Frame a door rough opening ___ - Tru-Burn

Frame a door rough opening ___ - Tru-Burn

Frame a door rough opening ___ - Tru-Burn

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Frame</strong> a <strong>door</strong> <strong>rough</strong> <strong>opening</strong> - Fine Homebuilding Article<br />

http://www.taunton.com/finehomebuilding/how-to/departments/building-sk...<br />

1 of 4 2/3/2009 7:55 AM<br />

<strong>Frame</strong> a <strong>door</strong> <strong>rough</strong> <strong>opening</strong><br />

A pro teaches you his three simple rules for framing <strong>rough</strong> <strong>opening</strong>s<br />

efficiently<br />

by Scott Grice<br />

If you can cut a 2x4 and drive a nail, then you have all the skills you need to frame a <strong>rough</strong> <strong>opening</strong><br />

for a <strong>door</strong>. As with most homebuilding tasks, however, there's a fine line between getting it done<br />

and doing it efficiently, without causing headaches down the line.<br />

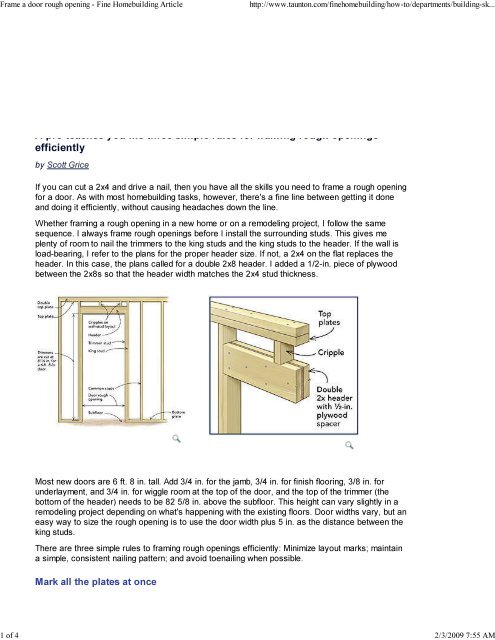

Whether framing a <strong>rough</strong> <strong>opening</strong> in a new home or on a remodeling project, I follow the same<br />

sequence. I always frame <strong>rough</strong> <strong>opening</strong>s before I install the surrounding studs. This gives me<br />

plenty of room to nail the trimmers to the king studs and the king studs to the header. If the wall is<br />

load-bearing, I refer to the plans for the proper header size. If not, a 2x4 on the flat replaces the<br />

header. In this case, the plans called for a double 2x8 header. I added a 1/2-in. piece of plywood<br />

between the 2x8s so that the header width matches the 2x4 stud thickness.<br />

Most new <strong>door</strong>s are 6 ft. 8 in. tall. Add 3/4 in. for the jamb, 3/4 in. for finish flooring, 3/8 in. for<br />

underlayment, and 3/4 in. for wiggle room at the top of the <strong>door</strong>, and the top of the trimmer (the<br />

bottom of the header) needs to be 82 5/8 in. above the subfloor. This height can vary slightly in a<br />

remodeling project depending on what's happening with the existing floors. Door widths vary, but an<br />

easy way to size the <strong>rough</strong> <strong>opening</strong> is to use the <strong>door</strong> width plus 5 in. as the distance between the<br />

king studs.<br />

There are three simple rules to framing <strong>rough</strong> <strong>opening</strong>s efficiently: Minimize layout marks; maintain<br />

a simple, consistent nailing pattern; and avoid toenailing when possible.<br />

Mark all the plates at once

<strong>Frame</strong> a <strong>door</strong> <strong>rough</strong> <strong>opening</strong> - Fine Homebuilding Article<br />

http://www.taunton.com/finehomebuilding/how-to/departments/building-sk...<br />

2 of 4 2/3/2009 7:55 AM<br />

Measure the distance between the king studs (<strong>door</strong><br />

width plus 5 in.). For efficiency, I mark only the inside<br />

edge of the king studs on the bottom and top plates. To<br />

the inside of the marks, I write T for trimmer. To the<br />

outside, I mark an X to indicate the king stud.<br />

TIP: Mark and measure at the same time. The<br />

rectangular shape of a carpenter’s pencil makes it easy<br />

to hold against the end of the tape.<br />

Mark the cripple locations. I save myself a little time<br />

and the potential confusion of too many lines by marking<br />

the cripple locations only on the top plate. The crow’s<br />

foot indicates the layout mark, and the X tells me which<br />

side of the line to locate the cripple. Later, I transfer<br />

these marks to the header.<br />

Assemble the parts, then transfer the layout

<strong>Frame</strong> a <strong>door</strong> <strong>rough</strong> <strong>opening</strong> - Fine Homebuilding Article<br />

http://www.taunton.com/finehomebuilding/how-to/departments/building-sk...<br />

3 of 4 2/3/2009 7:55 AM<br />

Keep edges flush. When assembling the king studs, the<br />

trimmers, and the header, I use my fingers, my eyes, and<br />

a Speed Square to keep all the edges flush. I alternate<br />

pairs of nails with single nails (like the #5 pattern on a<br />

domino) when nailing along the length of the trimmer or<br />

header. I separate nails by 16 in. for studs and by 8 in.<br />

for headers.<br />

Transfer the layout marks to the header. Before<br />

nailing the header in place, I align it with the king-stud<br />

marks I made on the top plate and transfer the cripple<br />

locations to the header.<br />

Just a hammer, please<br />

Sequence assembly to avoid toenailing<br />

First, fasten the header to the king stud. Before<br />

installing any adjacent studs or the top plate, I connect<br />

the header to the king stud. Again, I use the #5 domino<br />

nailing pattern. To stay friends with the finish carpenter<br />

and to avoid creating bumps in the wall, I keep the edges<br />

flush<br />

Add the cripples before the double top plate.<br />

Th<strong>rough</strong>-nailing is faster, stronger, and tidier than<br />

toenailing. Before adding the double top plate, I can<br />

th<strong>rough</strong>-nail into the king studs and the cripples. I nail the<br />

king studs on each side of the <strong>door</strong> before adding the<br />

cripples.

<strong>Frame</strong> a <strong>door</strong> <strong>rough</strong> <strong>opening</strong> - Fine Homebuilding Article<br />

http://www.taunton.com/finehomebuilding/how-to/departments/building-sk...<br />

4 of 4 2/3/2009 7:55 AM<br />

Nail the plate<br />

next to the<br />

studs. To<br />

save the<br />

plumbers and<br />

the<br />

electricians<br />

from ruining<br />

their drill bits, I<br />

keep nails<br />

close to the<br />

studs when<br />

fastening the<br />

bottom plate to<br />

the floor.<br />

Magazine<br />

extra: Watch<br />

a video of Scott framing this <strong>rough</strong> <strong>opening</strong> and hear why he uses a rigger's hatchet instead of a<br />

regular hammer.<br />

Photos by: John Ross, except where noted; drawing by: Dan Thornton<br />

From Fine Homebuilding 201, pp. 98-100<br />

January 14, 2009<br />

Related Topics: Framing | Doors | Interior Doors | New Construction | Remodeling<br />

Related Articles<br />

VIDEO: Learn to <strong>Frame</strong> a Rough Opening<br />

Scott Grice shares his method for framing <strong>rough</strong> <strong>door</strong> <strong>opening</strong>s efficiently<br />

by Scott Grice<br />

Weatherproofing Dormers<br />

Flashing dormers using peel-and-stick bowties<br />

by Rick Arnold<br />

A Home for the Next 50 Years<br />

Updated Arts & Crafts detailing enhances a home remodeled for baby boomers who plan to stay<br />

by John P.S. Salmen<br />

10 Rules for Framing<br />

Guidelines for working efficiently and knowing how good is good enough<br />

by Larry Haun<br />

Framing Floors With I-Joists<br />

Whether you're building a new house or remodeling an old one, engineered lumber can give you<br />

squeak-free floors with fewer callbacks<br />

by Rick Arnold, Mike Guertin