DAL 358 - NAD Klima

DAL 358 - NAD Klima

DAL 358 - NAD Klima

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Catalog 1.1.1<br />

Swirl diffuser<br />

<strong>DAL</strong> <strong>358</strong>

Concordia University, Montréal, Canada

<strong>NAD</strong> <strong>Klima</strong><br />

<strong>DAL</strong> <strong>358</strong> model<br />

<strong>DAL</strong> <strong>358</strong> 1<br />

<strong>DAL</strong> <strong>358</strong> 2<br />

Method of operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . <strong>DAL</strong> <strong>358</strong> 3<br />

Flow and direction of the air . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . <strong>DAL</strong> <strong>358</strong> 5<br />

Range of application and Quick selection . . . . . . . . . . . . . . . . . . . . . . . . <strong>DAL</strong> <strong>358</strong> 6<br />

Diagrams of performance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . <strong>DAL</strong> <strong>358</strong> 7<br />

Dimensions and Weight . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . <strong>DAL</strong> <strong>358</strong> 11<br />

<strong>DAL</strong> <strong>358</strong> 12<br />

<strong>DAL</strong> <strong>358</strong> 13<br />

<strong>DAL</strong> <strong>358</strong> 14<br />

content<br />

1.1.1 <strong>DAL</strong> <strong>358</strong> C

Cafeteria, CIMA+ ing. , Sherbrooke, Québec

<strong>NAD</strong> <strong>Klima</strong><br />

Swirl Diffuser<br />

Description, Areas of application and Benefits<br />

<strong>DAL</strong> <strong>358</strong> Swirl diffuser<br />

The <strong>DAL</strong> <strong>358</strong> is a high induction swirl<br />

airflow diffuser with a circular or<br />

square front plate. It has eccentric<br />

ABS cylinders and profiles controlling<br />

air stream.<br />

The <strong>DAL</strong> <strong>358</strong> permits optimal adaptation<br />

of the ventilation system to<br />

prevailing room requirements.<br />

Eccentric cylinders integrated into<br />

the front plate permit a variety of<br />

airstream configurations, even after<br />

installation.<br />

The <strong>DAL</strong> <strong>358</strong> technology provides<br />

high speed discharge air with relatively<br />

low sound power.<br />

The swirl airstream, the stability and<br />

the high induction generated from<br />

the very start of the discharge slot<br />

make the <strong>DAL</strong> <strong>358</strong> the diffuser of<br />

choice for high air flow rates and<br />

variable air volumes.<br />

Areas of application<br />

-High flow rate zones<br />

-Comfort zones<br />

-Offices with closed work spaces<br />

-Offices and clean rooms<br />

-Administrative centres<br />

-Computer(class-)rooms<br />

-Meeting rooms<br />

-Multi-purpose rooms<br />

-Systems with constant or variable<br />

airflow rates<br />

-Entrance halls (vertical air blast)<br />

Product benefits<br />

- Rapid reduction of speeds and<br />

temperature variations caused by<br />

high induction<br />

- Low sound power for high air flow<br />

rates<br />

- Stable swirl airflow and a variety of air<br />

blasts available in 1-2-3 directions<br />

- Eccentric cylinders allowing 1800 air<br />

blast adjustment<br />

- Possibility of changing airflow, even<br />

after installation<br />

- Possibility of reducing total airflow<br />

rate as much as 25% in VAV<br />

- Three times as much induction<br />

as a conventional 4-way diffuser<br />

- Possibility of eliminating peripheral<br />

heating due to diffuser heating<br />

- Fewer diffusers required<br />

- Possibility of reducing total air<br />

volumes of the various units, while<br />

meeting requirements<br />

in air mix quantity<br />

- Possibility of adapting to systems<br />

requiring constant or variable airflow<br />

rates<br />

Subject to technical changes. Version 04 / 06 / 2012<br />

1.1.1 <strong>DAL</strong> <strong>358</strong> 1

<strong>NAD</strong> <strong>Klima</strong><br />

Swirl Diffuser<br />

<strong>DAL</strong> <strong>358</strong> Configuration<br />

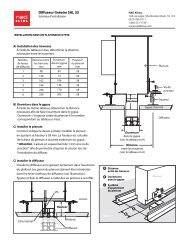

Whether on a square or circular front<br />

plate, the slots for the eccentric<br />

cylinders are generally arranged in a<br />

star pattern.<br />

<strong>DAL</strong> <strong>358</strong>-Q-300/400<br />

<strong>DAL</strong> <strong>358</strong>-Q-300/603<br />

<strong>DAL</strong> <strong>358</strong>-R-300<br />

The diffuser is mounted on a plenum.<br />

Up to a nominal size of 800, the front<br />

plate is secured by a concealed<br />

middle screw. In the case of the DN<br />

60 however, a reinforcement crossbar<br />

is required to secure the plate.<br />

Only the DN 800 has a different fastening<br />

configuration; screws are fastened<br />

at the 4 corners of the plate<br />

<strong>DAL</strong> <strong>358</strong>-Q-400/400<br />

<strong>DAL</strong> <strong>358</strong>-Q-400/603<br />

<strong>DAL</strong> <strong>358</strong>-R-400<br />

<strong>DAL</strong> <strong>358</strong>-Q-500/502<br />

<strong>DAL</strong> <strong>358</strong>-Q-500/603<br />

<strong>DAL</strong> <strong>358</strong>-R-500<br />

<strong>DAL</strong> <strong>358</strong>-Q-600/603<br />

<strong>DAL</strong> <strong>358</strong>-R-600<br />

<strong>DAL</strong> <strong>358</strong>-Q-800/800<br />

<strong>DAL</strong> <strong>358</strong>-R-800<br />

2 1.1.1 <strong>DAL</strong> <strong>358</strong><br />

Subject to technical changes. Version 23 / 08 / 2012

<strong>NAD</strong> <strong>Klima</strong><br />

Swirl Diffuser<br />

Method of operation<br />

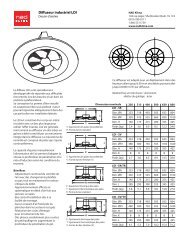

The eccentric cylinders, 100 mm in<br />

length, can pivot a full 3600. In their<br />

initial position, (1A and F6), the<br />

airflow will deviate by 900 with a<br />

constant discharge blast . Turning<br />

the cylinders to positions 2 1 and 6 5,<br />

for example, will reduce the section<br />

without tapering off and the air blast<br />

will increase. Adjustments 2 1 and 6<br />

5 are standard for North America<br />

because of the multiple VAV applications<br />

(variable air volume).<br />

The eccentric cylinder, aided by the<br />

profiles of the slots, creates a powerful<br />

channel into which the air is<br />

drawn. When nearing the exit of the<br />

cylinder, air depression takes place.<br />

Air Flow Behaviour<br />

The <strong>DAL</strong> <strong>358</strong> frontal plate has slots<br />

arranged in a characteristic star<br />

pattern. Turning the cylinders individually<br />

can produce a multitude of<br />

airstream patterns. In this manner,<br />

obstacles to efficient air flow can be<br />

avoided (lamp bases, ceiling drops,<br />

architectural columns, etc....). When<br />

installing in high ceilings (>5 m), a<br />

portion of the cylinders in the centre<br />

of the slot must be directed to<br />

produce a vertical blast (see figure 1).<br />

Use of the <strong>DAL</strong> <strong>358</strong> does not require<br />

a closed ceiling installation in order<br />

to produce a stable horizontal<br />

airflow. Despite the variety of air flow<br />

directions, all shapes have more or<br />

less the same sound power and<br />

pressure drop because of the specific<br />

design of the eccentric cylinder .<br />

Controlling the direction of airflow<br />

Air flow<br />

Indexing range<br />

min. max.<br />

Direction of airflow<br />

Cylinder position 1A<br />

Cylinder position 2 1<br />

Cylinder position 4 3<br />

Swirl air blast<br />

When positioning all the cylinders on 1<br />

A, a rotating air blast under the ceiling<br />

is produced in a swirling stream,<br />

creating a strong induction current.<br />

(standard setting).<br />

One-Sided Blast<br />

This air flow is obtained by positioning<br />

all of the cylinders on 1 A.<br />

Two-Sided Blast<br />

This blast on two sides is obtained by<br />

positioning all cylinders of one half on<br />

1A and those of the other half on F6.<br />

Cylinder position CD<br />

Schema 1<br />

Subject to technical changes. Version 04 / 06 / 2012<br />

1.1.1 <strong>DAL</strong> <strong>358</strong> 3

CIMA+ ing. , Sherbrooke, Québec

<strong>NAD</strong> <strong>Klima</strong><br />

Swirl Diffuser<br />

Vmax = Vmax simulation X f<br />

∆Pt = ∆Pt simulation X f<br />

LWA[dB] = LWA[dB] simulation X f<br />

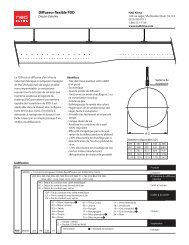

Flow and Direction of the air<br />

DN 600 360° helical flow<br />

ST = Standard helical flow (2 1)<br />

HL = Flow high-rise (>5m)<br />

(exterior 21 and center C D )<br />

VF = Vertical flow (C D)<br />

DN 300<br />

DN 600 180° 3-way helical<br />

3W = Flow 180° (wall) (2 1 - 3 4)<br />

DN 300<br />

DN 400<br />

DN 400<br />

DN 500<br />

DN 500<br />

DN 600<br />

Position 4 3<br />

Position 2 1<br />

DN 600<br />

Correction factor : f<br />

V MAX 1.0<br />

∆Pt 1.0<br />

L WA [dB] 1.0<br />

DN 800<br />

Correction factor : f<br />

V MAX 1.2<br />

∆Pt 1.3<br />

L WA [dB] 1.1<br />

DN 800<br />

DN 600 3-way 90˚<br />

3C = Flow 90° (corner) (2 1)<br />

DN 300<br />

DN 600 2 -way corner<br />

2L = Flow on both side by L<br />

(2 corridors) (2 1)<br />

DN 300<br />

DN 400<br />

DN 400<br />

DN 500<br />

DN 500<br />

DN 600<br />

DN 600<br />

Correction factor : f<br />

V MAX 1.4<br />

∆Pt 1.0<br />

L WA [dB] 1.0<br />

DN 800<br />

Correction factor : f<br />

V MAX<br />

∆Pt<br />

L WA [dB]<br />

1.7<br />

1.0<br />

1.0<br />

DN 800<br />

DN 600 2 opposite ways DN 600 1 way<br />

DN 300<br />

2W = Flow on two opposite sides (2 1 - 5 6)<br />

1W = Flow on one side (2 1)<br />

DN 300<br />

DN 400<br />

DN 400<br />

DN 500<br />

DN 500<br />

DN 600<br />

DN 600<br />

Correction factor : f<br />

V MAX 1.7<br />

∆Pt 1.0<br />

L WA [dB] 1.0<br />

DN 800<br />

Correction factor : f<br />

V MAX<br />

∆Pt<br />

L WA [dB]<br />

2.0<br />

1.0<br />

1.0<br />

DN 800<br />

Subject to technical changes. Version 08 / 05 / 2012<br />

1.1.1 <strong>DAL</strong> <strong>358</strong> 5

<strong>NAD</strong> <strong>Klima</strong><br />

Swirl Diffuser<br />

Range of application - Quick selection for <strong>DAL</strong> <strong>358</strong><br />

Height of<br />

the room<br />

Air flow by surface<br />

m 3 /h/m 2<br />

cfm/sq ft<br />

Nominal<br />

size<br />

DN<br />

Quantity of<br />

diffusers<br />

Airflow by diffuser<br />

m 3 /h<br />

cfm<br />

Min. distance<br />

diffuser<br />

(m)<br />

Min. distance<br />

wall<br />

(m)<br />

Critical<br />

X<br />

(m)<br />

Pressure<br />

difference<br />

∆P (Pa)<br />

Acoustic<br />

Power level<br />

Lw(dBA)<br />

9 0.5 DN 400 4 228 134 1.3 0.7 1.4 25 36<br />

2.44 m<br />

(8 ft) 1<br />

15<br />

27<br />

37<br />

2<br />

0.8<br />

1.5<br />

2<br />

DN 500<br />

DN 600<br />

DN 600<br />

3<br />

4<br />

4<br />

6<br />

366<br />

660<br />

609<br />

215<br />

388<br />

<strong>358</strong><br />

2.2<br />

4.2<br />

3.5<br />

6<br />

1.2<br />

2.2<br />

1.8<br />

7<br />

1.4<br />

1.9<br />

1.7<br />

25<br />

32<br />

26<br />

36<br />

43<br />

39<br />

9 0.5 DN 400 4 228 134 0.2 0.1 1.4 25 36<br />

3.05 m 15 0.8 DN 500 4 366 215 0.8 0.5 1.4 25 36<br />

(10 ft)<br />

27 1.5 DN 600 4 685 403 2.8 1.5 1.9 32 43<br />

37 2 DN 600 6 609 <strong>358</strong> 2.2 1.2 1.7 26 39<br />

9 0.5 DN 500 2 457 269 0.1 0.1 1.7 36 42<br />

4.0 m<br />

(13 ft)<br />

15<br />

27<br />

0.8<br />

1.5<br />

DN 500<br />

DN 600<br />

4<br />

4<br />

366<br />

685<br />

215<br />

403<br />

0.1<br />

0.8<br />

0.1<br />

0.6<br />

1.4<br />

1.9<br />

25<br />

32<br />

36<br />

43<br />

37 2 DN 800 4 914 537 1.6 0.9 1.8 28 44<br />

**Lw(dBA) : The absorption of the room is not considered. Column for any room from that height at the same volume of air by diffuser<br />

Column in reference to the example<br />

Specifications :<br />

- Room: L x W x H = 10 m x 10 m x 2.44m<br />

( 33 ft x 33 ft x 8 ft)<br />

- Total air flow in the room : 1550 cfm<br />

4<br />

- Initial temperature difference: ∆T = -10°C<br />

- Air velocity : 1.8 m = 0.25 m/s (50 cfm)<br />

- VAV : 25%<br />

Using the data on ceiling height 1 and airflow<br />

rate by surface (m 2 or sq. ft. 2 ), 2 choose the<br />

nominal size (DN) of the <strong>DAL</strong> <strong>358</strong>. 3<br />

Divide the total airflow rate of the room 4 by<br />

the ideal value of the air flow rate for the<br />

selected size. Adjust the quantity of diffusers to<br />

achieve symmetry in the room while respecting<br />

the maximum airflow rate in the optimal setting<br />

range. 5 Watch for minimal distance between<br />

diffusers and between diffusers 6 and walls. 7<br />

Connector diameter<br />

ød<br />

mm inches<br />

Location of the diffusers<br />

= minimum range of application<br />

= Optimal range of application<br />

(For minimum application in V.A.V.)<br />

(Maximum standard volume for<br />

office building)<br />

1.8 m (6 ft) Y<br />

Airflow pattern<br />

comfort line<br />

Scale grid: 1 m Blue: Air velocity >= 0.25 [m/s]<br />

= Maximal range of application<br />

(Noise level higher than 33 (43-10) dBA)<br />

300 12 DN 800<br />

opt<br />

540*<br />

250 10 DN 600<br />

opt 360*<br />

5<br />

200 8 DN 500<br />

opt<br />

240*<br />

150 6 DN 400<br />

opt<br />

130*<br />

150 6 DN 300<br />

opt 65*<br />

* Ideal operating value in cfm<br />

cfm<br />

L/s<br />

m /h<br />

Airflow<br />

20 30 40 50 60 70 80 100<br />

150 200 280 300 350 400 500 600 1000<br />

10 15 20 24 28 33 37 47 70 94 132 142 165 188 235<br />

283 472<br />

34 51 68 85 102 119 136 170 255 340 475 510 595 680 850 1020 1700<br />

V . Subject to technical changes. Version 10/ 04 / 2013<br />

6 1.1.1 <strong>DAL</strong> <strong>358</strong>

<strong>NAD</strong> <strong>Klima</strong><br />

Swirl Diffuser<br />

Stream rating diagram<br />

Notes :<br />

Room absorption is not factored in.<br />

For a comparison with North American values,<br />

reduce sound power by 10.<br />

Flow sub-ceiling<br />

Airflow V·<br />

CFM<br />

92<br />

[m /h]<br />

25 30 35 40 45 55 60 = L WA [dB(A)]<br />

2<br />

= L WA [dB(A)]<br />

= L WA [dB(A)]<br />

1 3<br />

L WA [dB(A)] =<br />

L WA [dB(A)] =<br />

Airflow distance after conjunction (y [m])<br />

11.5 10 8 6.5 5 3.25<br />

5<br />

1.5 0 Ft<br />

33<br />

in./H 2 O<br />

Pressure loss Pt [Pa]<br />

.04<br />

.08<br />

4<br />

.12<br />

.16<br />

.20<br />

.24<br />

.28<br />

.32<br />

.36<br />

.40<br />

29.5<br />

26<br />

23<br />

20<br />

16<br />

20<br />

m/s ft/min<br />

13<br />

30<br />

40<br />

10<br />

7<br />

60<br />

6<br />

8<br />

6.5<br />

5<br />

3.25<br />

Airflow distance x [m]<br />

Airflow velocity v max<br />

80<br />

100<br />

120<br />

140<br />

160<br />

180<br />

200<br />

<strong>DAL</strong> <strong>358</strong> - 8<br />

Subject to technical changes. Version 10 / 04 / 2013<br />

1.1.1 <strong>DAL</strong> <strong>358</strong> 7

<strong>NAD</strong> <strong>Klima</strong><br />

Swirl Diffuser<br />

Airflow performance diagram and Example<br />

Critical airflow distance<br />

DN400 et DN300<br />

Critical airflow distance x crit [m] Critical airflow distance x crit [m]<br />

10<br />

<strong>DAL</strong> <strong>358</strong> - DN 400 / 300<br />

Airflow V·<br />

Airflow V·<br />

∆T<br />

Temperature difference<br />

(0) (100) (200) (300) (400) (500)<br />

Critical airflow distance x crit [m]<br />

[m /h] Airflow V·<br />

∆T<br />

Temperature difference<br />

°C<br />

°C<br />

°C<br />

°C<br />

°C<br />

°C<br />

°C<br />

°C<br />

°C<br />

°C<br />

x crit [m] (DN300)<br />

Critical airflow distance x crit [m]<br />

[m /h] Airflow V·<br />

<strong>DAL</strong> <strong>358</strong> - DN 500<br />

[m /h]<br />

[m /h]<br />

∆T<br />

Temperature difference<br />

<strong>DAL</strong> <strong>358</strong> - DN 600 <strong>DAL</strong> <strong>358</strong> - DN 800<br />

∆T<br />

Temperature difference<br />

°C<br />

°C<br />

°C<br />

°C<br />

°C<br />

°C<br />

Temperature ratio<br />

°C<br />

°C<br />

°C<br />

°C<br />

Specifications :<br />

Height of ceiling:<br />

H= 3.00 m<br />

Airflow rate by diffuser: V O = 600 m3/h<br />

Maximum cooling:<br />

∆T 0 = -10°C<br />

Distance between diffusers: 2 x 1.7 = 3.4m<br />

Requirements:<br />

1. Nominal size of diffuser<br />

2. Sound power L WA<br />

3. Pressure drop ∆pt<br />

4. Maximum air velocity at nominal head<br />

level (1.8 m)<br />

5. Maximum temperature variation of<br />

ambient air at nominal head level<br />

6. Critical path of airflow (blast detaching<br />

itself from ceiling when cooling)<br />

Solution:<br />

1.From diagram" Range of Applications"<br />

we note the nominal size of DN600 1<br />

2, 3. From diagram "Airflow from Ceiling"<br />

for the DN 600 as diffuser and an airflow rate<br />

of 600 m3/h 2 we note the following values:<br />

Sound power: 39dB 3 (29 dB when factoring<br />

in room absorption)<br />

Total pressure drop: 25 Pa 4<br />

4. At nominal head level<br />

y = H - 1.80 = (3.00 m - 1.80 m = 1.20 m)<br />

and a horizontal airflow path of<br />

x-1.7 m<br />

0.18 m/s<br />

6<br />

7<br />

we note a maximum air velocity of<br />

5. For an airflow distance of<br />

(x+y) = 1.70 m + 1.20 m = 2,90 m 8<br />

and a DN 600, we note a temperature ratio of<br />

0.062°C 9 . The maximum temperature<br />

variation reached between room air and air<br />

blast at head level is 0.062 x 10°C = -0.62°C.<br />

5<br />

9<br />

6. From diagram "Critical Distance of Airflow"<br />

and an airflow rate of 600 m3/h with an initial<br />

temperature variation of ∆T0 =-10°C<br />

we come to a critical distance of airflow Xcrit<br />

= 1.7 m. 10<br />

∆Txy<br />

∆T<br />

8<br />

300<br />

x bzw. x + y [m]<br />

8 1.1.1 <strong>DAL</strong> <strong>358</strong><br />

Subject to technical changes. Version 13 / 08 / 2012

Laval University, Québec, Canada

TVA, Montréal, Canada

<strong>NAD</strong> <strong>Klima</strong><br />

Swirl Diffuser<br />

Dimensions<br />

<strong>DAL</strong><strong>358</strong> Dimension / Weight Square plenum <strong>DAL</strong><strong>358</strong> Dimension / Weight Round plenum<br />

Size DN 300/400 500 600 800 Size DN 300/400 500 600 800<br />

Cote A 400 502 603 800<br />

Cote B 76 82 68 66<br />

Cote C 251 312 347 411<br />

Cote ØD 150 200 250 300<br />

Cote E 12 12 12 12<br />

Cote F 387 488 584 790<br />

Poids [Kg] 5.2 7.1 11.5 14.6<br />

A eff [m 2 ] 0.0080/0.0134 0.0214 0.0347 0.0508<br />

Size ØA 400 500 600 800<br />

Size B 76 82 67 66<br />

Size C 252 312 347 411<br />

Size ØD 150 200 250 300<br />

Size E 8 8 8 8<br />

Size Ø F 392 492 592 792<br />

Weight [Kg] 4.2 6.2 8.5 14.1<br />

A eff [m 2 ] 0.0080/0.0134 0.0214 0.0347 0.0508<br />

with square plenum - lateral input<br />

Suspension hole, 4 x Ø6.3<br />

with round plenum - lateral input<br />

Suspension bracket (3)<br />

Flow control<br />

(optional)<br />

ØD<br />

Flow control<br />

(optional)<br />

Perfored metal sheet<br />

Perfored<br />

metal sheet<br />

B<br />

E<br />

C<br />

14<br />

F<br />

A<br />

Ø F<br />

Ø A<br />

with square plenum - top input<br />

ØD<br />

with round plenum - top input<br />

Flow control<br />

(optional)<br />

Flow control<br />

(optional)<br />

Perfored<br />

metal sheet<br />

C<br />

Perfored<br />

metal sheet<br />

E<br />

ØD<br />

C<br />

B<br />

E<br />

8<br />

ØD<br />

C<br />

E<br />

F<br />

A<br />

8<br />

Ø F<br />

Ø A<br />

Subject to technical changes. Version 22 / 05 / 2013<br />

1.1.1 <strong>DAL</strong> <strong>358</strong> 11

<strong>NAD</strong> <strong>Klima</strong><br />

Swirl Diffuser<br />

Correction factor of air flow<br />

for a reading with balometer<br />

To ensure adequate balancing of <strong>DAL</strong> <strong>358</strong><br />

type diffusers, it is recommended<br />

to use the correction factors of the<br />

airflow rate equivalent to the resistance<br />

generated by the balometer.<br />

These factors are valid for a ventilation<br />

system comprising at least 3 diffusers<br />

after a VAV unit or box. For less than 3<br />

diffusers with an automatic airflow rate<br />

setting, factors are lower than the stated<br />

ones.<br />

Such as indicated in the ALNOR manual,<br />

Appendix B - "Capture Hood Flow<br />

Resistance", the instrument's manufacturer<br />

recommends taking a reading at the<br />

ventilation duct and comparing it with<br />

one taken under the diffuser, with or<br />

without the balometer, in order to<br />

determine the correction factor.<br />

In order to avoid this procedure, we<br />

provide herein the correction factors<br />

needed for all <strong>DAL</strong> <strong>358</strong> diffuser models.<br />

<strong>DAL</strong> <strong>358</strong> - DN 300<br />

<strong>DAL</strong> <strong>358</strong> - DN 400<br />

100 50<br />

120 140 160 180 200 220 240 260 280 300 320 100 140 180 220 260 300 340<br />

120 160 200 240 280 320 360<br />

Adjustment: Helical - adjustment 21<br />

90<br />

80<br />

70<br />

Adjustment: Helical - adjustment 21<br />

160<br />

150<br />

140<br />

130<br />

60<br />

120<br />

50<br />

110<br />

40<br />

30<br />

20<br />

10<br />

100<br />

90<br />

80<br />

70<br />

10 20 30 40 50 60 70 80 90 80 90 100 110 120 130 140 150<br />

Air flow - Balometer (cfm)<br />

Air flow - Balometer (cfm)<br />

Balometer (cfm) 20 29 57 70 74 Balometer (cfm) 80 98 115 132 140<br />

Factor 1.00 1.01 1.05 1.06 1.07<br />

Factor 1.00 1.02 1.04 1.06 1.07<br />

Actual flow (cfm) 20 30 60 75 80 Actual flow (cfm) 80 100 120 140 150<br />

<strong>DAL</strong> <strong>358</strong> - DN 500<br />

Adjustment: Helical - adjustment 21<br />

400<br />

350<br />

300<br />

250<br />

200<br />

150<br />

<strong>DAL</strong> <strong>358</strong> - DN 600<br />

Adjustment: Helical - adjustment 21<br />

450<br />

400<br />

350<br />

300<br />

250<br />

200<br />

150<br />

100<br />

Air flow - Balometer (cfm)<br />

Air flow - Balometer (cfm)<br />

Balometer (cfm) 147 192 230 250 300 Balometer (cfm) 94 185 270 310 330<br />

Factor 1.02 1.04 1.08 1.12 1.13<br />

Factor 1.06 1.08 1.11 1.16 1.21<br />

Actual flow (cfm) 150 200 250 280 340 Actual flow (cfm) 100 200 300 350 400<br />

Actual flow at diffuser (cfm)<br />

Actual flow at diffuser (cfm)<br />

<strong>DAL</strong> <strong>358</strong> - DN 800<br />

Adjustment: Helical - adjustment 21<br />

650<br />

600<br />

550<br />

500<br />

450<br />

400<br />

350<br />

300<br />

250<br />

250 275 300 325 350 375 400 425 450 475 500<br />

Air flow - Balometer (cfm)<br />

Balometer (cfm) 360 392 415 446 480<br />

Factor 1.11 1.14 1.20 1.23 1.25<br />

Actual flow (cfm) 400 450 500 550 600<br />

Actual flow at diffuser (cfm)<br />

Actual flow at diffuser (cfm)<br />

Actual flow at diffuser (cfm)<br />

Identification Chart<br />

Y<br />

X<br />

DN<br />

300<br />

400<br />

500<br />

600<br />

800<br />

X (mm)<br />

603<br />

603<br />

603<br />

603<br />

803<br />

Y(mm)<br />

355<br />

355<br />

455<br />

552<br />

755<br />

12 1.1.1 <strong>DAL</strong> <strong>358</strong><br />

Subject to technical changes. Version 04 / 06 / 2012

<strong>NAD</strong> <strong>Klima</strong><br />

1 - Description and Physical Characteristics<br />

steel. Integrated slots in the frontal plate (circular or<br />

square) hold eccentric cylinders ensuring a high induc-<br />

1.2 The eccentric cylinders, 100 mm in length, are individually<br />

adjustable by rotating as much as 360°, each one<br />

on its own axis, inside the front plate. This design allows<br />

for a multitude of adjustments covering the range of air<br />

°<br />

360°).<br />

3 - Connection<br />

manufacturer. The plenum is made of 24-gauge galvanized<br />

steel and comprises a perforated stabilizing<br />

suspension points in accordance with paraseismic<br />

standards are provided. The input brace is centered on<br />

the side or on the top of the plenum, and its size is made<br />

The joints of the plenum are sealed with silicone caulking<br />

free of VOC emissions.<br />

ceiling or classic gypsum ceilings.<br />

(<strong>DAL</strong> <strong>358</strong> R and <strong>DAL</strong> <strong>358</strong> Q)<br />

1.4 Every plate is coated inside and outside with a baked<br />

polyester TGIC-enamel paint, providing a smooth,<br />

colour from the RAL colour chart or among special-order<br />

colours.<br />

1.5 Eccentric cylinders are available in black or white.<br />

4 - Balancing<br />

4.1 Balancing of the <strong>DAL</strong> <strong>358</strong> diffusers must be executed by<br />

a technician trained in ventilation system balancing with<br />

a professional certificate.<br />

4.2 The technician must take into consideration the correction<br />

factor for use of a balometer when regulating air<br />

volume.<br />

5 - Quality required: <strong>NAD</strong> <strong>Klima</strong>, model <strong>DAL</strong> <strong>358</strong><br />

2 -Performance<br />

even in situations requiring variable air volume -- in order<br />

the room (∆TXY = TR - TXY) and the initial temperature<br />

variation (∆TO = TR - TO). This ratio must perform a<br />

minimum of ∆TXY ÷ ∆TO ≤ 0.1.<br />

-<br />

tion software. This software indicates the pressure drop<br />

and sound power generated as well as a cross-sectional<br />

isothermal and heating modes. Upon demand from the<br />

engineer, the software can demonstrate a nominal<br />

velocity in an occupied zone of 0.25 m/s and can adapt to<br />

various requirements of air volume (25% to 100% of<br />

mode.<br />

Subject to technical changes. Version 04 / 06 / 2012<br />

1.1.1 <strong>DAL</strong> <strong>358</strong> 13

<strong>NAD</strong> <strong>Klima</strong><br />

<strong>DAL</strong> <strong>358</strong><br />

Product<br />

Q = Square<br />

R = Round<br />

300, 400, 500, 600, 800<br />

400, 502, 603, 800<br />

Nominal size<br />

(603 for 24''X24'' T-bar) Outer size<br />

HL = Flow high-rise (>5m) (exterior 21 and center CD)<br />

VF =<br />

1W = Flow on one side (2 1)<br />

2W = Flow on two opposite sides (2 1 - 5 6)<br />

2L = Flow on both side by L (2 corridors) (2 1)<br />

3C = Flow 90° (corner) (2 1)<br />

3W = Flow 180° (wall) (2 1 - 3 4)<br />

W = White roll and receptacle (RAL 9003)<br />

C = Cream roll and receptacle (RAL 9010)<br />

B = Black roll and receptacle<br />

X = Without roll<br />

9003 = White<br />

9010 = Cream<br />

_____ = RAL colour * (write the number of RAL colour)<br />

S = Plenum with lateral input<br />

T = Plenum with top input<br />

X = Without plenum<br />

X = Without insulation<br />

I = With acoustic insulation<br />

F =<br />

et<br />

X = Without damper<br />

D = With damper (for gypsum ceiling)<br />

Color of roll<br />

and receptacle<br />

Colour ( front plate)<br />

Plenum<br />

Insulation<br />

Damper<br />

<strong>DAL</strong><strong>358</strong> - Q - 300 - 400 - ST - W - 9003 - S - X - X<br />

Example<br />

Notes :<br />

Blue : Standard, in stock<br />

Write the number of 4 digits of the RAL color chart<br />

Our powder paint colors are available in the RAL color chart only.<br />

14 1.1.1 <strong>DAL</strong> <strong>358</strong><br />

Subject to technical changes. Version 23 / 08 / 2012

Concordia University, Montréal, Canada

www.nadklima.com<br />

<strong>NAD</strong> <strong>Klima</strong> 144, Léger Street, Sherbrooke (Québec), Canada J1L 1L9 • T : 819 780-0111 • 1 866 531-1739 • F : 819 780-1660 • info@nadklima.com