Heißkanaldüsen Typ SLT/-DLT Customer information

Heißkanaldüsen Typ SLT/-DLT Customer information

Heißkanaldüsen Typ SLT/-DLT Customer information

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

iA<br />

<strong>Heißkanaldüsen</strong> <strong>Typ</strong> <strong>SLT</strong>/-<strong>DLT</strong><br />

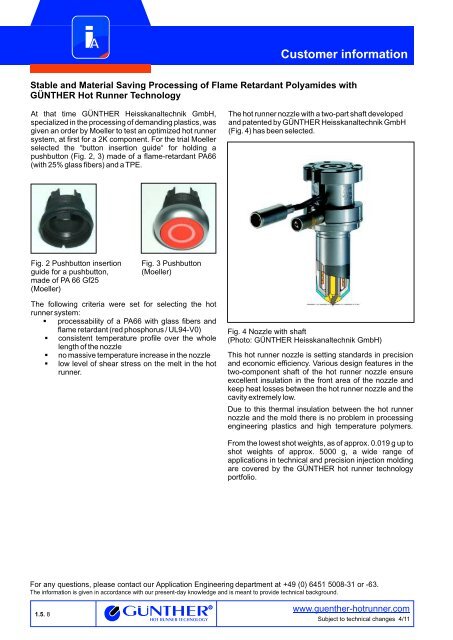

At that time GÜNTHER Heisskanaltechnik GmbH,<br />

specialized in the processing of demanding plastics, was<br />

given an order by Moeller to test an optimized hot runner<br />

system, at first for a 2K component. For the trial Moeller<br />

selected the “button insertion guide“ for holding a<br />

pushbutton (Fig. 2, 3) made of a flame-retardant PA66<br />

(with 25% glass fibers) and a TPE.<br />

Fig. 2 Pushbutton insertion<br />

guide for a pushbutton,<br />

made of PA 66 Gf25<br />

(Moeller)<br />

Fig. 3 Pushbutton<br />

(Moeller)<br />

The following criteria were set for selecting the hot<br />

runner system:<br />

� � �processability of a PA66 with glass fibers and<br />

flame retardant (red phosphorus / UL94-V0)<br />

�consistent temperature profile over the whole<br />

length of the nozzle<br />

�no massive temperature increase in the nozzle<br />

�low level of shear stress on the melt in the hot<br />

runner.<br />

<strong>Customer</strong> <strong>information</strong><br />

Stable and Material Saving Processing of Flame Retardant Polyamides with<br />

GÜNTHER Hot Runner Technology<br />

The hot runner nozzle with a two-part shaft developed<br />

and patented by GÜNTHER Heisskanaltechnik GmbH<br />

(Fig. 4) has been selected.<br />

Fig. 4 Nozzle with shaft<br />

(Photo: GÜNTHER Heisskanaltechnik GmbH)<br />

This hot runner nozzle is setting standards in precision<br />

and economic efficiency. Various design features in the<br />

two-component shaft of the hot runner nozzle ensure<br />

excellent insulation in the front area of the nozzle and<br />

keep heat losses between the hot runner nozzle and the<br />

cavity extremely low.<br />

Due to this thermal insulation between the hot runner<br />

nozzle and the mold there is no problem in processing<br />

engineering plastics and high temperature polymers.<br />

From the lowest shot weights, as of approx. 0.019 g up to<br />

shot weights of approx. 5000 g, a wide range of<br />

applications in technical and precision injection molding<br />

are covered by the GÜNTHER hot runner technology<br />

portfolio.<br />

For any questions, please contact our Application Engineering department at +49 (0) 6451 5008-31 or -63.<br />

The <strong>information</strong> is given in accordance with our present-day knowledge and is meant to provide technical background.<br />

.<br />

www.guenther-hotrunner.com<br />

1.5. 8<br />

Subject to technical changes 4/11