CS2 - SMC

CS2 - SMC

CS2 - SMC

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Air Cylinder<br />

Series <strong>CS2</strong><br />

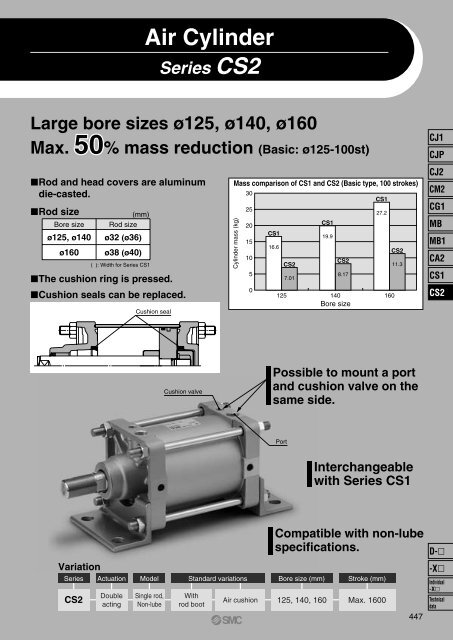

Large bore sizes ø125, ø140, ø160<br />

Max. 50% mass reduction (Basic: ø125-100st)<br />

Rod and head covers are aluminum<br />

die-casted.<br />

Rod size<br />

Bore size<br />

ø125, ø140<br />

ø160<br />

(mm)<br />

Rod size<br />

ø32 (ø36)<br />

ø38 (ø40)<br />

( ): Width for Series CS1<br />

The cushion ring is pressed.<br />

Cushion seals can be replaced.<br />

Cushion seal<br />

Mass comparison of CS1 and <strong>CS2</strong> (Basic type, 100 strokes)<br />

Cylinder mass (kg)<br />

30<br />

25<br />

20<br />

15<br />

10<br />

5<br />

0<br />

CS1<br />

16.6<br />

125<br />

<strong>CS2</strong><br />

7.01<br />

CS1<br />

19.9<br />

<strong>CS2</strong><br />

8.17<br />

140<br />

Bore size<br />

CS1<br />

27.2<br />

160<br />

<strong>CS2</strong><br />

11.3<br />

CJ1<br />

CJP<br />

CJ2<br />

CM2<br />

CG1<br />

MB<br />

MB1<br />

CA2<br />

CS1<br />

<strong>CS2</strong><br />

Cushion valve<br />

Possible to mount a port<br />

and cushion valve on the<br />

same side.<br />

Port<br />

Interchangeable<br />

with Series CS1<br />

Variation<br />

Series<br />

<strong>CS2</strong><br />

Actuation Model Standard variations<br />

Double<br />

acting<br />

Single rod,<br />

Non-lube<br />

With<br />

rod boot<br />

Air cushion<br />

Compatible with non-lube<br />

specifications.<br />

Bore size (mm)<br />

125, 140, 160<br />

Stroke (mm)<br />

Max. 1600<br />

447<br />

D-<br />

-X<br />

Individual<br />

-X<br />

Technical<br />

data

Air Cylinder<br />

Series <strong>CS2</strong><br />

ø125, ø140, ø160<br />

How to Order<br />

With auto switch<br />

<strong>CS2</strong><br />

CDS2 L<br />

With auto switch<br />

(Built-in magnet)<br />

Mounting<br />

B<br />

L<br />

F<br />

G<br />

C<br />

D<br />

T<br />

Built-in Magnet Cylinder Model<br />

If a built-in magnet cylinder without auto switch is<br />

required, there is no need to enter the symbol for<br />

auto switch.<br />

(Example) CDS2B125-200<br />

L<br />

Basic<br />

Foot<br />

Rod flange<br />

Head flange<br />

Single clevis<br />

Double clevis<br />

Center trunnion<br />

Bore size<br />

125<br />

140<br />

160<br />

125<br />

125<br />

125 mm<br />

140 mm<br />

160 mm<br />

Port thread type<br />

Nil<br />

TN<br />

TF<br />

Rc<br />

NPT<br />

G<br />

300<br />

300<br />

M9BW<br />

Auto switch<br />

Nil Without auto switch<br />

∗ Refer to the table below for the<br />

applicable auto switch model.<br />

Suffix for cylinder<br />

Nil<br />

None<br />

Rod boot J Nylon tarpaulin<br />

K Heat resistant tarpaulin<br />

∗ With air cushions on both sides only.<br />

Cylinder stroke (mm)<br />

(Maximum stroke → Refer to page 449.)<br />

Number of auto switches<br />

Nil<br />

3<br />

S<br />

n<br />

2 pcs.<br />

3 pcs.<br />

1 pc.<br />

“n” pcs.<br />

Applicable Auto Switches / For detailed auto switch specifications, refer to pages 1263 to 1371.<br />

Type<br />

Solid state switch<br />

Special function<br />

Diagnostic indication<br />

(2-color indication)<br />

Water resistant (2-color indication)<br />

Diagnostic indication (2-color indication)<br />

Electrical<br />

entry<br />

Grommet<br />

Terminal<br />

conduit<br />

Grommet<br />

3-wire (NPN)<br />

3-wire (PNP)<br />

2-wire<br />

3-wire (NPN)<br />

2-wire<br />

3-wire (NPN)<br />

3-wire (PNP)<br />

2-wire<br />

3-wire (NPN)<br />

3-wire (PNP)<br />

2-wire<br />

4-wire (NPN)<br />

3-wire<br />

(NPN equivalent)<br />

Grommet<br />

No<br />

—<br />

Yes<br />

No<br />

Terminal<br />

2-wire<br />

conduit<br />

Yes<br />

DIN terminal<br />

Diagnostic indication (2-color indication) Grommet<br />

∗ Lead wire length symbols: 0.5 m ·········· Nil (Example) M9NW<br />

1 m ··········· M (Example) M9NWM<br />

3 m ··········· L (Example) M9NWL<br />

5 m ··········· Z (Example) M9NWZ<br />

Reed switch<br />

Yes<br />

Yes<br />

Wiring<br />

(Output)<br />

24 V<br />

—<br />

24 V<br />

—<br />

24 V<br />

Load voltage<br />

Tie-rod<br />

mounting<br />

M9N<br />

M9P<br />

M9B<br />

J51<br />

—<br />

—<br />

M9NW<br />

M9PW<br />

M9BW<br />

M9NA<br />

M9PA<br />

M9BA<br />

F59F<br />

A96<br />

A93<br />

A90<br />

A54<br />

A64<br />

—<br />

—<br />

—<br />

A59W<br />

—<br />

—<br />

—<br />

—<br />

G39<br />

K39<br />

—<br />

—<br />

—<br />

—<br />

—<br />

—<br />

—<br />

—<br />

∗ Solid state auto switches marked with “” are produced upon receipt of order.<br />

∗ Since there are applicable auto switches other than listed, refer to page 460 for details.<br />

∗ For details about auto switches with pre-wired connector, refer to pages 1328 to 1329.<br />

∗ D-A9, M9, M9W, F9AL are shipped together (but not assembled). (Only auto switch mounting bracket is assembled at the time of shipment.)<br />

448<br />

—<br />

Indicator light<br />

DC<br />

5 V, 12 V<br />

12 V<br />

—<br />

5 V, 12 V<br />

12 V<br />

5 V, 12 V<br />

12 V<br />

5 V, 12 V<br />

12 V<br />

5 V, 12 V<br />

5 V<br />

AC<br />

—<br />

100 V, 200 V<br />

—<br />

—<br />

12 V 100 V<br />

5 V, 12 V 100 V or less<br />

100 V, 200 V<br />

200 V or less<br />

12 V —<br />

—<br />

100 V, 200 V<br />

—<br />

Auto switch model<br />

Band<br />

mounting<br />

—<br />

—<br />

—<br />

—<br />

A33<br />

A34<br />

A44<br />

—<br />

Lead wire length (m)<br />

0.5<br />

(Nil)<br />

1<br />

(M)<br />

3<br />

(L)<br />

5<br />

(Z)<br />

Pre-wired<br />

connector<br />

Applicable load<br />

IC circuit<br />

—<br />

IC circuit<br />

—<br />

IC circuit<br />

—<br />

IC circuit<br />

—<br />

IC circuit<br />

IC circuit<br />

—<br />

IC circuit<br />

—<br />

Relay,<br />

PLC<br />

—<br />

Relay,<br />

PLC<br />

PLC<br />

Relay,<br />

PLC

Air Cylinder<br />

Series <strong>CS2</strong><br />

Specifications<br />

JIS Symbol<br />

Double acting<br />

Rod Boot Material<br />

Symbol Material<br />

Max. ambient<br />

temperature<br />

J<br />

K<br />

Nylon tarpaulin<br />

Heat resistant tarpaulin<br />

70°C<br />

∗ Maximum ambient temperature for the rod boot itself.<br />

Bore size (mm) 125 140 160<br />

Action<br />

Fluid<br />

Proof pressure<br />

Maximum operating pressure<br />

Minimum operating pressure<br />

Piston speed<br />

Cushion<br />

Double acting, Single rod<br />

Air<br />

1.57 MPa<br />

0.97 MPa<br />

0.05 MPa<br />

50 to 500 mm/s<br />

Air cushion<br />

Ambient and fluid temperature<br />

Lubrication<br />

Stroke length tolerance (mm)<br />

Mounting<br />

Accessory<br />

Mounting<br />

Standard<br />

equipment Clevis pin<br />

Rod end nut<br />

Single knuckle joint<br />

Option Double knuckle joint<br />

(Knuckle pin,<br />

Cotter pin)<br />

Rod boot<br />

Maximum Stroke<br />

Mounting<br />

bracket<br />

110°C ∗ Bore size<br />

125<br />

140<br />

160<br />

Basic<br />

—<br />

<br />

<br />

<br />

<br />

0 to 70°C (No freezing)<br />

(Built-in magnet / With auto switch: 0 to 60°C)<br />

Not required (Non-lube)<br />

Stroke<br />

Tolerance<br />

+1.0<br />

250 or less<br />

0<br />

+1.2<br />

251 to 1000<br />

0<br />

+1.4<br />

1001 to 1200<br />

0<br />

+1.6<br />

1201 to 1400<br />

0<br />

+1.8<br />

1401 to 1600<br />

0<br />

Basic, Foot, Rod flange, Head flange,<br />

Single clevis, Double clevis, Center trunnion<br />

Foot<br />

—<br />

<br />

<br />

<br />

<br />

Rod<br />

flange<br />

—<br />

<br />

<br />

<br />

<br />

Head<br />

flange<br />

—<br />

<br />

<br />

<br />

<br />

Maximum stroke<br />

Basic, Head flange,<br />

Single clevis, Double clevis,<br />

Center trunnion<br />

1000 or less<br />

1200 or less<br />

Single<br />

clevis<br />

—<br />

<br />

<br />

<br />

<br />

Double<br />

clevis<br />

<br />

<br />

<br />

<br />

<br />

Foot, Rod flange<br />

1600 or less<br />

Center<br />

trunnion<br />

—<br />

<br />

<br />

<br />

<br />

(mm)<br />

CJ1<br />

CJP<br />

CJ2<br />

CM2<br />

CG1<br />

MB<br />

MB1<br />

CA2<br />

CS1<br />

<strong>CS2</strong><br />

Mounting Bracket Part No.<br />

Bore size (mm) 125<br />

140<br />

160<br />

Foot ∗<br />

Flange<br />

Single clevis<br />

Double clevis ∗∗<br />

<strong>CS2</strong>-L12<br />

<strong>CS2</strong>-F12<br />

<strong>CS2</strong>-C12<br />

<strong>CS2</strong>-D12<br />

<strong>CS2</strong>-L14<br />

<strong>CS2</strong>-F14<br />

<strong>CS2</strong>-C14<br />

<strong>CS2</strong>-D14<br />

<strong>CS2</strong>-L16<br />

<strong>CS2</strong>-F16<br />

<strong>CS2</strong>-C16<br />

<strong>CS2</strong>-D16<br />

∗ Order two foot brackets per cylinder.<br />

∗∗ When ordering the double clevis style, the clevis pin and 2 cotter pins are included as accessories.<br />

449<br />

D-<br />

-X<br />

Individual<br />

-X<br />

Technical<br />

data

Series <strong>CS2</strong><br />

Mass<br />

Basic<br />

mass<br />

Bore size (mm)<br />

Additional mass with magnet<br />

(With built-in magnet and auto switch)<br />

Additional mass per each 100 mm<br />

of stroke<br />

Accessory<br />

bracket<br />

Basic<br />

Foot<br />

Rod flange<br />

Head flange<br />

Single clevis<br />

Double clevis<br />

Trunnion<br />

Single knuckle<br />

Double knuckle (With<br />

Knuckle pin, Cotter pin)<br />

Rod end nut<br />

Calculation: (Example)<br />

<strong>CS2</strong>L160-500<br />

• Basic mass ······················· 12.45 (kg)<br />

• Additional mass ················ 2.23 (kg/100 mm)<br />

• Cylinder stroke ················· 500 (mm)<br />

[Calculation] 12.45 + 2.23 x 500/100 = 23.60 (kg)<br />

125 140 160<br />

5.46<br />

7.49<br />

8.51<br />

8.51<br />

8.53<br />

8.99<br />

9.59<br />

0.07<br />

1.55<br />

0.91<br />

1.37<br />

0.16<br />

Theoretical Output / Double Acting<br />

6.50<br />

9.50<br />

12.03<br />

12.03<br />

10.79<br />

11.54<br />

12.23<br />

0.07<br />

1.67<br />

1.16<br />

1.81<br />

0.16<br />

9.07<br />

12.45<br />

15.80<br />

15.80<br />

14.56<br />

15.41<br />

15.47<br />

0.08<br />

2.23<br />

1.56<br />

2.48<br />

0.23<br />

(kg)<br />

Bore size<br />

(mm)<br />

125, 140<br />

160<br />

Precautions<br />

Be sure to read before handling.<br />

Refer to front matters 54 and 55 for<br />

Safety Instructions and pages 3 to 11<br />

for Actuator and Auto Switch<br />

Precautions.<br />

Warning<br />

1. Do not use the cylinder as a shock<br />

absorber.<br />

Using the cylinder as a shock absorber may<br />

cause damage.<br />

2. Do not open the cushion valve beyond<br />

the stopper. As a retaining mechanism<br />

for the cushion valve, retaining ring is<br />

installed, and the cushion valve should<br />

not be opened beyond that point.<br />

If not operated in accordance with the above<br />

precautions, the cushion valve may be<br />

ejected from the cover when air pressure is<br />

supplied.<br />

3. Use the air cushion at the end of cylinder<br />

stroke.<br />

Caution<br />

1. Regarding the installation of a knuckle<br />

joint<br />

Please contact <strong>SMC</strong> if a knuckle joint must<br />

be installed on the piston rod by using the<br />

rod end nut.<br />

2. Regarding the screw-in of fittings when<br />

piping<br />

When ports and fittings are screwed in,<br />

tighten them with the proper tightening<br />

torque below.<br />

Connecting thread<br />

nominal size<br />

1/2<br />

3/4<br />

Proper tightening<br />

torque N·m<br />

28 to 30<br />

3. Do not deform cushion rings when<br />

removing and assembling.<br />

Cushion rings are press molded products. If<br />

a cushion ring bumps with something when<br />

removing and assembling, the air cushion<br />

may not function properly due to cushion<br />

ring deformation.<br />

Bore size<br />

(mm)<br />

Rod size<br />

(mm)<br />

Operating<br />

direction<br />

Piston area<br />

(mm 2 )<br />

OUT<br />

IN<br />

Unit: N<br />

Operating pressure (MPa)<br />

0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0<br />

125<br />

32<br />

OUT<br />

IN<br />

12300<br />

11500<br />

2460<br />

2300<br />

3690<br />

3450<br />

4920<br />

4600<br />

6150<br />

5750<br />

7380<br />

6900<br />

8610<br />

8050<br />

9840<br />

9200<br />

11100<br />

10400<br />

12300<br />

11500<br />

140<br />

32<br />

OUT<br />

IN<br />

15400<br />

14600<br />

3080<br />

2920<br />

4620<br />

4380<br />

6160<br />

5840<br />

7700<br />

7300<br />

9240<br />

8760<br />

10800<br />

10200<br />

12300<br />

11700<br />

13900<br />

13100<br />

15400<br />

14600<br />

160<br />

38<br />

OUT<br />

IN<br />

20100<br />

19000<br />

4020<br />

3800<br />

6030<br />

5700<br />

8040<br />

7600<br />

10100<br />

9500<br />

12100<br />

11400<br />

14100<br />

13300<br />

16100<br />

15200<br />

18100<br />

17100<br />

20100<br />

19000<br />

450

Air Cylinder Series <strong>CS2</strong><br />

Relation between Cylinder Size and Maximum Stroke<br />

The below table shows the applicable maximum stroke (in cm units), found by calculation assuming<br />

the case where the force generated by the cylinder itself acts as buckling force on the piston rod, or<br />

piston rod and cylinder tube.<br />

Therefore, it is possible to find the applicable maximum stroke for each cylinder size using the<br />

relationship between the size of the operating pressure and the cylinder support type, regardless of<br />

the load ratio.<br />

[Reference] If it is stopped with the external stopper on the cylinder extension side, even with a<br />

light load, the maximum generated force of the cylinder will act on the cylinder<br />

itself.<br />

P<br />

CJ1<br />

CJP<br />

Mounting<br />

Support bracket nominal symbol<br />

and schematic diagram<br />

Foot: L<br />

Rod flange:<br />

F<br />

Head flange:<br />

G<br />

W W W<br />

Nominal<br />

symbol<br />

L, F<br />

Operating pressure<br />

(MPa)<br />

0.3<br />

0.5<br />

0.7<br />

0.3<br />

Applicable max. stroke according to buckling strength<br />

125<br />

140<br />

160<br />

103<br />

92<br />

113<br />

79<br />

70<br />

86<br />

66<br />

58<br />

72<br />

45<br />

38<br />

47<br />

(cm)<br />

CJ2<br />

CM2<br />

CG1<br />

MB<br />

MB1<br />

CA2<br />

G<br />

0.5<br />

33<br />

27<br />

34<br />

CS1<br />

Head side trunnion:<br />

U<br />

Center trunnion:<br />

U<br />

CA1, CS1 type only<br />

C, D<br />

0.7<br />

0.3<br />

0.5<br />

26<br />

96<br />

71<br />

22<br />

83<br />

61<br />

27<br />

106<br />

76<br />

<strong>CS2</strong><br />

W<br />

W<br />

0.7<br />

59<br />

50<br />

62<br />

0.3<br />

135<br />

119<br />

147<br />

T<br />

0.5<br />

101<br />

89<br />

111<br />

0.7<br />

84<br />

74<br />

91<br />

Foot: L<br />

W<br />

Rod flange:<br />

F<br />

W<br />

Head flange:<br />

G<br />

W<br />

L, F<br />

0.3<br />

0.5<br />

301<br />

231<br />

267<br />

207<br />

330<br />

253<br />

0.7<br />

193<br />

172<br />

212<br />

0.3<br />

144<br />

126<br />

156<br />

G<br />

0.5<br />

109<br />

94<br />

118<br />

0.7<br />

90<br />

78<br />

97<br />

Foot: L<br />

W<br />

Rod flange:<br />

F<br />

W<br />

Head flange:<br />

G<br />

W<br />

L, F<br />

0.3<br />

0.5<br />

0.7<br />

433<br />

334<br />

281<br />

386<br />

297<br />

250<br />

476<br />

367<br />

309<br />

0.3<br />

210<br />

185<br />

229<br />

G<br />

0.5<br />

160<br />

141<br />

175<br />

0.7<br />

134<br />

117<br />

129<br />

D-<br />

-X<br />

451<br />

Individual<br />

-X<br />

Technical<br />

data

Series <strong>CS2</strong><br />

Construction<br />

JIS Symbol<br />

!9 !5 !0 !6 y q u i !7 @0 teor!8 !4 !3 @1 !2 w!1<br />

Component Parts<br />

No. Description<br />

1 Rod cover<br />

2 Head cover<br />

3 Cylinder tube<br />

4 Piston<br />

5 Piston rod<br />

6 Bushing<br />

7 Tie-rod<br />

8 Tie-rod nut<br />

9 Cushion ring<br />

10 Cushion valve<br />

11 Piston nut<br />

12 Flain washer<br />

13 Wear ring<br />

14 Magnet ∗<br />

15 Retaining ring<br />

∗ Built-in magnet type with auto switch<br />

Material<br />

Aluminum die-cast<br />

Aluminum die-cast<br />

Aluminum alloy<br />

Aluminum alloy<br />

Carbon steel<br />

Oil-impregnated sintered alloy<br />

Carbon steel<br />

Rolled steel<br />

Stainless steel<br />

Rolled steel<br />

Carbon steel<br />

Carbon steel<br />

Resin<br />

—<br />

Spring steel<br />

Note<br />

Hard anodized<br />

Chromated<br />

Hard chrome plated<br />

Zinc chromated<br />

Nickel plated<br />

Electroless nickel plated<br />

Nickel plated<br />

Nickel plated<br />

Phosphate coated<br />

No. Description Material Note<br />

16<br />

17<br />

18<br />

19<br />

20<br />

21<br />

Rod seal<br />

Cushion seal<br />

Piston seal<br />

Valve seal<br />

Tube gasket<br />

Piston gasket<br />

NBR<br />

Urethane<br />

NBR<br />

NBR<br />

NBR<br />

NBR<br />

Replacement Parts: Seal Kit<br />

Bore size (mm)<br />

125<br />

140<br />

160<br />

Kit no.<br />

<strong>CS2</strong>-125A-PS<br />

<strong>CS2</strong>-140A-PS<br />

<strong>CS2</strong>-160A-PS<br />

Content<br />

Set of nos.<br />

above !6, !7, !8, @0.<br />

∗ Seal kit includes a grease pack (40 g).<br />

Order with the following part number when only the grease pack is needed.<br />

Grease park part number: GR-S-010 (10 g), GR-S-020 (20 g)<br />

452

Air Cylinder Series <strong>CS2</strong><br />

Dimensions<br />

Basic: <strong>CS2</strong>B<br />

With rod boot<br />

Width across flats KA<br />

MM<br />

G<br />

G<br />

Port<br />

W V<br />

2 x RcP 4 x J Cushion valve<br />

CJ1<br />

øe<br />

øE<br />

øD<br />

CJP<br />

Bore size<br />

(mm)<br />

125<br />

140<br />

160<br />

Bore size<br />

(mm)<br />

125<br />

140<br />

160<br />

h + l<br />

l<br />

f<br />

ZZ1 + l + Stroke<br />

Stroke range<br />

(mm)<br />

Up to 1000<br />

Up to 1000<br />

Up to 1200<br />

N<br />

30.5<br />

30.5<br />

34.5<br />

P<br />

1/2<br />

1/2<br />

3/4<br />

A<br />

50<br />

50<br />

56<br />

S<br />

98<br />

98<br />

106<br />

AL<br />

47<br />

47<br />

53<br />

B<br />

143<br />

157<br />

177<br />

Without rod boot<br />

H ZZ<br />

110 235<br />

110 235<br />

120 256.5<br />

AL<br />

A<br />

C<br />

115<br />

128<br />

144<br />

e<br />

75<br />

75<br />

75<br />

K<br />

H<br />

D<br />

32<br />

32<br />

38<br />

F<br />

f<br />

40<br />

40<br />

40<br />

N<br />

E<br />

71<br />

71<br />

78.5<br />

∗ The minimum stroke with rod boot is 30 mm or more.<br />

∗∗ For auto switch mounting position and its mounting height, refer to page 458.<br />

∗∗∗ Refer to “Minimum Stroke for Auto Switch Mounting” on page 459.<br />

ZZ + Stroke<br />

F<br />

43<br />

43<br />

42<br />

S + Stroke<br />

G<br />

15<br />

15<br />

18<br />

With rod boot<br />

h l<br />

133 0.2 stroke<br />

133 0.2 stroke<br />

141 0.2 stroke<br />

J<br />

M14 x 1.5<br />

M14 x 1.5<br />

M16 x 1.5<br />

(mm)<br />

ZZ1<br />

258<br />

258<br />

277.5<br />

N<br />

M<br />

V<br />

15<br />

15<br />

15<br />

W<br />

17<br />

17<br />

20<br />

K<br />

15<br />

15<br />

17<br />

C<br />

B<br />

KA M<br />

27 27<br />

27 27<br />

34 30.5<br />

(mm)<br />

MM<br />

M30 x 1.5<br />

M30 x 1.5<br />

M36 x 1.5<br />

CJ2<br />

CM2<br />

CG1<br />

MB<br />

MB1<br />

CA2<br />

CS1<br />

<strong>CS2</strong><br />

Foot: <strong>CS2</strong>L<br />

With rod boot<br />

Width across flats KA<br />

MM<br />

A<br />

AL<br />

H<br />

K<br />

F<br />

G<br />

2 x RcP<br />

S + Stroke<br />

G<br />

Port<br />

W V<br />

4 x J Cushion valve<br />

øe<br />

øE<br />

øD<br />

4 x øLD<br />

LY<br />

LH<br />

l<br />

h + l<br />

f<br />

ZZ1 + l + Stroke<br />

LT<br />

Y<br />

X<br />

N<br />

LS + Stroke<br />

ZZ + Stroke<br />

N<br />

X<br />

Y<br />

LX<br />

C<br />

B<br />

(mm)<br />

Bore size<br />

(mm)<br />

125<br />

140<br />

160<br />

Stroke range<br />

(mm)<br />

Up to 1600<br />

Up to 1600<br />

Up to 1600<br />

A<br />

50<br />

50<br />

56<br />

AL<br />

47<br />

47<br />

53<br />

B<br />

145<br />

161<br />

182<br />

C<br />

115<br />

128<br />

144<br />

D<br />

32<br />

32<br />

38<br />

E<br />

71<br />

71<br />

78.5<br />

F<br />

43<br />

43<br />

42<br />

G<br />

15<br />

15<br />

18<br />

J<br />

M14 x 1.5<br />

M14 x 1.5<br />

M16 x 1.5<br />

V<br />

15<br />

15<br />

15<br />

W<br />

17<br />

17<br />

20<br />

K<br />

15<br />

15<br />

17<br />

KA<br />

27<br />

27<br />

34<br />

LD<br />

19<br />

19<br />

19<br />

LH<br />

85<br />

100<br />

106<br />

LS<br />

188<br />

188<br />

206<br />

Bore size<br />

(mm)<br />

125<br />

140<br />

160<br />

LT<br />

8<br />

9<br />

9<br />

LX<br />

100<br />

112<br />

118<br />

LY<br />

156.5<br />

178.5<br />

194.5<br />

MM<br />

M30 x 1.5<br />

M30 x 1.5<br />

M36 x 1.5<br />

N<br />

30.5<br />

30.5<br />

34.5<br />

P<br />

1/2<br />

1/2<br />

3/4<br />

∗ The minimum stroke with rod boot is 30 mm or more.<br />

∗∗ For auto switch mounting position and its mounting height, refer to page 458.<br />

∗∗∗ Refer to “Minimum Stroke for Auto Switch Mounting” on page 459.<br />

S<br />

98<br />

98<br />

106<br />

X<br />

45<br />

45<br />

50<br />

Y<br />

20<br />

30<br />

25<br />

Without rod boot<br />

H ZZ<br />

110 273<br />

110 283<br />

120 301<br />

e<br />

75<br />

75<br />

75<br />

f<br />

40<br />

40<br />

40<br />

With rod boot<br />

h l<br />

133 0.2 stroke<br />

133 0.2 stroke<br />

141 0.2 stroke<br />

(mm)<br />

ZZ1<br />

296<br />

306<br />

322<br />

453<br />

D-<br />

-X<br />

Individual<br />

-X<br />

Technical<br />

data

Series <strong>CS2</strong><br />

Dimensions<br />

Rod flange: <strong>CS2</strong>F<br />

With rod boot<br />

Width across flats KA<br />

MM<br />

G<br />

2 x RcP<br />

G<br />

4 x øFD<br />

4 x J<br />

Port<br />

W V<br />

Cushion valve<br />

øe<br />

øD<br />

B<br />

FY<br />

l f<br />

h+ l<br />

ZZ1+ l + Stroke<br />

AL<br />

A<br />

FT<br />

F<br />

K<br />

H<br />

N<br />

S + Stroke<br />

ZZ + Stroke<br />

N<br />

M<br />

C<br />

B<br />

FX<br />

FZ<br />

(mm)<br />

Bore size<br />

(mm)<br />

125<br />

140<br />

160<br />

Stroke range<br />

(mm)<br />

Up to 1600<br />

Up to 1600<br />

Up to 1600<br />

A<br />

50<br />

50<br />

56<br />

AL<br />

47<br />

47<br />

53<br />

B<br />

143<br />

157<br />

177<br />

B<br />

145<br />

160<br />

180<br />

C<br />

115<br />

128<br />

144<br />

D<br />

32<br />

32<br />

38<br />

E<br />

71<br />

71<br />

78.5<br />

F<br />

43<br />

43<br />

42<br />

FD<br />

19<br />

19<br />

19<br />

FT<br />

14<br />

20<br />

20<br />

FX<br />

190<br />

212<br />

236<br />

FY<br />

100<br />

112<br />

118<br />

FZ<br />

230<br />

255<br />

275<br />

G<br />

15<br />

15<br />

18<br />

J<br />

M14 x 1.5<br />

M14 x 1.5<br />

M16 x 1.5<br />

V<br />

15<br />

15<br />

15<br />

Bore size<br />

(mm)<br />

125<br />

140<br />

160<br />

W<br />

17<br />

17<br />

20<br />

K KA M MM N P S<br />

15<br />

15<br />

17<br />

27<br />

27<br />

34<br />

13<br />

13<br />

15<br />

M30 x 1.5<br />

M30 x 1.5<br />

M36 x 1.5<br />

30.5<br />

30.5<br />

34.5<br />

∗ The minimum stroke with rod boot is 30 mm or more.<br />

∗∗ For auto switch mounting position and its mounting height, refer to page 458.<br />

∗∗∗ Refer to “Minimum Stroke for Auto Switch Mounting” on page 459.<br />

1/2<br />

1/2<br />

3/4<br />

98<br />

98<br />

106<br />

Without rod boot<br />

H ZZ<br />

110 221<br />

110 221<br />

120 241<br />

e<br />

75<br />

75<br />

75<br />

f<br />

40<br />

40<br />

40<br />

With rod boot<br />

h l<br />

133 0.2 stroke<br />

133 0.2 stroke<br />

141 0.2 stroke<br />

(mm)<br />

ZZ1<br />

244<br />

244<br />

262<br />

Head flange: <strong>CS2</strong>G<br />

With rod boot<br />

Width across flats KA<br />

MM<br />

G<br />

2 x RcP<br />

G<br />

4 x øFD<br />

4 x J<br />

Port<br />

W V<br />

Cushion valve<br />

øe<br />

øD<br />

B<br />

FY<br />

l f<br />

h+ l<br />

ZZ1+ l + Stroke<br />

AL<br />

A<br />

K<br />

H<br />

F<br />

N<br />

ZZ + Stroke<br />

S + Stroke<br />

N<br />

FT<br />

C<br />

B<br />

FX<br />

FZ<br />

(mm)<br />

Bore size<br />

(mm)<br />

125<br />

140<br />

160<br />

Stroke range<br />

(mm)<br />

Up to 1000<br />

Up to 1000<br />

Up to 1200<br />

A<br />

50<br />

50<br />

56<br />

AL<br />

47<br />

47<br />

53<br />

B<br />

143<br />

157<br />

177<br />

B<br />

145<br />

160<br />

180<br />

C<br />

115<br />

128<br />

144<br />

D<br />

32<br />

32<br />

38<br />

E<br />

71<br />

71<br />

78.5<br />

F<br />

43<br />

43<br />

42<br />

FD<br />

19<br />

19<br />

19<br />

FT<br />

14<br />

20<br />

20<br />

FX<br />

190<br />

212<br />

236<br />

FY<br />

100<br />

112<br />

118<br />

FZ<br />

230<br />

255<br />

275<br />

G<br />

15<br />

15<br />

18<br />

J<br />

M14 x 1.5<br />

M14 x 1.5<br />

M16 x 1.5<br />

V<br />

15<br />

15<br />

15<br />

(mm)<br />

Bore size<br />

(mm)<br />

125<br />

140<br />

160<br />

454<br />

W K KA MM N P S<br />

17<br />

17<br />

20<br />

15<br />

15<br />

17<br />

27<br />

27<br />

34<br />

M30 x 1.5<br />

M30 x 1.5<br />

M36 x 1.5<br />

30.5<br />

30.5<br />

34.5<br />

1/2<br />

1/2<br />

3/4<br />

∗ The minimum stroke with rod boot is 30 mm or more.<br />

∗∗ For auto switch mounting position and its mounting height, refer to page 458.<br />

∗∗∗ Refer to “Minimum Stroke for Auto Switch Mounting” on page 459.<br />

98<br />

98<br />

106<br />

Without rod boot<br />

H ZZ<br />

110 222<br />

110 228<br />

120 246<br />

e<br />

75<br />

75<br />

75<br />

f<br />

40<br />

40<br />

40<br />

With rod boot<br />

h l<br />

133 0.2 stroke<br />

133 0.2 stroke<br />

141 0.2 stroke<br />

ZZ1<br />

245<br />

251<br />

267

Air Cylinder Series <strong>CS2</strong><br />

Dimensions<br />

Single clevis: <strong>CS2</strong>C<br />

With rod boot<br />

Width across flats KA<br />

MM<br />

G<br />

2 x RcP<br />

G<br />

øCDH10<br />

Port<br />

W V<br />

4 x J Cushion valve<br />

CJ1<br />

CJP<br />

øe<br />

øD<br />

CJ2<br />

l f<br />

h + l<br />

Z1 + l + Stroke<br />

ZZ1 + l + Stroke<br />

AL<br />

A<br />

K<br />

H<br />

F<br />

N<br />

S + Stroke<br />

Z + Stroke<br />

ZZ + Stroke<br />

N<br />

U<br />

CT<br />

L<br />

CX<br />

C<br />

B<br />

CM2<br />

CG1<br />

MB<br />

MB1<br />

CA2<br />

Double clevis: <strong>CS2</strong>D<br />

CS1<br />

<strong>CS2</strong><br />

With rod boot<br />

Width across flats KA<br />

MM<br />

G<br />

2 x RcP<br />

G<br />

øCD hole H10<br />

Shaft d9<br />

Port<br />

W V<br />

4 x J Cushion valve<br />

øe<br />

øD<br />

l f<br />

h + l<br />

Z1 + l + Stroke<br />

ZZ1 + l + Stroke<br />

AL<br />

A<br />

K<br />

H<br />

F<br />

N<br />

S + Stroke<br />

Z + Stroke<br />

ZZ + Stroke<br />

N<br />

CT<br />

L<br />

U<br />

CX<br />

CZ<br />

C<br />

B<br />

Bore size<br />

(mm)<br />

125<br />

140<br />

160<br />

Stroke range<br />

(mm)<br />

Up to 1000<br />

Up to 1000<br />

Up to 1200<br />

A<br />

50<br />

50<br />

56<br />

AL<br />

47<br />

47<br />

53<br />

B<br />

143<br />

157<br />

177<br />

C<br />

115<br />

128<br />

144<br />

CDH10<br />

25<br />

28<br />

32<br />

+0.084<br />

0<br />

+0.084<br />

0<br />

+0.100<br />

0<br />

CT<br />

17<br />

17<br />

20<br />

Single clevis<br />

CX<br />

–0.1<br />

32 –0.3<br />

–0.1<br />

36 –0.3<br />

–0.1<br />

40 –0.3<br />

Double clevis<br />

CX CZ<br />

+0.3<br />

32 +0.1 64<br />

+0.3<br />

36 +0.1 72<br />

+0.3<br />

40 +0.1 80<br />

0<br />

–0.2<br />

0<br />

–0.2<br />

0<br />

–0.2<br />

D<br />

32<br />

32<br />

38<br />

E<br />

71<br />

71<br />

78.5<br />

F<br />

43<br />

43<br />

42<br />

G<br />

15<br />

15<br />

18<br />

J<br />

M14 x 1.5<br />

M14 x 1.5<br />

M16 x 1.5<br />

V<br />

15<br />

15<br />

15<br />

(mm)<br />

W<br />

17<br />

17<br />

20<br />

Bore size<br />

(mm)<br />

125<br />

140<br />

160<br />

K KA L MM N P S U RR<br />

15<br />

15<br />

17<br />

27<br />

27<br />

34<br />

65<br />

75<br />

80<br />

M30 x 1.5<br />

M30 x 1.5<br />

M36 x 1.5<br />

30.5<br />

30.5<br />

34.5<br />

1/2<br />

1/2<br />

3/4<br />

98<br />

98<br />

106<br />

∗ The minimum stroke with rod boot is 30 mm or more.<br />

∗∗ For auto switch mounting position and its mounting height, refer to page 458.<br />

∗∗∗ Refer to “Minimum Stroke for Auto Switch Mounting” on page 459.<br />

35<br />

40<br />

45<br />

29<br />

32<br />

36<br />

Without rod boot<br />

H Z ZZ<br />

110 273 302<br />

110 283 315<br />

120 306 342<br />

e<br />

75<br />

75<br />

75<br />

f<br />

40<br />

40<br />

40<br />

With rod boot<br />

h l<br />

133 0.2 stroke<br />

133 0.2 stroke<br />

141 0.2 stroke<br />

Z1<br />

296<br />

306<br />

327<br />

(mm)<br />

ZZ1<br />

325<br />

338<br />

363<br />

455<br />

D-<br />

-X<br />

Individual<br />

-X<br />

Technical<br />

data

Series <strong>CS2</strong><br />

Dimensions<br />

Center trunnion: <strong>CS2</strong>T<br />

With rod boot<br />

Z1 + L + 1/2 stroke<br />

MM<br />

Width across<br />

flats KA<br />

Z+ 1/2 stroke<br />

G<br />

2 x RcP<br />

G<br />

Port<br />

W V<br />

4 x J Cushion valve<br />

R<br />

øe<br />

øE<br />

øD<br />

TY<br />

øTDe8<br />

l f<br />

h + l<br />

ZZ1 + l + Stroke<br />

AL<br />

A<br />

K<br />

H<br />

F<br />

N<br />

TT<br />

S + Stroke<br />

N<br />

M<br />

C<br />

B<br />

TX<br />

ZZ + Stroke<br />

TZ<br />

Bore size<br />

(mm)<br />

125<br />

140<br />

160<br />

Bore size<br />

(mm)<br />

125<br />

140<br />

160<br />

Stroke range<br />

(mm)<br />

25 to 1000<br />

30 to 1000<br />

35 to 1200<br />

A<br />

50<br />

50<br />

56<br />

AL<br />

47<br />

47<br />

53<br />

B<br />

143<br />

157<br />

177<br />

C<br />

115<br />

128<br />

144<br />

D<br />

32<br />

32<br />

38<br />

E<br />

71<br />

71<br />

78.5<br />

P R S TDe8 TT TX TY TZ<br />

1/2<br />

1/2<br />

3/4<br />

1<br />

1.5<br />

1.5<br />

98<br />

98<br />

106<br />

32<br />

36<br />

40<br />

–0.050<br />

–0.089<br />

–0.050<br />

–0.089<br />

–0.050<br />

–0.089<br />

∗ The minimum stroke with rod boot is 30 mm or more for ø125, ø140, and 35 mm or more for ø160.<br />

∗∗ For auto switch mounting position and its mounting height, refer to page 458.<br />

∗∗∗ Refer to “Minimum Stroke for Auto Switch Mounting” on page 459.<br />

50<br />

55<br />

60<br />

170<br />

190<br />

212<br />

164<br />

184<br />

204<br />

F<br />

43<br />

43<br />

42<br />

234<br />

262<br />

292<br />

G<br />

15<br />

15<br />

18<br />

J<br />

M14 x 1.5<br />

M14 x 1.5<br />

M16 x 1.5<br />

V<br />

15<br />

15<br />

15<br />

W<br />

17<br />

17<br />

20<br />

K<br />

15<br />

15<br />

17<br />

KA<br />

27<br />

27<br />

34<br />

M<br />

13<br />

13<br />

15<br />

Without rod boot<br />

With rod boot<br />

H Z ZZ e f h l<br />

110<br />

110<br />

120<br />

159<br />

159<br />

173<br />

221<br />

221<br />

241<br />

75<br />

75<br />

75<br />

40<br />

40<br />

40<br />

133<br />

133<br />

141<br />

0.2 stroke<br />

0.2 stroke<br />

0.2 stroke<br />

MM<br />

M30 x 1.5<br />

M30 x 1.5<br />

M36 x 1.5<br />

Z1<br />

182<br />

182<br />

194<br />

(mm)<br />

N<br />

30.5<br />

30.5<br />

34.5<br />

(mm)<br />

ZZ1<br />

244<br />

244<br />

262<br />

456

Air Cylinder / Series <strong>CS2</strong><br />

Accessory Bracket<br />

I Type Single Knuckle Joint∗<br />

Knuckle Pin / Clevis Pin<br />

ø<br />

ø<br />

x ø<br />

l<br />

ø<br />

CJ1<br />

CJP<br />

Part no.<br />

I-12A<br />

I-14A<br />

I-16A<br />

Applicable<br />

bore size<br />

(mm)<br />

125<br />

140<br />

160<br />

A1<br />

8<br />

8<br />

8<br />

A2<br />

54<br />

54<br />

60<br />

E1<br />

46<br />

48<br />

55<br />

L1<br />

100<br />

105<br />

110<br />

MM<br />

M30 x 1.5<br />

M30 x 1.5<br />

M36 x 1.5<br />

NDH10<br />

25<br />

28<br />

32<br />

+0.084<br />

0<br />

+0.084<br />

0<br />

+0.1<br />

0<br />

Material: Cast iron<br />

NX<br />

32<br />

36<br />

40<br />

–0.1<br />

–0.3<br />

–0.1<br />

–0.3<br />

–0.1<br />

–0.3<br />

RR1 U1<br />

27 33<br />

30 39<br />

34 39<br />

Applicable<br />

Part no. bore size (mm) Dd9<br />

IY-12<br />

IY-14<br />

IY-16<br />

125<br />

140<br />

160<br />

25<br />

28<br />

32<br />

∗ Cotter pin is included.<br />

–0.065<br />

–0.117<br />

–0.065<br />

–0.117<br />

–0.080<br />

–0.142<br />

L<br />

79.5<br />

86.5<br />

94.5<br />

Material: Carbon steel<br />

d Applicable<br />

l m (Drill through) cotter pin<br />

69.5 5 4 ø4 x 40<br />

76.5 5 4 ø4 x 40<br />

84.5 5 4 ø4 x 40<br />

CJ2<br />

CM2<br />

CG1<br />

MB<br />

Y Type Double Knuckle Joint∗<br />

Rod End Nut<br />

MB1<br />

CA2<br />

øND hole H10<br />

Shaft d9<br />

CS1<br />

ø<br />

<strong>CS2</strong><br />

Material: Cast iron<br />

Part no.<br />

Y-12A<br />

Y-14A<br />

Y-16A<br />

Applicable<br />

bore size<br />

(mm)<br />

125<br />

140<br />

160<br />

A1<br />

8<br />

8<br />

8<br />

∗ Use a single knuckle joint or a double knuckle joint individually.<br />

(Screw it entirely over the rod end threads and tighten it.)<br />

∗ Extend the dimensions of A, H. when using a single/double knuckle joint together with a rod end nut.<br />

(To extend dimensions A, H, refer to the below table, and specify the product as made-to-order -XAO.)<br />

∗ A pin and cotter pin are included with the double knuckled joint.<br />

E1<br />

L1<br />

MM<br />

46 100 M30 x 1.5 25<br />

48 105 M30 x 1.5 28<br />

55 110 M36 x 1.5 32<br />

NDH10<br />

+0.084<br />

0<br />

+0.084<br />

0<br />

+0.1<br />

0<br />

NX<br />

32<br />

36<br />

40<br />

+0.3<br />

+0.1<br />

+0.3<br />

+0.1<br />

+0.3<br />

+0.1<br />

NZ<br />

64<br />

72<br />

80<br />

–0.1<br />

–0.3<br />

–0.1<br />

–0.3<br />

–0.1<br />

–0.3<br />

RR1<br />

U1<br />

27 42<br />

30 47<br />

34 46<br />

Part no.<br />

NT-12<br />

NT-16<br />

Applicable<br />

bore size (mm)<br />

125/140<br />

160<br />

d<br />

M30 x 1.5<br />

M36 x 1.5<br />

Material: Rolled steel<br />

H B<br />

18 46<br />

21 55<br />

C D<br />

53.1 44<br />

63.5 53<br />

Single/Double Knuckle Joint<br />

A<br />

H<br />

α<br />

L1<br />

Symbol<br />

Bore<br />

size (mm)<br />

125<br />

140<br />

160<br />

H<br />

110<br />

110<br />

120<br />

A<br />

50<br />

50<br />

56<br />

α<br />

3.5<br />

3.5<br />

3.5<br />

H1<br />

L1<br />

100<br />

105<br />

110<br />

H1<br />

156.5<br />

161.5<br />

170.5<br />

Applicable knuckle joint part number<br />

I type single knuckle Y type double knuckle<br />

I-12A<br />

Y-12A<br />

I-14A<br />

Y-14A<br />

I-16A<br />

Y-16A<br />

A, H Dimensions when Mounting a<br />

Single/Double Knuckle Joint together<br />

with a Rod End Nut<br />

Bore size (mm)<br />

125<br />

140<br />

160<br />

A<br />

65<br />

65<br />

76<br />

H<br />

125<br />

125<br />

140<br />

D-<br />

-X<br />

Individual<br />

-X<br />

457<br />

Technical<br />

data

Series <strong>CS2</strong><br />

Auto Switch Proper Mounting Position (Detection at stroke end) and Its Mounting Height<br />

<br />

D-A3 type<br />

D-G3/K3 type<br />

A<br />

49<br />

G1/2<br />

Applicable cable O.D.<br />

ø6.8 to ø9.6<br />

≈ Hs<br />

<br />

D-A9/A9V type<br />

D-M9/M9V type<br />

D-M9W/M9WV type<br />

D-M9AL/M9AVL type<br />

A<br />

D-Z7/Z80 type<br />

D-Y59/Y69/Y7P/Y7PV type<br />

D-Y7W/Y7WV type<br />

D-Y7BAL type<br />

Auto switch<br />

≈ Hs<br />

34<br />

36 B<br />

Auto switch<br />

B<br />

D-A44 type<br />

A<br />

34.5<br />

G1/2<br />

Applicable cable O.D.<br />

ø6.8 to ø9.6<br />

≈ Hs<br />

A<br />

33<br />

≈ Hs<br />

56<br />

36<br />

Auto switch<br />

B<br />

B<br />

∗ The indicator light faces the inside.<br />

A<br />

30<br />

≈ Hs<br />

≈ Ht<br />

≈ Ht<br />

≈ Ht<br />

≈ Ht<br />

≈ Ht<br />

D-A5/A6 type<br />

Auto switch<br />

D-F5/J5/D-F5NTL type<br />

D-F5BAL/F59F type<br />

D-F5W/J59W type<br />

Auto switch<br />

B<br />

Auto Switch Proper Mounting Position<br />

Auto<br />

switch<br />

model<br />

Bore size A B A B A B A B A B A B A B<br />

125 4 4 8 8 1.5 1.5 0 0 2 2 4.5 4.5 9.5 9.5<br />

140 4 4 8 8 1.5 1.5 0 0 2 2 4.5 4.5 9.5 9.5<br />

160 4 4 8 8 1.5 1.5 0 0 2 2 4.5 4.5 9.5 9.5<br />

∗ Provided as guidelines for auto switch proper mounting position (detection at stroke end). When setting an auto switch, confirm the<br />

operation and adjust its mounting position.<br />

Auto Switch Mounting Height<br />

Auto<br />

switch<br />

model<br />

Bore size<br />

125<br />

140<br />

160<br />

458<br />

D-A9<br />

D-A9V<br />

D-A9<br />

D-A9V<br />

D-M9<br />

D-M9W<br />

D-M9AL<br />

Hs<br />

69<br />

76<br />

85<br />

Ht<br />

69.5<br />

76<br />

85<br />

D-M9<br />

D-M9V<br />

D-M9W<br />

D-M9WV<br />

D-M9AL<br />

D-M9AVL<br />

D-M9V<br />

D-M9WV<br />

D-M9AVL<br />

Hs<br />

71.5<br />

77.5<br />

86<br />

Ht<br />

69.5<br />

76<br />

85<br />

D-Z7/Z80<br />

D-Y5/Y6<br />

D-Y7P/Y7PV<br />

D-Y7W<br />

D-Y7WV<br />

D-Y7BAL<br />

D-Z7/Z80<br />

D-Y5/Y6<br />

D-Y7P<br />

D-Y7PV<br />

D-Y7W<br />

D-Y7WV<br />

D-Y7BAL<br />

Hs Ht<br />

69 69.5<br />

76 76<br />

85 85<br />

D-A5<br />

D-A6<br />

D-A3<br />

D-A44<br />

D-G39<br />

D-K39<br />

D-A3<br />

D-G39<br />

D-K39<br />

Hs<br />

116<br />

124<br />

134.5<br />

D-A59W<br />

D-A44<br />

Hs<br />

126<br />

134<br />

144.5<br />

D-F5W<br />

D-J59W<br />

D-F5BAL<br />

D-F5<br />

D-J5<br />

D-F59F<br />

D-A5<br />

D-A6<br />

D-A59W<br />

Hs<br />

75.5<br />

81<br />

89<br />

Ht<br />

69.5<br />

76.5<br />

87.5<br />

D-F5NTL<br />

(mm)<br />

(mm)<br />

D-F5<br />

D-J5<br />

D-F5W<br />

D-J59W<br />

D-F5BAL<br />

D-F59F<br />

D-F5NTL<br />

Hs Ht<br />

74.5 70<br />

80 76.5<br />

88 87.5

Air Cylinder Series <strong>CS2</strong><br />

Minimum Stroke for Auto Switch Mounting<br />

Auto switch model<br />

D-A9<br />

D-A9V<br />

D-M9<br />

D-M9W<br />

D-M9V<br />

D-M9WV<br />

D-M9AL<br />

D-M9AVL<br />

D-A5/A6<br />

D-A59W<br />

D-F5/J5<br />

D-F5W<br />

D-J59W<br />

D-F5BAL<br />

D-F59F<br />

D-F5NTL<br />

D-A3<br />

D-G39<br />

D-K39<br />

D-A44<br />

D-Z7<br />

D-Z80<br />

D-Y59<br />

D-Y7P<br />

D-Y7W<br />

D-Y69<br />

D-Y7PV<br />

D-Y7WV<br />

D-Y7BAL<br />

Number of auto switches<br />

mounted<br />

With 2 pcs. (Different surfaces,<br />

Same surface), With 1 pc.<br />

With n pcs.<br />

With 2 pcs. (Different surfaces,<br />

Same surface), With 1 pc.<br />

With n pcs.<br />

With 2 pcs. (Different surfaces,<br />

Same surface), With 1 pc.<br />

With n pcs.<br />

With 2 pcs. (Different surfaces,<br />

Same surface), With 1 pc.<br />

With n pcs.<br />

With 2 pcs. (Different surfaces,<br />

Same surface), With 1 pc.<br />

With n pcs.<br />

With 2 pcs. (Different surfaces,<br />

Same surface), With 1 pc.<br />

With 2 pcs. (Different surfaces,<br />

Same surface), With 1 pc.<br />

With n pcs. (Same surface)<br />

With 2 pcs. (Different surfaces,<br />

Same surface), With 1 pc.<br />

With n pcs. (Same surface)<br />

With<br />

2 pcs.<br />

With n pcs.<br />

With<br />

2 pcs.<br />

With n pcs.<br />

With n pcs.<br />

Different surfaces<br />

Same surface<br />

Different surfaces<br />

Same surface<br />

With 1 pc.<br />

Different surfaces<br />

Same surface<br />

Different surfaces<br />

Same surface<br />

With 1 pc.<br />

With 2 pcs. (Different surfaces,<br />

Same surface), With 1 pc.<br />

With n pcs.<br />

With 2 pcs. (Different surfaces,<br />

Same surface), With 1 pc.<br />

With n pcs.<br />

With 2 pcs. (Different surfaces,<br />

Same surface), With 1 pc.<br />

With n pcs.<br />

Mounting brackets<br />

other than center trunnion<br />

15<br />

15 + 40 (n–2)<br />

2<br />

(n = 2, 4, 6, 8···)<br />

10<br />

(n – 2)<br />

10 + 30 2<br />

(n = 2, 4, 6, 8···)<br />

15<br />

(n – 2)<br />

15 + 40 2<br />

(n = 2, 4, 6, 8···)<br />

10<br />

(n – 2)<br />

10 + 30 2<br />

(n = 2, 4, 6, 8···)<br />

25<br />

(n – 2)<br />

25 + 55 2<br />

(n = 2, 4, 6, 8···)<br />

35<br />

(n – 2)<br />

35 + 55 2<br />

(n = 2, 4, 6, 8···)<br />

35<br />

100<br />

15<br />

(n – 2)<br />

15 + 40 2<br />

(n = 2, 4, 6, 8···)<br />

10<br />

(n – 2)<br />

10 + 30 2<br />

(n = 2, 4, 6, 8···)<br />

20<br />

(n – 2)<br />

20 + 45 2<br />

(n = 2, 4, 6, 8···)<br />

100<br />

Center trunnion<br />

n: Number of auto switches (mm)<br />

ø125 ø140 ø160<br />

(n – 4)<br />

100 + 40 2<br />

(n = 4, 8, 12, 16···)<br />

75<br />

(n – 4)<br />

75 + 30 2<br />

(n = 4, 8, 12, 16···)<br />

105<br />

(n – 4)<br />

105 + 40 2<br />

(n = 4, 8, 12, 16···)<br />

80<br />

(n – 4)<br />

80 + 30 2<br />

(n = 4, 8, 12, 16···)<br />

20 115<br />

(n – 2)<br />

20 + 40 2<br />

(n = 2, 4, 6, 8···)<br />

35 + 30(n – 2)<br />

100 + 100(n – 2)<br />

15<br />

35<br />

55<br />

35 + 30(n – 2)<br />

55 + 55(n – 2)<br />

15<br />

(n – 4)<br />

115 + 40 2<br />

(n = 4, 8, 12, 16···)<br />

15 90<br />

(n – 2)<br />

15 + 30 2<br />

(n = 2, 4, 6, 8···)<br />

(n – 4)<br />

90 + 30 2<br />

(n = 4, 8, 12, 16···)<br />

125<br />

(n – 4)<br />

125 + 55 2<br />

(n = 4, 8, 12, 16···)<br />

145<br />

(n – 4)<br />

145 + 55 2<br />

(n = 4, 8, 12, 16···)<br />

105<br />

(n – 4)<br />

105 + 40 2<br />

(n = 4, 8, 12, 16···)<br />

90<br />

(n – 4)<br />

90 + 30 2<br />

(n = 4, 8, 12, 16···)<br />

115<br />

(n – 4)<br />

115 + 45 2<br />

(n = 4, 8, 12, 16···)<br />

105<br />

(n – 4)<br />

105 + 40 2<br />

(n = 4, 8, 12, 16···)<br />

80<br />

(n – 4)<br />

80 + 30 2<br />

(n = 4, 8, 12, 16···)<br />

110<br />

(n – 4)<br />

110 + 40 2<br />

(n = 4, 8, 12, 16···)<br />

85<br />

(n – 4)<br />

85 + 30 2<br />

(n = 4, 8, 12, 16···)<br />

110<br />

110 + 30(n – 2)<br />

(n = 2, 4, 6, 8···)<br />

110 + 100(n – 2)<br />

(n = 2, 4, 6, 8···)<br />

110<br />

110<br />

110 + 30(n – 2)<br />

(n = 2, 4, 6, 8···)<br />

110 + 50(n – 2)<br />

(n = 2, 4, 6, 8···)<br />

110<br />

110<br />

(n – 4)<br />

110 + 40 2<br />

(n = 4, 8, 12, 16···)<br />

95<br />

(n – 4)<br />

95 + 30 2<br />

(n = 4, 8, 12, 16···)<br />

120<br />

(n – 4)<br />

120 + 45 2<br />

(n = 4, 8, 12, 16···)<br />

120<br />

(n – 4)<br />

120 + 40 2<br />

(n = 4, 8, 12, 16···)<br />

95<br />

(n – 4)<br />

95 + 30 2<br />

(n = 4, 8, 12, 16···)<br />

135<br />

(n – 4)<br />

135 + 55 2<br />

(n = 4, 8, 12, 16···)<br />

155<br />

(n – 4)<br />

155 + 55 2<br />

(n = 4, 8, 12, 16···)<br />

110<br />

(n – 4)<br />

110 + 40 2<br />

(n = 4, 8, 12, 16···)<br />

85<br />

(n – 4)<br />

85 + 30 2<br />

(n = 4, 8, 12, 16···)<br />

115<br />

(n – 4)<br />

115 + 40 2<br />

(n = 4, 8, 12, 16···)<br />

90<br />

(n – 4)<br />

90 + 30 2<br />

(n = 4, 8, 12, 16···)<br />

115<br />

(n – 4)<br />

115 + 40 2<br />

(n = 4, 8, 12, 16···)<br />

100<br />

(n – 4)<br />

100 + 30 2<br />

(n = 4, 8, 12, 16···)<br />

125<br />

(n – 4)<br />

125 + 45 2<br />

(n = 4, 8, 12, 16···)<br />

459<br />

CJ1<br />

CJP<br />

CJ2<br />

CM2<br />

CG1<br />

MB<br />

MB1<br />

CA2<br />

CS1<br />

<strong>CS2</strong><br />

D-<br />

-X<br />

Individual<br />

-X<br />

Technical<br />

data

Series <strong>CS2</strong><br />

Operating Range<br />

(mm)<br />

Auto switch model<br />

Bore size<br />

125 140 160<br />

D-A9/A9V<br />

D-M9/M9V<br />

D-M9W/M9WV<br />

D-M9AL/M9AVL<br />

D-Z7/Z80<br />

D-A3/A44<br />

D-A5/A6<br />

D-A59W<br />

D-Y59/Y69<br />

D-Y7P/Y7PV<br />

D-Y7W/Y7WV<br />

D-Y7BAL<br />

D-F5/J5/F5W<br />

D-J59W/F5BAL<br />

D-F5NTL/F59F<br />

D-G39/K39<br />

12<br />

6<br />

14<br />

10<br />

17<br />

12<br />

5<br />

11<br />

12.5<br />

6.5<br />

14.5<br />

10<br />

17<br />

13<br />

5<br />

11<br />

11.5<br />

6.5<br />

13<br />

10<br />

17<br />

7<br />

5.5<br />

10<br />

∗ Since this is a guideline including hysteresis, not meant to be<br />

guaranteed.<br />

(Assuming approximately ±30% dispersion.)<br />

There may be the case it will vary substantially depending on an<br />

ambient environment.<br />

Auto Switch Mounting Bracket Part No.<br />

Auto switch model<br />

D-A9/A9V<br />

D-M9/M9V<br />

D-M9W/M9WV<br />

D-M9AL/M9AVL<br />

D-A5/A6<br />

D-A59W<br />

D-F5/J5<br />

D-F5NTL<br />

D-F5W/J59W<br />

D-F5BAL/F59F<br />

D-A3/A44<br />

D-G39/K39<br />

D-Z7/Z80<br />

D-Y59/Y69<br />

D-Y7P/Y7PV<br />

D-Y7W/Y7WV<br />

D-Y7BAL<br />

ø125<br />

BS5-125<br />

BT-12<br />

BS4-125<br />

Bore size (mm)<br />

ø140<br />

BS5-125<br />

BT-12<br />

BS4-125<br />

ø160<br />

BS5-160<br />

BT-16<br />

BS1-125 BS1-140 BS1-160<br />

BS4-160<br />

[Mounting screws set made of stainless steel]<br />

The following set of mounting screws made of stainless steel (including set screws) is<br />

also available. Use it in accordance with the operating environment. (Please order the<br />

auto switch mounting bracket separately, since it is not included.)<br />

BBA1: For D-A5, A6, F5, J5 type<br />

“D-F5BAL” auto switch is set on the cylinder with the stainless steel screws above when<br />

shipped.<br />

When only an auto switch is shipped independently, “BBA1” screws are attached.<br />

Note) When using the D-M9AL/M9AVL or Y7BAL model, do not use the steel set<br />

screw which is included with the auto switch mounting bracket in the above table<br />

(BS5-, BS4-). Please separately prepare the stainless steel screw set<br />

(BBA1), and select and use the M4 x 8L stainless steel set screw included in BBA1.<br />

Note 1) Refer to age 1365 for the details of BBA1 screws.<br />

• Shows an example of mounting the<br />

D-A9(V), M9(V), M9W(V),<br />

M9A(V)L model.<br />

460<br />

Other than the applicable auto switches listed in “How to Order”, the following auto switches can be mounted.<br />

For detailed specifications, refer to pages 1263 to 1371.<br />

Type<br />

Reed auto switch<br />

Solid state auto switch<br />

Model<br />

D-A90V<br />

D-A93V, A96V<br />

D-Z73, Z76<br />

D-A53, A56<br />

D-A67<br />

D-Z80<br />

D-F59, F5P, J59<br />

D-Y59A, Y59B, Y7P<br />

D-F59W, F5PW, J59W<br />

D-Y7NW, Y7PW, Y7BW<br />

D-F5BAL, Y7BAL<br />

D-F5NTL<br />

D-M9NV, M9PV, M9BV<br />

D-Y69A, Y69B, Y7PV<br />

D-M9NWV, M9PWV, M9BWV<br />

D-Y7NWV, Y7PWV, Y7BWV<br />

D-M9NAVL, M9PAVL, M9BAVL<br />

Electrical entry (Direction)<br />

Grommet (Perpendicular)<br />

Grommet (in-line)<br />

Grommet (in-line)<br />

Grommet (Perpendicular)<br />

Features<br />

Without indicator light<br />

∗ With pre-wired connector is available for solid state auto switches. For details, refer to pages 1328 to 1329.<br />

∗ Normally closed (NC = b contact), solid state switches (D-F9G, F9H, Y7G, Y7H type) are also available. For details, refer to pages 1290 to 1292.<br />

—<br />

Without indicator light<br />

—<br />

2-color indication<br />

Water resistant (2-color indication)<br />

With timer<br />

—<br />

2-color indication<br />

Water resistant (2-color indication)