Insulated Control Dampers, Model ICD - Greenheck

Insulated Control Dampers, Model ICD - Greenheck

Insulated Control Dampers, Model ICD - Greenheck

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

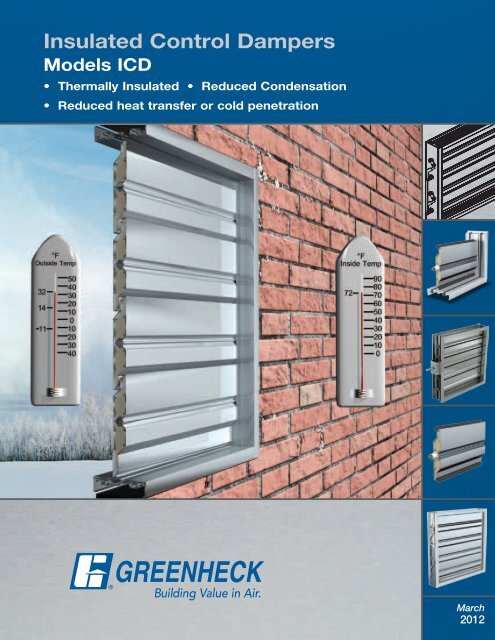

<strong>Insulated</strong> <strong>Control</strong> <strong>Dampers</strong><br />

<strong>Model</strong>s <strong>ICD</strong><br />

• Thermally <strong>Insulated</strong> • Reduced Condensation<br />

• Reduced heat transfer or cold penetration<br />

1<br />

March<br />

2012

<strong>Insulated</strong> <strong>Control</strong> <strong>Dampers</strong><br />

®<br />

<strong>Greenheck</strong>’s <strong>ICD</strong> series of dampers was developed for applications where it is necessary to minimize<br />

the transfer of heat or cold penetration and reduce condensation. The thermally broken frame provides<br />

an insulating barrier in the ductwork. Thermally broken blades separate the warm and cold air inside the<br />

ductwork. Silicone jamb seals effectively seal the penetration of air from one side of the blade to the other.<br />

Design Features<br />

Variable Symmetric Blade Design (VSB)<br />

<strong>Greenheck</strong>’s Variable Symmetrical Blade (VSB) design<br />

uses a combination of three symmetrical blade sizes (4,<br />

5, and 6 inch) to maximize the free area at any damper<br />

height by reducing blade stop height. Traditional damper<br />

designs use a single blade width that requires oversized<br />

blade stops, limiting free area when the blades are<br />

open. The VSB design allows for consistent operating<br />

characteristics regardless of airflow direction.<br />

• Increases Mounting Flexibility - Symmetrical blades<br />

have identical operating characteristics regardless<br />

of airflow direction. This allows a <strong>Greenheck</strong> control<br />

damper to be mounted in either direction of flow, an<br />

advantage when installing with space constraints.<br />

• Increases Free Area - Traditional damper designs<br />

with a single blade width require oversized blade stops,<br />

limiting free area when the blades are open (Figure 1).<br />

<strong>Greenheck</strong> is able to reduce blade stop height, which<br />

maximizes free area, and increases damper<br />

performance. AMCA certified pressure<br />

drop lets you know that the published data<br />

is accurate to help you better design your<br />

system.<br />

• Reduces Actuator Torque - If an unsymmetrical<br />

blade closes against airflow, a large amount of torque<br />

is needed because the air distribution is unbalanced.<br />

<strong>Greenheck</strong>’s VSB design balances airflow on each side<br />

of a symmetrical blade, reducing the torque required to<br />

operate the damper. The use of symmetrical blades has<br />

allowed <strong>Greenheck</strong> to reduce the sizes and quantities of<br />

actuators used on our dampers.<br />

The <strong>ICD</strong> series damper blades feature thermally broken<br />

airfoil shaped blade with polyurethane foam.<br />

Airflow works<br />

against<br />

actuator<br />

Actuator<br />

Torque<br />

Unbalanced Blade<br />

Requires Higher Torque<br />

Airflow works<br />

against<br />

actuator<br />

Airflow<br />

works with<br />

actuator<br />

Actuator<br />

Torque<br />

Balanced Blade<br />

Requires Less Torque<br />

Parallel versus Opposed Blade Operation<br />

<strong>Greenheck</strong>’s <strong>ICD</strong> series dampers are offered with either<br />

opposed or parallel blade operation. Parallel blade<br />

orientation is typically used when the damper operates<br />

in two positions, open or closed. The damper blades<br />

open or close in the same direction. Opposed blade<br />

orientation is typically used on dampers that modulate<br />

airflow. Adjacent damper blades will open or close<br />

opposite one another.<br />

1/2 in.<br />

(13mm)<br />

1/2 in.<br />

(13mm)<br />

1/2 in.<br />

(13mm)<br />

1/2 in.<br />

(13mm)<br />

2<br />

5 in.<br />

(127mm)<br />

5 in.<br />

(127mm)

<strong>Insulated</strong> <strong>Control</strong> <strong>Dampers</strong><br />

®<br />

Design Features<br />

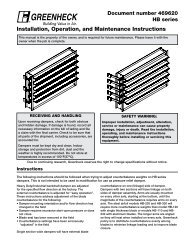

Frame<br />

There are four frame types available:<br />

• Quick Connect for easy connection to duct<br />

• Channel<br />

• Single Flange<br />

• Reversed Flange<br />

The <strong>ICD</strong>-44 features an extruded aluminum frame.<br />

The <strong>ICD</strong>-45 features an aluminum frame with two<br />

polyurethane resin gaps and insulated on four sides<br />

with polystyrene.<br />

Quick<br />

Connect<br />

Channel<br />

Single<br />

Flange<br />

Reverse<br />

Flange<br />

Linkage<br />

<strong>Greenheck</strong>’s <strong>ICD</strong> series dampers have blade linkage<br />

concealed in the insulated frame. This prevents any<br />

transfer point for cold or heat, unlike some of our<br />

competitor’s products. The linkage is engineered to<br />

accurately control each and every blade without need<br />

for adjustment.<br />

No Top or Bottom<br />

<strong>ICD</strong> series dampers are designed for installation in<br />

any position with the blades horizontal. As shown, the<br />

damper can be turned over so the actuator is on the left<br />

or right side.<br />

Blade & Jamb Seals<br />

Silicone blade and jamb seals stay flexible in cold<br />

temperatures.<br />

The <strong>ICD</strong>-44 features silicone blade seal with 304SS<br />

jamb seals with optional silicone jamb seals. The<br />

<strong>ICD</strong>-45 features silicone blade and jamb seals.<br />

Bearings<br />

Dual bearing with acetal inner sleeve and flanged outer<br />

bearing features no metal-to-metal or metal-to-plastic<br />

contact.<br />

3

Quick Selection Chart<br />

®<br />

Maximum Velocity ft/min. (m/s)<br />

<strong>ICD</strong>-44<br />

4000<br />

(20.3)<br />

<strong>ICD</strong>-45<br />

4000<br />

(20.3)<br />

Maximum Pressure in. wg (kPa) 8 (2) 8 (2)<br />

Temperature range °F (°C)<br />

Frame<br />

Frame Gauge<br />

-70 to 200<br />

(-56 to 93)<br />

-70 to 200<br />

(-56 to 93)<br />

<strong>Insulated</strong> Thermally Broken Aluminum - X<br />

Aluminum X -<br />

.125 in.<br />

(3.2mm)<br />

.125 in.<br />

(3.2mm)<br />

Channel X O<br />

Frame Type<br />

Quick Connect O X<br />

Reverse Flange O O<br />

Single Flange O O<br />

Blade Action<br />

Parallel O O<br />

Opposed X X<br />

Blade Type <strong>Insulated</strong> Thermally Broken X X<br />

Blade Material Extruded Aluminum Airfoil X X<br />

Blade Seal Silicone X X<br />

Jamb Seal<br />

304SS X -<br />

Silicone O X<br />

Axle Bearings Dual Bearing with Acetal Inner Sleeve X X<br />

Axle Material<br />

Plated Steel X X<br />

304SS O O<br />

Linkage<br />

Plated Steel X X<br />

304SS O O<br />

Anodize O O<br />

Baked Enamel O O<br />

Epoxy O O<br />

Paint Finishes* Hi Pro Polyester O O<br />

Industrial Epoxy O O<br />

Kynar/Hylar (70%) O O<br />

Permatector O O<br />

Sizing<br />

Inches (mm)<br />

Minimum Size<br />

Channel, Single or<br />

Reverse Flange<br />

Quick Connect<br />

Maximum Single Section Size<br />

Maximum Multi<br />

Section Size<br />

Channel, Single or<br />

Reverse Flange<br />

Quick Connect<br />

* Additional lead time is required. Consult factory.<br />

12 x 7<br />

(305 x 178)<br />

12 x 6<br />

(305 x 152)<br />

48 x 74<br />

(1219 x 1880)<br />

144 x 148<br />

(3658 x 3759)<br />

96 x 148<br />

(2438 x 3759)<br />

12 x 7<br />

(305 x 178)<br />

12 x 6<br />

(305 x 152)<br />

48 x 74<br />

(1219 x 1880)<br />

144 x 120<br />

(3658 x 3048)<br />

96 x 120<br />

(2438 x 3048)<br />

4

Damper Performance<br />

Testing Criteria<br />

®<br />

Thermal Performance<br />

During thermal performance test, per ASTM Standard C1363-97<br />

conducted at Architectural Testing Laboratories (ATI), the <strong>ICD</strong>-45<br />

outperformed competitor’s thermally broken dampers.<br />

(Report #53166.01-201-46)<br />

Dry Ice Test<br />

The thermal breaks in the damper blades and frame reduce the<br />

transfer of heat from the “cool side” to the “warm side”. When<br />

compared to a standard airfoil blade design, <strong>ICD</strong> airfoil blade,<br />

with thermal breaks, prevents ice from forming on the opposite<br />

side of the blade.<br />

Specimen Thermal Resistance (R value)<br />

<strong>Greenheck</strong><br />

<strong>ICD</strong>-45<br />

Brand A<br />

Brand B<br />

Leakage Test<br />

<strong>ICD</strong> series dampers meet the IECC (International Energy Conservation Code) requirements for damper<br />

leakage ratings of at 3 cfm/ft 2 @ 1 in. wg (54.8 cmh/m 2 @ .25 kPa) or less when integral to the building<br />

envelope. Leakage testing was performed at Environ Laboratories at a temperature of -40°F. The <strong>ICD</strong>-45 was<br />

rated at less than 3 cfm/ft 2 @ 1 in. wg (54.8 cmh/m 2 @ .25 kPa) or 8 cfm/ft 2 @ 4 in. wg (146.3 cmh/m 2 @ 1 kPa).<br />

Comparing a 36 in. x 36 in. (914mm x 914mm) damper, <strong>Greenheck</strong>’s <strong>ICD</strong> series has the lowest leakage in the<br />

industry.<br />

<strong>Greenheck</strong><br />

Brand A<br />

Brand B<br />

5

Damper Performance<br />

Testing Criteria<br />

®<br />

Pressure drop testing was conducted in accordance with AMCA Standard 500-D using the three<br />

configurations shown. All data has been corrected to represent standard air at a density of<br />

.075 lb/ft 3 (1.201 kg/m 3 ).<br />

Actual pressure drop found in any HVAC system is a combination of many factors. This pressure drop<br />

information along with an analysis of other system influences should be used to estimate actual pressure<br />

losses for a damper installed in a given HVAC system.<br />

Figure 5.3 Illustrates a fully ducted damper. This configuration has the lowest pressure drop of the three<br />

test configurations because entrance and exit losses are minimized by straight duct runs upstream and<br />

downstream of the damper.<br />

Figure 5.2 Illustrates a ducted damper exhausting air into an open area. This configuration has a lower<br />

pressure drop than Figure 5.5 because entrance losses are minimized by a straight duct run upstream of the<br />

damper.<br />

Figure 5.5 Illustrates a plenum mounted damper. This configuration has the highest pressure drop because<br />

of extremely high entrance and exit losses due to the sudden changes of area in the system.<br />

5D<br />

6D<br />

Figure 5D 5.3<br />

6D<br />

5D<br />

re 5.3<br />

Figure 5D 5.2<br />

Figure 5.5<br />

re 5.2<br />

D=<br />

4 (W) (H)<br />

3.14<br />

D=Duct length<br />

W=Damper width<br />

H=Damper height<br />

Figure 5.5<br />

4 (W) (H) When comparing a 24 in. x 24 in. (610mm x 610mm)<br />

3.14 damper, <strong>Greenheck</strong>’s <strong>ICD</strong> series has the lowest<br />

pressure drop in the industry which means lower fan<br />

cost or smaller damper size required.<br />

Brand B<br />

Brand A<br />

<strong>Greenheck</strong><br />

6

Damper Performance<br />

Testing Criteria<br />

®<br />

Dimension<br />

Inches (mm)<br />

Velocity -<br />

ft/min. (m/s)<br />

AMCA Figure 5.2 Pressure Drop<br />

12 x 12<br />

(305 x 305)<br />

24 x 24<br />

(610 x 610)<br />

36 x 36<br />

(914 x 914)<br />

Pressure Drop - in. wg (Pa)<br />

12 x 48<br />

(305 x 1219)<br />

48 x 12<br />

(1219 x 305)<br />

500 (2.5) .03 (7.5) .02 (5) .01 (2.5) .01 (2.5) .03 (7.5)<br />

1000 (5.1) .11 (27.4) .08 (19.9) .05 (12.5) .06 (14.9) .14 (34.8)<br />

1500 (7.6) .25 (62.3) .19 (47.3) .11 (27.4) .14 (34.8) .32 (79.7)<br />

2000 (10.2) .45 (112) .34 (84.7) .21 (52.3) .25 (62.3) .57 (142)<br />

2500 (12.7) .71 (176.9) .53 (132) .33 (82.2) .40 (99.6) .89 (221.7)<br />

3000 (15.2) 1.03 (256.6) .77 (191.8) .47 (117.1) .57 (142) 1.29 (321.3)<br />

3500 (17.8) 1.40 (348.7) 1.05 (261.5) .64 (159.4) .78 (194.3) 1.76 (438.4)<br />

4000 (20.3) 1.83 (455.8) 1.37 (341.3) .84 (209.2) 1.02 (254.1) 2.30 (572.9)<br />

Dimension<br />

(in.)<br />

Velocity -<br />

ft/min. (m/s)<br />

AMCA Figure 5.3 Pressure Drop<br />

12 x 12<br />

(305 x 305)<br />

24 x 24<br />

(610 x 610)<br />

36 x 36<br />

(914 x 914)<br />

Pressure Drop - in. wg (Pa)<br />

12 x 48<br />

(305 x 1219)<br />

48 x 12<br />

(1219 x 305)<br />

500 (2.5) .01 (2.5) .01 (2.5) .01 (2.5) .01 (2.5) .04 (10)<br />

1000 (5.1) .04 (10) .03 (7.5) .02 (5) .02 (5) .06 (14.9)<br />

1500 (7.6) .09 (22.4) .08 (19.9) .04 (10) .06 (14.9) .14 (34.8)<br />

2000 (10.2) .17 (42.3) .14 (34.8) .08 (19.9) .10 (24.9) .25 (62.3)<br />

2500 (12.7) .26 (64.7) .22 (54.8) .12 (29.9) .17 (42.3) .40 (99.6)<br />

3000 (15.2) .38 (94.6) .32 (79.7) .18 (44.8) .24 (59.8) .58 (144.5)<br />

3500 (17.8) .52 (129.5) .43 (107.1) .24 (59.8) .33 (82.2) .79 (196.7)<br />

4000 (20.3) .67 (166.9) .57 (142) .32 (79.7) .43 (107.1) 1.03 (256.6)<br />

Dimension<br />

(in.)<br />

Velocity -<br />

ft/min. (m/s)<br />

AMCA Figure 5.5 Pressure Drop<br />

12 x 12<br />

(305 x 305)<br />

24 x 24<br />

(610 x 610)<br />

36 x 36<br />

(914 x 914)<br />

Pressure Drop - in. wg (Pa)<br />

12 x 48<br />

(305 x 1219)<br />

48 x 12<br />

(1219 x 3050<br />

500 (2.5) .05 (12.5) .05 (12.5) .03 (7.5) .04 (10) .05 (12.5)<br />

1000 (5.1) .23 (57.3) .21 (52.3) .14 (34.8) .18 (44.8) .22 (54.8)<br />

1500 (7.6) .52 (129.5) .47 (117.1) .33 (82.2) .42 (104.6) .51 (127)<br />

2000 (10.2) .93 (231.7) .84 (209.2) .58 (144.5) .74 (184.3) .90 (224.2)<br />

2500 (12.7) 1.44 (358.7) 1.32 (328.8) .91 (226.7) 1.16 (288.9) 1.41 (351.2)<br />

3000 (15.2) 2.08 (518.1) 1.9 (473.3) 1.31 (326.3) 1.68 (418.5) 2.04 (508.1)<br />

3500 (17.8) 2.83 (704.9) 2.59 (645.1) 1.79 (445.9) 2.28 (567.9) 2.78 (692.5)<br />

4000 (20.3) 3.70 (921.6) 3.39 (844.4) 2.34 (582.9) 2.98 (742.3) 3.70 (921.6)<br />

<strong>Greenheck</strong> Fan Corporation certifies that the model<br />

<strong>ICD</strong>-44 and <strong>ICD</strong>-45 shown herein is licensed to<br />

bear the AMCA Seal. The ratings shown are based<br />

on tests and procedures performed in accordance<br />

with AMCA Publication 511 and comply with<br />

the requirements of the AMCA Certified Ratings<br />

Programs. The AMCA Certified Ratings Seal applies<br />

to air performance ratings only.<br />

7

The <strong>Greenheck</strong> Difference<br />

<strong>Greenheck</strong> dampers bring the same quality engineering and manufacturing that has earned<br />

<strong>Greenheck</strong> its position as an industry leader. Aggressive research and development keeps<br />

<strong>Greenheck</strong> a major player in the damper and louver industry.<br />

<strong>Greenheck</strong> has the most UL classified dampers and largest<br />

selection of AMCA licensed dampers and louvers in the<br />

industry.<br />

In-House Testing<br />

State-of-the-art laboratory and testing facilities have always<br />

been important to <strong>Greenheck</strong>’s continuing business success.<br />

A laboratory facility devoted exclusively to development and<br />

testing of damper and louver related products for testing to<br />

the latest versions of AMCA, ANSI, ASHRAE, UL, Miami-Dade<br />

County, and other industry standards of performance.<br />

Enjoy <strong>Greenheck</strong>’s extraordinary service, before, during<br />

and after the sale.<br />

<strong>Greenheck</strong> offers added value to our wide selection of top performing, energy-efficient products<br />

by providing several unique <strong>Greenheck</strong> service programs.<br />

• Our Quick Delivery Program ensures shipment of our in-stock products within 24 hours of<br />

placing your order. Our Quick Build made-to-order products can be produced in 1-3-5-10- or<br />

15-day production cycles, depending upon their complexity.<br />

• <strong>Greenheck</strong>’s free Computer Aided Product Selection program (CAPS), rated by many as<br />

the best in the industry, helps you conveniently and efficiently select the right products for the<br />

challenge at hand.<br />

• <strong>Greenheck</strong> has been Green for a long time! Our energy-saving products and ongoing<br />

corporate commitment to sustainability can help you qualify for LEED credits.<br />

• Our 3D service allows you to download at no charge lightweight, easy-to-use AutoDesk <br />

Revit 3D drawings for many of our ventilation products.<br />

Find out more about these special <strong>Greenheck</strong> services at greenheck.com<br />

Our Warranty<br />

<strong>Greenheck</strong> warrants this equipment to be free from defects in material and workmanship for a period<br />

of one year from the shipment date. Any units or parts which prove defective during the warranty<br />

period will be replaced at our option when returned to our factory, transportation prepaid. Motors are<br />

warranted by the motor manufacturer for a period of one year. Should motors furnished by <strong>Greenheck</strong><br />

prove defective during this period, they should be returned to the nearest authorized motor service<br />

station. <strong>Greenheck</strong> will not be responsible for any removal or installation costs.<br />

As a result of our commitment to continuous improvement, <strong>Greenheck</strong> reserves the right to change<br />

specifications without notice.<br />

Prepared to Support<br />

Green Building Efforts<br />

P.O. Box 410 • Schofield, WI 54476-0410 • Phone (715) 359-6171 • greenheck.com<br />

00.DMP.1005 R2 3-2012 IP<br />

Copyright © 2012 <strong>Greenheck</strong> Fan Corp.