Thermo Scientific Apex 500 Rx Pharmaceutical Metal ... - Cole-Parmer

Thermo Scientific Apex 500 Rx Pharmaceutical Metal ... - Cole-Parmer

Thermo Scientific Apex 500 Rx Pharmaceutical Metal ... - Cole-Parmer

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

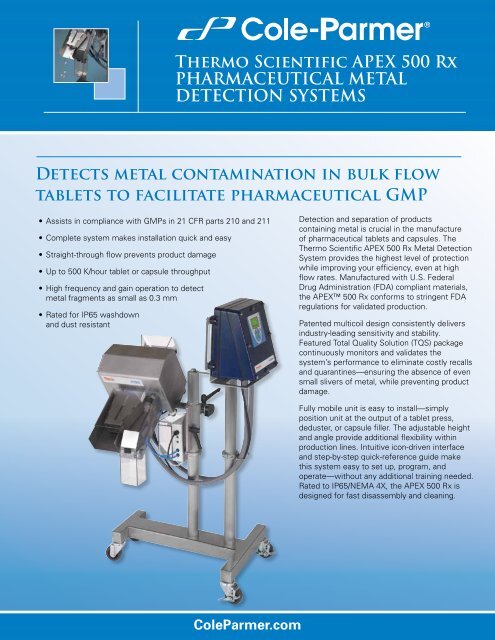

<strong>Thermo</strong> <strong>Scientific</strong> APEX <strong>500</strong> <strong>Rx</strong><br />

PHARMACEUTICAL METAL<br />

DETECTION SYSTEMS<br />

Detects metal contamination in bulk flow<br />

tablets to facilitate pharmaceutical GMP<br />

• Assists in compliance with GMPs in 21 CFR parts 210 and 211<br />

• Complete system makes installation quick and easy<br />

• Straight-through flow prevents product damage<br />

• Up to <strong>500</strong> K/hour tablet or capsule throughput<br />

• High frequency and gain operation to detect<br />

metal fragments as small as 0.3 mm<br />

• Rated for IP65 washdown<br />

and dust resistant<br />

Detection and separation of products<br />

containing metal is crucial in the manufacture<br />

of pharmaceutical tablets and capsules. The<br />

<strong>Thermo</strong> <strong>Scientific</strong> APEX <strong>500</strong> <strong>Rx</strong> <strong>Metal</strong> Detection<br />

System provides the highest level of protection<br />

while improving your efficiency, even at high<br />

flow rates. Manufactured with U.S. Federal<br />

Drug Administration (FDA) compliant materials,<br />

the APEX <strong>500</strong> <strong>Rx</strong> conforms to stringent FDA<br />

regulations for validated production.<br />

Patented multicoil design consistently delivers<br />

industry-leading sensitivity and stability.<br />

Featured Total Quality Solution (TQS) package<br />

continuously monitors and validates the<br />

system’s performance to eliminate costly recalls<br />

and quarantines—ensuring the absence of even<br />

small slivers of metal, while preventing product<br />

damage.<br />

Fully mobile unit is easy to install—simply<br />

position unit at the output of a tablet press,<br />

deduster, or capsule filler. The adjustable height<br />

and angle provide additional flexibility within<br />

production lines. Intuitive icon-driven interface<br />

and step-by-step quick-reference guide make<br />

this system easy to set up, program, and<br />

operate—without any additional training needed.<br />

Rated to IP65/NEMA 4X, the APEX <strong>500</strong> <strong>Rx</strong> is<br />

designed for fast disassembly and cleaning.<br />

<strong>Cole</strong><strong>Parmer</strong>.com

In the U.S.<br />

625 E. Bunker Court<br />

Vernon Hills, IL 60061<br />

Call toll-free 800-323-4340<br />

Phone: 847-549-7600<br />

Fax: 847-247-2929<br />

www.coleparmer.com<br />

In Canada<br />

Call toll-free 800-363-5900<br />

Phone: 514-355-6100<br />

Fax: 514-355-7119<br />

www.coleparmer.ca<br />

In India<br />

Phone: 91-22-6716-2222<br />

Fax: 91-22-6716-2211<br />

www.coleparmer.in<br />

In the United Kingdom<br />

Free phone: 0<strong>500</strong>-345-300<br />

Phone: 020-8574-7556<br />

Fax: 020-8574-7543<br />

www.coleparmer.co.uk<br />

International customers<br />

Call 847-549-7600 to reach our<br />

International Sales Department<br />

or contact your local dealer.<br />

FREE TECHNICAL<br />

APPLICATIONS ASSISTANCE!<br />

Applications<br />

<strong>Metal</strong> contamination detection in bulk flow tablets<br />

or capsules<br />

Performance Specifications<br />

Product speed: 1.7 to 3300 ft/min (0.5 to 1000 m/min)<br />

Operating conditions: 14 to 104°F (–10 to 40°C), 20 to 80% RH noncondensing<br />

Electrical supply: 85 to 260 VAC single-phase plus earth ground 47 to<br />

65 Hz, 100 watts max<br />

Air supply: 5.5 bar (80 psi) nominal, 4 bar (60 psi) minimum<br />

Outputs (six relays): 250 VAC, 2 A max; 50 VDC, 1 A max<br />

Output allocation (selectable via menu): Reject 1, reject 2, fault, alarm,<br />

warning, QA lamp<br />

Inputs (six): Active 12 VDC + 12 V auxiliary supply for input sensors<br />

Input allocation (selectable via menu): Speed sensor, keylock, product<br />

select 1, product select 2, infeed PEC, reject confirmation 1 (bin full),<br />

reject confirmation 2, external suppression<br />

Construction: 304 stainless steel straight-lined case (high polish optional).<br />

All plastics used are FDA approved.<br />

Protection ratings: IP65, ATEX zone 22, hazardous location Class II,<br />

Division 2, Groups F & G head and electronics only<br />

Help-text, users’ guide languages: English, Spanish, French, German, Italian,<br />

Dutch, Chinese, Russian, Czech, Polish<br />

®<br />

C<br />

US<br />

Catalog number Aperture size Product chute height †<br />

ML-54502-25 3.9" x 1" (100 x 25 mm) 0.87" (22 mm)<br />

ML-54502-26 3.9" x 1.4" (100 x 35 mm) 1.25" (32 mm)<br />

ML-54502-27 3.9" x 2" (100 x 50 mm) 1.85" (47 mm)<br />

† To ensure the product does not jam in the chute, select a product chute height larger than the largest tablet dimension.<br />

What’s included: <strong>Metal</strong> detector head, height/angle-adjustable stand with locking casters,<br />

complete fail-safe pneumatic rejecter system, test disks, and documentation on CD (users’<br />

guides and installation instructions, quick-reference guide, and PC software simulator).<br />

For further information,<br />

go to <strong>Cole</strong><strong>Parmer</strong>.com/APEX<strong>500</strong>RX<br />

3222.1<br />

<strong>Cole</strong><strong>Parmer</strong>.com