Kromschroder MODULINE Brochure - Combustion 911

Kromschroder MODULINE Brochure - Combustion 911

Kromschroder MODULINE Brochure - Combustion 911

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

–<br />

–<br />

–<br />

–<br />

–<br />

–<br />

Filter<br />

+<br />

Pressure<br />

monitoring<br />

+<br />

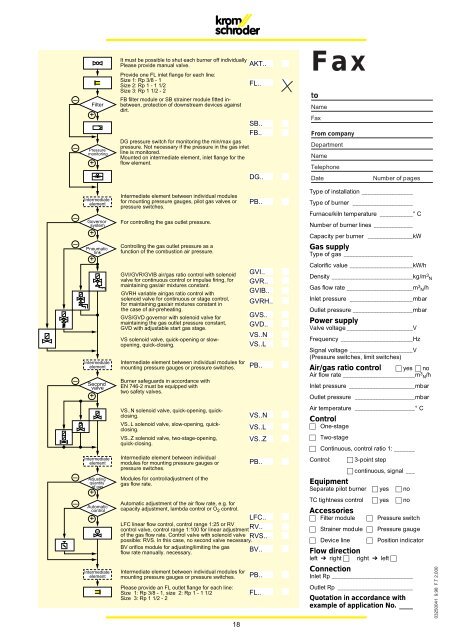

It must be possible to shut each burner off individually<br />

Please provide manual valve.<br />

Provide one FL inlet flange for each line:<br />

Size 1: Rp 3/8 - 1<br />

Size 2: Rp 1 - 1 1/2<br />

Size 3: Rp 1 1/2 - 2<br />

FB filter module or SB strainer module fitted inbetween,<br />

protection of downstream devices against<br />

dirt.<br />

DG pressure switch for monitoring the min/max gas<br />

pressure. Not necessary if the pressure in the gas inlet<br />

line is monitored.<br />

Mounted on intermediate element, inlet flange for the<br />

flow element.<br />

AKT..<br />

FL..<br />

SB..<br />

FB..<br />

DG..<br />

A<br />

F<br />

S<br />

F<br />

D<br />

Fax<br />

to<br />

Name<br />

Fax<br />

From company<br />

Department<br />

Name<br />

Telephone<br />

Date<br />

Number of pages<br />

–<br />

Intermediate<br />

element<br />

Governor<br />

system<br />

+<br />

Pneumatic<br />

link<br />

+<br />

Intermediate<br />

element<br />

Second<br />

valve<br />

+<br />

Intermediate element between individual modules<br />

for mounting pressure gauges, pilot gas valves or<br />

pressure switches.<br />

For controlling the gas outlet pressure.<br />

Controlling the gas outlet pressure as a<br />

function of the combustion air pressure.<br />

GVI/GVR/GVIB air/gas ratio control with solenoid<br />

valve for continuous control or impulse firing, for<br />

maintaining gas/air mixtures constant.<br />

GVRH variable air/gas ratio control with<br />

solenoid valve for continuous or stage control,<br />

for maintaining gas/air mixtures constant in<br />

the case of air-preheating.<br />

GVS/GVD governor with solenoid valve for<br />

maintaining the gas outlet pressure constant,<br />

GVD with adjustable start gas stage.<br />

VS solenoid valve, quick-opening or slowopening,<br />

quick-closing.<br />

Intermediate element between individual modules for<br />

mounting pressure gauges or pressure switches.<br />

Burner safeguards in accordance with<br />

EN 746-2 must be equipped with<br />

two safety valves.<br />

PB..<br />

GVI..<br />

GVR..<br />

GVIB..<br />

GVRH..<br />

GVS..<br />

GVD..<br />

VS..N<br />

VS..L<br />

PB..<br />

P<br />

G<br />

G<br />

G<br />

G<br />

G<br />

G<br />

V<br />

V<br />

P<br />

Type of installation _________________<br />

Type of burner ____________________<br />

Furnace/kiln temperature ___________° C<br />

Number of burner lines _____________<br />

Capacity per burner _______________kW<br />

Gas supply<br />

Type of gas _______________________<br />

Calorific value _____________________kW/h<br />

Density ___________________________kg/m 3 N<br />

Gas flow rate ______________________m 3 N/h<br />

Inlet pressure _____________________mbar<br />

Outlet pressure ____________________mbar<br />

Power supply<br />

Valve voltage ______________________V<br />

Frequency ________________________Hz<br />

Signal voltage _____________________V<br />

(Pressure switches, limit switches)<br />

Air/gas ratio control yes no<br />

Air flow rate ________________________m 3 N/h<br />

Inlet pressure ______________________mbar<br />

Outlet pressure ____________________mbar<br />

Intermediate<br />

element<br />

Adjusting<br />

quantity<br />

of gas<br />

+<br />

Automatic<br />

control<br />

+<br />

M<br />

Intermediate<br />

element<br />

VS..N solenoid valve, quick-opening, quickclosing.<br />

VS..L solenoid valve, slow-opening, quickclosing.<br />

VS..Z solenoid valve, two-stage-opening,<br />

quick-closing.<br />

Intermediate element between individual<br />

modules for mounting pressure gauges or<br />

pressure switches.<br />

Modules for control/adjustment of the<br />

gas flow rate.<br />

Automatic adjustment of the air flow rate, e.g. for<br />

capacity adjustment, lambda control or O 2 control.<br />

LFC..<br />

LFC linear flow control, control range 1:25 or RV<br />

control valve, control range 1:100 for linear adjustment RV..<br />

of the gas flow rate. Control valve with solenoid valve RVS..<br />

possible: RVS. In this case, no second valve necessary.<br />

BV orifice module for adjusting/limiting the gas BV..<br />

flow rate manually. necessary.<br />

Intermediate element between individual modules for<br />

mounting pressure gauges or pressure switches.<br />

Please provide an FL outlet flange for each line:<br />

Size 1: Rp 3/8 - 1, size 2: Rp 1 - 1 1/2<br />

Size 3: Rp 1 1/2 - 2<br />

VS..N<br />

VS..L<br />

VS..Z<br />

PB..<br />

PB..<br />

FL..<br />

V<br />

V<br />

V<br />

P<br />

L<br />

R<br />

R<br />

B<br />

P<br />

F<br />

Air temperature ____________________° C<br />

Control<br />

One-stage<br />

Two-stage<br />

Continuous, control ratio 1: _______<br />

Control: 3-point step<br />

continuous, signal ___<br />

Equipment<br />

Separate pilot burner yes no<br />

TC tightness control yes no<br />

Accessories<br />

Filter module Pressure switch<br />

Strainer module Pressure gauge<br />

Device line Position indicator<br />

Flow direction<br />

left ➔ right right ➔ left <br />

Connection<br />

Inlet Rp ___________________________<br />

Outlet Rp _________________________<br />

Quotation in accordance with<br />

example of application No. ____<br />

03250041 9.98 F.T 2.000<br />

18