Coating - Aimcal

Coating - Aimcal

Coating - Aimcal

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

creative<br />

COATING solutions<br />

“ ifficult” and “demanding” are two words that define custom coating applications ...<br />

Dthere’s<br />

nothing easy about it.<br />

At Davis-Standard, we embrace challenges with unmatched resources and expertise. Our<br />

custom engineering and R&D capabilities enable us to build equipment specific to your<br />

needs. Best of all, our technology is focused on energy efficiency and cost savings to<br />

improve your bottom line.<br />

Whether your application is:<br />

� Electronic Displays � Medical<br />

� Solar Cells � Battery<br />

� Graphite Composite<br />

We are here to help you find the right coating solution for your application.<br />

Our team is your team. Put us to work for you.<br />

Converting Machinery<br />

46 North First St.<br />

Fulton, NY 13069-1297 USA<br />

Tel: (315) 598-7121<br />

Fax: (315) 593-0396<br />

www.davis-standard.com<br />

36 South Adamsville Road<br />

Bridgewater, NJ 08807-0671 USA<br />

Tel: (908) 722-6000<br />

Fax: (908) 722-6444<br />

www.davis-standard.com<br />

Converting Systems<br />

Mettmanner Strasse 51<br />

D-40699 Erkrath/Düsseldorf<br />

GERMANY<br />

Tel: +49-211-2404-0<br />

Fax: +49-211-2404-281<br />

www.er-we-pa.de<br />

Room 6717, Apollo Building<br />

1440 Yan An Road (M)<br />

Shanghai 200040, P.R. CHINA<br />

Tel: +86-21-6103 1713<br />

Fax: +86-21-6133 1886<br />

www.davis-standard.com.cn<br />

Davis-Standard, LLC | #1 Extrusion Drive | Pawcatuck, CT 06379-2313 | USA | Tel: (860) 599-1010 | Fax: (860) 599-6258 | www.davis-standard.com<br />

|<br />

Converting customer ideas<br />

into successful products.<br />

Cast Film<br />

Extrusion <strong>Coating</strong> & Laminating<br />

Blown Film<br />

Liquid <strong>Coating</strong> & Laminating<br />

Unwinding & Winding<br />

Pelletizing<br />

Industrial Blow Molding<br />

Process Control<br />

Advance Program

AIMCAL<br />

Association of international Metallizers,<br />

coaters and Laminators<br />

The Association of International Metallizers, Coaters and Laminators (AIMCAL), founded in 1970, is a global nonprofit<br />

trade association representing converters of metallized, laminated and coated flexible substrates and their suppliers.<br />

Activities<br />

Web Handling conference: Biennial forum for the advancement of web handling technology featuring papers by<br />

leading consultants and manufacturers of web handling equipment and accessories.<br />

Web coating conference: Forum for member and non-member company personnel in operations, quality control and<br />

engineering to examine technical; production; plant and new technology issues.<br />

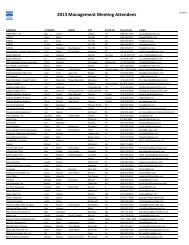

Management Meeting: March forum for executive and marketing management personnel from member companies to<br />

review economic forecasts, develop new management techniques and network with fellow members.<br />

AiMcAL converting school: Focused technical training by leading consultants in the industry, held year round in the<br />

US, Europe and India. www.convertingschool.com.<br />

ceMA slitting & Rewinding Fundamentals seminar: Semi-annual forum focusing on slitting and rewinding<br />

operations of paper, film, nonwovens and other continuous flexible materials.<br />

ceMA coating & Laminating Fundamentals seminar: Annual event covering the fundamentals of web coating from<br />

unwind to rewind.<br />

AiMcAL Jobs: Resource for member companies to place job openings and review submitted resumes.<br />

AiMcAL Blogs: Technical resources for the web coating industry: Vacuum Web <strong>Coating</strong>, Web <strong>Coating</strong>, Web<br />

Handling & Converting, Substrate Secrets, Drives for Web Handling and The Converting Curmudgeon.<br />

www.convertingquarterly.com.<br />

Ask AiMcAL: Service to source products and services within the converting community.<br />

Webinars: Ongoing schedule of new technical webinars, as well as an archive of recorded webinars available to<br />

members only.<br />

competitions: Annual awards for best Metallized or Vacuum Coated Products, Technology of the Year and<br />

Sustainable Product.<br />

PuBLicAtions<br />

AiMcAL sourceBook: Index of member capabilities, products, equipment and services. Executive summaries of<br />

management techniques, roll to roll markets and technology innovation.<br />

Converting Quarterly: The official technical magazine of AIMCAL, published quarterly in print and electronic formats.<br />

Each issue features expert technical content, including insights from industry consultants.<br />

Metallizing technical Reference v/ Metal Adhesion test Kit: Metallized film test methods, characteristics and<br />

capabilities.<br />

technical conference Proceedings: AIMCAL and International Vacuum Web <strong>Coating</strong> Conference Proceedings.<br />

technical Resources: Bookstore, subscription services, software, technical tutorials and more.<br />

AiMcAL network Websites: aimcal.org, cema-converting.org, convertingquarterly.com, convertingschool.com.<br />

www.aimcal.org | 1

AiMcAL BoARD oF DiRectoRs<br />

(VOLUnTEERS FROM MEMBER COMPAnIES)<br />

President<br />

Robert Connelly, Madico, Inc.<br />

vice President<br />

Dan Bemi, MEGTEC Systems Inc.<br />

treasurer<br />

Danis Roy, Terphane Inc<br />

Past President<br />

Liz Josephson, Applied Materials<br />

AiMcAL coMMittee cHAiRs<br />

(VOLUnTEERS FROM MEMBER COMPAnIES)<br />

Awards & competition committee<br />

Randy Apperson, Finzer Roller<br />

coating & Laminating – usA committee<br />

Gregory Williams, Exopack Advanced <strong>Coating</strong>s<br />

Mike Sellers, Advance Systems, Inc.<br />

coating & Laminating – europe committee<br />

Giancarlo Caimmi, nordmeccanica<br />

Ginger Cushing, Michelman<br />

economics committee<br />

Bill Stratton, Adhesives Research<br />

AiMcAL stAFF<br />

executive Director<br />

Craig S. Sheppard<br />

senior Administrator<br />

Tracey Ingram<br />

event Planner<br />

Erin Davis<br />

AiMcAL oFFices<br />

usA<br />

201 Springs Street<br />

Fort Mill, SC 29715<br />

USA<br />

Phone: 803-802-7820<br />

Fax: 803-802-7821<br />

E-mail: aimcal@aimcal.org<br />

2 | 2012 AIMCAL SourceBook<br />

Directors at Large<br />

David Bryant, Vacuum Depositing Inc.<br />

Mark Montsinger, Bryce Corporation<br />

Gary Phillips, Solar Gard Saint-Gobain<br />

Ingrid Brase, Henkel Corporation<br />

Dante Ferrari, Celplast Metallized Products<br />

Doug Krasucki, R.D. Specialties, Inc.<br />

vacuum Web coating – usA committee<br />

Greg Tullo, Bobst - General Vacuum<br />

Andrew Jack, Bobst - General Vacuum<br />

vacuum Web coating – europe committee<br />

Ulrich Schmoll, Kennametal<br />

Sharon Louch, Swansea University<br />

Web Handling committee<br />

Ken Guhse, Honeywell Healthcare & Packaging<br />

communications Manager<br />

Steve Bright<br />

editor-in-chief, Converting Quarterly<br />

Mark Spaulding<br />

europe<br />

PO Box 69533<br />

1060 CA Amsterdam<br />

The netherlands<br />

Phone: 0031 (0)20 8208635<br />

Fax: 0031 (0)20 8208634<br />

E-mail: aimcal@aimcal.org

oveRvieW<br />

CEMA is the only organization designed specifically to serve the needs of converting equipment manufacturers by<br />

offering unique benefits and services.<br />

Mission<br />

Our mission is to promote, advance and represent the interests of converting manufacturers in the industry and<br />

markets served.<br />

GoALs<br />

• To advance the use of converting equipment.<br />

• To provide opportunities for the exchange of ideas.<br />

• To lobby on behalf of the industry concerning legislation and regulations that may have an impact on the industry.<br />

• To provide educational opportunities for the membership and the industry.<br />

• To establish and maintain liaison between organizations with similar interests.<br />

HistoRY<br />

CEMA was founded in 1984 and is the only organization that exists specifically to serve and address the unique needs<br />

and concerns of converting equipment manufacturers. Effective April 1, 2003, CEMA became a full operating division<br />

of AIMCAL.<br />

LeADeRsHiP<br />

coating / Laminating seminar co-chair<br />

Doug R. Krasucki, R.D. Specialties, Inc.<br />

slitting / Rewinding seminar co-chair<br />

Doug Brockelbank, The Montalvo Corporation<br />

Advisors<br />

Sean Craig, Maxcess International<br />

Seamus Lafferty, Stanford/Accraply<br />

John Looser, new Era Converting Machinery, Inc.<br />

Juliet Midlik, Prime UV Systems<br />

Leo nadolske, CPP EXPO<br />

Dave Rumson, Slitting Consultant<br />

Michael Sellers, Advance Systems, Inc.<br />

Tim Walker, TJWalker & Associates, Inc.<br />

Keon Wild, Davis-Standard, LLC<br />

www.aimcal.org | 3

AIMCAL in 5 minutes<br />

AIMCAL<br />

The Association of International Metallizers, Coaters and Laminators<br />

(AIMCAL) serves as the premier global trade association for the<br />

�exible metallizing, coating and laminating industry. AIMCAL<br />

provides resources, services and information to the industry, while<br />

promoting the products and services of member companies.<br />

Watch the “AIMCAL in 5 minutes” video<br />

at www.aimcal.org and see how AIMCAL<br />

membership can bene�t your company.<br />

Contact AIMCAL today to become a member.<br />

Apply online at www.aimcal.org or phone 803-802-7820.

TAbLe of ConTenTs<br />

AIMCAL Overview ...........................................................................................................................................1<br />

CEMA Overview ..............................................................................................................................................3<br />

AIMCAL Member Companies ..........................................................................................................................6<br />

AIMCAL Member Capabilities .........................................................................................................................8<br />

AIMCAL Member Company Profiles..............................................................................................................34<br />

AIMCAL Technical Advisory Panel ................................................................................................................89<br />

2012 Events Calendar .................................................................................................................................108<br />

AIMCAL Premium Members ........................................................................................................................111<br />

eXecutive suMMARies (A LooK AHeAD)<br />

Global Consolidation .....................................................................................................................................94<br />

By Thomas E. Blaige, CEO/managing director, Blaige & Co.<br />

Flexible Packaging ........................................................................................................................................95<br />

By Paul Gaster, PCI Films Consulting, Ltd.<br />

Labels & Labelstocks.....................................................................................................................................96<br />

By Mike Fairley, director-strategic development, Labels and Packaging Group, Tarsus<br />

Vacuum-Coated & Metallized Materials ........................................................................................................97<br />

By Corey M. Reardon, president/CEO, AWA Alexander Watson Associates<br />

Release Liners...............................................................................................................................................98<br />

By Corey M. Reardon, president/CEO, AWA Alexander Watson Associates<br />

Photovoltaics .................................................................................................................................................99<br />

By Paula Mints, director-energy, principal analyst-solar services program, Navigant<br />

Thin-Film Batteries ......................................................................................................................................101<br />

By Anthony Sudano, president, Sudano Consulting, Inc.<br />

Extrusion Laminating & Film Making ...........................................................................................................102<br />

By Eldridge M. Mount, Ph.D., president, EMMOUNT Technologies<br />

Vacuum Deposition .....................................................................................................................................104<br />

By Charles A. Bishop, Ph.D., president, C.A. Bishop Consulting, Ltd.<br />

Web <strong>Coating</strong> ................................................................................................................................................105<br />

By Edward D. Cohen, Ph.D., president, Edward D. Cohen Consulting, Inc.<br />

Slitting & Winding ........................................................................................................................................106<br />

By David Rumson, slitting educator/consultant, DR Consulting<br />

Web Handling ..............................................................................................................................................107<br />

By David R. Roisum, Ph.D., president, Finishing Technologies<br />

www.aimcal.org | 5

AIMCAL Member Companies<br />

3 Sigma Corporation<br />

A & B Films Pte Ltd<br />

ABBA Roller, LLc<br />

Acucote<br />

Adchem Corporation<br />

Adhesive Applications<br />

Adhesives Research, Inc.<br />

Advance Systems, Inc.<br />

AET Films<br />

AJ Plast Public company Limited<br />

Akzonobel specialty Plastics<br />

American Roller Company<br />

AmTopp Div., Inteplast Group Ltd.<br />

Amsterdam Metallized Products BV<br />

Angstrom Sciences, Inc.<br />

Anguil Environmental Systems, Inc.<br />

Apical Division, Kaneka texas corporation<br />

Applied Materials<br />

Arab Medical Packing co.<br />

Arlon, Inc.<br />

Ashland Performance Materials<br />

Atlas converting equipment Ltd.<br />

Avery Dennison<br />

BASF Corporation<br />

Bobst Group north America<br />

Bostik, Inc.<br />

BPR Plastics<br />

Brady Worldwide, coated Products<br />

Bryce corporation<br />

c2 coating & converting<br />

C.A. Litzler Co., Inc.<br />

Camvac Ltd.<br />

Canslit, Inc.<br />

Catalina Graphic Films, Inc.<br />

catalytic Products international<br />

Catbridge Machinery<br />

cBc<br />

CCT (<strong>Coating</strong> & Converting Technologies)<br />

celplast Metallized Products Ltd.<br />

Chase Corporation<br />

chemsultants international<br />

Circonix Technologies, LLC<br />

Clemson University Dept. of Packaging Science<br />

Commonwealth Laminating & <strong>Coating</strong> Inc.<br />

ConQuip, Inc.<br />

converting Quarterly<br />

cork industries, inc.<br />

corning incorporated<br />

cPP eXPo<br />

Crown Roll Leaf, Inc.<br />

Cytec Industries<br />

D&K Group, inc.<br />

Dark Field Technologies<br />

Darly Custom Technology, Inc.<br />

Davis-standard converting systems<br />

Deposition Technology Innovations<br />

Dienes Corporation<br />

Donaldson Company, Inc.<br />

DoW chemical company<br />

DOW Kokam<br />

6 | 2012 AIMCAL SourceBook<br />

DunMoRe corporation<br />

DuPont teijin Films<br />

Enercon Industries<br />

Erhardt + Leimer Inc.<br />

esK ceramics<br />

ester industries Limited<br />

Exopack Advanced <strong>Coating</strong>s<br />

Extrusion Dies Industries LLC.<br />

ExxonMobil Chemical, Films Business<br />

Faustel, inc.<br />

Filmquest Group inc.<br />

FILMtech, Inc.<br />

Finzer Roller<br />

First technology innovation, inc.<br />

Flex America inc.<br />

Flexible Packaging Magazine<br />

FLeXcon company, inc.<br />

Fox River Associates<br />

Fox Valley Technical College<br />

Franklin Adhesives & Polymers<br />

Galileo Vacuum Systems, Inc.<br />

General Metallisers Ltd.<br />

Glatfelter<br />

Global Technologies LLC<br />

Goldenrod corporation<br />

Graphic Packaging International, Inc.<br />

Green Bay Packaging Inc.<br />

Griff Paper and Film<br />

Gulf Packaging Industries Ltd.<br />

Hanita <strong>Coating</strong>s<br />

Harper Corporation of America<br />

Hazen Paper co.<br />

Henkel corporation<br />

Heraeus Materials Technology<br />

Hewlett Packard Company<br />

Honeywell Healthcare & Packaging<br />

Hueck Folien GmbH<br />

Hutchison Miller Sales Co.<br />

Imperial Rubber Products, Inc.<br />

Impreglon, Inc.<br />

InTEGRITY Roller Services<br />

Intertape Polymer Group<br />

intrAL inc.<br />

JBF RAK LLC<br />

JDsu-Flex Products Group<br />

Jennerjahn Machine, Inc.<br />

Jessup Mfg. Co.<br />

JX nippon AnCI, Inc.<br />

Johnson Controls Advanced Power Solutions<br />

Johnson Laminating & <strong>Coating</strong>, Inc.<br />

Kazan national Research Technological University<br />

Kennametal sintec usA<br />

Kollmorgen<br />

Kroenert GmbH & Co KG<br />

Kurt J. Lesker Company<br />

Label technology<br />

Lamart Corp.<br />

L.C.O.A.<br />

Leybold optics GmbH<br />

Loparex

Mack Brooks exhibitions inc.<br />

MACtac<br />

Madico, inc.<br />

Malaga Produtos Metalizados Ltda.<br />

MAnFISA (Manufacturas Irular, S.A.)<br />

Materion Large Area coatings<br />

Maxcess International Corporation<br />

Max Daetwyler Corporation<br />

Measureitall.com<br />

MeGtec systems<br />

Menges Roller Company<br />

Mica Corporation<br />

Michelman<br />

Midwest engineering<br />

MiRWec Film, inc.<br />

Mississippi Polymers, Inc.<br />

Mitsubishi Polyester Film, inc.<br />

MOCOn<br />

Momentive Specialty Chemicals<br />

Montalvo Corporation<br />

MPi technologies, inc.<br />

MTI & Polyexe Corporation<br />

Multifilm Packaging corp.<br />

nDC Infrared Engineering<br />

new era converting Machinery, inc.<br />

nORDMECCAnICA nA Ltd.<br />

novacentrix<br />

noW Plastics<br />

OASIS Alignment Services, Inc.<br />

olbrich Machinery<br />

Optimation Technology, Inc.<br />

Parkinson technologies inc.<br />

PFFc – Paper, Film & Foil converter<br />

Pillar Technologies, an ITW Company<br />

Polymag Tek<br />

Polymer Science Inc.<br />

Polypacks Industries<br />

Polyplex corporation Limited<br />

Polytype America Corp., Converting Technology Sys<br />

PPG industries / teslin® substrate<br />

Precision <strong>Coating</strong>s, Inc.<br />

Premier Dies Corporation<br />

Presco<br />

Pres-On<br />

PRIME UV Systems, Inc.<br />

Printpack, Inc.<br />

Protect-all, inc.<br />

PRUFTECHnIK Service, Inc.<br />

Quickdraft<br />

Radiant Energy Systems, Inc.<br />

Rayven Inc.<br />

R. D. specialties<br />

Roche Diagnostics<br />

Rochester Institute of Technology<br />

Rockwell Automation<br />

Roethel GmbH & Co. KG<br />

Roll Technology Corp.<br />

Rol-Vac, LP<br />

Rotadyne<br />

Royal Adhesives & Sealants<br />

Roysons Corporation<br />

San Jose State University<br />

SCA Tissue nA<br />

Schenk Vision Systems<br />

Schmid Vacuum Technology GmbH<br />

Schober USA Inc.<br />

SDI<br />

Sensory Analytics, LLC<br />

shanghai Luxin Packing Materials<br />

shapedWire / solon specialty Wire<br />

sheldahl<br />

siemens industry, inc.<br />

Sierra <strong>Coating</strong> Technologies<br />

Sigma Technologies Int., Inc.<br />

Sion Power Corporation<br />

sKc inc.<br />

solar Gard saint-Gobain<br />

solutia’s Performance Films Division<br />

sonoco Products company<br />

Southwall Technologies, Inc.<br />

Speedmet A.S. Ltd<br />

Spooner Industries Inc.<br />

Stanford – An Accraply Company<br />

State University of new York at Binghamton<br />

Sun Chemical Corporation<br />

Sung An Machinery Co., Ltd.<br />

Super Film Ambalaj Sanayi ve Ticaret A.S.<br />

Swansea University<br />

taghleef industries LLc<br />

Technical <strong>Coating</strong> International, Inc.<br />

Tekra Corp.<br />

terphane, inc.<br />

tesa tape, inc.<br />

thelamco, inc.<br />

Thermo Scientific<br />

Tilt-lock<br />

Tollcoating by Carestream<br />

toray Plastics (America), inc.<br />

Transilwrap Company, Inc.<br />

unifoil corp.<br />

University Gent<br />

University of Leeds<br />

University of Massachusetts<br />

University of Oxford<br />

University of the West of Scotland<br />

UPM Raflatac, Inc.<br />

vacumet corp.<br />

vacuum Depositing, inc.<br />

vacuum technology & coating Magazine<br />

Vast Films, Ltd.<br />

Vetaphone<br />

vistana<br />

VOn ARDEnnE Anlagentechnik GmbH<br />

Web Plastics Company<br />

Web systems, inc.<br />

Western Michigan University<br />

Wintriss Engineering Corp.<br />

Worthen industries<br />

XericWeb Drying systems<br />

Yeagle Technology Inc.<br />

www.aimcal.org | 7

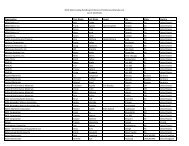

Member Capabilities<br />

Converter<br />

Capabilities<br />

<strong>Coating</strong>, Laminating, Printing<br />

Processes<br />

COATING<br />

1-Film<br />

2-Foil<br />

3-Paper<br />

4-Woven<br />

5-Non-Woven<br />

6-Clean Room<br />

7-Multi-Station<br />

8-Water Base<br />

9-Solvent Base<br />

10-Solvent Free<br />

100% Solids<br />

3 Sigma Corporation 1,2,3,4,5<br />

Adchem Corporation 1,2,3,4,5<br />

Adhesives Research, Inc. 9<br />

Bryce Corporation 1<br />

Catalina Graphic Films 2<br />

CCT (<strong>Coating</strong> & Converting Technologies)<br />

1,2,3,4,5,9<br />

Chase Corporation 1,2,3,4,5,6,8,9<br />

Chemsultants International 1,2,3,4,5,8,9<br />

D&K Group, Inc. 1,2,3<br />

Dow Chemical Company 1,2,3<br />

DUNMORE Corporation 1,2,4,5,7,8,9<br />

First Technology Innovation Inc<br />

1,2,5,6,7,8,9<br />

Glatfelter 1,3<br />

Griff Paper and Film 1,2,3,4,5<br />

Henkel Corporation 1,2,3<br />

Intertape Polymer Group 1,2,3,7<br />

Jessup Manufacturing Company 1,2,3,4,5<br />

KROENERT GmbH & Co KG 1,2,3,5,6,7<br />

Label Technology 1,2,3,8<br />

Lamart Corp. 1,2,3,4<br />

Loparex LLC 1,3,5<br />

Malaga Produtos Metalizados Ltd. 1,2,3<br />

MIRWEC Film, Inc. 2,3,4,5,6,8,9<br />

MPI Technologies, Inc. 1,3,4<br />

Polymer Science, Inc. 1,2,3,4,5,6,7,8,9<br />

Polyplex Corporation Ltd. 1,6,7,8,9<br />

Pres-on Corp. 1,3,4,8,9<br />

Printpack Inc. 1<br />

Protect-all, Inc. 1,2,3<br />

Rayven Inc. 1,3,5<br />

Roethel GmbH & Co KG 1,2,3,4,5,6,7,8<br />

Roysons Corporation 1,3,4,5<br />

Sierra <strong>Coating</strong> Technologies 1,3,5<br />

Solar Gard Saint-Gobain 1,3,4,5,6,8,9<br />

Tekra Corporation 1,6<br />

UPM Raflatac, Inc. 1,3<br />

Air Knife<br />

Bryce Corporation 1<br />

General Metallisers Ltd. 3<br />

Hazen Paper Co. 1,2,3<br />

Hutchison Miller Sales Company 2,3<br />

Parkinson Technologies 1,2,3,4,5,6<br />

Printpack Inc. 1<br />

Technical <strong>Coating</strong> Int’l, Inc. 1,2,3,4,5,9<br />

Unifoil Corp. 1,2,3,7,8,9<br />

Curtain<br />

KROENERT GmbH & Co KG<br />

1,2,3,4,5,6,7,8,9<br />

Optimation Technology, Inc. 1,3,8,9<br />

Tollcoating by Carestream 1,3,7,8<br />

Direct Gravure<br />

3 Sigma Corporation 1,2,3,4,5,8,9<br />

8 | 2012 AIMCAL SourceBook<br />

AkzoNobel Specialty Plastics 1,6,7,8,9<br />

Amsterdam Metallized Products B.V.<br />

1,3,8,9<br />

Arlon, Inc. 1,2,3,5,6,8,9<br />

Brady Worldwide, Coated Products<br />

1,2,3,4,5,6,7,8,9<br />

Camvac Ltd. 1<br />

Catalina Graphic Films 2,8,9<br />

CBC 1,2,3,4,5,7,8<br />

Chase Corporation 1,2,3,4,5,8,9<br />

Chemsultants International 1,2,3,4,5,8,9<br />

Commonwealth Laminating & <strong>Coating</strong>,<br />

Inc. 1,8,9<br />

D&K Group, Inc. 1,2,3,4,5,8,9<br />

Dow Chemical Company 1,2,3,7,8,9<br />

DUNMORE Corporation 1,2,3,4,5,7,8,9<br />

Exopack Advanced <strong>Coating</strong>s<br />

1,2,3,4,5,6,7,8,9<br />

Filmquest Group Inc. 1<br />

First Technology Innovation Inc<br />

1,2,5,6,7,8,9<br />

Flex America Inc. 1,2,3,7,9<br />

FLEXcon 1,2,4,5,8,9<br />

General Metallisers Ltd. 3<br />

Glatfelter 3,8<br />

Graphic Packaging International, Inc.<br />

1,3,7,8,9<br />

Hanita <strong>Coating</strong>s 1,6,8,9<br />

Hazen Paper Co. 1,2,3,8,9<br />

Henkel Corporation 1,2,3,8,9<br />

Hueck Folien GmbH 1,2,3,4,5,7,8,9<br />

Hutchison Miller Sales Company 2,3,7,8,9<br />

Intertape Polymer Group 1,2,3,7,9<br />

JBF RAK LLC 1,8<br />

Johnson Laminating & <strong>Coating</strong>, Inc.<br />

1,2,5,6,7,8,9<br />

KROENERT GmbH & Co KG<br />

1,2,3,4,5,6,7,8,9<br />

Lamart Corp. 1,2,3,4,5,8,9<br />

Loparex LLC 1,2,3,4,5,6,7,8,9<br />

Malaga Produtos Metalizados Ltd.<br />

1,2,3,8,9<br />

MIRWEC Film, Inc. 1,2,3,4,5,6,8,9<br />

Mississippi Polymers, Inc.<br />

1,2,3,4,5,6,7,8,9<br />

MPI Technologies, Inc. 1,3<br />

Multifilm Packaging Corp. 1,8<br />

Optimation Technology, Inc. 1,3,8,9<br />

Polymer Science, Inc. 1,2,3,4,5,6,7,8,9<br />

Polypacks Industries 1,3,7,8,9<br />

Polyplex Corporation Ltd. 1,6,7,8,9<br />

Precision <strong>Coating</strong>s Inc. 1,2,3,4,5,6,7,8,9<br />

Printpack Inc. 1,7,8,9<br />

Protect-all, Inc. 1,2,3,4,5,8<br />

Rayven Inc. 1,3,5,7,8,9<br />

Sierra <strong>Coating</strong> Technologies 1,3,4,5,6<br />

Solar Gard Saint-Gobain<br />

1,2,3,3,4,4,5,6,7,8,8,9<br />

Solutia’s Performance Films Division<br />

1,2,6,8,9<br />

Technical <strong>Coating</strong> Int’l, Inc.<br />

1,2,3,4,5,6,7,8,9<br />

Tekra Corporation 1,6,8,9<br />

Terphane Inc. 1<br />

thelamco, inc. 1,2,3,4,5,8,9<br />

Tollcoating by Carestream 1,3,5,7,8,9<br />

Transilwrap Company, Inc. 8,9<br />

Unifoil Corp. 1,2,3,7,8,9<br />

Vacumet Corp. 1,3,7,8,9<br />

Electron Beams<br />

Graphic Packaging International, Inc.<br />

1,3,7<br />

Henkel Corporation 1,2,3<br />

Intertape Polymer Group 1,2<br />

Loparex LLC 1,2,3,4,5,6,7,8,9<br />

MPI Technologies, Inc. 1,3,4,5<br />

Sigma Technologies International, Inc.<br />

1,2,3,4,5<br />

Extrusion<br />

Bryce Corporation 1,3,5<br />

Chase Corporation 1,2,3,4,5<br />

D&K Group, Inc. 1,2,3,4<br />

Flex America Inc. 1,2,3<br />

FLEXcon 1,2,4,5,8,9<br />

Graphic Packaging International, Inc.<br />

1,3,7<br />

Intertape Polymer Group 1,2,7<br />

Loparex LLC 1,2,3,4,5,6,7,8,9<br />

Multifilm Packaging Corp. 1<br />

Optimation Technology, Inc. 1,3,8,9<br />

Parkinson Technologies 1,2,3,4,5,6<br />

Polymer Science, Inc. 1,2,3,4,5,6,7,8,9<br />

Polyplex Corporation Ltd. 1,6,7,8,9<br />

Precision <strong>Coating</strong>s Inc. 1,2,3,4,5,6,7,8,9<br />

Printpack Inc. 1,7<br />

Protect-all, Inc. 1,2,3,4,5<br />

Roethel GmbH & Co KG 1,2,3,4,5,6,7,8<br />

Solar Gard Saint-Gobain 1,6<br />

Tollcoating by Carestream 1,3,5,7,8,9<br />

Transilwrap Company, Inc. 1,5<br />

Knife Over Roll<br />

Acucote Inc. 1,2,3,4,5,8<br />

Adchem Corporation 1,2,3,4,5,8,9<br />

Adhesive Applications 9<br />

Adhesives Research, Inc. 1,9<br />

Arlon, Inc. 1,2,5,6,8,9<br />

Catalina Graphic Films 1,2,3,8<br />

Chase Corporation 1,2,3,4,5,8,9<br />

Chemsultants International 1,2,3,4,5,8,9<br />

Dow Chemical Company 1,2,3,7,8,9<br />

FLEXcon 1,2,4,5,8,9<br />

Hanita <strong>Coating</strong>s 1,6,8,9<br />

Hueck Folien GmbH 1,2,3,4,5,7,8<br />

Intertape Polymer Group 1,2,3,7,9<br />

Jessup Manufacturing Company<br />

1,2,3,4,5,8,9<br />

KROENERT GmbH & Co KG<br />

1,2,3,5,6,7,8,9<br />

Lamart Corp. 1,3,4<br />

Madico, Inc. 1,2,7,8,9<br />

Malaga Produtos Metalizados Ltd.<br />

1,2,3,8,9<br />

Polymer Science, Inc. 1,2,3,4,5,6,7,8,9<br />

Polypacks Industries 1,3,7,8,9<br />

Precision <strong>Coating</strong>s Inc. 1,2,3,4,5,6,7,8,9<br />

Pres-on Corp. 1,3,4,8,9<br />

Sheldahl 1,2,4,5,6,7,8,9<br />

Solar Gard Saint-Gobain 1,2,3,5,8,8,9<br />

Technical <strong>Coating</strong> Int’l, Inc.<br />

1,2,3,4,5,6,7,8,9<br />

tesa tape, inc. 1,9<br />

Mayer Rod<br />

3 Sigma Corporation 1,2,3,4,5,8,9<br />

Adchem Corporation 1,2,3,4,5,8,9<br />

Adhesive Applications 8<br />

Apical Division, Kaneka Texas<br />

Corporation 1,8<br />

Arlon, Inc. 1,3,5,8<br />

Brady Worldwide, Coated Products<br />

1,2,3,4,5,6,7,8,9<br />

Bryce Corporation 1<br />

Catalina Graphic Films 1,2,3,8<br />

CBC 1,3,4,5,7,8<br />

Chase Corporation 1,2,3,4,5,8,9<br />

Chemsultants International 1,2,3,4,5,8,9<br />

Dow Chemical Company 1,2,3,7,8,9<br />

DUNMORE Corporation 1,2,4,5,8,9<br />

Exopack Advanced <strong>Coating</strong>s<br />

1,2,3,4,5,6,7,8,9<br />

First Technology Innovation Inc<br />

1,2,5,6,7,8,9<br />

FLEXcon 1,2,4,5,8,9<br />

General Metallisers Ltd. 3<br />

Hanita <strong>Coating</strong>s 1,6,8,9<br />

Hutchison Miller Sales Company 2,3,7,8<br />

Intertape Polymer Group 1,2,3,7<br />

Jessup Manufacturing Company<br />

1,2,3,4,5,8,9<br />

Johnson Laminating & <strong>Coating</strong>, Inc.<br />

1,2,5,6,7,8,9<br />

KROENERT GmbH & Co KG<br />

1,2,3,5,6,7,8,9<br />

Lamart Corp. 1,2,3,4,5,8,9<br />

Loparex LLC 1,2,3,4,5,6,7,8,9<br />

Madico, Inc. 1,2,7,8,9<br />

Polypacks Industries 1,3,7,8,9<br />

Precision <strong>Coating</strong>s Inc. 1,2,3,4,5,6,7,8,9<br />

Rayven Inc. 1,3,5,7,8,9<br />

Roysons Corporation 1,3<br />

Solar Gard Saint-Gobain 1,2,5,6,7,9<br />

Technical <strong>Coating</strong> Int’l, Inc. 1,2,3,4,5,8,9<br />

tesa tape, inc. 1,7,9<br />

Tollcoating by Carestream 1,3,5,7,8,9<br />

Unifoil Corp. 1,2,3,7,8,9<br />

Offset Gravure<br />

Chase Corporation 1,2,3,4,5,6,8,9<br />

Chemsultants International 1,2,3,4,5,8,9<br />

Dow Chemical Company 1,2,3,7,8,9<br />

DUNMORE Corporation 1,2,3,4,5,7,8,9<br />

FLEXcon 1,2,4,5,8,9<br />

General Metallisers Ltd. 3<br />

Glatfelter 3,8<br />

Graphic Packaging International, Inc.<br />

1,2,3<br />

Intertape Polymer Group 1,2,3<br />

KROENERT GmbH & Co KG<br />

1,2,3,5,6,7,8,9<br />

Lamart Corp. 1,2,3<br />

Loparex LLC 1,2,3,4,5,6,7,8,9<br />

MPI Technologies, Inc. 1,3<br />

MTI & Polyexe Corporation 1,2,3,4,5,8<br />

Optimation Technology, Inc. 1,3,8,9<br />

Printpack Inc. 1,7,8,9<br />

Rayven Inc. 1,3,5<br />

Sierra <strong>Coating</strong> Technologies 1,3,4,5,6,8<br />

Solutia’s Performance Films Division<br />

1,2,6,8,9<br />

Vacumet Corp. 1,3,7,8,9<br />

Reverse Gravure<br />

AkzoNobel Specialty Plastics 1,6,7,8,9<br />

Arlon, Inc. 1,2,3,8<br />

Brady Worldwide, Coated Products<br />

1,2,3,4,5,6,7,8,9<br />

CBC 1,2,3,4,5,7,8<br />

Chemsultants International 1,2,3,4,5,8,9<br />

Commonwealth Laminating & <strong>Coating</strong>,<br />

Inc. 1,8,9<br />

D&K Group, Inc. 1,2,3,4,5,8,9<br />

Dow Chemical Company 1,2,3,7,8,9<br />

DUNMORE Corporation 1,2,3,4,5,7,8,9<br />

Filmquest Group Inc. 1<br />

First Technology Innovation Inc<br />

1,2,5,6,7,8,9<br />

FLEXcon 1,2,4,5,8,9<br />

Glatfelter 3,8<br />

Hanita <strong>Coating</strong>s 1,6,8,9<br />

Hueck Folien GmbH 1,2,3,4,5,7,8<br />

Intertape Polymer Group 1,2,3<br />

Johnson Laminating & <strong>Coating</strong>, Inc.<br />

1,2,5,6,7,8,9<br />

KROENERT GmbH & Co KG<br />

1,2,3,5,6,7,8,9<br />

Lamart Corp. 1,2,3,4,5,8,9

Loparex LLC 1,2,3,4,5,6,7,8,9<br />

MPI Technologies, Inc. 1,3<br />

Optimation Technology, Inc. 1,3,8,9<br />

Polymer Science, Inc. 1,2,3,4,5,6,7,8,9<br />

Printpack Inc. 1,7,8,9<br />

Protect-all, Inc. 1,2,3,4,5,8<br />

Sierra <strong>Coating</strong> Technologies 1,3,4,5,8<br />

Solar Gard Saint-Gobain 3,5,9<br />

Solutia’s Performance Films Division<br />

1,2,6,8,9<br />

Technical <strong>Coating</strong> Int’l, Inc. 1,2,3,4,5,8,9<br />

Tekra Corporation 1,6,8,9<br />

Terphane Inc. 1<br />

Tollcoating by Carestream 1,3,5,7,8,9<br />

Vacumet Corp. 1,3,7,8,9<br />

Reverse Roll<br />

3 Sigma Corporation 1,2,3,4,5,8,9<br />

Acucote Inc. 1,2,3,4,5,8<br />

Adchem Corporation 1,2,3,4,5,8,9<br />

Adhesives Research, Inc. 1,2,3,4,5,8,9<br />

AkzoNobel Specialty Plastics 1,6,7,8,9<br />

Arlon, Inc. 1,2,3,5,6,8,9<br />

Brady Worldwide, Coated Products<br />

1,2,3,4,5,6,7,8,9<br />

Bryce Corporation 1<br />

Chase Corporation 1,2,3,4,5,8,9<br />

Chemsultants International 1,2,3,4,5,8,9<br />

Dow Chemical Company 1,2,3,7,8,9<br />

DUNMORE Corporation 1,8,9<br />

Exopack Advanced <strong>Coating</strong>s<br />

1,2,3,4,5,6,7,8,9<br />

First Technology Innovation Inc<br />

1,2,5,6,7,8,9<br />

FLEXcon 1,2,4,5,8,9<br />

Griff Paper and Film 1,2,3,4,5<br />

Hanita <strong>Coating</strong>s 1,6,8,9<br />

Intertape Polymer Group 1,2,3,9<br />

KROENERT GmbH & Co KG<br />

1,2,3,5,6,7,8,9<br />

Lamart Corp. 1,2,3,4,5,8,9<br />

Optimation Technology, Inc. 1,3,8,9<br />

Polymer Science, Inc. 1,2,3,4,5,6,7,8,9<br />

Protect-all, Inc. 1,2,3,4,5,8<br />

Sheldahl 1,2,4,5,6,7,8,9<br />

Solar Gard Saint-Gobain 1,2,3,4,5,6,8,9<br />

Tollcoating by Carestream 1,3,5,7,8,9<br />

Slide<br />

KROENERT GmbH & Co KG<br />

1,2,3,5,6,7,8,9<br />

Optimation Technology, Inc. 1,3,8,9<br />

Tollcoating by Carestream 1,3,5,7,8,9<br />

Slot Die<br />

3 Sigma Corporation 1,2,3,4,5<br />

Adchem Corporation 1,2,3,4,5,8,9<br />

Adhesive Applications 8<br />

Adhesives Research, Inc. 1,2,3,4,5,8,9<br />

AkzoNobel Specialty Plastics 1,6,7,8,9<br />

Apical Division, Kaneka Texas<br />

Corporation 1<br />

Brady Worldwide, Coated Products<br />

1,2,3,4,5,6,7,8,9<br />

Bryce Corporation 1<br />

Catalina Graphic Films 1,2,3,8<br />

CCT (<strong>Coating</strong> & Converting Technologies)<br />

1,2,3,4,5,9<br />

Chemsultants International 1,2,3,4,5,8,9<br />

D&K Group, Inc. 1,2,3,4,5,8,9<br />

DUNMORE Corporation 1,2,3,4,5,7,8,9<br />

Exopack Advanced <strong>Coating</strong>s<br />

1,2,3,4,5,6,7,8,9<br />

First Technology Innovation Inc 1,6,9<br />

FLEXcon 1,2,4,5,8,9<br />

Intertape Polymer Group 1,2,3<br />

Johnson Laminating & <strong>Coating</strong>, Inc.<br />

1,2,5,6,7,8,9<br />

KROENERT GmbH & Co KG<br />

1,2,3,5,6,7,8,9<br />

MIRWEC Film, Inc. 1,2,3,4,5,6,8,9<br />

Optimation Technology, Inc. 1,3,8,9<br />

Polymer Science, Inc. 1,2,3,4,5,6,7,8,9<br />

Precision <strong>Coating</strong>s Inc. 1,2,3,4,5,6,7,8,9<br />

Pres-on Corp. 1,2,3,4<br />

Rayven Inc. 1,2,4,5,7,8,9<br />

Roethel GmbH & Co KG 1,2,3,4,5,6,7,8<br />

Sheldahl 1,2,4,5,6,7,8,9<br />

Sierra <strong>Coating</strong> Technologies 1,3,4,5,8<br />

SION Power Corporation 9<br />

Solar Gard Saint-Gobain 1,2,5,6,7,9<br />

Solutia’s Performance Films Division<br />

1,2,6,8,9<br />

Tollcoating by Carestream 1,3,5,7,8,9<br />

Ultra Violet<br />

Adhesives Research, Inc. 1<br />

Catalina Graphic Films 8<br />

Chase Corporation 1,2,3,4,5<br />

Commonwealth Laminating & <strong>Coating</strong>,<br />

Inc. 1,8,9<br />

DUNMORE Corporation 1,2,3,4,5,7,8,9<br />

Exopack Advanced <strong>Coating</strong>s<br />

1,2,3,4,5,6,7,8,9<br />

Glatfelter 1,3<br />

Graphic Packaging International, Inc.<br />

1,2,3,7<br />

Hanita <strong>Coating</strong>s 1,6,8,9<br />

Hueck Folien GmbH 1,2,3,4,5,7,8<br />

Johnson Laminating & <strong>Coating</strong>, Inc.<br />

1,2,5,6,7,8,9<br />

Lamart Corp. 1,2,3,4<br />

Loparex LLC 1,2,3,4,5,6,7,8,9<br />

MIRWEC Film, Inc. 1,2,3,4,5,6,8,9<br />

MPI Technologies, Inc. 1,3<br />

Polymer Science, Inc. 1,2,3,4,5,6,7,8,9<br />

Protect-all, Inc. 1,2,3,4,5<br />

Rayven Inc. 1,3,5<br />

Sigma Technologies International, Inc.<br />

1,2,3,4,5<br />

SION Power Corporation 9<br />

Solar Gard Saint-Gobain 1,2,5,6,9<br />

Solutia’s Performance Films Division 1,6,9<br />

Tekra Corporation 1,6,8,9<br />

LAMINATING<br />

3 Sigma Corporation 1,2,3,4,5,8,9<br />

Acucote Inc. 1,2,3,4,5,8<br />

Adchem Corporation 1,2,3,4,5,8,9<br />

Adhesive Applications 1,2,3,4,5,8,9<br />

Adhesives Research, Inc. 1,2,3,4,5<br />

AkzoNobel Specialty Plastics 1,4,5,6,7,8,9<br />

Amsterdam Metallized Products B.V.<br />

1,2,3,8,9<br />

Apical Division, Kaneka Texas<br />

Corporation 1<br />

Arlon, Inc. 1,2,3,5,7<br />

Brady Worldwide, Coated Products<br />

1,2,3,4,5,6,7,8,9<br />

Bryce Corporation 1,3,5<br />

Camvac Ltd. 1,8,9<br />

Catalina Graphic Films 1,2,8<br />

CCT (<strong>Coating</strong> & Converting Technologies)<br />

1,2,3,4,5,9<br />

Chase Corporation 1,2,3,4,5,6,8,9<br />

Chemsultants International 1,2,3,4,5,8,9<br />

Commonwealth Laminating & <strong>Coating</strong>,<br />

Inc. 1,8,9<br />

D&K Group, Inc. 1,2,3,4,5,8,9<br />

Dow Chemical Company 1,2,3,8,9<br />

DUNMORE Corporation 1,2,3,4,5,7,8,9,10<br />

Exopack Advanced <strong>Coating</strong>s<br />

1,2,3,4,5,6,7,8,9<br />

First Technology Innovation Inc<br />

1,2,3,5,6,7,8,9<br />

Flex America Inc. 1,2,3,9<br />

FLEXcon 1,2,4,5,8,9<br />

General Metallisers Ltd. 3<br />

Graphic Packaging International, Inc.<br />

1,2,3,7,8<br />

Griff Paper and Film 1,2,3,4,5<br />

Hanita <strong>Coating</strong>s 1,2,6,8,9<br />

Hazen Paper Co. 1,2,3<br />

Henkel Corporation 1,2,3,7,8,9<br />

Hueck Folien GmbH 1,2,3,4,5,7,8,9<br />

Hutchison Miller Sales Company 2,3,8<br />

Intertape Polymer Group 1,2,3,4,5<br />

Jessup Manufacturing Company<br />

1,2,3,4,5,8,9<br />

Johnson Laminating & <strong>Coating</strong>, Inc.<br />

1,2,5,6,7,8,9<br />

JX Nippon ANCI, Inc. 1,2,3,5<br />

KROENERT GmbH & Co KG<br />

1,2,3,5,6,7,8,9,10<br />

Label Technology 1,2,3,8<br />

Lamart Corp. 1,2,3,4,5,8,9<br />

Madico, Inc. 1,2,7,8,9<br />

Malaga Produtos Metalizados Ltd.<br />

1,2,3,8,9<br />

MIRWEC Film, Inc. 1,2,3,4,5,6,8,9<br />

MPI Technologies, Inc. 1,3,4,5<br />

Multifilm Packaging Corp. 1,2,3,10<br />

Optimation Technology, Inc. 1,3,8,9<br />

Parkinson Technologies 1,2,3,4,5,6<br />

Polymer Science, Inc. 1,2,3,4,5,6,7,8,9<br />

Polypacks Industries 1,3,8,9<br />

Precision <strong>Coating</strong>s Inc. 1,2,3,4,5,6,7,8,9<br />

Presco 1,4,5<br />

Pres-on Corp. 1,3,4,8,9<br />

Printpack Inc. 1,7,8,9<br />

Protect-all, Inc. 1,2,3,4,5,8<br />

Rayven Inc. 1,2,3,8,9<br />

Roethel GmbH & Co KG 1,2,3,4,5,7,8<br />

Roysons Corporation 1,3,4,5,8,9<br />

Sheldahl 1,2,4,5,6,7,8,9<br />

Sierra <strong>Coating</strong> Technologies 1,3,4,5,6,8<br />

Solar Gard Saint-Gobain 1,2,3,4,5,6,8,9<br />

Solutia’s Performance Films Division<br />

1,2,6,8,9<br />

Technical <strong>Coating</strong> Int’l, Inc.<br />

1,2,3,4,5,6,7,8,9<br />

Tekra Corporation 1,6<br />

thelamco, inc. 1,2,3,4,5,8,9<br />

Transilwrap Company, Inc. 1<br />

Unifoil Corp. 1,2,3,7,8,9<br />

UPM Raflatac, Inc. 1,3,8<br />

PILOT COATING<br />

3 Sigma Corporation 1,2,3,4,5,8,9<br />

Acucote Inc. 1,2,3,4,5,8<br />

Adchem Corporation 1,2,3,4,5,8,9<br />

Adhesives Research, Inc. 1,2,3,4,5,9<br />

AkzoNobel Specialty Plastics 1,6,7,8,9<br />

Arlon, Inc. 1,2,3,4,5,6,8,9<br />

Bostik, Inc. 1,2,8,9<br />

Brady Worldwide, Coated Products<br />

1,2,3,4,5,6,7,8,9<br />

Catalina Graphic Films 1,2,3,8<br />

Chemsultants International 1,2,3,4,5,8,9<br />

D&K Group, Inc. 1,2,3,4,5,8,9<br />

Dow Chemical Company 1,2,3,7,8,9<br />

Exopack Advanced <strong>Coating</strong>s 1,2,6,7,8,9<br />

Glatfelter 1,3,8<br />

Graphic Packaging International, Inc.<br />

1,2,3,4,5,7,8,9<br />

Griff Paper and Film 1,2,3,4,5<br />

Hanita <strong>Coating</strong>s 1,6,8,9<br />

Henkel Corporation 1,2,3,8,9<br />

Hueck Folien GmbH 1,2,3,4,5,7,8,9<br />

Intertape Polymer Group 1,2,3<br />

JDSU-Flex Products Group 1,2,3,6,9<br />

JX Nippon ANCI, Inc. 1,2,3,5<br />

KROENERT GmbH & Co KG<br />

1,2,3,5,6,7,8,9<br />

Label Technology 1,2,3,8<br />

Lamart Corp. 1,2,3,4,5,8,9<br />

Loparex LLC 1,2,3,4,5,6,7,8,9<br />

Madico, Inc. 1,2,7,8,9<br />

MIRWEC Film, Inc. 1,2,3,4,5,6,7,8,9<br />

MPI Technologies, Inc. 1,3,4,5<br />

Optimation Technology, Inc. 1,3,8,9<br />

Polymer Science, Inc. 1,2,3,4,5,6,7,8,9<br />

Precision <strong>Coating</strong>s Inc. 1,2,3,4,5,6,7,8,9<br />

Premier Dies Corporation 1,2,3,4,5,8<br />

Printpack Inc. 1,2,8,9<br />

Protect-all, Inc. 1,2,3,4,5,8<br />

Radiant Energy Systems, Inc.<br />

1,2,3,4,5,8,9<br />

Roethel GmbH & Co KG 1,2,3,4,5,6,7,8<br />

Sheldahl 1,2,4,5,6,7,8,9<br />

Sigma Technologies International, Inc.<br />

1,2,3,4,5<br />

SION Power Corporation 9<br />

Solar Gard Saint-Gobain 1,2,3,4,5,8,9<br />

Solutia’s Performance Films Division<br />

1,2,8,9<br />

Spooner Industries Inc. 1,2,3,4,8,9<br />

Technical <strong>Coating</strong> Int’l, Inc.<br />

1,2,3,4,5,6,7,8,9<br />

tesa tape, inc. 1<br />

thelamco, inc. 1,2,3,4,5,8,9<br />

Transilwrap Company, Inc. 1<br />

Unifoil Corp. 1,2,3,7,8,9<br />

PRINTING<br />

Flexographic<br />

Bryce Corporation 1,3,7,8,9<br />

Chase Corporation 1,2,3,4,5,6,8,9<br />

Glatfelter 1,3<br />

Graphic Packaging International, Inc.<br />

1,3,7,8<br />

Griff Paper and Film 1,2,3<br />

Hewlett-Packard Company Media<br />

Division 3<br />

Intertape Polymer Group 1,2,3<br />

JDSU-Flex Products Group 1,3<br />

KROENERT GmbH & Co KG<br />

1,2,3,6,7,8,9<br />

Label Technology 1,2,3,8<br />

Lamart Corp. 1<br />

Loparex LLC 1,2,3,4,5,6,7,8,9<br />

MPI Technologies, Inc. 1,3<br />

Multifilm Packaging Corp. 1,3,9<br />

Polymer Science, Inc. 1,2,3,4,5,6,7,8,9<br />

Presco 1,9<br />

Printpack Inc. 1,3,7,8,9<br />

Rayven Inc. 1,3,5<br />

Roethel GmbH & Co KG 1,2,3,4,5,8<br />

Sierra <strong>Coating</strong> Technologies 3,8<br />

Super Film Ambalaj Sanayi ve<br />

Ticaret A.S. 1<br />

Gravure<br />

AkzoNobel Specialty Plastics 1,7,8,9<br />

Chase Corporation 1,2,3,4,5,6,8,9<br />

D&K Group, Inc. 1,3,8,9<br />

DUNMORE Corporation 1,2,8,9<br />

Filmquest Group Inc. 1<br />

First Technology Innovation Inc 1,6,8,9<br />

Flex America Inc. 1,2,3,9<br />

Graphic Packaging International, Inc.<br />

1,3,7,8,9<br />

Griff Paper and Film 1,2,3<br />

www.aimcal.org | 9<br />

Member Capabilities

Member Capabilities<br />

Hazen Paper Co. 1,2,3,8,9<br />

Hueck Folien GmbH 1,2,3,4,5,7,8,9<br />

Hutchison Miller Sales Company 2,3,7,8,9<br />

Intertape Polymer Group 1,2,3<br />

KROENERT GmbH & Co KG<br />

1,2,3,6,7,8,9<br />

Lamart Corp. 1<br />

Malaga Produtos Metalizados Ltd.<br />

1,2,3,8,9<br />

Polymer Science, Inc. 1,2,3,4,5,6,7,8,9<br />

Polypacks Industries 1,3,7,8,9<br />

Printpack Inc. 1,3,7,8,9<br />

Roysons Corporation 1,3,4,5,8,9<br />

Solar Gard Saint-Gobain 1,3,5,8,9<br />

Technical <strong>Coating</strong> Int’l, Inc. 1,3,7,8,9<br />

Transilwrap Company, Inc. 1<br />

Other Converting Processes<br />

Calendering<br />

CBC<br />

General Metallisers Ltd.<br />

Glatfelter<br />

Intertape Polymer Group<br />

JX Nippon ANCI, Inc.<br />

Lamart Corp.<br />

Mississippi Polymers, Inc.<br />

Optimation Technology, Inc.<br />

Polymer Science, Inc.<br />

Printpack Inc.<br />

Unifoil Corp.<br />

Die-Cutting<br />

Adhesive Applications<br />

Arlon, Inc.<br />

Brady Worldwide, Coated Products<br />

Bryce Corporation<br />

D&K Group, Inc.<br />

Filmquest Group Inc.<br />

Griff Paper and Film<br />

Hewlett-Packard Company Media Division<br />

Hueck Folien GmbH<br />

JDSU-Flex Products Group<br />

Jessup Manufacturing Company<br />

Label Technology<br />

Materion Large Area <strong>Coating</strong>s<br />

Optimation Technology, Inc.<br />

Polymer Science, Inc.<br />

Pres-on Corp.<br />

Roethel GmbH & Co KG<br />

Sheldahl<br />

Transilwrap Company, Inc.<br />

Dyeing<br />

D&K Group, Inc.<br />

Filmquest Group Inc.<br />

FLEXcon<br />

Hanita <strong>Coating</strong>s<br />

Hueck Folien GmbH<br />

Jessup Manufacturing Company<br />

Sigma Technologies International, Inc.<br />

Solutia’s Performance Films Division<br />

Embossing<br />

AET Films<br />

AkzoNobel Specialty Plastics<br />

Amsterdam Metallized Products B.V.<br />

Bryce Corporation<br />

CBC<br />

Chase Corporation<br />

Filmquest Group Inc.<br />

FLEXcon<br />

General Metallisers Ltd.<br />

Hazen Paper Co.<br />

Hueck Folien GmbH<br />

Hutchison Miller Sales Company<br />

10 | 2012 AIMCAL SourceBook<br />

Jessup Manufacturing Company<br />

JX Nippon ANCI, Inc.<br />

Label Technology<br />

Malaga Produtos Metalizados Ltd.<br />

MPI Technologies, Inc.<br />

MTI & Polyexe Corporation<br />

Polymer Science, Inc.<br />

Printpack Inc.<br />

Roethel GmbH & Co KG<br />

Roysons Corporation<br />

Sheldahl<br />

Solutia’s Performance Films Division<br />

Unifoil Corp.<br />

Vacumet Corp.<br />

Perforating<br />

Arlon, Inc.<br />

Bryce Corporation<br />

Chase Corporation<br />

D&K Group, Inc.<br />

DUNMORE Corporation<br />

Filmquest Group Inc.<br />

Hewlett-Packard Company Media Division<br />

Intertape Polymer Group<br />

Jessup Manufacturing Company<br />

Label Technology<br />

Loparex LLC<br />

Optimation Technology, Inc.<br />

Polymer Science, Inc.<br />

Presco<br />

Pres-on Corp.<br />

Printpack Inc.<br />

Roethel GmbH & Co KG<br />

Sheldahl<br />

Super Film Ambalaj Sanayi ve<br />

Ticaret A.S.<br />

tesa tape, inc.<br />

thelamco, inc.<br />

Transilwrap Company, Inc.<br />

Sheeting<br />

3 Sigma Corporation<br />

Acucote Inc.<br />

Adchem Corporation<br />

Adhesive Applications<br />

Adhesives Research, Inc.<br />

AET Films<br />

Amsterdam Metallized Products B.V.<br />

AmTopp Div of Inteplast Group<br />

Arlon, Inc.<br />

Brady Worldwide, Coated Products<br />

Catalina Graphic Films<br />

CBC<br />

Chase Corporation<br />

D&K Group, Inc.<br />

Exopack Advanced <strong>Coating</strong>s<br />

Filmquest Group Inc.<br />

FLEXcon<br />

General Metallisers Ltd.<br />

Glatfelter<br />

Griff Paper and Film<br />

Hazen Paper Co.<br />

Hewlett-Packard Company Media Division<br />

Hueck Folien GmbH<br />

Hutchison Miller Sales Company<br />

Jessup Manufacturing Company<br />

L.C.O.A. Laminating Company of America<br />

Label Technology<br />

Lamart Corp.<br />

Loparex LLC<br />

Madico, Inc.<br />

Malaga Produtos Metalizados Ltd.<br />

MPI Technologies, Inc.<br />

Optimation Technology, Inc.<br />

Polymer Science, Inc.<br />

Polypacks Industries<br />

Precision <strong>Coating</strong>s Inc.<br />

Pres-on Corp.<br />

Protect-all, Inc.<br />

Rayven Inc.<br />

Roethel GmbH & Co KG<br />

Sheldahl<br />

Technical <strong>Coating</strong> Int’l, Inc.<br />

Tollcoating by Carestream<br />

Transilwrap Company, Inc.<br />

Unifoil Corp.<br />

Vacumet Corp.<br />

Vistana<br />

Slitting<br />

3 Sigma Corporation<br />

Acucote Inc.<br />

Adchem Corporation<br />

Adhesive Applications<br />

Adhesives Research, Inc.<br />

AET Films<br />

AJ Plast Public Company Limited<br />

AkzoNobel Specialty Plastics<br />

Amsterdam Metallized Products B.V.<br />

AmTopp Div of Inteplast Group<br />

Apical Division, Kaneka Texas<br />

Corporation<br />

Arlon, Inc.<br />

Brady Worldwide, Coated Products<br />

Bryce Corporation<br />

Camvac Ltd.<br />

Canslit Inc.<br />

Catalina Graphic Films<br />

CBC<br />

CCT (<strong>Coating</strong> & Converting Technologies)<br />

Celplast Metallized Products<br />

Chase Corporation<br />

Chemsultants International<br />

D&K Group, Inc.<br />

Dow Chemical Company<br />

DUNMORE Corporation<br />

Exopack Advanced <strong>Coating</strong>s<br />

Filmquest Group Inc.<br />

First Technology Innovation Inc<br />

Flex America Inc.<br />

FLEXcon<br />

General Metallisers Ltd.<br />

Glatfelter<br />

Griff Paper and Film<br />

Hanita <strong>Coating</strong>s<br />

Hazen Paper Co.<br />

Hewlett-Packard Company Media Division<br />

Hueck Folien GmbH<br />

Hutchison Miller Sales Company<br />

Intertape Polymer Group<br />

JDSU-Flex Products Group<br />

Jessup Manufacturing Company<br />

Johnson Laminating & <strong>Coating</strong>, Inc.<br />

JX Nippon ANCI, Inc.<br />

L.C.O.A. Laminating Company of America<br />

Label Technology<br />

Lamart Corp.<br />

Loparex LLC<br />

Madico, Inc.<br />

Malaga Produtos Metalizados Ltd.<br />

Materion Large Area <strong>Coating</strong>s<br />

Mississippi Polymers, Inc.<br />

MPI Technologies, Inc.<br />

MTI & Polyexe Corporation<br />

Optimation Technology, Inc.<br />

Parkinson Technologies<br />

Polymer Science, Inc.<br />

Polypacks Industries<br />

Polyplex Corporation Ltd.<br />

Precision <strong>Coating</strong>s Inc.<br />

Presco<br />

Pres-on Corp.<br />

Printpack Inc.<br />

Protect-all, Inc.<br />

Rayven Inc.<br />

Roethel GmbH & Co KG<br />

Rol-Vac, LP<br />

Roysons Corporation<br />

Sheldahl<br />

Sierra <strong>Coating</strong> Technologies<br />

Solar Gard Saint-Gobain<br />

Solutia’s Performance Films Division<br />

Super Film Ambalaj Sanayi ve<br />

Ticaret A.S.<br />

Technical <strong>Coating</strong> Int’l, Inc.<br />

tesa tape, inc.<br />

thelamco, inc.<br />

Tollcoating by Carestream<br />

Transilwrap Company, Inc.<br />

Unifoil Corp.<br />

UPM Raflatac, Inc.<br />

Vacumet Corp.<br />

Vistana<br />

Solution Preparation<br />

Amsterdam Metallized Products B.V.<br />

CBC<br />

Chemsultants International<br />

Jessup Manufacturing Company<br />

New Era Converting Machinery, Inc.<br />

Precision <strong>Coating</strong>s Inc.<br />

Tollcoating by Carestream<br />

Toray Plastics America Inc.<br />

De-Metallizing<br />

Griff Paper and Film<br />

Multifilm Packaging Corp.<br />

Vast Films, Ltd.<br />

Vacuum <strong>Coating</strong> Processes<br />

1-Aluminum<br />

2-Other Metals<br />

3-ITO<br />

4-Other Non-Metals<br />

5-Multi-Layers<br />

EVAPORATIVE<br />

AET Films 1<br />

Filmquest Group Inc. 1<br />

Kurt J. Lesker Co. Inc. 1,2,3,4,5<br />

CVD<br />

Malaga Produtos Metalizados Ltd. 2,1<br />

Electron Beam<br />

JDSU-Flex Products Group 1,2,4,5<br />

Kurt J. Lesker Co. Inc. 1,2,3,4,5<br />

Sheldahl 1,2,3,4,5<br />

Sigma Technologies International, Inc.<br />

1,2,4<br />

Vast Films, Ltd. 1,2,4,5<br />

Induction<br />

Flex America Inc. 1<br />

MPI Technologies, Inc. 1<br />

Monomer Evaporation<br />

JBF RAK LLC 1<br />

University of Oxford, Department of<br />

Materials 4,5<br />

Resistance<br />

AJ Plast Public Company Limited 1<br />

Amsterdam Metallized Products B.V. 1<br />

AmTopp Div of Inteplast Group 1<br />

Bryce Corporation 1<br />

Camvac Ltd. 1

Member Capabilities<br />

Canslit Inc. 1<br />

Celplast Metallized Products 1,2<br />

DUNMORE Corporation 1,2<br />

FILMtech, Inc. 1,4<br />

General Metallisers Ltd. 1<br />

Glatfelter 1<br />

Graphic Packaging International, Inc. 1,2<br />

Hanita <strong>Coating</strong>s 1,2,5<br />

Hueck Folien GmbH 1,2,4<br />

JDSU-Flex Products Group 1,2,5<br />

Kurt J. Lesker Co. Inc. 1,2,3,4,5<br />

Madico, Inc. 1<br />

Multifilm Packaging Corp. 1<br />

Polypacks Industries 1<br />

Polyplex Corporation Ltd. 1<br />

Printpack Inc. 1,2<br />

Rol-Vac, LP 1<br />

Schmid Vacuum Technology GmbH 1<br />

Sheldahl 1,2,3,4,5<br />

Sigma Technologies International, Inc. 1<br />

SION Power Corporation 4,5<br />

Solutia’s Performance Films Division 1,2,4<br />

Super Film Ambalaj Sanayi ve Ticaret<br />

A.S. 1<br />

Terphane Inc. 1<br />

University of Oxford, Department of<br />

Materials 1,2,4,5<br />

Vacumet Corp. 1,2<br />

Vacuum Depositing Inc. 1,2,3,5<br />

Vast Films, Ltd. 1,2,5<br />

SPUTTERING<br />

Angstrom Sciences Inc. 1,2,3,4,5<br />

Deposition Technology Innovations<br />

1,2,3,4,5<br />

Hanita <strong>Coating</strong>s 1,2,5<br />

JDSU-Flex Products Group 1,2,3,4,5<br />

Kurt J. Lesker Co. Inc. 1,2,3,4,5<br />

Materion Large Area <strong>Coating</strong>s 1,2,3,4,5<br />

Polymer Science, Inc. 1,2,3,4,5<br />

Schmid Vacuum Technology GmbH<br />

1,2,3,4,5<br />

Sheldahl 1,2,3,4,5<br />

Sigma Technologies International, Inc.<br />

1,2,3,4,5<br />

SION Power Corporation 4,5<br />

Solar Gard Saint-Gobain 1,2,3,4,5<br />

Solutia’s Performance Films Division<br />

1,2,3,4,5<br />

Southwall Technologies, Inc. 1,2,3,4,5<br />

University of Oxford, Department of<br />

Materials 1,2,5<br />

Vacuum Depositing Inc. 1,2,3,5<br />

STRIPING<br />

Patterned<br />

Camvac Ltd. 1<br />

Filmquest Group Inc. 1<br />

FILMtech, Inc. 1<br />

Hueck Folien GmbH 1,2,4<br />

Polymer Science, Inc. 1,2,3,4,5<br />

Polypacks Industries 1<br />

Sheldahl 1,2,3,4,5<br />

Sigma Technologies International, Inc.<br />

1,4,5<br />

SION Power Corporation 4,5<br />

Vast Films, Ltd. 1,2,5<br />

Striping<br />

Camvac Ltd. 1<br />

Celplast Metallized Products 1<br />

Deposition Technology Innovations<br />

1,2,3,4,5<br />

DUNMORE Corporation 1,2<br />

Filmquest Group Inc. 1<br />

FILMtech, Inc. 1<br />

12 | 2012 AIMCAL SourceBook<br />

Hueck Folien GmbH 1,2,4<br />

Materion Large Area <strong>Coating</strong>s 1,2,3,4,5<br />

Multifilm Packaging Corp. 1<br />

Polymer Science, Inc. 1,2,3,4,5<br />

Polypacks Industries 1<br />

Printpack Inc. 1<br />

Rol-Vac, LP 1<br />

Sheldahl 1,2,3,4,5<br />

Sigma Technologies International, Inc.<br />

1,4,5<br />

SION Power Corporation 4,5<br />

Solutia’s Performance Films Division<br />

1,2,3,4,5<br />

Vacuum Depositing Inc. 1,2,3,5<br />

Vast Films, Ltd. 1,2,5<br />

TRANSFER<br />

Amsterdam Metallized Products B.V. 1<br />

DUNMORE Corporation 1,2<br />

Flex America Inc. 1<br />

General Metallisers Ltd. 1<br />

Hazen Paper Co. 1<br />

JBF RAK LLC 1<br />

MPI Technologies, Inc. 1<br />

Polypacks Industries 1<br />

Schmid Vacuum Technology GmbH 1<br />

Sheldahl 1,2,3,4,5<br />

Unifoil Corp. 1<br />

Vast Films, Ltd. 1,2,5<br />

Products Converted<br />

ANTI-REFLECTION FILMS<br />

ATLAS CONVERTING EQUIPMENT<br />

LTD.<br />

CBC<br />

D&K Group, Inc.<br />

DUNMORE Corporation<br />

Exopack Advanced <strong>Coating</strong>s<br />

Filmquest Group Inc.<br />

First Technology Innovation Inc<br />

Hueck Folien GmbH<br />

Jessup Manufacturing Company<br />

Johnson Laminating & <strong>Coating</strong>, Inc.<br />

Lamart Corp.<br />

Madico, Inc.<br />

Materion Large Area <strong>Coating</strong>s<br />

MIRWEC Film, Inc.<br />

MTI & Polyexe Corporation<br />

Polymer Science, Inc.<br />

Precision <strong>Coating</strong>s Inc.<br />

Protect-all, Inc.<br />

Roethel GmbH & Co KG<br />

Sigma Technologies International, Inc.<br />

Solar Gard Saint-Gobain<br />

Solutia’s Performance Films Division<br />

Southwall Technologies, Inc.<br />

Technical <strong>Coating</strong> Int’l, Inc.<br />

Tekra Corporation<br />

Tollcoating by Carestream<br />

Vacuum Depositing Inc.<br />

Vistana<br />

ANTI-STATIC FILMS<br />

Acucote Inc.<br />

Brady Worldwide, Coated Products<br />

Camvac Ltd.<br />

Canslit Inc.<br />

Catalina Graphic Films<br />

CBC<br />

Celplast Metallized Products<br />

Chase Corporation<br />

D&K Group, Inc.<br />

DUNMORE Corporation<br />

ESTER INDUSTRIES LIMITED<br />

Exopack Advanced <strong>Coating</strong>s<br />

Filmquest Group Inc.<br />

FILMtech, Inc.<br />

First Technology Innovation Inc<br />

Hanita <strong>Coating</strong>s<br />

Hueck Folien GmbH<br />

JBF RAK LLC<br />

Jessup Manufacturing Company<br />

Johnson Laminating & <strong>Coating</strong>, Inc.<br />

Lamart Corp.<br />

Materion Large Area <strong>Coating</strong>s<br />

MIRWEC Film, Inc.<br />

Mitsubishi Polyester Film, Inc.<br />

MPI Technologies, Inc.<br />

MTI & Polyexe Corporation<br />

Polymer Science, Inc.<br />

Precision <strong>Coating</strong>s Inc.<br />

Presco<br />

Printpack Inc.<br />

Protect-all, Inc.<br />

Roethel GmbH & Co KG<br />

Sierra <strong>Coating</strong> Technologies<br />

Sigma Technologies International, Inc.<br />

Solar Gard Saint-Gobain<br />

Solutia’s Performance Films Division<br />

Southwall Technologies, Inc.<br />

Technical <strong>Coating</strong> Int’l, Inc.<br />

Tekra Corporation<br />

thelamco, inc.<br />

Tollcoating by Carestream<br />

Transilwrap Company, Inc.<br />

Vacumet Corp.<br />

Vacuum Depositing Inc.<br />

Vast Films, Ltd.<br />

Vistana<br />

BAGS<br />

ATLAS CONVERTING EQUIPMENT<br />

LTD.<br />

Bryce Corporation<br />

FILMtech, Inc.<br />

Flex America Inc.<br />

Printpack Inc.<br />

thelamco, inc.<br />

BATTERY COMPONENTS<br />

CBC<br />

Chase Corporation<br />

DUNMORE Corporation<br />

Exopack Advanced <strong>Coating</strong>s<br />

Filmquest Group Inc.<br />

Hueck Folien GmbH<br />

Lamart Corp.<br />

Polymer Science, Inc.<br />

Protect-all, Inc.<br />

Sierra <strong>Coating</strong> Technologies<br />

SION Power Corporation<br />

BIODEGRADABLE FILMS<br />

Acucote Inc.<br />

Amsterdam Metallized Products B.V.<br />

CBC<br />

Filmquest Group Inc.<br />

Intertape Polymer Group<br />

JX Nippon ANCI, Inc.<br />

Label Technology<br />

MTI & Polyexe Corporation<br />

Printpack Inc.<br />

Protect-all, Inc.<br />

Sierra <strong>Coating</strong> Technologies<br />

University of Oxford, Department of<br />

Materials<br />

Vistana<br />

CAPACITORS<br />

Canslit Inc.<br />

Exopack Advanced <strong>Coating</strong>s<br />

Hueck Folien GmbH<br />

Polymer Science, Inc.<br />

Sigma Technologies International, Inc.<br />

Solar Gard Saint-Gobain<br />

Tollcoating by Carestream<br />

Vast Films, Ltd.<br />

CONDUCTIVE FILMS/PAPERS<br />

Adhesives Research, Inc.<br />

Brady Worldwide, Coated Products<br />

Canslit Inc.<br />

Catalina Graphic Films<br />

CBC<br />

Celplast Metallized Products<br />

Chase Corporation<br />

D&K Group, Inc.<br />

DUNMORE Corporation<br />

Exopack Advanced <strong>Coating</strong>s<br />

Filmquest Group Inc.<br />

FLEXcon<br />

Glatfelter<br />

Griff Paper and Film<br />

Hanita <strong>Coating</strong>s<br />

Hueck Folien GmbH<br />

Jessup Manufacturing Company<br />

Lamart Corp.<br />

Malaga Produtos Metalizados Ltd.<br />

Materion Large Area <strong>Coating</strong>s<br />

Polymer Science, Inc.<br />

Precision <strong>Coating</strong>s Inc.<br />

Presco<br />

Pres-on Corp.<br />

Protect-all, Inc.<br />

Roethel GmbH & Co KG<br />

Sheldahl<br />

Sierra <strong>Coating</strong> Technologies<br />

Sigma Technologies International, Inc.<br />

Solar Gard Saint-Gobain<br />

Solutia’s Performance Films Division<br />

Southwall Technologies, Inc.<br />

Technical <strong>Coating</strong> Int’l, Inc.<br />

thelamco, inc.<br />

Tollcoating by Carestream<br />

Vacumet Corp.<br />

Vast Films, Ltd.<br />

Vistana<br />

CRT DISPLAY FILMS<br />

Adhesives Research, Inc.<br />

D&K Group, Inc.<br />

Exopack Advanced <strong>Coating</strong>s<br />

Hueck Folien GmbH<br />

Johnson Laminating & <strong>Coating</strong>, Inc.<br />

MIRWEC Film, Inc.<br />

Polymer Science, Inc.<br />

Precision <strong>Coating</strong>s Inc.<br />

Protect-all, Inc.<br />

Sheldahl<br />

Sigma Technologies International, Inc.<br />

Solar Gard Saint-Gobain<br />

Solutia’s Performance Films Division<br />

Southwall Technologies, Inc.<br />

Tekra Corporation<br />

Tollcoating by Carestream<br />

DECALS<br />

Arlon, Inc.<br />

Brady Worldwide, Coated Products<br />

Catalina Graphic Films<br />

CBC<br />

Celplast Metallized Products<br />

Chemsultants International<br />

D&K Group, Inc.<br />

DUNMORE Corporation<br />

Exopack Advanced <strong>Coating</strong>s

Filmquest Group Inc.<br />

FLEXcon<br />

Griff Paper and Film<br />

Hueck Folien GmbH<br />

Jessup Manufacturing Company<br />

Polymer Science, Inc.<br />

Protect-all, Inc.<br />

Rayven Inc.<br />

Solar Gard Saint-Gobain<br />

Tekra Corporation<br />

thelamco, inc.<br />

Tollcoating by Carestream<br />

Vacumet Corp.<br />

DECORATIVE FILMS<br />

3 Sigma Corporation<br />

Acucote Inc.<br />

AET Films<br />

AkzoNobel Specialty Plastics<br />

Amsterdam Metallized Products B.V.<br />

Arlon, Inc.<br />

ATLAS CONVERTING EQUIPMENT<br />

LTD.<br />

Bryce Corporation<br />

Camvac Ltd.<br />

Canslit Inc.<br />

Catalina Graphic Films<br />

CBC<br />

Celplast Metallized Products<br />

Chase Corporation<br />

Crown Roll Leaf, Inc.<br />

D&K Group, Inc.<br />

DUNMORE Corporation<br />

Exopack Advanced <strong>Coating</strong>s<br />

ExxonMobil Chemical<br />

Filmquest Group Inc.<br />

FILMtech, Inc.<br />

First Technology Innovation Inc<br />

Flex America Inc.<br />

FLEXcon<br />

Griff Paper and Film<br />

Hanita <strong>Coating</strong>s<br />

Hazen Paper Co.<br />

Hueck Folien GmbH<br />

Hutchison Miller Sales Company<br />

JDSU-Flex Products Group<br />

Jessup Manufacturing Company<br />

JX Nippon ANCI, Inc.<br />

Lamart Corp.<br />

Madico, Inc.<br />

Malaga Produtos Metalizados Ltd.<br />

Materion Large Area <strong>Coating</strong>s<br />

MPI Technologies, Inc.<br />

Polymer Science, Inc.<br />

Polypacks Industries<br />

Presco<br />

Printpack Inc.<br />

Protect-all, Inc.<br />

Rayven Inc.<br />

Roethel GmbH & Co KG<br />

Rol-Vac, LP<br />

Roysons Corporation<br />

Sierra <strong>Coating</strong> Technologies<br />

Sigma Technologies International, Inc.<br />

Solar Gard Saint-Gobain<br />

Solutia’s Performance Films Division<br />

Technical <strong>Coating</strong> Int’l, Inc.<br />

Tekra Corporation<br />

Terphane Inc.<br />

thelamco, inc.<br />

Unifoil Corp.<br />

University of Oxford, Department of<br />

Materials<br />

Vacumet Corp.<br />

Vast Films, Ltd.<br />

DECORATIVE FOILS<br />

3 Sigma Corporation<br />

Acucote Inc.<br />

Arlon, Inc.<br />

Catalina Graphic Films<br />

Chase Corporation<br />

Crown Roll Leaf, Inc.<br />

D&K Group, Inc.<br />

DUNMORE Corporation<br />

Exopack Advanced <strong>Coating</strong>s<br />

Filmquest Group Inc.<br />

Hazen Paper Co.<br />

Hueck Folien GmbH<br />

Hutchison Miller Sales Company<br />

JDSU-Flex Products Group<br />

Jessup Manufacturing Company<br />

Lamart Corp.<br />

Malaga Produtos Metalizados Ltd.<br />

Polymer Science, Inc.<br />

Polypacks Industries<br />

Protect-all, Inc.<br />

Rayven Inc.<br />

Roethel GmbH & Co KG<br />

Sigma Technologies International, Inc.<br />

Solar Gard Saint-Gobain<br />

Solutia’s Performance Films Division<br />

Technical <strong>Coating</strong> Int’l, Inc.<br />

Unifoil Corp.<br />

DECORATIVE PAINT<br />

AkzoNobel Specialty Plastics<br />

D&K Group, Inc.<br />

JDSU-Flex Products Group<br />

DECORATIVE PAPERS<br />

3 Sigma Corporation<br />

Acucote Inc.<br />

Amsterdam Metallized Products B.V.<br />

ATLAS CONVERTING EQUIPMENT<br />

LTD.<br />

CBC<br />

Chase Corporation<br />

D&K Group, Inc.<br />

Flex America Inc.<br />

General Metallisers Ltd.<br />

Glatfelter<br />

Griff Paper and Film<br />

Hazen Paper Co.<br />

Hewlett-Packard Company Media Division<br />

Hueck Folien GmbH<br />

Hutchison Miller Sales Company<br />

Jessup Manufacturing Company<br />

Lamart Corp.<br />

Malaga Produtos Metalizados Ltd.<br />

Polymer Science, Inc.<br />

Polypacks Industries<br />

Protect-all, Inc.<br />

Rayven Inc.<br />

Roethel GmbH & Co KG<br />

Roysons Corporation<br />

Sierra <strong>Coating</strong> Technologies<br />

Sigma Technologies International, Inc.<br />

Technical <strong>Coating</strong> Int’l, Inc.<br />

thelamco, inc.<br />

Unifoil Corp.<br />

Vacumet Corp.<br />

www.aimcal.org | 13<br />

Member Capabilities

Member Capabilities<br />

DIAGNOSTIC FILM<br />

CBC<br />

D&K Group, Inc.<br />

DUNMORE Corporation<br />

ESTER INDUSTRIES LIMITED<br />

Filmquest Group Inc.<br />

Hueck Folien GmbH<br />

Jessup Manufacturing Company<br />

Materion Large Area <strong>Coating</strong>s<br />

MIRWEC Film, Inc.<br />

Polymer Science, Inc.<br />

Sheldahl<br />

Sigma Technologies International, Inc.<br />

Solar Gard Saint-Gobain<br />

Tollcoating by Carestream<br />

Vistana<br />

DIAZO FILMS/PAPERS<br />

Exopack Advanced <strong>Coating</strong>s<br />

Filmquest Group Inc.<br />

Hueck Folien GmbH<br />

MIRWEC Film, Inc.<br />

Polymer Science, Inc.<br />

Precision <strong>Coating</strong>s Inc.<br />

Tollcoating by Carestream<br />

Transilwrap Company, Inc.<br />

DIELECTRICS<br />

Arlon, Inc.<br />

Brady Worldwide, Coated Products<br />

CBC<br />

Celplast Metallized Products<br />

Chase Corporation<br />

DUNMORE Corporation<br />

Exopack Advanced <strong>Coating</strong>s<br />

Filmquest Group Inc.<br />

Griff Paper and Film<br />

Hanita <strong>Coating</strong>s<br />

Hueck Folien GmbH<br />

JDSU-Flex Products Group<br />

Lamart Corp.<br />

Materion Large Area <strong>Coating</strong>s<br />

MIRWEC Film, Inc.<br />

Polymer Science, Inc.<br />

Precision <strong>Coating</strong>s Inc.<br />

Roethel GmbH & Co KG<br />

Sigma Technologies International, Inc.<br />

Solar Gard Saint-Gobain<br />

Southwall Technologies, Inc.<br />

Tollcoating by Carestream<br />

University of Oxford, Department of<br />

Materials<br />

Vacuum Depositing Inc.<br />

Vast Films, Ltd.<br />

Vistana<br />

DISPLAY COMPONENTS<br />

Adhesives Research, Inc.<br />

AkzoNobel Specialty Plastics<br />

Amsterdam Metallized Products B.V.<br />

Canslit Inc.<br />

Celplast Metallized Products<br />

DUNMORE Corporation<br />

Exopack Advanced <strong>Coating</strong>s<br />

General Metallisers Ltd.<br />

Hewlett-Packard Company Media Division<br />

Hueck Folien GmbH<br />

Jessup Manufacturing Company<br />

Johnson Laminating & <strong>Coating</strong>, Inc.<br />

Lamart Corp.<br />

Materion Large Area <strong>Coating</strong>s<br />

MIRWEC Film, Inc.<br />

Polymer Science, Inc.<br />

Precision <strong>Coating</strong>s Inc.<br />

Pres-on Corp.<br />

Protect-all, Inc.<br />

Sheldahl<br />

14 | 2012 AIMCAL SourceBook<br />

Sigma Technologies International, Inc.<br />

Solar Gard Saint-Gobain<br />

Solutia’s Performance Films Division<br />

Southwall Technologies, Inc.<br />

Tollcoating by Carestream<br />

Unifoil Corp.<br />

Vistana<br />

DISSOLVABLE FILMS<br />

3 Sigma Corporation<br />

Acucote Inc.<br />

Adhesives Research, Inc.<br />

DUNMORE Corporation<br />

Polymer Science, Inc.<br />

EMBOSSED FILMS<br />

Acucote Inc.<br />

AET Films<br />

ATLAS CONVERTING EQUIPMENT<br />

LTD.<br />

Bryce Corporation<br />

Catalina Graphic Films<br />

Celplast Metallized Products<br />

Chase Corporation<br />

Crown Roll Leaf, Inc.<br />

D&K Group, Inc.<br />

DUNMORE Corporation<br />

Exopack Advanced <strong>Coating</strong>s<br />

Filmquest Group Inc.<br />

First Technology Innovation Inc<br />

FLEXcon<br />

Griff Paper and Film<br />

Hueck Folien GmbH<br />

JDSU-Flex Products Group<br />

Jessup Manufacturing Company<br />

JX Nippon ANCI, Inc.<br />

Lamart Corp.<br />

Malaga Produtos Metalizados Ltd.<br />

MTI & Polyexe Corporation<br />

Polymer Science, Inc.<br />

Presco<br />

Pres-on Corp.<br />

Printpack Inc.<br />

Protect-all, Inc.<br />

Roethel GmbH & Co KG<br />

Roysons Corporation<br />

Sheldahl<br />

Solar Gard Saint-Gobain<br />

Solutia’s Performance Films Division<br />

Unifoil Corp.<br />

Vacumet Corp.<br />

Vacuum Depositing Inc.<br />

Vast Films, Ltd.<br />

Vistana<br />

EMBOSSED PAPERS<br />

Acucote Inc.<br />

ATLAS CONVERTING EQUIPMENT<br />

LTD.<br />

CBC<br />

Chase Corporation<br />

D&K Group, Inc.<br />

General Metallisers Ltd.<br />

Griff Paper and Film<br />

Hazen Paper Co.<br />

Hueck Folien GmbH<br />

Hutchison Miller Sales Company<br />

Jessup Manufacturing Company<br />

JX Nippon ANCI, Inc.<br />

Lamart Corp.<br />

Malaga Produtos Metalizados Ltd.<br />

Polymer Science, Inc.<br />

Protect-all, Inc.<br />

Roethel GmbH & Co KG<br />

Sierra <strong>Coating</strong> Technologies<br />

thelamco, inc.<br />

Unifoil Corp.<br />

Vacumet Corp.<br />

Vast Films, Ltd.<br />

Vistana<br />

FLEXIBLE CIRCUIT LAMINATES<br />

Arlon, Inc.<br />

Brady Worldwide, Coated Products<br />

D&K Group, Inc.<br />

DUNMORE Corporation<br />

Exopack Advanced <strong>Coating</strong>s<br />

Filmquest Group Inc.<br />

FLEXcon<br />

Graphic Packaging International, Inc.<br />

Hanita <strong>Coating</strong>s<br />

Hueck Folien GmbH<br />

Jessup Manufacturing Company<br />

Johnson Laminating & <strong>Coating</strong>, Inc.<br />

Lamart Corp.<br />

Materion Large Area <strong>Coating</strong>s<br />

MIRWEC Film, Inc.<br />

Polymer Science, Inc.<br />

Protect-all, Inc.<br />

Sheldahl<br />

Solar Gard Saint-Gobain<br />

Technical <strong>Coating</strong> Int’l, Inc.<br />

Vistana<br />

FLEXIBLE PACKAGING<br />

AET Films<br />

Amsterdam Metallized Products B.V.<br />

ATLAS CONVERTING EQUIPMENT<br />

LTD.<br />

Bryce Corporation<br />

Camvac Ltd.<br />

Canslit Inc.<br />

CBC<br />

Celplast Metallized Products<br />

Chase Corporation<br />

D&K Group, Inc.<br />

DUNMORE Corporation<br />

ESTER INDUSTRIES LIMITED<br />

Exopack Advanced <strong>Coating</strong>s<br />

Filmquest Group Inc.<br />

FILMtech, Inc.<br />

Flex America Inc.<br />

Griff Paper and Film<br />

Hanita <strong>Coating</strong>s<br />

Hewlett-Packard Company Media Division<br />