lIne DIFFuSIOn Furnace - Despatch Industries

lIne DIFFuSIOn Furnace - Despatch Industries

lIne DIFFuSIOn Furnace - Despatch Industries

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

INSPIRED INNOVATION<br />

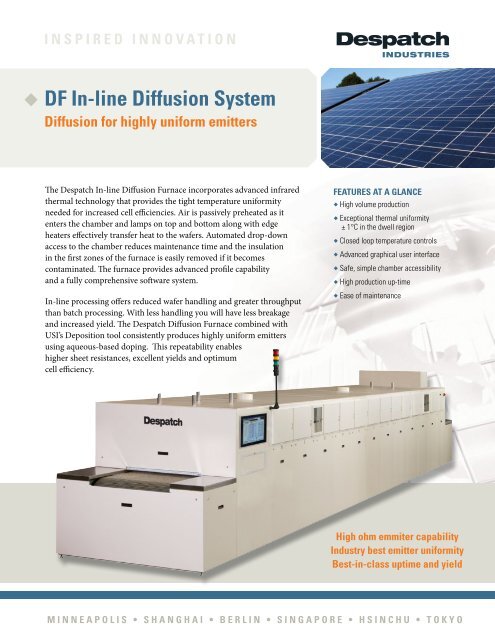

u DF In-line Diffusion System<br />

Diffusion for highly uniform emitters<br />

The <strong>Despatch</strong> In-line Diffusion <strong>Furnace</strong> incorporates advanced infrared<br />

thermal technology that provides the tight temperature uniformity<br />

needed for increased cell efficiencies. Air is passively preheated as it<br />

enters the chamber and lamps on top and bottom along with edge<br />

heaters effectively transfer heat to the wafers. Automated drop-down<br />

access to the chamber reduces maintenance time and the insulation<br />

in the first zones of the furnace is easily removed if it becomes<br />

contaminated. The furnace provides advanced profile capability<br />

and a fully comprehensive software system.<br />

In-line processing offers reduced wafer handling and greater throughput<br />

than batch processing. With less handling you will have less breakage<br />

and increased yield. The <strong>Despatch</strong> Diffusion <strong>Furnace</strong> combined with<br />

USI’s Deposition tool consistently produces highly uniform emitters<br />

using aqueous-based doping. This repeatability enables<br />

higher sheet resistances, excellent yields and optimum<br />

cell efficiency.<br />

features at a glance<br />

u High volume production<br />

u Exceptional thermal uniformity<br />

± 1°C in the dwell region<br />

u Closed loop temperature controls<br />

u Advanced graphical user interface<br />

u Safe, simple chamber accessibility<br />

u High production up-time<br />

u Ease of maintenance<br />

High ohm emmiter capability<br />

Industry best emitter uniformity<br />

Best-in-class uptime and yield<br />

Minneapolis • Shanghai • Berlin • Singapore • hsinchu • TOKYO

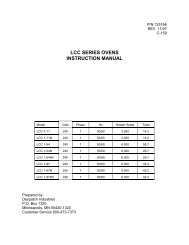

PRODUCT CONFIGURATION<br />

System size<br />

(length x width x height)<br />

Standard entrance table<br />

Heated length<br />

Cooling length<br />

Standard exit table<br />

Conveyor type<br />

Conveyor height above floor<br />

Product clearance<br />

Number of Lanes (156 x 156 mm) 5<br />

Conveyor width<br />

PROCESS CAPABILITIES<br />

Maximum temperature<br />

Approx. throughput (156 x 156 mm)<br />

Conveyor speed range<br />

Conveyor speed accuracy ± 0.5%<br />

Conveyor speed control<br />

Wafer size<br />

Sheet resistance<br />

DF 3630 production scale<br />

15,329 × 1,870 × 1,750 mm (603.5 x 74 x 69 inches)<br />

914 mm (36 inch)<br />

10,516 mm (414 inch)<br />

1,829 mm (72 inch)<br />

914 mm (36 inch)<br />

Lightweight balance spiral weave, Nichrome V material<br />

97.8 cm +/-3.6 cm (38.4 in +/-1.5 in)<br />

6.4 mm (0.25 inch)<br />

914 mm (36 inch)<br />

1000 °C (1832 °F)<br />

1200-1400 wafers/hr<br />

10–100 cm/min (4-40 ipm)<br />

Closed loop feedback<br />

100x100, 125x125, 156x156 mm (4, 5, 6 inch)<br />

Option for 210 x 210 mm (8 inch) support<br />

40 to >120 ohm/sq configurable<br />

In-line diffusion furnace<br />

u Tight temperature control for maximum<br />

process window<br />

u Maximum up-time for higher yields<br />

u Process profiles for high efficiency solar cells<br />

OPTIONS<br />

u Water-cooled heat exchanger<br />

u Failed element monitor<br />

u Master production control interface<br />

u Profiling systems<br />

u Ultrasonic belt cleaner/dryer<br />

u Uninterruptible power supply<br />

u Extended process profiles<br />

u Conveyor table extensions<br />

u CE Compliance<br />

A plasma system is<br />

available for chemicalfree<br />

conditioning of the<br />

wafer surface.<br />

Integrated Process<br />

Control System<br />

u Doper/<strong>Furnace</strong> recipe creation<br />

u Process window monitoring with<br />

audible and visual alarming<br />

u Real-time process window display<br />

u Data logging<br />

u Process repeatability<br />

The <strong>Despatch</strong> Diffusion <strong>Furnace</strong> combined with USI’s Deposition<br />

tool is a reliable system for highly uniform emitters.<br />

global offices<br />

Germany: +49 30 629 073 410 / europe@despatch.com<br />

China: +86-21-62365868 / shanghai@despatch.com<br />

Taiwan: +886-3-6588484 / taiwan@despatch.com<br />

Japan: +81-42-729-5355 / japan@despatch.com<br />

USA headquarters<br />

Phone: 1-952-469-5424<br />

toll free usa: 1-888-337-7282<br />

fax: 1-952-469-4513<br />

sales@despatch.com<br />

service@despatch.com<br />

www.despatch.com<br />

8860 207th Street West<br />

Minneapolis, MN 55044 USA<br />

© 2011 <strong>Despatch</strong> <strong>Industries</strong>. All rights reserved. <strong>Despatch</strong> is a registered trademark of <strong>Despatch</strong> <strong>Industries</strong> in the U.S. and other countries. DF-6-11