INSTALLATION INSTRUCTIONS HS25 SERIES UNITS - Lennox

INSTALLATION INSTRUCTIONS HS25 SERIES UNITS - Lennox

INSTALLATION INSTRUCTIONS HS25 SERIES UNITS - Lennox

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

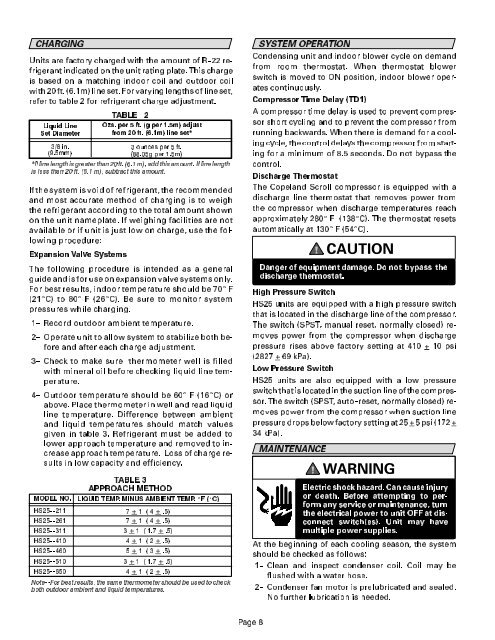

CHARGING<br />

Units are factory charged with the amount of R--22 refrigerant<br />

indicated on the unit rating plate. This charge<br />

is based on a matching indoor coil and outdoor coil<br />

with 20 ft. (6.1m) line set. For varying lengths of line set,<br />

refer to table 2 for refrigerant charge adjustment.<br />

/LTXLG /LQH<br />

6HW 'LDPHWHU<br />

LQ<br />

PP<br />

7$%/( <br />

2]V SHU IW J SHU P DGMXVW<br />

IURP IW P OLQH VHW<br />

RXQFHV SHU IW<br />

J SHU P<br />

,I OLQH OHQJWK LV JUHDWHU WKDQ IW P DGG WKLV DPRXQW ,I OLQH OHQJWK<br />

LV OHVV WKDQ IW P VXEWUDFW WKLV DPRXQW<br />

If the system is void of refrigerant, the recommended<br />

and most accurate method of charging is to weigh<br />

the refrigerant according to the total amount shown<br />

on the unit nameplate. If weighing facilities are not<br />

available or if unit is just low on charge, use the following<br />

procedure:<br />

([SDQVLRQ 9DOYH 6\VWHPV<br />

The following procedure is intended as a general<br />

guide and is for use on expansion valve systems only.<br />

For best results, indoor temperature should be 70E F<br />

(21EC) to 80E F (26EC). Be sure to monitor system<br />

pressures while charging.<br />

1-- Record outdoor ambient temperature.<br />

2-- Operate unit to allow system to stabilize both before<br />

and after each charge adjustment.<br />

3-- Check to make sure thermometer well is filled<br />

with mineral oil before checking liquid line temperature.<br />

4-- Outdoor temperature should be 60E F(16EC) or<br />

above. Place thermometer in well and read liquid<br />

line temperature. Difference between ambient<br />

and liquid temperatures should match values<br />

given in table 3. Refrigerant must be added to<br />

lower approach temperature and removed to increase<br />

approach temperature. Loss of charge results<br />

in low capacity and efficiency.<br />

02'(/ 12<br />

+6 <br />

+6 <br />

+6 <br />

+6 <br />

+6 <br />

+6 <br />

+6 <br />

7$%/( <br />

$3352$&+ 0(7+2'<br />

/,48,' 7(03 0,186 $0%,(17 7(03 E) E&<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

1RWH )RU EHVW UHVXOWV WKH VDPH WKHUPRPHWHU VKRXOG EH XVHG WR FKHFN<br />

ERWK RXWGRRU DPELHQW DQG OLTXLG WHPSHUDWXUHV<br />

SYSTEM OPERATION<br />

Condensing unit and indoor blower cycle on demand<br />

from room thermostat. When thermostat blower<br />

switch is moved to ON position, indoor blower operates<br />

continuously.<br />

Compressor Time Delay (TD1)<br />

A compressor time delay is used to prevent compressor<br />

short cycling and to prevent the compressor from<br />

running backwards. When there is demand for a cooling<br />

cycle, the control delays the compressor from starting<br />

for a minimum of 8.5 seconds. Do not bypass the<br />

control.<br />

Discharge Thermostat<br />

The Copeland Scroll compressor is equipped with a<br />

discharge line thermostat that removes power from<br />

the compressor when discharge temperatures reach<br />

approximately 280E F (138EC). The thermostat resets<br />

automatically at 130E F (54EC).<br />

CAUTION<br />

Danger of equipment damage. Do not bypass the<br />

discharge thermostat.<br />

High Pressure Switch<br />

<strong>HS25</strong> units are equipped with a high pressure switch<br />

that is located in the discharge line of the compressor.<br />

The switch (SPST, manual reset, normally closed) removes<br />

power from the compressor when discharge<br />

pressure rises above factory setting at 410 + 10 psi<br />

(2827 + 69 kPa).<br />

Low Pressure Switch<br />

<strong>HS25</strong> units are also equipped with a low pressure<br />

switch that is located in the suction line of the compressor.<br />

The switch (SPST, auto--reset, normally closed) removes<br />

power from the compressor when suction line<br />

pressure drops below factory setting at 25 +5 psi (172 +<br />

34 kPa).<br />

MAINTENANCE<br />

WARNING<br />

Electric shock hazard. Can cause injury<br />

or death. Before attempting to perform<br />

any service or maintenance, turn<br />

the electrical power to unit OFF at disconnect<br />

switch(es). Unit may have<br />

multiple power supplies.<br />

At the beginning of each cooling season, the system<br />

should be checked as follows:<br />

1-- Clean and inspect condenser coil. Coil may be<br />

flushed with a water hose.<br />

2-- Condenser fan motor is prelubricated and sealed.<br />

No further lubrication is needed.<br />

3DJH