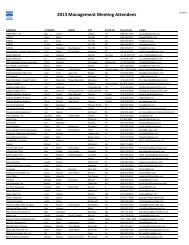

2011 AIMCAL MARCH MANAGEMENT MEETING Speakers

2011 AIMCAL MARCH MANAGEMENT MEETING Speakers

2011 AIMCAL MARCH MANAGEMENT MEETING Speakers

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>AIMCAL</strong><br />

<strong>AIMCAL</strong><br />

A Publication of the Association of International Metallizers, Coaters and Laminators<br />

Holiday 2010<br />

<strong>AIMCAL</strong>news<br />

Association News<br />

page 2<br />

Management Meeting<br />

page 2<br />

CEMA Division<br />

page 8<br />

On the Economic Front<br />

page 9<br />

New Members<br />

page 11<br />

People on the Move<br />

page 12<br />

Member News<br />

page 16<br />

From the Blogs…<br />

page 28<br />

www.<strong>AIMCAL</strong>.org

<strong>2011</strong> <strong>AIMCAL</strong> <strong>MARCH</strong><br />

<strong>MANAGEMENT</strong> <strong>MEETING</strong><br />

FORWARD FOCUSED | LEADERSHIP | ECONOMICS<br />

<strong>Speakers</strong>:<br />

Peter Schutz - Former CEO of Porsche AG<br />

“Leadership - the Driving Force” - From his best selling book, “The Driving Force”,<br />

Mr. Schutz will present why the only sustainable advantage that companies<br />

have is getting extraordinary results from ordinary people.<br />

Jack Kaine - Speaker and instructor on negotiation<br />

“Negotiating for Success” - Negotiating is more than gaining the favor of people<br />

from whom you want things.<br />

Robert Fry - Dupont Economist<br />

“Global Economic Update” - Provides a look at the economic indicators and<br />

forecasts that are shaping our industry.<br />

J. Christen Adams - Attorney and former Justice Department prosecutor<br />

“The US Department of Justice and the Rule of Law” - Former lead prosecutor<br />

of the New Black Party in the US Justice Department, Christen Adams has<br />

appeared on all the major news networks as a whistleblower to DOJ positions<br />

which he believes are outside of established objective legal standards.<br />

Keith Blankenship - Attorney and speaker on trademark protection<br />

“The Legal Aspects of Branding” - The legal aspects of acquiring and protecting<br />

goodwill in your company’s name, products, and services.<br />

PLUS: Industry Overviews on the global PET and OPP<br />

March 20 - 23, <strong>2011</strong><br />

The Bolders Resort<br />

Carefree, Arizona<br />

Go to www.<strong>AIMCAL</strong>.org for details

<strong>AIMCAL</strong><br />

<strong>AIMCAL</strong> serves as the global forum for the flexible metallizing,<br />

coating and laminating industry by providing<br />

resources, services and information that promote and<br />

encourage use of member companies’ products and<br />

services while seeking solutions of interest; collecting<br />

and distributing information to improve awareness; and<br />

fostering an environment that maintains relationships<br />

and a spirit of cooperation among member companies.<br />

2010 BOARD OF DIRECTORS<br />

President<br />

Liz Josephson, Applied Materials Corporation<br />

315-682-7081 • fax 315-682-1406<br />

Vice President<br />

Bob Connelly, Madico, Inc.<br />

(781) 756-4154 • fax (781) 935-0548<br />

Treasurer<br />

Dan Bemi, MEGTEC Systems<br />

262-255-3275 • fax 262-255-3578<br />

Past President<br />

Mike Engel, FLEXcon Co., Inc.<br />

508-885-8243 • fax 508-885-1402<br />

DIRECTORS AT LARGE<br />

David Bryant, Vacuum Depositing Inc.<br />

502-969-4227 • fax 502-969-3378<br />

Mark Montsinger, Bryce Corp.<br />

901-369-5120 • fax 901-369-5572<br />

Gary Phillips, Bekaert Specialty Films, LLC<br />

858-614-1268 • fax 858-614-1468<br />

Dan Roy, Terphane Inc.<br />

585-657-5827 • fax 585-657-5838<br />

Steve Sedlak, ESK Ceramics<br />

800-833-7608 • fax 734-944-1375<br />

Ron Schmidt, Maxcess International Corporation<br />

405-752-7863 fax (405) 755-8425<br />

COMMITTEE CHAIRS<br />

Awards & Competition Committee<br />

Steve Sedlak, ESK Ceramics, USA<br />

800-833-7608 • fax 734-944-1375<br />

Coating & Laminating Committee<br />

Ingrid Brase, Henkel Adhesives<br />

908-685-5088 • fax 908-685-5061<br />

Gregory Williams, Exopack Advanced Coatings<br />

800-688-9171 • fax 704-845-4307<br />

Resistance Vacuum Web Coating Committee -<br />

RVWCC<br />

Greg Tullo, Bobst Group, General Vacuum<br />

919-846-5560 • fax 919-870-1182<br />

Andrew Jack, Bobst Group, General Vacuum<br />

(44)1706-622442 • fax (44)1706-6224422<br />

Environmental Committee<br />

Chris Anguil, Anguil Environmental Systems, Inc.<br />

414-365-6400• fax 414-365-6410<br />

Economics Committee<br />

Bill Stratton, Adhesives Research<br />

717-227-3254• fax 717 235-8466<br />

Safety Committee<br />

Tim Carroll, DUNMORE Corp<br />

215-781-8895• fax 215-781-9293<br />

Web Handling Committee<br />

Ron Schmidt, Maxcess International Corporation<br />

405-752-7863 fax 405-755-8425<br />

<strong>AIMCAL</strong><br />

Executive Director - Craig Sheppard<br />

Senior Executive Assistant - Tracey Ingram<br />

Events Manager - Linda Couto<br />

201 Springs St. • Fort Mill, SC 29715<br />

803-802-7820 • fax 803-802-7821<br />

E-Mail: aimcal@aimcal.org Web: www.aimcal.org<br />

Newsletter Editor - Hallie Forcinio<br />

216-351-5824 • fax 216-351-5684<br />

CONVERTING QUARTERLY<br />

Editorial: Mark Spaulding<br />

262.697.0525 • mark@aimcal.org<br />

Advertising: Cindi Stocker<br />

785.271.5801 • cindi@petersonpublications.com<br />

Copyright © 2010 <strong>AIMCAL</strong><br />

HO L I D A Y 2010<br />

From the President<br />

Liz Josephson, President<br />

As our name change to the Association of<br />

International Metallizers, Coaters and Laminators<br />

becomes official, <strong>AIMCAL</strong> is looking forward to a busy<br />

and productive <strong>2011</strong> that will generate many benefits<br />

for members and the customers we serve.<br />

In a brand new venture for the association, <strong>AIMCAL</strong> will begin publishing<br />

a trade magazine for the converting industry. Scheduled to premiere in<br />

February <strong>2011</strong>, Converting Quarterly features strong technical content from<br />

some of the best technical minds in the industry. Led by veteran converting<br />

journalist Mark Spaulding as associate publisher and editor-in-chief,<br />

the quarterly print magazine is supported by a 24/7 Website plus a weekly<br />

e-newsletter that is already keeping everyone up-to-date on the latest news<br />

in the international web coating community. Members are encouraged to<br />

support this new industry service and take advantage of the opportunities it<br />

presents to raise the profile of your company and products. Suggestions for<br />

editorial content are always welcome, and don’t forget members are eligible<br />

for discounted ad rates. In addition, revenues from the magazine will be reinvested<br />

in <strong>AIMCAL</strong> to generate new benefits for members and the industry at<br />

large.<br />

A strong Converting School curriculum has been assembled for <strong>2011</strong> with<br />

courses scheduled in both the United States and Belgium. Classes begin in<br />

April. The complete schedule is printed on p. 5, and registration materials<br />

are available on <strong>AIMCAL</strong>’s redesigned Website, cal.org.<br />

www.aim-<br />

If you haven’t visited lately, make sure you check out<br />

the new Website. It combines a cleaner look with simpler<br />

navigation. With drop-down menus and many direct<br />

links, it’s easy to locate the information you need. Since the<br />

redesign coincides with a move to a newer platform, the<br />

Website is now easier to update and expand to keep information<br />

current and accessible.<br />

Another not-to-be-missed event, <strong>AIMCAL</strong>’s annual<br />

Management Meeting, will be held March 20-23, <strong>2011</strong>, at<br />

The Boulders Resort in Carefree, Arizona. The strong program<br />

with its mix of educational and networking sessions<br />

makes this a must-attend event for all members of top management<br />

in the converting industry.<br />

I hope to see you there,<br />

Liz Josephson<br />

President of <strong>AIMCAL</strong><br />

Dear Fellow<br />

<strong>AIMCAL</strong> Members:<br />

AIM<br />

ASSO<br />

INDUSTRIA<br />

COATERS<br />

www.aimcal.org Holiday 2010 1

Holiday 2010<br />

Association News<br />

<strong>AIMCAL</strong><br />

Members to Hold<br />

Management<br />

Meeting in<br />

Arizona<br />

<strong>AIMCAL</strong>’s annual Management<br />

Meeting will be held March<br />

20-23, <strong>2011</strong>, at The Boulders<br />

Resort in Carefree, Arizona, near<br />

Scottsdale.<br />

Sponsors include Dow Packaging<br />

& Converting, Elgin, Illinois, DuPont<br />

Teijin Films, Chester, Virgina and<br />

Toray Plastics (America), Inc., North<br />

Kingstown, Rhode Island.<br />

Dow, DuPont and Toray are primary sponsors of the<br />

<strong>2011</strong> edition of <strong>AIMCAL</strong>’s annual Management Meeting.<br />

In the keynote address on<br />

Monday, March 21, <strong>2011</strong>, Peter Schultz<br />

of Harris & Schultz Inc., Naples, Florida,<br />

will discuss how to manage ordinary<br />

people for extraordinary results, drawing<br />

on his experiences as chief executive<br />

officer of Porsche AG.<br />

Other sessions include the<br />

<strong>AIMCAL</strong> Annual Meeting and a presentation<br />

by J. Christian Adams, counsel at<br />

General Counsel P.C., McLean, Virginia.<br />

Referred to by many as the Justice<br />

Department whistleblower, Adams<br />

was the lead prosecutor in the Black<br />

Panther voter intimidation lawsuit that<br />

the Department of Justice (DOJ0 opted to<br />

drop. He will discuss how current DOJ<br />

2 Holiday 2010 www.aimcal.org<br />

policies are impacting businesses, civil<br />

rights and the rule of law.<br />

Improving negotiating skills is the<br />

goal of Jack Kaine of J.W. Kaine Ltd.,<br />

Kansas City, Missouri, in his half-day<br />

workshop, Negotiating for Success.<br />

Kaine, who has taught negotiating at<br />

several universities and presents courses<br />

to dozens of audiences each year, will<br />

discuss practical ways to improve negotiating<br />

skills, reveal the three elements to<br />

take under control during a negotiation,<br />

and provide tips for creating a positive<br />

climate and using questions effectively.<br />

Brand protection is the subject of a<br />

session led by M. Keith Blankenship,<br />

partner at<br />

General<br />

Counsel, P.C.<br />

Blankenship<br />

will discuss<br />

branding<br />

issues related<br />

to the converting<br />

industry<br />

and explain<br />

how to acquire<br />

trademark<br />

rights without<br />

the expense of<br />

agency filings.<br />

Robert C. Fry Jr., Ph.D.<br />

Dupont Economist<br />

Other sessions<br />

include the always-fascinating<br />

Global Economic Update from Dr.<br />

Robert Fry, senior associate economist<br />

at DuPont, Wilmington, Delaware; and<br />

updates on the oriented polypropylene<br />

film and polyester film industries.<br />

In addition to the business-building<br />

sessions, the agenda includes many<br />

of the meeting’s traditional networking<br />

features that everyone enjoys including<br />

the Awards Dinner and Presentation on<br />

Sunday, March 20, <strong>2011</strong>, the shotgunstart<br />

Golf Scramble at 1:30 p.m. on<br />

Tuesday, March 22, and the Dine-around<br />

on Tuesday evening. Non-golfers may<br />

sign up for an optional Desert Four<br />

Wheel Jeep Drive Adventure on Tuesday<br />

afternoon.<br />

Hotel reservations should be made<br />

as soon as possible by calling the Group<br />

Line at +1 888-318-4319 or online at<br />

www.theboulders.com. When calling the<br />

Group Line, please reference <strong>AIMCAL</strong><br />

to receive the group rate. Website<br />

reservations will require the Group/<br />

Convention Code, AAAI03, which is<br />

case sensitive. Meeting registration<br />

materials are available on the <strong>AIMCAL</strong><br />

Website, www.aimcal.org.<br />

Fall Technical<br />

Conference<br />

Draws Positive<br />

Reviews, Great<br />

Presentations<br />

The <strong>AIMCAL</strong> Fall Technical<br />

Conference, October 17-20, 2010, in<br />

Myrtle Beach, South Carolina, drew<br />

a good crowd and rave reviews from<br />

attendees.<br />

With all the great presentations,<br />

judges had a tough job choosing the<br />

recipients of the 2010 John Matteucci<br />

Technical Excellence Awards. One presentation<br />

was recognized in each conference<br />

track. Both papers will be published<br />

in February <strong>2011</strong> in the premiere<br />

issue of Converting Quarterly, <strong>AIMCAL</strong>’s<br />

new technical publication and Website<br />

for the web-processing, converting and<br />

finishing industry.<br />

In the Coating/Laminating Track,<br />

the 2010 John Matteucci Technical<br />

Excellence Award went to Steve Zagar,<br />

Jeff Quass, and Dan Bemi of MEGTEC<br />

Systems, Inc., DePere, Wisconsin, for<br />

the presentation, Drying Laboratory<br />

Methods for the Development of<br />

Complex Empirical Drying Data. The<br />

paper, which included several case<br />

studies, described tools and laboratory<br />

methods used to visualize drying characteristics<br />

and develop the empirical<br />

drying rate data needed to refine and<br />

enhance the efficacy of predictive theoretical<br />

models.<br />

In the Vacuum Web Coating Track,<br />

Nick Copeland and Robert Astbury of<br />

General Vacuum Equipment, part of<br />

Bobst Group North America, Flexible<br />

Materials, Charlotte, North Carolina,<br />

and Donald J. McClure, Ph.D., of<br />

Acuity Consulting and Training, Siren,<br />

Wisconsin, received top honors for<br />

a two-part presentation, Evaporated<br />

Aluminum on Polyester: Optical,<br />

Electrical and Barrier Properties as a<br />

Function of Thickness and Time. Part I

described the measurement of optical,<br />

electrical, and barrier properties relative<br />

to aluminum film thickness and time,<br />

as well as how optical density varies<br />

across and down the web. Part II examined<br />

a suite of analytical measurements<br />

to characterize film thicknesses and<br />

discussed how film thickness can predict<br />

optical and electrical properties.<br />

Judges also named seven Honorable<br />

Mention recipients.<br />

In the Coating/Laminating Track,<br />

Honorable Mentions were presented to:<br />

• William M. Stratton of Adhesives<br />

Research, Inc., Glen Rock,<br />

Pennsylvania, for his presentation,<br />

Lean Planning and Replenishment Pull<br />

Systems;<br />

• Terry Thompson of PCT Engineered<br />

Systems, LLC, Davenport, Iowa, for<br />

New Developments in Low Energy EB<br />

Equipment;<br />

• Jim Miceli of Rockwell Automation,<br />

Milwaukee, Wisconsin, for What Have<br />

Your Drives Done for You Lately?; and<br />

• Bob Oesterreich of Air Liquide<br />

Industrial US, Houston, Texas, for<br />

Gas Phase Priming - Applications &<br />

Benefits.<br />

In the Vacuum Web Coating Track,<br />

Honorable Mentions recognized:<br />

• Mark Hodgson of Dupont Teijin<br />

Films, Chester, Virginia, for Cleaning<br />

of Polyester Films Prior to Vacuum<br />

Coating;<br />

• Dante Ferrari of Celplast Metallized<br />

Products, Toronto, Ontario, Canada, for<br />

Properties of EB Top-Coated Metallized<br />

Films Prepared in Vacuum; and<br />

• Charles L. Geraci, Ph.D., of the<br />

National Institute for Occupational<br />

Safety and Health (NIOSH),<br />

Washington, D.C., for Nanotechnology<br />

in the Workplace: NIOSH Research to<br />

Meet the Challenge.<br />

The Matteucci Awards program<br />

continues a tradition established by<br />

the International Vacuum Web Coating<br />

Conference, which merged with<br />

<strong>AIMCAL</strong>’s Fall Technical Conference<br />

in 2001. It is named in honor of John<br />

Matteucci (1938-2000), a world-renowned<br />

expert in vacuum coating technology<br />

and equipment.<br />

<strong>AIMCAL</strong> Prepares<br />

for the Launch of<br />

CQ and a New Era<br />

<strong>AIMCAL</strong> begins a new era in<br />

February <strong>2011</strong> with the launch of<br />

Converting Quarterly (CQ). The new<br />

technical journal for the global converting<br />

industry includes print and online<br />

versions. A weekly e-newsletter and<br />

Website are already live. Subscribe to<br />

the print or electronic CQ at www.convertingquarterly.com.<br />

As the launch date approaches,<br />

<strong>AIMCAL</strong> News chats with Mark<br />

Spaulding, associate publisher and editor<br />

in chief of CQ, about the journey so<br />

far and what we’ll be reading.<br />

<strong>AIMCAL</strong> News: CQ has been serving<br />

the web-processing industry for four<br />

months now. How are things going?<br />

Mark: I’m enjoying the positive<br />

response we’ve been getting for our new<br />

venture from converters, suppliers, academia,<br />

and the industry in general. The<br />

Website, our weekly eNewsletter and<br />

the print magazine (which premieres in<br />

February <strong>2011</strong>) have all been receiving<br />

a warm reception. There’s strong sup<br />

port for our focus on technical-journal<br />

articles as well as the Q&A technical<br />

columns and Blogs. I think our readers<br />

and followers understand that we’re<br />

providing a unique resource of technical<br />

information that’s otherwise missing<br />

from the marketplace.<br />

<strong>AIMCAL</strong> News: How is the relationship<br />

with <strong>AIMCAL</strong> working out?<br />

Mark: It’s good to be part of <strong>AIMCAL</strong><br />

where its mission of providing value<br />

to the industry is more important than<br />

corporate profits. I see Converting<br />

Quarterly as an essential part of the<br />

three-legged operational platform any<br />

association must have. The education<br />

and tradeshow presence <strong>AIMCAL</strong> has<br />

had for 40 years, is now being joined<br />

by publishing with CQ and our online<br />

offerings.<br />

<strong>AIMCAL</strong>’s strong international<br />

presence is already going a long way<br />

toward making CQ a global medium<br />

for the industry. We’ve gotten plenty of<br />

interest from foreign members who are<br />

approaching us with editorial contributions<br />

and as advertising prospects.<br />

<strong>AIMCAL</strong> News: What can readers<br />

expect to see in the first issue of the<br />

magazine?<br />

Mark: Along with a half dozen technical<br />

articles on web handling, webcoating<br />

and finishing, there will be a<br />

detailed market-focus series on printed<br />

electronics and photovoltaics. Dr. Peter<br />

Harrop of IDTechEx will cover developments<br />

in various web-printing methods<br />

for flexible electronics and solar cells.<br />

Rory Wolf of Enercon Industries will<br />

describe surface-treating processes for<br />

photovoltaics, and Prof. Malcolm Keif<br />

of Cal Poly will provide a primer/glossary<br />

for printed electronics. We’ll also<br />

be publishing the two Mattuecci Awardwinning<br />

papers from the 2010 <strong>AIMCAL</strong><br />

Fall Technical Conference.<br />

<strong>AIMCAL</strong> News: Will Converting<br />

Quarterly replace the <strong>AIMCAL</strong><br />

Newsletter?<br />

Mark: No. The <strong>AIMCAL</strong> News will<br />

still be published regularly for all association<br />

members. But instead of being<br />

printed and mailed, it will be email<br />

delivered in a digital format, letting<br />

readers print out the pages or articles<br />

they want. There also will be a condensed<br />

version in the CQ magazine.<br />

This will allow <strong>AIMCAL</strong> to directly reach<br />

the thousands of CQ subscribers, who<br />

are not yet <strong>AIMCAL</strong> members, with<br />

association news.<br />

<strong>AIMCAL</strong> News: What other digital/<br />

online initiatives is CQ taking?<br />

Mark: From the get-go, CQ has<br />

been on the forefront of social media<br />

with LinkedIn and Twitter. I’m posting<br />

industry news and Blog items on both<br />

accounts just about daily, and I often<br />

report from tradeshows and conferences<br />

through our live Twitter feeds. One<br />

measure of our online success is that the<br />

amount of time people spend at convertingquarterly.com<br />

is 50 percent higher<br />

than the Internet average.<br />

<strong>AIMCAL</strong> News: Some people say<br />

print is dead. Why not just be completely<br />

online?<br />

Mark: Sure. That might be the way<br />

to go someday, but I think the technology<br />

isn’t there just yet. Think of it this<br />

way: Instant coffee didn’t kill the coffee<br />

market. It just offered the product in a<br />

different form. That’s kind of what we’re<br />

doing, too. Offering our technical content<br />

in multiple forms—print and online.<br />

Some of our technical articles will be<br />

rather long and obviously much easier<br />

to read in print, along with the true portability<br />

of a printed magazine. We’ll still<br />

have a digital edition available for those<br />

who want to electronically page through<br />

an issue. And you can then print out the<br />

articles you want.<br />

<strong>AIMCAL</strong> News: Any other thoughts?<br />

Mark: On a personal level, I’m really<br />

enjoying my 30-second commute to the<br />

office. Working at home has its pros and<br />

cons, but in the winter it’s much better<br />

than the 100-mile roundtrip commute I<br />

used to have. Go Packers!<br />

Save the Date<br />

<strong>AIMCAL</strong> Fall Technical<br />

Conference<br />

October 23-26, <strong>2011</strong><br />

Peppermill Resort, Reno,<br />

Nevada<br />

www.aimcal.org Holiday 2010 3

Members<br />

Technical committees<br />

Begin<br />

Palnning for <strong>2011</strong><br />

<strong>AIMCAL</strong>’s technical committees will<br />

start meeting soon to begin planning<br />

the Fall Technical Conference <strong>2011</strong>. It<br />

will take place October 23-26, <strong>2011</strong> at the<br />

Peppermill Resort in Reno, Nevada, and<br />

is expected to consist of its two traditional<br />

tracks, Vacuum Web Coating and<br />

Coating/Laminating, as well as several<br />

joint sessions.<br />

“We encourage all members to<br />

get involved on a committee,” says<br />

Craig Sheppard, executive director<br />

of <strong>AIMCAL</strong>. If interested in serving on<br />

any of the technical committees that<br />

organize the program, please contact<br />

Sheppard at craig@aimcal.org.<br />

New Year Rings<br />

in New Name -<br />

<strong>AIMCAL</strong><br />

At the stroke of midnight on New<br />

Year’s Eve, <strong>AIMCAL</strong> officially becomes<br />

the Association of International<br />

Metallizers, Coaters and Laminators.<br />

The replacement of “Industrial” with<br />

“International” reflects the increasingly<br />

global presence of the group, which<br />

currently has members from more<br />

than 15 countries. <strong>AIMCAL</strong> members<br />

voted overwhelmingly in favor of the<br />

name change in March 2010 during<br />

the group’s Management Meeting in La<br />

Jolla, California.<br />

“<strong>AIMCAL</strong> truly has become the global<br />

leader for the converting industry,”<br />

says <strong>AIMCAL</strong> President Liz Josephson,<br />

sales manager for Web Coating<br />

Products at Applied Materials, Inc.,<br />

Fairfield, California. “For the past several<br />

years, our presence at international<br />

forums has been growing,” she notes,<br />

adding, “We have organized pavilions<br />

at international trade shows and<br />

presented Converting School courses<br />

in Europe and India, as well as in the<br />

United States.”<br />

The global converting community<br />

also benefits from a wide array of<br />

Internet-based offerings including educational<br />

webinars and other technical<br />

resources (www.convertingportal.com),<br />

job board (www.<strong>AIMCAL</strong>jobs.com), and<br />

4 Holiday 2010 www.aimcal.org<br />

the newly redesigned <strong>AIMCAL</strong> Website<br />

(www.aimcal.org).<br />

To expand services to the global converting<br />

community, <strong>AIMCAL</strong> is launching<br />

Converting Quarterly magazine in<br />

February <strong>2011</strong> and is already emailing<br />

its weekly companion, Converting<br />

Quarterly ENews. A related Website<br />

(www.convertingquarterly.com) and<br />

social media sites, including six blogs --<br />

Converting Curmudgeon, Vacuum Web<br />

Coating, Web Coating, Web Handling<br />

and Converting, Substrate Secrets and<br />

Drives for Web Handling -- provide<br />

access to technical information 24/7.<br />

“There always was some confusion<br />

about what was meant by ‘industrial,’”<br />

recalls Craig Sheppard, executive director<br />

of the association, which celebrated<br />

its 40 th birthday in 2010. “This is a name<br />

that will serve us well for the next 40<br />

years,” he concludes.<br />

Converting<br />

School Schedules<br />

19 Courses<br />

The <strong>2011</strong> edition of <strong>AIMCAL</strong><br />

Converting School consists of courses<br />

held in both the United States and<br />

Europe. The first of 19 classes, Web<br />

Coating and Drying, begins April 5,<br />

<strong>2011</strong>, in Brussels, Belgium. The school<br />

year ends in Brussels on October 14 with<br />

the conclusion of Web Processing for<br />

Barrier. The 17 classes in between are<br />

divided among Brussels, Philadelphia,<br />

Pennsylvania, and Ontario, California.<br />

Most courses are held at least<br />

once in the United States and once in<br />

Europe. Subjects include Optimizing<br />

Extrusion-Based Lamination and<br />

Coating, Web Handling and Converting,<br />

Winding: Machines, Mechanics<br />

and Measurements, Drives in Web<br />

Handling and Converting, and Solution<br />

Preparation and Mixing.<br />

Popular instructors returning for<br />

<strong>2011</strong> include Dr, Jonathan Summers, Dr.<br />

Harvey Thompson, Dr. Eldridge Mount,<br />

Dr. David Roisum, Dr. Charles Bishop,<br />

Clarence Klassen, Dr. Ted Lightfoot, and<br />

Dr. Kenneth McCarthy.<br />

The complete schedule is shown in<br />

the accompanying table. Full details<br />

and registration materials may be found<br />

on the <strong>AIMCAL</strong> Website, www.aimcal.<br />

org. See the schedule On next page.<br />

<strong>2011</strong> Membership<br />

Deadline<br />

Approaches<br />

Premium Membership Carries<br />

Many Perks<br />

It’s membership renewal time.<br />

Upgrading to Premium status more than<br />

pays for itself during the year. Only $42<br />

more per month, delivers benefits worth<br />

more than $2000! Premium Membership<br />

costs $2495 and provides all the benefits<br />

of basic membership, plus:<br />

• One 2-for-1 registration to a<br />

Converting School class (value $899)<br />

• One 2-for-1 registration to a CEMA<br />

Fundamentals Seminar (value $525)<br />

• One 30-day premium listing on<br />

<strong>AIMCAL</strong> Jobs (value $150)<br />

• Logo identification and bold listing<br />

with company profile in the <strong>AIMCAL</strong><br />

SourceBook – printed, online, and<br />

in the reprint that will accompany<br />

the third-quarter issue of Converting<br />

Quarterly<br />

• Identification as a Premium Member<br />

in the <strong>AIMCAL</strong> SourceBook<br />

• Banner ad in the SourceBook online<br />

directory.<br />

• Customization of the online company<br />

profile to include links, banners, special<br />

promotions, new products, etc.<br />

• Special discounts for advertising in<br />

Converting Quarterly<br />

Basic Membership welcomes all the<br />

member’s employees to the <strong>AIMCAL</strong><br />

community and provides the following<br />

benefits:<br />

• Full access to the <strong>AIMCAL</strong> Members<br />

Only area on the Website, including<br />

conference proceedings, Ask <strong>AIMCAL</strong>,<br />

business leads, economic/research<br />

reports and resumes sent to <strong>AIMCAL</strong><br />

Jobs<br />

• Quarterly <strong>AIMCAL</strong> Economic Index<br />

report on the state of the industry<br />

• Company profile and directory<br />

listing in the printed and online<br />

SourceBook – including publication in<br />

the new Converting Quarterly (thirdquarter<br />

issue)<br />

• Member discounts on <strong>AIMCAL</strong> meetings,<br />

conferences, seminars, technical<br />

resources, Converting Quarterly ads,<br />

and more<br />

• Free job opening postings on the<br />

<strong>AIMCAL</strong> Jobs Website and access to all<br />

submitted resumes<br />

• Free corporate access to the<br />

<strong>AIMCAL</strong> Audio Library<br />

• Business leads from the Ask <strong>AIMCAL</strong><br />

service

• Free membership in CEMA, the<br />

Converting Equipment Manufacturers<br />

Association to all eligible companies.<br />

• Subscription to Converting Quarterly<br />

for all members on the <strong>AIMCAL</strong> mailing<br />

list<br />

• Posting of your company news on<br />

<strong>AIMCAL</strong> Websites and in <strong>AIMCAL</strong><br />

News<br />

Basic Membership costs $1995. To<br />

renew online, visit www.aimcal.org.<br />

Website Features<br />

Easier Navigation<br />

An array of drop-down menus and<br />

quick links makes the <strong>AIMCAL</strong> Website<br />

easier to use. With Member News, the<br />

<strong>AIMCAL</strong> SourceBook and Ask <strong>AIMCAL</strong><br />

featured prominently on the new home<br />

page, visitors can find resources quickly<br />

and identify potential suppliers.<br />

The redesign also moves the Website<br />

to a new technology platform, making it<br />

easier to update and expand. For more<br />

information, visit www.aimcal.org.<br />

Are You LinkedIn?<br />

Members can join the <strong>AIMCAL</strong><br />

Group on LinkedIn and open new networking<br />

doors. If you’re not already a<br />

LinkedIn member, create a free account<br />

at www.linkedin.com. Once you have an<br />

account, click on the Groups Directory,<br />

search for <strong>AIMCAL</strong>, and click on Join<br />

Group.<br />

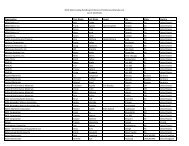

Converting School <strong>2011</strong> Schedule<br />

<strong>AIMCAL</strong> Organizes<br />

Technical<br />

Program and<br />

Pavilion at First<br />

ICE USA<br />

<strong>AIMCAL</strong> will support its members<br />

and the first edition of ICE USA, April 6-8,<br />

<strong>2011</strong>, at the Orange County Convention<br />

Center in Orlando, Florida, by organizing<br />

an <strong>AIMCAL</strong> Pavilion as well as a<br />

technical conference program.<br />

Conference sessions are organized<br />

in three tracks: Web Coating,<br />

Web Handling/Winding, and Package<br />

Printing and Converting. Each day<br />

opens at 9 a.m. with a market-oriented<br />

keynote address. On Wednesday,<br />

April 6, Thomas Blaige of Blaige &<br />

DATE COURSE LOCATION INSTRUCTOR<br />

April 5-6 Web Coating and Drying Brussels, Belgium<br />

April 7-8<br />

Optimizing Extrusion-Based Lamination<br />

and Coating Technology<br />

Brussels, Belgium<br />

Dr. Jonathon Summers<br />

Dr. Bruce Ikin<br />

Dr. Nick Kapur<br />

Dr. Eldridge Mount<br />

April 12-13 Web Handling and Converting Philadelphia, Pennsylvania Dr. David Roisum<br />

April 14-15<br />

Winding: Machines, Mechanics<br />

and Measurements<br />

Philadelphia, Pennsylvania<br />

Dr. David Roisum<br />

April 14-15 Web Processing for Barrier Philadelphia, Pennsylvania Dr. Charles Bishop<br />

May 10-11<br />

Drives in Web Handling<br />

and Converting<br />

Philadelphia, Pennsylvania<br />

Clarence Klassen<br />

May 10-11 Web Handling and Converting Brussels, Belgium Dr. David Roisum<br />

May 12-13<br />

May 12-13<br />

Optimizing Extrusion-Based<br />

Lamination and Coating Technology<br />

Winding: Machines, Mechanics<br />

and Measurements<br />

Philadelphia, Pennsylvania<br />

Brussels, Belgium<br />

May 24-25 Web Coating and Drying Ontario, California<br />

Dr. Eldridge Mount<br />

Dr. David Roisum<br />

Dr. Ed Cohen<br />

Dr. E.J. (Ted) Lightfoot<br />

May 26-27 Solution Preparation and Mixing Ontario, California Dr. Kenneth McCarthy<br />

August 23-24 Web Coating and Drying Brussels, Belgium<br />

Dr. Jonathon Summers<br />

Dr. Harvey Thompson<br />

Dr. Bruce Ikin<br />

August 25-26 Solution Preparation and Mixing Brussels, Belgium Dr. Kenneth McCarthy<br />

September 13-14 Web Handling and Converting Ontario, California Dr. David Roisum<br />

September 15-16<br />

Winding: Machines, Mechanics<br />

and Measurements<br />

Ontario, California<br />

October 3-4 Web Coating and Drying Philadelphia, Pennsylvania<br />

Dr. David Roisum<br />

Dr. Ed Cohen<br />

Dr. E.J. (Ted) Lightfoot<br />

October 5-6 Solution Preparation and Mixing Philadelphia, Pennsylvania Dr. Kenneth McCarthy<br />

October 11-12<br />

Drives in Web Handling<br />

and Converting<br />

Brussels, Belgium<br />

Clarence Klassen<br />

October 13-14 Web Processing for Barrier Brussels, Belgium Dr. Charles Bishop<br />

www.aimcal.org Holiday 2010 5

Co., Chicago, Illinois, discusses Global<br />

Consolidation in the Packaging Industry.<br />

On Thursday, April 7, Frank Perkowski<br />

of Business Development Advisory, Inc.,<br />

Marietta, Georgia, speaks about Future<br />

Outlook, Challenges, and Opportunities<br />

in Paper Based Packaging Markets.<br />

Friday, April 8, sees Corey Reardon of<br />

AWA Alexander Watson Associates,<br />

Amsterdam, The Netherlands, presenting<br />

an Overview of the Global Label Market.<br />

Web Coating/Laminating track topics<br />

include optimized die technology,<br />

plasma treatment, coatweight and thickness<br />

measurement, and drying technologies.<br />

Topics in the Web Handling/<br />

Winding track include conveyance roller<br />

nip mechanics, precision tension control,<br />

simulation of drive systems, and quantifying<br />

web bagginess. Package Printing<br />

and Converting track topics include solvent-related<br />

emissions, advances in color<br />

measurement, laser processing of flexible<br />

packaging materials and ultravioletcurable<br />

pressure-sensitive adhesives.<br />

Cost is $79 for a one-day pass, $149 for<br />

a three-day pass. All conference passes<br />

include a three-day pass to the ICE USA<br />

show floor. A complete agenda may be<br />

found on the <strong>AIMCAL</strong> Website, www.<br />

aimcal.org/events/ice-usa-<strong>2011</strong>.aspx.<br />

On Tuesday, April 5, immediately<br />

prior to the show, CEMA will<br />

offer its popular seminars, Slitting<br />

and Rewinding Fundamentals for<br />

Converters and Coating and Laminating<br />

Fundamentals for Converters.<br />

Participation in either seminar provides<br />

a free pass to the show as well as an<br />

invitation from the show organizer to<br />

participate in the Exhibitors Reception,<br />

which takes place immediately following<br />

the conclusion of the seminar (see story,<br />

p. 8).<br />

Participants in the <strong>AIMCAL</strong> Pavilion<br />

receive a 10 x 10-foot, turnkey, hard wall<br />

booth including carpeting, a table and<br />

two chairs, counter with storage, lights,<br />

electrical outlet, header and logo graphics.<br />

For more details, check out the<br />

<strong>AIMCAL</strong> and ICE Websites, www.aimcal.<br />

org and www.ice-x-usa.com, respectively.<br />

ICE USA Launches<br />

Social Media<br />

Network<br />

The ICE USA Social Media Network,<br />

launched by ICE USA, Burlington,<br />

Massachusetts, facilitates online conversations,<br />

information sharing, and idea<br />

6 Holiday 2010 www.aimcal.org<br />

generation within the worldwide converting<br />

industry. The new network will be<br />

driven by social media sites, Facebook,<br />

Twitter, LinkedIn, and YouTube, plus the<br />

new ICE USA <strong>2011</strong> Blog at www.iceusa<strong>2011</strong>.wordpress.com.<br />

The various platforms such as Twitter<br />

and Facebook allow individuals to converse<br />

on a variety of topics ranging from<br />

technical issues to career advice. The<br />

ICE USA network will feature content<br />

from social media platforms, blogs, videos,<br />

surveys, chats, personal profiles and<br />

links to case histories, articles, product<br />

updates, and other valuable information<br />

from leading industry resources. It also<br />

will provide updates on ICE USA, April<br />

6-8, <strong>2011</strong>, in Orlando, Florida.<br />

AWA Issues<br />

Report on Wine<br />

Labeling Market<br />

With pressure-sensitive solutions<br />

enjoying the most significant growth<br />

today and forecast to continue to take<br />

an increased market share around the<br />

world, wine labeling is one of the most<br />

dynamic market niches for product identification<br />

and decoration technologies,<br />

according to a study by AWA Alexander<br />

Watson Associates, Amsterdam, The<br />

Netherlands.<br />

The AWAreness Report, Global<br />

Wine and Wine Label Market &<br />

Technology Review 2010, provides an<br />

up-to-the-minute overview of the opportunities<br />

for label producers, material suppliers,<br />

and wine makers. Outlining the<br />

overall structure of the global wine market<br />

and its defined geographical regions,<br />

the report drills down into wine labeling<br />

in those regions, growth drivers, threats,<br />

and opportunities. It details the available<br />

wine label materials and formats,<br />

and examines the available product<br />

decoration technologies in partnership<br />

with today’s chosen packaging styles,<br />

from glass and plastic bottles to aseptic<br />

cartons, metal cans, and pouches. Wine<br />

label converting is discussed, and the<br />

report concludes with a directory of suppliers<br />

of label materials and labels.<br />

Details of the AWAreness Report,<br />

Global Wine and Wine Label Market<br />

& Technology Review 2010, are available<br />

on the AWA Alexander Watson<br />

Associates Website. For more information,<br />

visit www.awa-bv.com.<br />

CPP EXPO Sets<br />

Attendance<br />

Record, Plans <strong>2011</strong><br />

and 2012 Events<br />

A record 7,239 attendees toured CPP<br />

EXPO, October 31-November 3, 2010, in<br />

Chicago, Illinois. Every industry sector<br />

improved attendance including tag and<br />

label, flexible packaging, folding carton,<br />

and corrugated. “With the current<br />

uncertainty in the economy, it is great to<br />

see these types of numbers,” says Leo<br />

Nadolske of H.A. Bruno, LLC, Paramus,<br />

New Jersey, the show organizer.<br />

The <strong>2011</strong> edition of CPP EXPO, which<br />

includes an <strong>AIMCAL</strong> Pavilion, will be colocated<br />

once more with PACK EXPO Las<br />

Vegas, September 26-28, <strong>2011</strong>, at the Las<br />

Vegas Convention Center.<br />

In 2012, the event will switch to new<br />

schedule: CPP EXPO will take place<br />

regionally in even-numbered years<br />

and hold a new international event in<br />

Chicago in odd-numbered years. The<br />

schedule for 2012-2014 includes:<br />

• April 18-19, 2012, CPP EXPO – The<br />

Cleveland Show, I-X Center, Cleveland,<br />

Ohio<br />

• April 2013, CPP EXPO – The<br />

Main International Event, Stephens<br />

Convention Center, Rosemont, Illinois<br />

(near Chicago’s O’Hare Airport)<br />

• May 2014, CPP EXPO – The Vegas<br />

Show, Mandalay Bay Convention<br />

Center, Las Vegas, Nevada<br />

“While we will always look back with<br />

gratitude toward PACK EXPO and the<br />

Packaging Machinery Manufacturers<br />

Institute for allowing us to develop and<br />

co-locate CPP EXPO alongside PACK<br />

EXPO; it has always been our mutual<br />

understanding that one day, we would…<br />

separate our shows,” says Nadolske.<br />

“The demographic analysis of our<br />

attendees influenced the decision to<br />

bring events to Cleveland, Chicago and<br />

Las Vegas,” he notes, adding, “We are<br />

taking our shows directly to the customers.”<br />

For more information, visit www.<br />

cppexpo.com.

www.aimcal.org Holiday 2010 7

President<br />

Doug Krasucki,<br />

R.D. Specialties<br />

Vice President<br />

Doug Brockelbank,<br />

The Montalvo Corporation<br />

Secretary/Treasurer<br />

Sean Craig,<br />

Maxcess International<br />

TRUSTEES<br />

Seamus Lafferty, Stanford/An<br />

Accraply Company<br />

John Looser, Faustel, Inc.<br />

Leo Nadolske, CPP EXPO<br />

Dave Rumson, Sltting Consultant<br />

Michael Sellers, Advance<br />

Systems, Inc.<br />

Tim Walker, TJ Walker and<br />

Associates<br />

Keon Wild, Davis-Standard, LLC<br />

MISSION<br />

Our mission is to promote,<br />

advance and represent the<br />

interests of converting<br />

manufacturers in the industry<br />

and markets served.<br />

GOALS<br />

A. To advance the use of converting<br />

equipment.<br />

B. To provide opportunities for<br />

the exchange of ideas.<br />

C. To lobby on behalf of the<br />

industry concerning legislation<br />

and regulations that may have<br />

impact on the industry.<br />

D. To provide educational opportunities<br />

for the membership<br />

and the industry.<br />

E. To establish and maintain liaison<br />

between organizations<br />

with similar interests.<br />

Ho l i d ay 2010<br />

President’s<br />

Message<br />

All Systems Go?<br />

As I write this (I<br />

have to put that in<br />

because change can<br />

happen overnight)<br />

the economy is picking<br />

up, consumer<br />

spending is picking<br />

up and retailers<br />

have added a percent<br />

to their predictions<br />

of the year over year increase in<br />

Christmas spending. Most converters<br />

and their suppliers have been growing<br />

all year and at better rates than the<br />

overall economy and certainly better<br />

than retail. So will <strong>2011</strong> be even better<br />

than 2010? My financial advisor is still<br />

waiting for that correction to happen<br />

before he recommends getting back<br />

into stocks. One thing we do know is<br />

we have to be ready for the future. We<br />

can always cut back (and we’ve gotten<br />

very good at that) but we also need to be<br />

ready for the uptick or we will miss out<br />

on sales opportunities and fall behind<br />

the competition. So, we need to keep<br />

investing in our infrastructure and our<br />

people so we’re ready for the future.<br />

That’s a great lead in to the <strong>2011</strong> CEMA<br />

Fundamentals Seminar that focuses on<br />

Slitting and Rewinding and Coating and<br />

Laminating. The Seminar is co-locating<br />

with ICE in Orlando, Florida this coming<br />

April. The Seminar is designed<br />

for new engineers and experienced<br />

operators. It’s also an excellent way<br />

for converting equipment people to see<br />

where they fit in to the bigger picture.<br />

So, if you’re a converter or an equip<br />

ment supplier, there is sure to be some of<br />

your people who could benefit from the<br />

Fundamentals Seminar and help you<br />

get ready for the future. Here’s hoping<br />

your <strong>2011</strong> is even better than expected.<br />

Doug Krasucki<br />

R.D. Specialties, Webster, New York<br />

President, CEMA<br />

CEMA Schedules<br />

Pre-ICE USA<br />

Seminars<br />

CEMA will hold both of its<br />

Fundamentals seminars on Tuesday, April<br />

5, <strong>2011</strong>, the day before ICE USA opens. The<br />

seminars will take place at the Orange<br />

County Convention Center, where ICE<br />

USA will be held April 6-8.<br />

The cost of either seminar is $295 and<br />

includes a free visitor badge for ICE USA<br />

as well as an invitation to an end-of-theday<br />

Exhibitor Reception, sponsored by the<br />

show organizers.<br />

The Slitting and Rewinding<br />

Fundamentals for Converters is designed<br />

for anyone involved in slitting and rewinding<br />

of paper, film, nonwovens, and other<br />

continuous flexible materials. Experts in<br />

slitting and rewinding equipment will discuss<br />

best practices related to winding, slitting,<br />

cores and cutting, retrofitting, chucks,<br />

shafts, spreading, and guiding. Content<br />

targets both novice and experienced personnel<br />

and includes question-and-answer<br />

sessions throughout the day.<br />

The Coating and Laminating<br />

Fundamentals for Converters seminar is<br />

designed for beginners and more experienced<br />

personnel involved in coating and<br />

laminating of paper, film, nonwovens,<br />

and other continuous flexible materials.<br />

Each step of the web coating operation<br />

is covered from unwind to rewind.<br />

Knowledgeable instructors provide real<br />

world advice for improving productivity,<br />

reducing downtime and waste, and<br />

increasing yield and throughput. Frequent<br />

question-and-answer periods make it possible<br />

for presenters to address specific<br />

concerns. For more information, visit www.<br />

aimcal.org/events/cema-fundamentalsseminars/overview.aspx.<br />

Free Webinar<br />

Series:<br />

<strong>AIMCAL</strong> Webinars on converting<br />

topics are now accessible via the<br />

Converting Portal,<br />

www.convertingportal.com.<br />

The free series, which began early<br />

in 2009, discusses relevant<br />

topics and technology<br />

developments with leading experts.<br />

Register at www.convertingportal.<br />

com/webinarSchedule.htm<br />

8 Holiday 2010 www.aimcal.org

Ro B e R T FR y<br />

On the<br />

Economic<br />

Front<br />

Signs of<br />

Reacceleration<br />

U.S. economic data released so far in<br />

November 2010 have been surprisingly<br />

positive and may point to a reacceleration<br />

in U.S. growth after the below-trend<br />

growth of the second and third quarters.<br />

The flood of positive data reports<br />

began on November 1, when a jump in<br />

the Institute of Supply Management’s<br />

Manufacturing Index (the PMI) pointed<br />

to stronger growth in the manufacturing<br />

sector in October. This was later confirmed<br />

by data<br />

on industrial<br />

production in<br />

manufacturing,<br />

which<br />

showed a<br />

0.5% increase<br />

in October<br />

(and upward<br />

revisions to<br />

August and<br />

September).<br />

Perhaps<br />

most notably,<br />

the ISM New<br />

Orders Index,<br />

Robert C. Fry Jr., Ph.D.<br />

Dupont Economist<br />

the component of the PMI that leads<br />

industrial production, jumped from 51.1<br />

in September to 58.9 in October. The<br />

level of the Index is consistent with solid<br />

growth in manufacturing during the next<br />

month or two.<br />

The jump in the Index, should it continue,<br />

would signal an acceleration of<br />

growth next spring. One might be tempted<br />

to dismiss the jump in the PMI as a<br />

one-month blip, but a big jump in the<br />

Philadelphia Fed Survey in November<br />

suggests another good month for the<br />

PMI. The ISM’s Non-manufacturing Index<br />

also jumped in October. The business<br />

activity index rose to 58.4, which is consistent<br />

with a 3.1% annualized growth<br />

rate in GDP, better than most forecasts<br />

for fourth quarter growth.<br />

Motor vehicle sales rose in October<br />

to their highest level since September<br />

2008 (excluding August 2009, when sales<br />

were boosted by the “cash-for-clunkers”<br />

program). This helped power retail sales<br />

to a 1.2% increase, the biggest since<br />

March. Excluding autos and gasoline,<br />

retail sales rose 0.4% in October and<br />

have risen 1.8% from July to October<br />

after declining from March to July.<br />

Employment growth was also much<br />

better than<br />

expected in<br />

October. Payroll<br />

employment<br />

rose by 151,000,<br />

and declines<br />

in the prior two<br />

months were<br />

revised smaller<br />

by a total of<br />

110,000. Private<br />

sector employment<br />

was up<br />

159,000, the<br />

fourth consecutive<br />

increase<br />

of more than<br />

100,000 and the<br />

tenth consecutive<br />

increase overall. A decline in new<br />

claims for unemployment insurance suggests<br />

that the improvement in job growth<br />

seen in October could persist.<br />

Major leading indexes also rose in<br />

October. The Conference Board’s Index<br />

of Leading Economic Indicators rose<br />

0.5% for a second straight month. The<br />

major U.S. leading indexes published by<br />

the Economic Cycle Research Institute<br />

(ECRI) were also up. Some of the rise in<br />

the leading indexes and the brightening<br />

in the outlook generally is the result of<br />

an increase in stock prices. Despite some<br />

recent declines, the Dow Jones Industrial<br />

Average is up about 15% since early July.<br />

This is partly the (intended) result of the<br />

Federal Reserve’s program to buy longterm<br />

Treasury securities. With the yearover-year<br />

change in the Consumer Price<br />

Index excluding food and energy at an<br />

all-time low in October, this “quantitative<br />

easing” is likely to continue.<br />

The only bad reports so far this<br />

month have been for the beleaguered<br />

housing sector. Housing starts fell 11.7%<br />

in October, taking them to the lowest<br />

level since their April 2009 cyclical<br />

trough. Increases in housing permits (in<br />

October) and the National Association<br />

of Home Builders Housing Market Index<br />

(in November) were much too small to<br />

signal a significant near-term increase<br />

in starts.<br />

Data from China also point to a reacceleration.<br />

Although the year-over-year<br />

growth rates for industrial production<br />

published by the National Bureau of<br />

Statistics show stable growth in the 13%-<br />

14% range, data seasonally adjusted by<br />

this office show production growing at<br />

a 16% annual rate from July to October<br />

after growing at just a 1.5% rate from<br />

March to July. Both of the purchasing<br />

managers’ indexes (PMIs) published for<br />

China rose in October, with the new<br />

www.aimcal.org Holiday 2010 9

orders indexes rising into the high 50s.<br />

However, the reacceleration in China<br />

could be mostly behind us. The People’s<br />

Bank of China has raised reserve<br />

requirements for the fifth time this year<br />

to slow inflation and is likely to raise<br />

interest rates before the end of the year.<br />

This would presumably slow growth next<br />

year. Allowing the Yuan to appreciate<br />

against the dollar, perhaps necessary to<br />

keep quantitative easing in the United<br />

States from causing unacceptably high<br />

inflation in China, would also curb<br />

export-led growth.<br />

PMIs (total and new orders) also<br />

turned up in the Euro-Zone, United<br />

Kingdom, and India in October after<br />

recent declines. The PMI rose to a new<br />

cyclical high in Poland, where growth in<br />

industrial production is nearly as strong<br />

as in China. PMIs fell in Japan and in<br />

Korea. The latter is a bit of a concern<br />

since Korea tends to lead the global<br />

economy. Except in China and perhaps<br />

Taiwan, industrial production indexes,<br />

which have a long publication lag in<br />

many countries, do not show any acceleration<br />

yet. On a seasonally adjusted<br />

basis, production has been flat to slightly<br />

down over the last several months in<br />

Japan, India, Korea, and Brazil. Any<br />

reacceleration is either prospective or too<br />

recent to be captured by the industrial<br />

production data.<br />

The biggest source of uncertainty<br />

about the global economic outlook is<br />

Europe. In the aggregate, the European<br />

economy is doing better than expected<br />

(so far) as strength in Germany, Sweden,<br />

and Poland has offset weakness in<br />

Greece, Portugal, Spain, and Ireland.<br />

Easier monetary policy, to aid countries<br />

affected by sovereign debt crises (Ireland<br />

being the most current example) could<br />

continue to boost growth in the healthier<br />

economies. However, a spreading financial<br />

crisis combined with fiscal consolidation<br />

could ultimately slow growth<br />

even in the stronger countries.<br />

The good run of<br />

economic data in<br />

the United States,<br />

particularly the<br />

improvement in<br />

leading indicators,<br />

does not mean that<br />

the U.S. economy<br />

will now experience<br />

the kind of strong<br />

recovery that typically<br />

follows a deep<br />

recession; recovery<br />

will remain sub-par.<br />

It does mean that<br />

the risk of falling<br />

back into recession<br />

has declined<br />

and that growth is<br />

likely to be stronger in <strong>2011</strong> than previously<br />

thought. A temporary extension<br />

of the Bush tax cuts, more likely now<br />

than before the elections, would bolster<br />

the case for stronger growth. But even<br />

if growth throughout <strong>2011</strong> is no stronger<br />

than previously expected, better-thanexpected<br />

growth in the fourth quarter of<br />

2010 will mean that forecasts for annual<br />

growth rates in <strong>2011</strong> need to be revised<br />

up. Nevertheless, annual growth is likely<br />

to be no higher in the United States in<br />

<strong>2011</strong> than in 2010 and will be lower in<br />

most of the world. Furthermore, even if<br />

sequential (month-to-month, quarter-toquarter)<br />

growth accelerates soon, yearover-year<br />

growth is likely to slow into<br />

the second quarter of next year before it<br />

turns up again.<br />

Copyright © 2010 E. I. du Pont de<br />

Nemours and Company. All rights<br />

reserved. Reprinted with permission.<br />

Save the Dates<br />

March Management<br />

Meeting <strong>2011</strong><br />

March 20-23, <strong>2011</strong><br />

The Boulders Resort<br />

Carefree, Arizona<br />

<strong>AIMCAL</strong><br />

Index<br />

Optimism Fades<br />

With eight out of 10 indicators falling,<br />

the Current General Activity Index<br />

in <strong>AIMCAL</strong>’s Business Outlook Survey<br />

plummeted 16 points to 45.85 in the third<br />

quarter of 2010 from 61.70 at the end of<br />

the second quarter of 2010.<br />

On the bright side, the Number of<br />

Employees and Capital Expenditures<br />

indicators registered increases for the<br />

quarter. In addition, even with the<br />

decline in the Current General Activity<br />

Index, it’s 10 points higher than it was at<br />

the end of the third quarter in 2009.<br />

Optimism about <strong>2011</strong> has slipped<br />

three points since the six-month forcast at<br />

the end of the second quarter of 2010 and<br />

six points since the third quarter of 2009.<br />

Although <strong>AIMCAL</strong> members scored six<br />

out of 10 forecasted business indicators<br />

positively, lower confidence in New<br />

Orders, Delivery Time, Inventories and<br />

Average Employee Work Week dragged<br />

the Forecasted General Activity Index<br />

down.<br />

The third quarter 2010 survey<br />

includes responses from 48 member<br />

companies: 15 converters, 15 equipment<br />

suppliers, 13 material suppliers and five<br />

firms that participate in more than one of<br />

the business segments. The full report is<br />

available in the Members Only section of<br />

the <strong>AIMCAL</strong> Website, www.aimcal.org.<br />

GOT NEWS?<br />

If your company has a<br />

People On The Move<br />

announcement or press<br />

release for Member News,<br />

send it via email to:<br />

Tracey@<strong>AIMCAL</strong>.org<br />

Please include the subject<br />

line:<br />

GOT NEWS?<br />

10 Holiday 2010 www.aimcal.org

Ho l i d ay 2010<br />

New Member Profiles<br />

7 New Companies<br />

Join <strong>AIMCAL</strong><br />

<strong>AIMCAL</strong> membership roster<br />

grew by six since the last<br />

newsletter. New members<br />

include Chemsultants International,<br />

Mentor, Ohio; Galileo Vacuum Systems,<br />

Alpharetta, Georgia; Plextronics, Inc.,<br />

Pittsburgh, Pennsylvania; Sensory<br />

Analytics, LLC, Greensboro, North<br />

Carolina; Web Plastics Co., Houston,<br />

Texas; and Yeagle Technology Inc.,<br />

Ashford, Connecticut, University of<br />

Massachusetts, Amherst, Massachusetts.<br />

Chemsultants International<br />

(www.chemsultants.com)<br />

Chemsultants provides product<br />

development and consulting services<br />

and offers comprehensive pilot coating<br />

and small scale specialty coating and<br />

slitting services. Other services include<br />

consulting, training, and education<br />

related to adhesives, inks, and specialty<br />

coatings. An A2LA-accredited<br />

laboratory provides full-service testing<br />

for adhesives, coatings, and materials.<br />

Subsidiary ChemInstruments, Inc.<br />

manufactures instruments for adhesive<br />

and materials testing and also produces<br />

test sample preparation equipment<br />

including lab coaters and laminators.<br />

ChemInstruments equipment is used<br />

in both research and development<br />

labs and production floor quality<br />

assurance/control environments.<br />

Sales contact is:<br />

Joe Mausar<br />

+1 440-974-3080<br />

jmausar@chemsultants.com<br />

Galileo Vacuum Systems,<br />

Inc.<br />

(www.galileovacuum.com)<br />

Galileo Vacuum Systems (GVS) is<br />

a leading manufacturer of vacuum<br />

web coating equipment with more<br />

than 400 installations worldwide. The<br />

company is based in Prato, Italy; the<br />

North American subsidiary, Galileo<br />

Vacuum Systems Inc., has provided<br />

marketing and product support to the<br />

American continent since 1986. In 2009<br />

GVS merged with Galileo Nanotech,<br />

a corporation created by the Russian<br />

State Corporation of Nanotechnologies<br />

(RUSNANO). Products include the<br />

GAMMA-S multi-chamber and multiprocess<br />

system with hybrid deposition<br />

technologies for flexible displays, solar<br />

cells, antireflective films, and metallic<br />

pigments; the GAMMA-P multi-chamber,<br />

high-productivity metallizer for roll<br />

diameters up to 1.8 meters (78 inches) for<br />

metallized paper, nonwovens, and specialty<br />

fabrics; 2- to 4-meter-wide (80-160<br />

inch) GOLD wide-web aluminum metallizer<br />

for packaging films, decorative,<br />

and other functional products; and 1.2-<br />

and 1.6-meter-wide (50 inch and 65 inch)<br />

V 8 Series aluminum metallizer. A wide<br />

range of options make this machine<br />

a flexible tool for converters and toll<br />

metallizers: high-resolution patterning<br />

(Flexomet), stripe metallizing, highbarrier<br />

coatings. Additionally, Galileo<br />

manufactures a full range of matching<br />

slitter-rewinders and web-handling<br />

equipment. Equipment integration<br />

encompasses commonality of design for<br />

the handling of metallized films as well<br />

as full data compatibility.<br />

Sales contact is:<br />

Paolo Raugei, executive vice president<br />

+1 678-691-5695 ext. 101<br />

praugei@att.net<br />

Plextronics, Inc.<br />

(www.plextronics.com)<br />

Plextronics specializes in printed<br />

solar, lighting, and other electronics,<br />

with a focus on organic solar cell and<br />

organic light-emitting diode lighting,<br />

specifically the conductive inks and<br />

process technologies that enable those<br />

and similar applications.<br />

Sales contact is:<br />

Kelly Weinheimer<br />

+1 412-423-2030 ext.100<br />

kweinheimer@plextronics.com<br />

Sensory Analytics, LLC<br />

(www.sensoryanalytics.com)<br />

Sensory Analytics supplies<br />

SpecMetrix Lab and In-line film and<br />

coating measurement systems. The<br />

noncontact, nonradioactive, and<br />

nondestructive systems improve<br />

production quality and throughput<br />

while reducing labor, material, and<br />

spoilage costs. These environmentally<br />

preferred tools reliably measure coating<br />

thickness or film weight on a wide<br />

range of coating applications where<br />

transparent, semitransparent, and<br />

opaque coatings are used as protective<br />

barriers on a wide variety of substrates.<br />

SpecMetrix® systems provide<br />

a noncontact, nonradioactive means<br />

to measure ultraviolet coatings, hard<br />

coat, adhesives, barrier coatings, and<br />

other finishes on films, metals, and<br />

other substrates. SpecMetrix® systems<br />

deliver real-time coating thickness or<br />

film weight data for wet or dry coatings,<br />

thereby increasing production<br />

throughput and improving in-process<br />

quality control.<br />

Sales contact is:<br />

Vivian Poteat<br />

+1 336-315-6090<br />

Vivian@sensoryanalytics.com<br />

Web Plastics Company<br />

(www.webplasticscompany.com)<br />

Houston-based Web Plastics Co.<br />

distributes flexible packaging films<br />

including all grades of polyester and<br />

biaxially oriented polypropylene.<br />

Sales contact is:<br />

Srinivasan Sridhar<br />

+1 281-880-6566<br />

sridhar@webplco.com<br />

Yeagle Technology Inc.<br />

(www.ytionline.com)<br />

Yeagle Technology sells new and<br />

pre-owned high vacuum chambers,<br />

parts, and expendables. It also customizes<br />

and services the equipment and<br />

offers related training courses.<br />

Sales contact is:<br />

+1 860-429-1908<br />

sales@ytionline.com<br />

University of<br />

Massachusetts<br />

(www.umass.edu/)<br />

The Center for Hierarchical<br />

Manufacturing (CHM) is an NSF<br />

funded Nanoscale Science and<br />

Engineering Center (NSEC) at UMass<br />

Amherst with a mission to take the<br />

directed and additive driven selfassembly<br />

and nanoimprint lithographic<br />

technologies developed here from<br />

batch processing on silicon to roll-toroll<br />

processing on flexible substrates.<br />

We believe that the technology will be<br />

of significant interest to your member<br />

companies manufacturing flexible<br />

electronics, batteries, photovoltaics or<br />

sensors.<br />

Key Contact:<br />

Paul Clark<br />

+1 413-545-1334<br />

pclark@polysci.umass.edu<br />

www.aimcal.org Holiday 2010 11

People on the<br />

Move<br />

At Adhesives<br />

Research, Inc., Glen<br />

Rock, Pennsylvania,<br />

George Stolakis has<br />

been promoted to<br />

president. As president,<br />

Stolakis will<br />

George Stolakis oversee the company’s<br />

Adhesives Research<br />

division, ARx, LLC, and ARmark<br />

Authentication Technologies, LLC.<br />

Stolakis has been with the company<br />

since 1994 and most recently served as<br />

vice president and general manager<br />

of the Adhesives Research division,<br />

which manufactures highly customized,<br />

high-performance adhesives, tapes,<br />

adhesive-coated products, films, and<br />

laminates for the pharmaceutical, medical,<br />

electronics, pulp and paper, and<br />

specialty industrial markets. His tenure<br />

at Adhesives Research also includes<br />

several management positions within<br />

the company’s pharmaceutical and<br />

splicing business units including general<br />

manager, vice president, and national<br />

sales manager. Stolakis is a resident of<br />

York, Pennsylvania. He holds a Bachelor<br />

degree in Marketing from Michigan<br />

State University, East Lansing, Michigan.<br />

For more information, visit www.adhesivesresearch.com.<br />

***<br />

Maxcess, Oklahoma City, Oklahoma,<br />

has promoted Darren Irons to global<br />

product manager<br />

– Fife Guiding and<br />

Inspection. Irons joined<br />

Maxcess in 2007 as<br />

global product manager<br />

– MAGPOWR<br />

Tension Control where<br />

Darren Irons<br />

he launched several<br />

product improvements<br />

to help customers improve productivity,<br />

including IP67-rated load cells, an<br />

expanded line of magnetic particle<br />

brakes, and a new tension control. The<br />

new product launch experience will<br />

be invaluable as Maxcess extends the<br />

Fife product portfolio. Prior to joining<br />

Maxcess, Irons served Texas Instruments,<br />

Inc., Dallas, Texas, in various positions<br />

including product manager, product line<br />

strategy manager, and product marketing<br />

manager. He holds an Executive<br />

MBA in Finance and Marketing from<br />

Baylor University, Waco, Texas.<br />

Chris Harper<br />

Chris Harper succeeds Irons as<br />

global product manager – MAGPOWR<br />

Tension Control. Harper joined<br />

MAGPOWR in 1991 and has worked as<br />

a service technician and in customer<br />

support. In 2002 he became a district<br />

manager, serving as<br />

a local contact to help<br />

Maxcess customers<br />

in Indiana, Kentucky,<br />

and Michigan<br />

achieve a diverse<br />

range of production<br />

goals using Fife,<br />

MAGPOWR, and<br />

Tidland products. He brings a holistic<br />

view of the web handling process and<br />

a deep understanding of how guiding,<br />

winding, slitting, inspection, and tension<br />

control contribute to production quality.<br />

In other personnel news, Maxcess<br />

has named Ron Suenram its first director<br />

of Emerging Markets. He will help Fife,<br />

MAGPOWR, and Tidland customers in<br />

rapidly growing markets interact with<br />

the company’s expanding network of<br />

global production facilities. Suenram<br />

joined Fife Corp. in<br />

1979 and has held<br />

various positions in<br />

manufacturing, quality<br />

assurance, sales,<br />

and marketing during<br />

his 31-year history<br />

Ron Suenram<br />

with the company.<br />

Most recently he<br />

served as global product manager for<br />

Fife Guiding and Inspection. During his<br />

role as product manager, he introduced<br />

several products to help customers<br />

improve efficiency, including D-MAX,<br />

the industry’s first web guide controller<br />

to speak plain English, and the TruWide<br />

Ultrasonic Sensor, the first sensor to<br />

simultaneously detect multiple webs of<br />

material.<br />

Another personnel change at<br />

Maxcess involves the promotion of Ron<br />

Schmidt to vice president - Asia Pacific.<br />

He will be responsible for sales growth<br />

throughout Asia, South America, and<br />

other emerging markets, with additional<br />

responsibility<br />

for Maxcess factories<br />

and offices in Japan,<br />

India, Singapore,<br />

and Brazil. Formerly<br />

vice president of<br />

Market Development,<br />

Ron Schmidt<br />

Schmidt has directly<br />

contributed to the success<br />

of Maxcess during his 34-year tenure<br />

with the company, holding various<br />

leadership positions within manufacturing,<br />

sales, marketing, and corporate<br />

development. He has also demonstrated<br />

Maxcess’ commitment to the improve<br />

ment of the web handling industry<br />

through active participation in industry<br />

associations. Most recently, he served<br />

as president and trustee of <strong>AIMCAL</strong>’s<br />

CEMA Division. He is a current board<br />

member of <strong>AIMCAL</strong> and chairman of its<br />

Web Handling Group and AWEB conference.<br />

As the new vice president of Global<br />

Operations at Maxcess, Doug Knudtson<br />

facilitates the sharing of best practices<br />

among the company’s<br />

operations worldwide.<br />

Knudtson brings<br />

extensive human<br />

resource, quality,<br />

and operational<br />

experience to the<br />

Doug Knudtson<br />

Maxcess executive<br />

team, most recently<br />

as the president of Scott Office Systems,<br />

Livonia, Michigan. Prior to that he spent<br />

19 years with Brady Corp., Milwaukee,<br />

Wisconsin, in a variety of roles, including<br />

vice president of Global Operations,<br />

where he oversaw 65 manufacturing<br />

facilities in 20 countries. Knudtson holds<br />

a Bachelor degree from the University<br />

of Wisconsin. “Doug has a deep understanding<br />

of what it takes to be a worldclass<br />

company through experience in<br />

supply chain, manufacturing, quality,<br />

lean practices, inventory management,<br />

and logistics,” says Greg Jehlik, chief<br />

executive officer of Maxcess.<br />

With his promotion to sales manager,<br />

North America,<br />

Darrell Whiteside<br />

manages one of the<br />

largest networks<br />

of factory-trained<br />

salespeople in the<br />

industry to enhance<br />

Darrell Whiteside local sales efforts for<br />

12 Holiday 2010 www.aimcal.org

Fife, MAGPOWR and Tidland products.<br />

Whiteside joined MAGPOWR in 1999,<br />

assuming responsibilities for international<br />