Heißkanaldüsen Typ SLT/-DLT Customer information

Heißkanaldüsen Typ SLT/-DLT Customer information

Heißkanaldüsen Typ SLT/-DLT Customer information

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

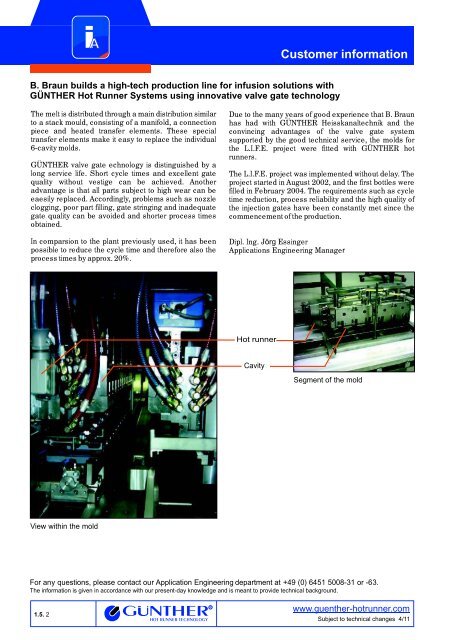

View within the mold<br />

1.5. 2<br />

iA<br />

<strong>Heißkanaldüsen</strong> <strong>Typ</strong> <strong>SLT</strong>/-<strong>DLT</strong> <strong>Customer</strong> <strong>information</strong><br />

B. Braun builds a high-tech production line for infusion solutions with<br />

GÜNTHER Hot Runner Systems using innovative valve gate technology<br />

The melt is distributed through a main distribution similar<br />

to a stack mould, consisting of a manifold, a connection<br />

piece and heated transfer elements. These special<br />

transfer elements make it easy to replace the individual<br />

6-cavity molds.<br />

GÜNTHER valve gate echnology is distinguished by a<br />

long service life. Short cycle times and excellent gate<br />

quality without vestige can be achieved. Another<br />

advantage is that all parts subject to high wear can be<br />

eaesily replaced. Accordingly, problems such as nozzle<br />

clogging, poor part filling, gate stringing and inadequate<br />

gate quality can be avoided and shorter process times<br />

obtained.<br />

In comparsion to the plant previously used, it has been<br />

possible to reduce the cycle time and therefore also the<br />

process times by approx. 20%.<br />

Due to the many years of good experience that B. Braun<br />

has had with GÜNTHER Heisskanaltechnik and the<br />

convincing advantages of the valve gate system<br />

supported by the good technical service, the molds for<br />

the L.I.F.E. project were fitted with GÜNTHER hot<br />

runners.<br />

The L.I.F.E. project was implemented without delay. The<br />

project started in August 2002, and the first bottles were<br />

filled in February 2004. The requirements such as cycle<br />

time reduction, process reliability and the high quality of<br />

the injection gates have been constantly met since the<br />

commencement of the production.<br />

Dipl. Ing. Jörg Essinger<br />

Applications Engineering Manager<br />

Hot runner<br />

Cavity<br />

Segment of the mold<br />

For any questions, please contact our Application Engineering department at +49 (0) 6451 5008-31 or -63.<br />

The <strong>information</strong> is given in accordance with our present-day knowledge and is meant to provide technical background.<br />

www.guenther-hotrunner.com<br />

Subject to technical changes 4/11