1301295806-PUNJAB - State Monitor1.pdf - Industrial Products

1301295806-PUNJAB - State Monitor1.pdf - Industrial Products

1301295806-PUNJAB - State Monitor1.pdf - Industrial Products

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

C M Y K<br />

Interface<br />

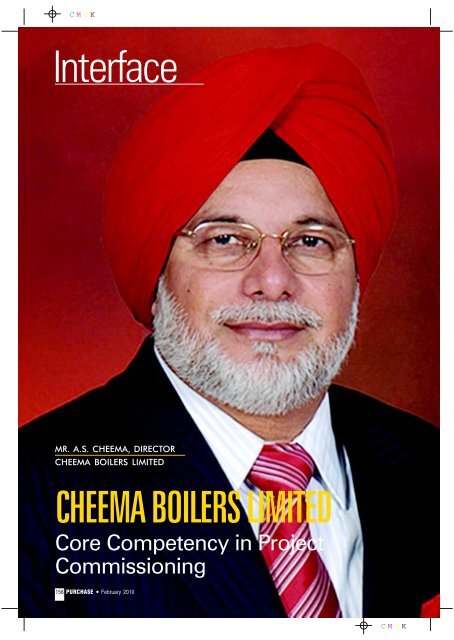

MR. A.S. CHEEMA, DIRECTOR<br />

CHEEMA BOILERS LIMITED<br />

CHEEMA BOILERS LIMITED<br />

Core Competency in Project<br />

Commissioning<br />

156 PURCHASE ◆ February 2010<br />

C M Y K

C M Y K<br />

Punjab<br />

<strong>State</strong> Monitor<br />

5 TPH, 10.50 KG/CM 2 Boiler<br />

Project M/s. Duli Chand Narender Kumar Exports (P) Ltd. (Got 3 Repeat Orders)<br />

Q & A<br />

Q & A<br />

Q & A<br />

Key factors responsible in establishing your industry in Punjab.<br />

The promoters belong to Northern India and have good <strong>Industrial</strong> relations & are well<br />

versed with the area. Further, as most of the boiler manufacturing companies are in the<br />

eastern & southern regions of the India, there was good potential of this product in this<br />

region. Congenial relations between employees & the employer and healthy working<br />

environment are other factors for setting up the unit in Punjab. Besides this, the<br />

availability of raw materials / vendors within this vicinity, good infrastructure,<br />

connectivity with Road/Train/Air are the other key reasons for establishing this unit in<br />

Punjab.<br />

Elaborate on your manufacturing locations, location of plants, investments, technology and human<br />

resources.<br />

CBL has sizeable state of the art manufacturing facilities that produce ‘A’ grade quality<br />

goods. The company has a longstanding experience in the manufacturing of boilers and<br />

boiler house auxiliaries.<br />

The Company has three plants, two plants are located at Kurali (near Chandigarh)<br />

having total area of 122000 square meters, and one at Nalagarh (HP).<br />

Significant achievements in company’s history<br />

In the last 10 years of operation, the company has established its name in the Boiler<br />

Industry with internal core competency in Engineering, Manufacturing, Project<br />

commissioning. Till date CBL has more than 900 customers from India and abroad in its<br />

reference list.<br />

CBL has maintained a consistent thrust towards growth. Today, it stands tall as the<br />

leader in steam boilers technology providers and has many revolutionary innovations to<br />

its credit. Through its constant evolution and advancement as an organization, it has set<br />

the milestone of being able to contribute to the nation both economically and socially.<br />

CBL has been honoured for pioneering in developing distillery waste fired boiler and<br />

making the distillery ‘0’ discharge. This technology benefits in two ways - the distillery<br />

waste (which is hazardous to environment) is consumed and power is generated by<br />

using the waste. The company has maintained consistent growth of 50% annually. CBL<br />

is continuously making profits. Repeat orders from renowned industrial groups are<br />

testimony of our products & quality services. CBL started manufacturing low pressure<br />

February 2010 ◆ PURCHASE 157<br />

C M Y K

C M Y K<br />

<strong>State</strong> Monitor<br />

Punjab<br />

40 TPH, 65 KG/CM 2 Boiler<br />

Project M/s. Indian Acrylics Limited<br />

(Got 6 Repeat Orders)<br />

boilers i.e. smoke tube, energypac, hypac, powerpac and now is manufacturing highpressure<br />

boilers.<br />

Q & A<br />

Q & A<br />

Q & A<br />

Growth prospects for your industry in the state and in India<br />

Since there is always a demand for power for overall developments, therefore there<br />

are unlimited growth opportunities for the company. CBL is manufacturing power boilers<br />

for independent power plants and cogeneration. CBL expects continuous annual growth<br />

rate to be above 50% for the coming years.<br />

Challenges towards development in the state and solutions for the same<br />

As a matter of fact, Punjab is safe and has a work conducive atmosphere. There is<br />

scope for growth within the state where the state Government is industry friendly and<br />

has better law and order situation. In the region there is need to improve the power<br />

supply which of course is an opportunity for CBL as we are manufacturing boilers for the<br />

power sector. More vocational, skill development center and high quality educational /<br />

professional Institutes require to be set up to meet the increased skilled manpower and<br />

other professional<br />

personnel.<br />

A Brief on your products<br />

and applications.<br />

CBL is<br />

manufacturing the<br />

following various<br />

types of boilers and<br />

boiler house<br />

auxiliaries:-<br />

LP Boilers : Low<br />

Pressure Process<br />

boilers - useful for<br />

process industries<br />

e.g. rice mills, paper<br />

mills, etc. Use of fuels<br />

– Petcoke, Baggase,<br />

14 TPH, 28 KG/CM 2 Boiler<br />

Project M/s. Reliance Industries Ltd.<br />

(Got 2 Repeat Orders)<br />

158 PURCHASE ◆ February 2010<br />

C M Y K

C M Y K<br />

Punjab<br />

<strong>State</strong> Monitor<br />

40 TPH 45 kg/cm2 Slop Fired Boiler<br />

Project M/s India Glycols Limited (4 repeat orders<br />

rice husk, wood chips, coal, etc.<br />

HP Boilers : High Pressure Co-generation boilers, Slop Fired Boilers. Use of fuel -<br />

Coal, Biomass, Gas, Spent Wash, etc.<br />

WHRBs : Waste Heat Recovery Boilers – useful for steel industries, sponge iron<br />

plants. Source of heat -– waste heat from furnace.<br />

Pollution control Equipments: Electro Static Precipitator (ESP), Water Bath Scrubber,<br />

Treema Cyclone to minimize the pollution level.<br />

Others: Fuel Handling System, Ash Handling System, Fans, etc.<br />

Q & A<br />

Q & A<br />

Q & A<br />

Q & A<br />

For engineering innovations - outline your company’s focus on R&D.<br />

CBL is very keen on R&D activities. Number of innovative products have already<br />

been designed, developed and commercialized. At our establishment, we have an<br />

exclusive R&D facility and well-versed technocrats who are working on the development<br />

of more and more sophisticated equipments.<br />

We have developed ‘Distillery Waste Fired Incineration Boiler’ which is patented for<br />

CBL only. After installment of this boiler, the distillery will become 100% zero discharge<br />

of liquids.<br />

Your comments on the energy scenario in the state and your vision for powering progress<br />

We are quite satisfied with the energy scenario in the state. However, there should<br />

be more improvement for providing electric power to the industries, which will enable<br />

un-interrupted production.<br />

Do you see enhanced opportunities for greater investments in the state?<br />

As our product is in great demand, we are continuously expanding our business by<br />

investing in production capabilities, technology, infrastructure, manpower, etc.<br />

Your views on the present industrial climate in the state.<br />

In a single word I would say comparatively “Better than other states” but there is still<br />

scope for improvement.<br />

February 2010 ◆ PURCHASE 159<br />

C M Y K