INSTALLATION INSTRUCTIONS - Lennox

INSTALLATION INSTRUCTIONS - Lennox

INSTALLATION INSTRUCTIONS - Lennox

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

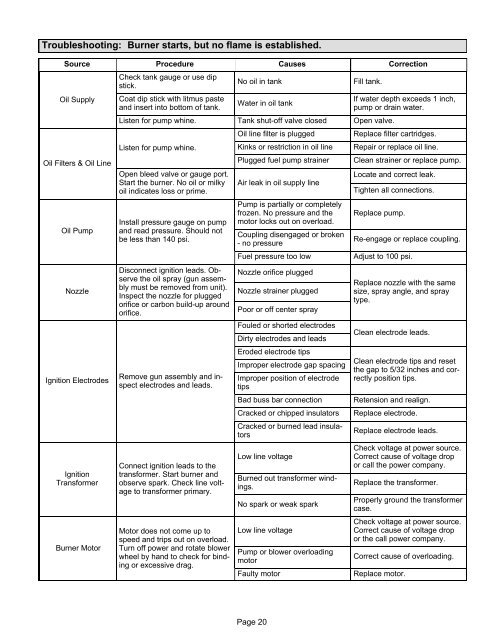

Troubleshooting: Burner starts, but no flame is established.<br />

Source Procedure Causes Correction<br />

Oil Supply<br />

Oil Filters & Oil Line<br />

Oil Pump<br />

Nozzle<br />

Ignition Electrodes<br />

Ignition<br />

Transformer<br />

Burner Motor<br />

Check tank gauge or use dip<br />

stick.<br />

Coat dip stick with litmus paste<br />

and insert into bottom of tank.<br />

No oil in tank<br />

Water in oil tank<br />

Fill tank.<br />

Listen for pump whine. Tank shut−off valve closed Open valve.<br />

Listen for pump whine.<br />

Open bleed valve or gauge port.<br />

Start the burner. No oil or milky<br />

oil indicates loss or prime.<br />

Install pressure gauge on pump<br />

and read pressure. Should not<br />

be less than 140 psi.<br />

Disconnect ignition leads. Observe<br />

the oil spray (gun assembly<br />

must be removed from unit).<br />

Inspect the nozzle for plugged<br />

orifice or carbon build−up around<br />

orifice.<br />

Remove gun assembly and inspect<br />

electrodes and leads.<br />

Connect ignition leads to the<br />

transformer. Start burner and<br />

observe spark. Check line voltage<br />

to transformer primary.<br />

Motor does not come up to<br />

speed and trips out on overload.<br />

Turn off power and rotate blower<br />

wheel by hand to check for binding<br />

or excessive drag.<br />

Oil line filter is plugged<br />

Kinks or restriction in oil line<br />

Plugged fuel pump strainer<br />

Air leak in oil supply line<br />

Pump is partially or completely<br />

frozen. No pressure and the<br />

motor locks out on overload.<br />

Coupling disengaged or broken<br />

− no pressure<br />

Fuel pressure too low<br />

Nozzle orifice plugged<br />

Nozzle strainer plugged<br />

Poor or off center spray<br />

Fouled or shorted electrodes<br />

Dirty electrodes and leads<br />

Eroded electrode tips<br />

Improper electrode gap spacing<br />

Improper position of electrode<br />

tips<br />

Bad buss bar connection<br />

Cracked or chipped insulators<br />

Cracked or burned lead insulators<br />

Low line voltage<br />

Burned out transformer windings.<br />

No spark or weak spark<br />

Low line voltage<br />

Pump or blower overloading<br />

motor<br />

Faulty motor<br />

If water depth exceeds 1 inch,<br />

pump or drain water.<br />

Replace filter cartridges.<br />

Repair or replace oil line.<br />

Clean strainer or replace pump.<br />

Locate and correct leak.<br />

Tighten all connections.<br />

Replace pump.<br />

Re−engage or replace coupling.<br />

Adjust to 100 psi.<br />

Replace nozzle with the same<br />

size, spray angle, and spray<br />

type.<br />

Clean electrode leads.<br />

Clean electrode tips and reset<br />

the gap to 5/32 inches and correctly<br />

position tips.<br />

Retension and realign.<br />

Replace electrode.<br />

Replace electrode leads.<br />

Check voltage at power source.<br />

Correct cause of voltage drop<br />

or call the power company.<br />

Replace the transformer.<br />

Properly ground the transformer<br />

case.<br />

Check voltage at power source.<br />

Correct cause of voltage drop<br />

or the call power company.<br />

Correct cause of overloading.<br />

Replace motor.<br />

Page 20