Coating - Aimcal

Coating - Aimcal

Coating - Aimcal

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

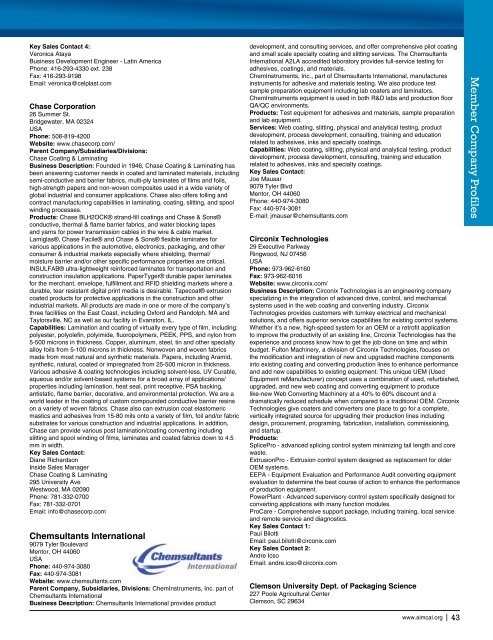

Key sales contact 4:<br />

Veronica Ataya<br />

Business Development Engineer - Latin America<br />

Phone: 416-293-4330 ext. 238<br />

Fax: 416-293-9198<br />

Email: veronica@celplast.com<br />

chase corporation<br />

26 Summer St.<br />

Bridgewater, MA 02324<br />

USA<br />

Phone: 508-819-4200<br />

Website: www.chasecorp.com/<br />

Parent company/subsidiaries/Divisions:<br />

Chase <strong>Coating</strong> & Laminating<br />

Business Description: Founded in 1946, Chase <strong>Coating</strong> & Laminating has<br />

been answering customer needs in coated and laminated materials, including<br />

semi-conductive and barrier fabrics, multi-ply laminates of films and foils,<br />

high-strength papers and non-woven composites used in a wide variety of<br />

global industrial and consumer applications. Chase also offers tolling and<br />

contract manufacturing capabilities in laminating, coating, slitting, and spool<br />

winding processes.<br />

Products: Chase BLH2OCK® strand-fill coatings and Chase & Sons®<br />

conductive, thermal & flame barrier fabrics, and water blocking tapes<br />

and yarns for power transmission cables in the wire & cable market.<br />

Lamiglas®, Chase Facile® and Chase & Sons® flexible laminates for<br />

various applications in the automotive, electronics, packaging, and other<br />

consumer & industrial markets especially where shielding, thermal/<br />

moisture barrier and/or other specific performance properties are critical.<br />

InSULFAB® ultra-lightweight reinforced laminates for transportation and<br />

construction insulation applications. PaperTyger® durable paper laminates<br />

for the merchant, envelope, fulfillment and RFID shielding markets where a<br />

durable, tear resistant digital print media is desirable. Tapecoat® extrusion<br />

coated products for protective applications in the construction and other<br />

industrial markets. All products are made in one or more of the company’s<br />

three facilities on the East Coast, including Oxford and Randolph, MA and<br />

Taylorsville, nC as well as our facility in Evanston, IL.<br />

capabilities: Lamination and coating of virtually every type of film, including:<br />

polyester, polyolefin, polyimide, fluoropolymers, PEEK, PPS, and nylon from<br />

5-500 microns in thickness. Copper, aluminum, steel, tin and other specialty<br />

alloy foils from 5-100 microns in thickness. nonwoven and woven fabrics<br />

made from most natural and synthetic materials. Papers, including Aramid,<br />

synthetic, natural, coated or impregnated from 25-500 micron in thickness.<br />

Various adhesive & coating technologies including solvent-less, UV Curable,<br />

aqueous and/or solvent-based systems for a broad array of applications/<br />

properties including lamination, heat seal, print receptive, PSA backing,<br />

antistatic, flame barrier, decorative, and environmental protection. We are a<br />

world leader in the coating of custom compounded conductive barrier resins<br />

on a variety of woven fabrics. Chase also can extrusion coat elastomeric<br />

mastics and adhesives from 15-80 mils onto a variety of film, foil and/or fabric<br />

substrates for various construction and industrial applications. In addition,<br />

Chase can provide various post lamination/coating converting including<br />

slitting and spool winding of films, laminates and coated fabrics down to 4.5<br />

mm in width.<br />

Key sales contact:<br />

Diane Richardson<br />

Inside Sales Manager<br />

Chase <strong>Coating</strong> & Laminating<br />

295 University Ave<br />

Westwood, MA 02090<br />

Phone: 781-332-0700<br />

Fax: 781-332-0701<br />

Email: info@chasecorp.com<br />

chemsultants international<br />

9079 Tyler Boulevard<br />

Mentor, OH 44060<br />

USA<br />

Phone: 440-974-3080<br />

Fax: 440-974-3081<br />

Website: www.chemsultants.com<br />

Parent company, subsidiaries, Divisions: ChemInstruments, Inc. part of<br />

Chemsultants International<br />

Business Description: Chemsultants International provides product<br />

development, and consulting services, and offer comprehensive pilot coating<br />

and small scale specialty coating and slitting services. The Chemsultants<br />

International A2LA accredited laboratory provides full-service testing for<br />

adhesives, coatings, and materials.<br />

ChemInstruments, Inc., part of Chemsultants International, manufactures<br />

instruments for adhesive and materials testing. We also produce test<br />

sample preparation equipment including lab coaters and laminators.<br />

ChemInstruments equipment is used in both R&D labs and production floor<br />

QA/QC environments.<br />

Products: Test equipment for adhesives and materials, sample preparation<br />

and lab equipment.<br />

services: Web coating, slitting, physical and analytical testing, product<br />

development, process development, consulting, training and education<br />

related to adhesives, inks and specialty coatings.<br />

capabilities: Web coating, slitting, physical and analytical testing, product<br />

development, process development, consulting, training and education<br />

related to adhesives, inks and specialty coatings.<br />

Key sales contact:<br />

Joe Mausar<br />

9079 Tyler Blvd<br />

Mentor, OH 44060<br />

Phone: 440-974-3080<br />

Fax: 440-974-3081<br />

E-mail: jmausar@chemsultants.com<br />

circonix technologies<br />

29 Executive Parkway<br />

Ringwood, nJ 07456<br />

USA<br />

Phone: 973-962-6160<br />

Fax: 973-962-6016<br />

Website: www.circonix.com/<br />

Business Description: Circonix Technologies is an engineering company<br />

specializing in the integration of advanced drive, control, and mechanical<br />

systems used in the web coating and converting industry. Circonix<br />

Technologies provides customers with turnkey electrical and mechanical<br />

solutions, and offers superior service capabilities for existing control systems.<br />

Whether it’s a new, high-speed system for an OEM or a retrofit application<br />

to improve the productivity of an existing line, Circonix Technologies has the<br />

experience and process know how to get the job done on time and within<br />

budget. Fulton Machinery, a division of Circonix Technologies, focuses on<br />

the modification and integration of new and upgraded machine components<br />

into existing coating and converting production lines to enhance performance<br />

and add new capabilities to existing equipment. This unique UEM (Used<br />

Equipment reManufacturer) concept uses a combination of used, refurbished,<br />

upgraded, and new web coating and converting equipment to produce<br />

like-new Web Converting Machinery at a 40% to 60% discount and a<br />

dramatically reduced schedule when compared to a traditional OEM. Circonix<br />

Technologies give coaters and converters one place to go for a complete,<br />

vertically integrated source for upgrading their production lines including<br />

design, procurement, programing, fabrication, installation, commissioning,<br />

and startup.<br />

Products:<br />

SplicePro - advanced splicing control system minimizing tail length and core<br />

waste.<br />

ExtrusionPro - Extrusion control system designed as replacement for older<br />

OEM systems.<br />

EEPA - Equipment Evaluation and Performance Audit converting equipment<br />

evaluation to determine the best course of action to enhance the performance<br />

of production equipment.<br />

PowerPlant - Advanced supervisory control system specifically designed for<br />

converting applications with many function modules.<br />

ProCare - Comprehensive support package, including training, local service<br />

and remote service and diagnostics.<br />

Key sales contact 1:<br />

Paul Bilotti<br />

Email: paul.bilotti@circonix.com<br />

Key sales contact 2:<br />

Andre Icso<br />

Email: andre.icso@circonix.com<br />

clemson university Dept. of Packaging science<br />

227 Poole Agricultural Center<br />

Clemson, SC 29634<br />

www.aimcal.org | 43<br />

Member Company Profiles