistance as well as<br />

quality of shift-change oper<strong>at</strong>ion.<br />

3.4 Automotive hub bearings<br />

About 50% of frictional torque occurring on a wheel<br />

bearing results from sliding friction on contact surface<br />

of seal(s). Therefore, the use of hub bearings fe<strong>at</strong>uring<br />

reduced sliding resistance is effective in reducing the<br />

CO2 emissions from the vehicle th<strong>at</strong> incorpor<strong>at</strong>es low<br />

friction wheel bearings. However, reduced frictional<br />

resistance on a given seal often means jeopardized<br />

sealing performance of th<strong>at</strong> seal. Therefore, there has<br />

been a challenge of meeting conflicting needs for<br />

reduced frictional resistance and improved sealing<br />

performance.<br />

<strong>SNR</strong> has developed a unique tribological effectcapable<br />

seal th<strong>at</strong> boasts approx. 11% reduction in<br />

sliding resistance and 22% improvement in sealing<br />

performance, by improving lubric<strong>at</strong>ion quality on the<br />

sliding surface of seal lip. As <strong>SNR</strong> has applied the<br />

above-mentioned development concept to its currently<br />

present seal products, cost reduction and reduced<br />

development lead time have been achieved.<br />

3.4.1 Advantages of tribological effect-capable<br />

seal products<br />

On our newly developed tribological effect-capable<br />

seals, the lip sliding surface of the slinger is uniquely<br />

shaped so th<strong>at</strong> oil film is readily formed on it.<br />

1.0<br />

Running torque Nm<br />

0.8<br />

0.6<br />

0.4<br />

Competitor’s tapered roller bearing<br />

0.2<br />

<strong>SNR</strong> low torque tapered roller bearing<br />

0<br />

0 200 400 600 800 1000 1200 1400 1600 1800 2000<br />

Running speed min -1<br />

Fig. 16 Torque measurements with rot<strong>at</strong>ions<br />

-39-

![[New Product] Unit Products for Office Equipment - NTN](https://img.yumpu.com/27154451/1/184x260/new-product-unit-products-for-office-equipment-ntn.jpg?quality=85)

![[New Product] Development of Oil-impregnated Sintered ... - NTN](https://img.yumpu.com/27154427/1/184x260/new-product-development-of-oil-impregnated-sintered-ntn.jpg?quality=85)