Universidad del Turabo Heterogeneous Catalysis Applied To ...

Universidad del Turabo Heterogeneous Catalysis Applied To ...

Universidad del Turabo Heterogeneous Catalysis Applied To ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Universidad</strong> <strong>del</strong> <strong>Turabo</strong><br />

<strong>Heterogeneous</strong> <strong>Catalysis</strong> <strong>Applied</strong> <strong>To</strong> Advanced Oxidation Processes (AOPs) For<br />

Degradation of Organic Pollutants<br />

By<br />

María <strong>del</strong> Carmen Cotto-Maldonado<br />

BS, Biology, University of Puerto Rico<br />

BS, Chemistry, Interamerican University<br />

MS, Environmental Health, University of Puerto Rico<br />

Dissertation<br />

Submitted to the School of Science and Technology<br />

in partial fulfillment of the requirements for<br />

the degree of Doctor of Philosophy<br />

in Environmental Science<br />

(Chemistry Option)<br />

Gurabo, Puerto Rico<br />

May, 2012

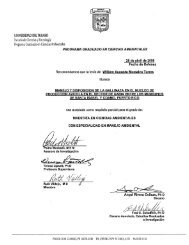

<strong>Universidad</strong> <strong>del</strong> <strong>Turabo</strong><br />

A dissertation submitted in partial fulfillment of<br />

the requirement for the degree of<br />

Doctor of Philosophy<br />

4/24/2012<br />

<strong>Heterogeneous</strong> <strong>Catalysis</strong> <strong>Applied</strong> <strong>To</strong> Advanced Oxidation Processes (AOPs) For<br />

Degradation of Organic Pollutants<br />

Maria <strong>del</strong> Carmen Cotto-Maldonado<br />

Approved:<br />

________________________________<br />

Francisco M Marquez Linares, PhD<br />

Research Advisor<br />

______________________________<br />

Marlio Paredes, PhD<br />

Member<br />

________________________________<br />

Jose J Duconge, PhD<br />

Member<br />

______________________________<br />

Angel L Morales Cruz, PhD<br />

Member<br />

________________________________<br />

Santander Nieto, PhD<br />

Member<br />

________________________________<br />

Fred C Schaffner, PhD<br />

Associate Dean, Graduates Studies<br />

and Research<br />

______________________________<br />

Teresa Lipsett, PhD<br />

Dean<br />

ii

© Copyright 2012<br />

María <strong>del</strong> Carmen Cotto-Maldonado. All Right Reserved.

Dedications<br />

<strong>To</strong> my angels in Heaven and Earth…<br />

<strong>To</strong> my Family<br />

iii

Acknowledgments<br />

One day a friend said to me that sometimes it is necessary to touch the thorn of<br />

the rose to reach the flower and I wish to say thanks to all of those people that helped<br />

and supported me during this journey.<br />

I wish to say thanks to Dr Francisco M Marquez-Linares for your mentoring. I<br />

read in some place that a mentor is someone that not only helps the student to direct the<br />

investigation project, but is part of it. Thanks for your patience, support and help, to<br />

teach me what is a good professor and a human being, and as it is said in Puerto Rico:<br />

“pasar conmigo la zarza y el guayacán”. It has been an honor being your student.<br />

Thanks to the members of my dissertation committee; Dr Jose J Duconge, Dr<br />

Santander Nieto Ramos, Dr Marlio Paredes and Dr Angel L Morales Cruz for your<br />

support and trust during this process.<br />

Thanks to Dr Fred Schaffner, Associated Dean for the Graduate Studies and<br />

Research at the <strong>Universidad</strong> <strong>del</strong> <strong>Turabo</strong> for your guide and advice during all of this time.<br />

Many people collaborated in different forms to develop this research. Thanks to<br />

Dr Carmen Morant, Dr Eduardo Elizalde and Ms Teresa Campo at the <strong>Universidad</strong><br />

Autónoma de Madrid for all of your collaboration. I really appreciated all of your help<br />

and support.<br />

<strong>To</strong> Dr Angel Rivera Collazo and Dr. Angel Ojeda at <strong>Universidad</strong> <strong>del</strong><br />

<strong>Turabo</strong>, for your time.<br />

<strong>To</strong> my friends Mr Abraham (Kike) E Garcia, Ms Carmen Bonilla Rivera, Ms<br />

Veronica Castro Simmons and Ms Gloria M Herrera for all of your help, thanks to share<br />

with me the best of you during the long hours of laboratory work. Finally, but no less<br />

important, thanks to my friend Ms Karlo Malave-Llamas for the “phone call” that initiated<br />

this journey.<br />

iv

Curriculum Vitae<br />

Maria <strong>del</strong> C Cotto-Maldonado<br />

Education<br />

2004-Present<br />

PhD in Environmental Science, University of <strong>Turabo</strong>, Gurabo,<br />

Puerto Rico.<br />

2002-2006 BS in Chemistry, Inter American, Metropolitan Campus, Río<br />

Piedras, Puerto Rico<br />

1994-1997 MS in Environmental Health, University of Puerto Rico, Medical<br />

Science Campus, Río Piedras, Puerto Rico<br />

1987-1992 BS in Biology, University of Puerto Rico, Río Piedras Campus,<br />

Río Piedras, Puerto Rico<br />

Academic Honors, Awards and Achievements<br />

2011 Scientific Authors Award, Vice-Chancellor Office of Academic Affairs,<br />

University of <strong>Turabo</strong>, Gurabo Campus, Gurabo, Puerto Rico<br />

2010 Minigrant Award, Associate Dean Office of Graduate Studies, School of<br />

Science and Technology, University of <strong>Turabo</strong>, Gurabo Campus, Gurabo,<br />

Puerto Rico<br />

2009 Scientific Authors Award, Vice-Chancellor Office of Academic Affairs,<br />

University of <strong>Turabo</strong>, Gurabo Campus, Gurabo, Puerto Rico<br />

Minigrant Awards, Associate Dean Office of Graduate Studies, School of<br />

Science and Technology, University of <strong>Turabo</strong>, Gurabo Campus, Gurabo,<br />

Puerto Rico<br />

v

2008 Minigrant Award, Dean Office of Graduate Studies, School of Science<br />

and Technology, University of <strong>Turabo</strong>, Gurabo Campus, Gurabo, Puerto<br />

Rico<br />

Scientific Authors Awards, Vice-Chancellor Office of Academic Affair,<br />

University of <strong>Turabo</strong>, Gurabo Campus, Gurabo, Puerto Rico<br />

2006 Graduate with Honors of the InterAmerican University, Metropolitan<br />

Campus<br />

2005 Founder Member of the Environmental Science Doctoral Student<br />

Association at University of <strong>Turabo</strong><br />

2003 Second Place in the Inorganic Advance Chemistry Competitions 2003<br />

(Olimpiadas de Química 2003), InterAmerican University, Metropolitan<br />

Campus<br />

1995 Founder Member of the Environmental Health Student Association at the<br />

University of Puerto Rico, Medical Science Campus<br />

1993 Graduate with Honors (Cum Laude) of the University of Puerto Rico, Río<br />

Piedras Campus<br />

Scientific Meetings<br />

12. Cotto M, Campo T, Elizalde E, Morant C, Marquez F. 2011. Hydrothermal<br />

Synthesis and Photocatalytic Activity of Titanium Oxide Nanowires Poster<br />

session presented at: 43rd IUPAC World Chemistry Congress, August 2011. San<br />

Juan PR.<br />

11. Cotto M, Masa A, Garcia A, Duconge J, Campo T, Elizalde E, Morant C,<br />

Márquez F.2011. ZnCd Based Photocatalysts for Hydrogen Production from<br />

Water under Visible-UV Light. Poster session presented at: 43rd IUPAC World<br />

Chemistry Congress, August 2011. San Juan PR.<br />

vi

10. Herrera GM, Campo T, Cotto M, Sanz JM, Elizalde E, Morant C, Marquez F.<br />

2011. Synthesis and Characterization of Hollow Magnetite Microspheres. Poster<br />

session presented at: 43rd IUPAC World Chemistry Congress, August 2011. San<br />

Juan PR.<br />

9. Herrera GM, Campo T, Cotto M, Sanz JM, Elizalde E, Morant C, Marquez F.<br />

2011. Preparation of Hollow Magnetite Microspheres and their Applications as<br />

Drugs Carriers. Poster session presented at: 43rd IUPAC World Chemistry<br />

Congress, August 2011. San Juan PR.<br />

8. Campo T, Marquez F, Cotto M, Elizalde E, Morant C. 2011. Silicon Nanowires<br />

grown from Silicon Substrates for Ion-Li Batteries Applications. Poster session<br />

presented at: 43rd IUPAC World Chemistry Congress, August 2011. San Juan<br />

PR.<br />

7. Duconge J, Bonilla C, Garcia A, Herrera GM, Cotto M, Campo T, Elizalde E,<br />

Morant C Marquez F. 2012. Synthesis and Characterization of Copper Oxide<br />

Nanowires. Poster session presented at: 43rd IUPAC World Chemistry<br />

Congress, August 2011. San Juan PR.<br />

6. Duconge J, Bonilla C, Cotto M, Herrera GM, Campo T, Elizalde E, Morant C,<br />

Marquez F. 2012. Hydrothermal Synthesis of Crystalline CuO Nanorods. Poster<br />

session presented at: 43rd IUPAC World Chemistry Congress, August 2011. San<br />

Juan PR.<br />

5. Herrera GM, Felix H, Campo T, Cotto M, Sanz JM, Elizalde E, Morant C,<br />

Hernández-Rivera S, Márquez F. 2012. Synthesis and characterization of Au<br />

coated TiO2 nanowires as ERS solid substrates. Poster session presented at:<br />

43rd IUPAC World Chemistry Congress, August 2011. San Juan PR.<br />

vii

4. Cotto-Maldonado MC, Roque-Malherbe R, Nieto S, Duconge J. 2008. Phenol<br />

Decomposition by Mechanical Activation of Rutile. Poster session presented at:<br />

28th Congreso Latinoamericano de Quimica. 2008. San Juan, Puerto Rico.<br />

3. Cotto MC, Malave K. 2003. Environmental Health Risk Communication for<br />

Hispanic Communities. Presented at: 2003 ATSDR Partners in Public Health<br />

Meeting. March 3-5 2003, Atlanta, Georgia.<br />

2. Cotto MC. Risk Communication. Presented at: University of Puerto Rico. [Rio<br />

Piedras (PR)]:University of Puerto Rico, Medical Science Campus.<br />

1. Marcantoni C, Cotto MC. 1998. Growth of Microbial Population in the<br />

Schmutzdecke of a Slow Sand Filter and its Relationship with Treated Water.<br />

Poster session presented at: AWWA Annual Conference June 21-25 1998,<br />

Dallas, Texas.<br />

Scientific Papers<br />

10. Cotto M, Duconge J, Campo T, Elizalde E, Morant C, Márquez F. Hydrothermal<br />

Synthesis and Catalytic Activity of TiO 2 nanowires. (<strong>To</strong> be submitted to J Catal).<br />

9. Marquez F, Masa A, Cotto M, Bonilla C, Garcia A, Duconge J, Campo T, Elizalde<br />

E, Morant C. Photocatalytic Hydrogen Production by Water Splitting using<br />

ZnCdFeS nanoparticles under UV-Vis Light Irradiation. (<strong>To</strong> be submitted to Int J<br />

Hydrogen Energy).<br />

8. Marquez F, Cotto M, Campo T, Elizalde E, Morant C. Photocatalytic degradation<br />

of Rhodamine B on different nanostructured catalyst. (<strong>To</strong> be submitted to Soft<br />

Nanoscience Lett).<br />

7. Marquez F, Cotto M, Bonilla C, Duconge J, Campo T, Elizalde E, Morant C. High<br />

Catalytic Activity of CuO Nanorods Synthesized by an Hydrothermal Approach.<br />

(Submitted to J Catal)<br />

viii

6. Marquez FM, Herrera GM, Campo T, Cotto MC, Duconge J, Sanz JM, Elizalde E,<br />

Perales O, Morant C. 2012. Preparation of hollow magnetite microspheres and<br />

their applications as drug carriers. Nanoscale Res Lett 7: 210.<br />

5. Marquez F, Campo T, Cotto M, Polanco R, Roque R, Fierro P, Sanz JM, Elizalde<br />

E, Morant C. 2011. Synthesis and Characterization of Monodisperse Magnetite<br />

Hollow Microsphere. Soft Nanoscience Lett: 25-32.<br />

4. Malave K, Cotto-Maldonado MC. 2010. Community environmental risk in<br />

developing countries. Environmental and Human Health: Risk Management in<br />

Developing Countries. Taylor and Francis Group.<br />

3. Cotto MC, Emiliano A, Nieto S, Duconge J, Roque-Malherbe R. 2009.<br />

Degradation of Phenol by Mechanical Activation of a Rutile Catalyst. J Colloid<br />

Interf Sci. 339: 133-139.<br />

2. Marcantoni C, Cotto MC. 1998. Growth of Microbial Population in the<br />

Schmutzdecke of a Slow Sand Filter and its Relationship with Treated Water.<br />

Proceedings of the AWWA Annual Conference. June 21-25 1998, Dallas<br />

(Texas). Vol. C, p. 751-776.<br />

1. Marcantoni C, Maldonado E, Cotto, MC. 1996. Determinación de las densidades<br />

poblacionales microbiológicas existentes en el schmutzdecke de un filtro de<br />

arena lento y su relación con la calidad <strong>del</strong> efluente [master’s thesis].[Rio Piedras<br />

(PR)]:University of Puerto Rico, Medical Science Campus.<br />

ix

Table of Contents<br />

Page<br />

List of Tables ................................................................................................................ xiv<br />

List of Figures ................................................................................................................ xv<br />

List of Appendices ........................................................................................................xxii<br />

Abstract ....................................................................................................................... xxiii<br />

Resumen .....................................................................................................................xxiv<br />

Chapter One. Introduction ............................................................................................... 1<br />

ChapterTwo. Experimental Techniques ....................................................................... 276<br />

2.01. X-Ray Diffraction (XRD) ................................................................................. 276<br />

2.02. Magnetic Susceptibility ..................................................................................... 29<br />

2.03. Thermogravimetric Analysis (TGA) .................................................................. 32<br />

2.04. Specific Surface Area (BET) ............................................................................ 34<br />

2.05. Raman Spectroscopy ....................................................................................... 36<br />

2.06. X-Ray Photoelectron Spectroscopy (XPS) ....................................................... 40<br />

2.07. Field Emission Scanning Microscopy (FE-SEM)............................................... 42<br />

2.08. <strong>To</strong>tal Organic Carbon Analysis ......................................................................... 45<br />

2.09. UV-Visible Spectroscopy .................................................................................. 46<br />

2.10. Fluorescence Spectroscopy .............................................................................. 49<br />

Chapter Three. Synthesis Procedures ........................................................................... 52<br />

3.1. Synthesis of Titanium Oxide Nanowires ............................................................. 52<br />

3.2. Synthesis of Zinc Oxide ..................................................................................... 53<br />

3.3. Synthesis of Titanium Oxide@Multiwalled Carbon Nanotubes ........................... 53<br />

3.3.1. Carbon Nanotubes Modification ................................................................... 53<br />

3.3.2. Synthesis and Incorporation of the Titanium Oxide on the MWCNT ............. 54<br />

3.4. Synthesis of Capped Magnetite Nanoparticles ................................................... 54<br />

3.5. Synthesis of Iron Oxide Nanowires .................................................................... 55<br />

Chapter Four.Material Characterization ..........................................................………….57<br />

4.1. Photocatalysis .................................................................................................... 57<br />

x

Page<br />

4.1.1. Titanium Oxide (TiO 2 , Rutile Phase) ............................................................ 57<br />

4.1.2. Titanium Oxide (TiO 2 , Anatase Phase) ........................................................ 61<br />

4.1.3. Titanium Oxide Nanowires ........................................................................... 65<br />

4.1.4. Titanium Oxide @Multiwalled Carbon Nanotubes ........................................ 68<br />

4.1.5. Zinc Oxide ................................................................................................... 73<br />

4.2. Fenton Catalysts ................................................................................................ 76<br />

4.2.1. Iron Oxide Nanowires (Fe 2 O 3 NWs) .............................................................. 76<br />

4.2.2. Capped Magnetite Nanoparticles (Fe 3 O 4 ) .................................................... 81<br />

4.2.3. Ferrous Chloride (FeCl 2 ).............................................................................. 86<br />

4.2.4. Copper Oxide (CuO).................................................................................... 88<br />

Chapter Five. Results and Discussion ........................................................................... 91<br />

5.1. Defining the Experimental Parameters ............................................................... 91<br />

5.1.1. Effects of the Concentration ......................................................................... 91<br />

5.1.2. Effects of the pH .......................................................................................... 94<br />

5.1.3. Effects of Temperature ................................................................................ 95<br />

5.2. Photochemical degradation ................................................................................ 96<br />

5.2.1. Description of the Photocatalytic System ................................................... 100<br />

5.3. Sono-Fenton Process ...................................................................................... 117<br />

5.3.1. Description of the Sono-Fenton System ..................................................... 117<br />

5.4. Photo-Fenton Process ..................................................................................... 124<br />

5.4.1. Description of the Photo-Fenton System .................................................... 124<br />

5.5. Statistical analysis ............................................................................................ 129<br />

Chapter Six. Conclusion .............................................................................................. 132<br />

Literature Cited ............................................................................................................ 134<br />

Appendix One. Dyes Solutions .................................................................................... 151<br />

Appendix Two. Photocatalytic Process ........................................................................ 152<br />

Appendix Three. Sono-Fenton Process ....................................................................... 182<br />

xi

Appendix Four. Photo-Fenton Process……………………………………………………..206<br />

xii

List of Tables<br />

Page<br />

Table 1.1. Characteristics of the most important dyes classes 19<br />

Table 5.1. Basic information of the studied organic compounds 103<br />

Table 5.2.<br />

Degradation percent of dye solutions during the<br />

Photocatalytic Process 107<br />

Table 5.3.<br />

Kinetic reaction rates and R2 values for the degradation<br />

reaction of the organic compounds during the<br />

photocatalytic process 109<br />

Table 5.4.<br />

Kinetic reaction rates and R2 values for de degradation<br />

reaction of the organic compounds during the sono-Fenton<br />

process 120<br />

Table 5.5.<br />

Kinetic reaction rates and R2 values for de degradation<br />

reaction of the organic compunds during the sono-Fenton<br />

process 122<br />

Table 5.6.<br />

Degradation percent of dye solutions during the Photo-<br />

Fenton Process 127<br />

Table 5.7.<br />

Kinetic reaction rates and R2 values for the degradation<br />

reaction of the organic compounds during the photo-<br />

Fenton process 129<br />

xiii

List of Figures<br />

Page<br />

Figure 1.01.<br />

Schematic diagram for the photoexcitation process in a<br />

semiconductor via photon irradiation 8<br />

Figure 1.02. Molecular structure of Methylene blue 20<br />

Figure 1.03. Molecular structure of Rhodamine B 21<br />

Figure 1.04. Molecular structure of the Methyl Orange 22<br />

Figure 1.05.<br />

Molecular structure of Crystal Violet and the molecular<br />

structure of Methyl Violet 23<br />

Figure 1.06. Molecular structure of p-amino benzoic acid (pABA) 24<br />

Figure 2.01.<br />

Schematic representation of the diffraction process from<br />

atoms in a crystalline lattice 28<br />

Figure 2.02. Images of the PANalytical XRD system 29<br />

Figure 2.03. Typical hysteresis loop of capped magnetite nanoparticles 30<br />

Figure 2.04. VSM components 31<br />

Figure 2.05. Lake Shore-7400 Vibrating Sample Magnetometer 32<br />

Figure 2.06. Schematic illustration of the TGA instrument 33<br />

Figure 2.07. Thermal Gravimetric Analysis (TGA), TA instrument, Q500 34<br />

Figure 2.08.<br />

Micromeritics ASAP 2020 Accelerated Surface Area<br />

and Porosimetry 36<br />

Figure 2.09. Raman vibrational and scattering modes 38<br />

Figure 2.10. Image of the micro Raman scattering equipment 39<br />

Figure 2.11. Perkin-Elmer PHI 3027 spectrometer and VG Escalab 210<br />

Spectrometer 42<br />

Figure 2.12. Main components of a FE-SEM instrument 44<br />

xiv

Figure 2.13. FE-SEM JEOL JM-6400 microscope 44<br />

Figure 2.14.<br />

TOC analyzer (Tekmar Dohmann Phoenix 8000 UV-<br />

Persulfate TOC Analyzer 46<br />

Figure 2.15.<br />

Image of the Leco CHNS 932 analyzer and scheme of its<br />

different components parts 46<br />

Figure 2.16.<br />

Representation of the different electronic transitions<br />

generated during the absorption process under UV-Visible<br />

irradiation 48<br />

Figure 2.17.<br />

Image of the fluorescence spectrophotometer Varian Cary<br />

Eclipse and a diagram of the fluorescence spectrometer 51<br />

Figure 3.01.<br />

Image of the CVD system and scheme of the CVD system<br />

and thermal treatment used for the synthesis of the Fe 2 O 3<br />

nanowires 56<br />

Figure 4.01.<br />

FE-SEM image of the titanium oxide (rutile phase) at a<br />

magnification of 5000x 58<br />

Figure 4.02. TGA scan of titanium oxide (rutile phase) 58<br />

Figure 4.03. Raman spectrum of TiO 2 sample (rutile phase) 59<br />

Figure 4.04. XPS spectrum corresponding to the O1s region of the TiO 2<br />

catalyst (rutile phase) 60<br />

Figure 4.05. XPS spectrum corresponding to the Ti2p region of the TiO 2<br />

catalyst (rutile phase) 60<br />

Figure 4.06.<br />

XRD diffraction pattern for TiO 2 -Anatase, TiO 2 -Rutile,<br />

TiO 2 @MWCNTs and TiO 2 NWs 61<br />

Figure 4.07.<br />

FE-SEM image of the titanium oxide (anatese phase) at a<br />

magnification of 50 000x 62<br />

Figure 4.08. TGA scan of titanium oxide (anatase phase) 62<br />

xv

Figure 4.09.<br />

Raman spectrum of titanium oxide catalyst (anatase<br />

phase) 63<br />

Figure 4.10.<br />

XPS spectrum of Ti2p peak on titanium oxide (anatase<br />

phase) 64<br />

Figure 4.11.<br />

XPS spectrum of TiO 2 showing the O1s transition<br />

(anatase phase) 64<br />

Figure 4.12.<br />

FE-SEM image of the as-synthesized TiO 2 NWs at different<br />

Magnifications 65<br />

Figure 4.13. TGA analysis of the as-synthesized TiO 2 NWs 66<br />

Figure 4.14. Raman spectrum of the as-synthesized TiO 2 NWs 67<br />

Figure 4.15. XPS spectrum of Ti2p region of the as-synthesized TiO 2 NWs 67<br />

Figure 4.16. XPS spectrum of O1s region of the as-synthesized TiO 2 NWs 68<br />

Figure 4.17. FE-SEM image of the as-synthesized TiO 2 @MWCNTs 69<br />

Figure 4.18. TGA analysis of the as-synthesized TiO 2 @MWCNTs 70<br />

Figure 4.19. Raman spectrum of the as-synthesized TiO 2 @MWCNTs 71<br />

Figure 4.20.<br />

XPS spectrum corresponding to the C1s region of the as-<br />

synthesized TiO 2 @MWCNTs catalyst 72<br />

Figure 4.21.<br />

XPS spectrum corresponding to the Ti2p region of the as-<br />

synthesized TiO 2 @MWCNTs catalyst 72<br />

Figure 4.22.<br />

XPS spectrum corresponding to the O1s region of the as-<br />

synthesized TiO 2 @MWCNTs catalyst 73<br />

Figure 4.23.<br />

FE-SEM image of the as-synthesized ZnO particles at<br />

different magnification 74<br />

Figure 4.24. TG curve of the as-synthesized ZnO particles 75<br />

Figure 4.25. Raman spectrum of the as-synthesized ZnO particles 75<br />

Figure 4.26. XRD diffraction pattern of the as-synthesized ZnO particles 76<br />

xvi

Figure 4.27.<br />

FE-SEM image of the as- as-synthesized iron oxide<br />

nanowires (Fe 2 O 3 NWs) at different magnifications 77<br />

Figure 4.28. TG curve of raw Fe 2 O 3 NWs 77<br />

Figure 4.29.<br />

XPS spectrum corresponding to the Fe2p region of the as-<br />

synthesized Fe 2 O 3 NWs 78<br />

Figure 4.30.<br />

XPS spectrum corresponding to the O1s region of the as-<br />

synthesized Fe 2 O 3 NWs 79<br />

Figure 4.31. Raman spectrum of the as-synthesized Fe 2 O 3 NWs particles 79<br />

Figure 4.32.<br />

Magnetic susceptibility of the as-synthesized Fe 2 O 3 NWs,<br />

measured at room temperature 80<br />

Figure 4.33.<br />

XRD diffraction patterns of Fe 2 O 3 NWs synthesized at<br />

600 °C and 700 °C at atmspheric pressure and in flowing<br />

Oxygen 81<br />

Figure 4.34.<br />

FE-SEM images of the as-synthesized capped magnetite<br />

nanoparticles (Fe 3 O 4 ) at different magnifications 83<br />

Figure 4.35.<br />

XPS spectrum corresponding to the Fe2p region, of the as-<br />

synthesized capped magnetite nanoparticles (Fe 3 O 4 ) 84<br />

Figure 4.36.<br />

XPS spectrum corresponding to the O1s region, of the as-<br />

synthesized capped magnetite nanoparticles (Fe 3 O 4 ) 84<br />

Figure 4.37.<br />

Raman spectrum of the as-synthesized capped magnetite<br />

Nanoparticles 85<br />

Figure 4.38.<br />

Temperature effect on the magnetite properties of the<br />

magnetite at different temperatures 85<br />

Figure 4.39. TG curve of the ferrous chloride 86<br />

Figure 4.40.<br />

XPS spectrum corresponding to the Cl2p region, of the<br />

FeCl 2 catalyst 87<br />

xvii

Figure 4.41.<br />

XPS spectrum corresponding to the Fe2p region, of the<br />

FeCl 2 catalyst 87<br />

Figure 4.42. XRD diffraction pattern of the FeCl 2 catalyst 88<br />

Figure 4.43. FE-SEM images of CuO at different magnification 89<br />

Figure 4.44. TG curve of the cupric oxide catalyst 89<br />

Figure 4.45. XRD diffraction pattern of the CuO catalyst 90<br />

Figure 5.01.<br />

Effects of the concentration of anatase on the<br />

photodegradation process of RhB 92<br />

Figure 5.02.<br />

Effects of the catalyst and hydrogen peroxide on the<br />

photodegradation process of RhB 93<br />

Figure 5.03.<br />

Effects of the pH of the reaction mixture on the<br />

photodegradation process of RhB 94<br />

Figure 5.04.<br />

Effects of the temperature of the solution on the<br />

photodegradation process of RhB 96<br />

Figure 5.05.<br />

Experimental setup used during this research, without<br />

irradiation and during the irradiation 101<br />

Figure 5.06. Dye solution used during the investigation 101<br />

Figure 5.07. Methylene blue visible absorption spectrum 102<br />

Figure 5.08.<br />

Visible absorbance abd fluorescence spectrum of MB in<br />

presence of rutile 104<br />

Figure 5.09.<br />

Possible degradation intermediates of RhB during the<br />

photocatalytic process 105<br />

Figure 5.10.<br />

Graphic of the percent of degradation of the different<br />

organic compounds by the Photocatalytic process 107<br />

Figure 5.11.<br />

Regression curve of the Methylene Blue (MB) with rutile<br />

under photochemical process 108<br />

xviii

Figure 5.12.<br />

Possible processes involved in the degradation reaction<br />

using TiO 2 as catalyst 112<br />

Figure 5.13.<br />

Absorption spectrum corresponding to the degradation of<br />

Rhodamine B by TiO 2 @MWCNTs under photochemical<br />

Process 113<br />

Figure 5.14. Four principal by-products of the MO degradation process 115<br />

Figure 5.15.<br />

Possible intermediates of degradation of MO during the<br />

photocatalytic degradation 116<br />

Figure 5.16.<br />

Schematic diagram of the sonochemical generation of the<br />

degradation radicals 118<br />

Figure 5.17.<br />

Degradation curves of RhB; UV-vis absorbance , TOC,<br />

fluorescence and dye solution before and after the sono-<br />

Fenton degradation process 119<br />

Figure 5.18.<br />

Graphic of percent of degradation of the organic<br />

compounds by the Sono-Fenton process 120<br />

Figure 5.19. Regression curve of the Methylene Blue (MB) with Fe 3 O 4<br />

under sono-Fenton process 121<br />

Figure 5.20.<br />

Scheme of the different areas of interest during the<br />

sonochemical process 124<br />

Figure 5.21.<br />

Degradation curves of MO; UV-vis absorbance, TOC,<br />

fluorescence and dye solution before and after the photo-<br />

Fenton degradation process 126<br />

Figure 5.22.<br />

Graphic of percent of degradation of the organic<br />

compounds by the Photo-Fenton process 128<br />

Figure 5.23. Regression curve of the Methylene Blue (MB) with Fe 3 O 4<br />

during photo-Fenton degradation process 128<br />

xix

Figure 5.24.<br />

Graphic of comparison between the Photocatalytic process<br />

and the Photo-Fenton process 130<br />

Figure 5.25.<br />

Graphic of comparison between the Photocatalytic process<br />

and the Sono-Fenton process for MB, RhB and MO 131<br />

xx

List of Appendices<br />

Page<br />

Appendix One Dyes Solutions 151<br />

Appendix Two Photocatalytic Process 152<br />

Appendix Three Sono-Fenton Process 182<br />

Appendix Four Photo-Fenton Process 206<br />

xxi

Abstract<br />

María <strong>del</strong> Carmen Cotto-Maldonado (PhD, Environmental Science)<br />

<strong>Heterogeneous</strong> <strong>Catalysis</strong> <strong>Applied</strong> <strong>To</strong> Advanced Oxidation Processes (AOPs) For<br />

Degradation of Organic Pollutants<br />

(April/2012)<br />

Abstract of a doctoral dissertation at the <strong>Universidad</strong> <strong>del</strong> <strong>Turabo</strong><br />

Dissertation supervised by Professor Francisco M Marquez Linares<br />

No. of pages in text 260<br />

Water is an essencial resource for humankind and biomes.<br />

Actually, the<br />

pollution of the water resources, specially the contamination of the fresh water is great<br />

concern in our society. Develop of new and more efficient method for degradation of<br />

pollutant in water increase the research in this area, especially in the AOPs. During this<br />

investigation a comparison between different AOPs methods (photocatalysis, sono-<br />

Fenton and photo-Fenton) to determine the most efficient process of them was done. <strong>To</strong><br />

reach our goal, different catalysts, namely TiO 2 nanowires, TiO 2 @CNTs, ZnO<br />

nanoparticles, Fe 2 O 3 nanowires and magnetite nanoparticles were synthesized and<br />

characterized by different techniques including FE-SEM, TGA, specific surface area<br />

(BET), XRD, Raman spectroscopy, XPS and magnetic susceptibility. Commercial and<br />

synthesized catalysts were used in photocatalysis, sono-Fenton and photo-Fenton<br />

processes for the degradation of mo<strong>del</strong> organic compounds (Methylene Blue,<br />

Rhodamine B, Methyl Orange, Gential Violet, Methyl Violet and p-aminobenzoic acid).<br />

According with the experimental results, no significant differences were observed<br />

between the photo-Fenton and sono-Fenton processes when the same catalysts were<br />

used. For the photocatalytic process, the more effective catalyst was TiO 2 NWs and for<br />

the sono-Fenton and photo-Fenton processes, the more effective catalyst was FeCl 2 .<br />

xxii

Resumen<br />

María <strong>del</strong> Carmen Cotto Maldonado (PhD, Environmental Science)<br />

<strong>Heterogeneous</strong> <strong>Catalysis</strong> <strong>Applied</strong> <strong>To</strong> Advanced Oxidation Processes (AOPs) For<br />

Degradation of Organic Pollutants<br />

(Abril/2012)<br />

Resumen de disertación doctoral en <strong>Universidad</strong> <strong>del</strong> <strong>Turabo</strong><br />

Disertación fue supervisada por el Profesor Francisco M Marquez Linares<br />

No. de páginas 260<br />

El agua es un recurso esencial para la vida humana y los biomas. Actualmente,<br />

la contaminación de los recursos acuáticos, especialmente de la contaminación de los<br />

abastos de agua potable ha creado una gran preocupación en nuestra sociedad. El<br />

desarrollo de nuevos y más eficientes métodos para la degradación de los<br />

contaminantes en agua se ha incrementado, especialmente en la utilización de los<br />

procesos de oxidación avanzada (AOPs, por sus siglas en ingles).<br />

Durante esta<br />

investigación se llevó a cabo una comparación de la eficiencia entre diferentes procesos<br />

de “AOPs” (fotocatálisis, sono-Fenton y foto-Fenton). Para alcanzar la meta de nuestra<br />

investigación se han sintetizado diferentes catalizadores como nanohilos de TiO 2 , TiO 2<br />

depositado sobre nanotubos de carbono, partículas de ZnO, nanohilos de Fe 2 O 3 y<br />

nanopartículas de magnetita. Estos materiales han sido caracterizados mediante<br />

diferentes técnicas entre las que se incluyen microscopia electrónica de barrido con<br />

emisión de campo (FE-SEM, por sus siglas en inglés) análisis termogravimétrico,<br />

determinación de área específica (BET), difracción de rayos X (DRX), espectroscopia<br />

Raman, espectroscopia fotoelectrónica de rayos X (XPS, por sus siglas en inglés) y<br />

susceptibilidad magnética. Estos catalizadores de síntesis y otros comerciales fueron<br />

utilizados en los procesos de degradación estudiados (fotocatálisis, sono-Fenton y foto-<br />

xxiii

Fenton). El Azul de metileno, Rodamina B, Naranja de metilo, Cristal Violeta y ácido p-<br />

amino benzoico fueron los compuestos orgánicos mo<strong>del</strong>os utilizados durante los<br />

procesos de degradación.<br />

Según los resultados experimentales, no se observan<br />

diferencias significativas entre los procesos sono-Fenton y foto-Fenton cuando los<br />

mismos catalizadores son utilizados. En el proceso fotocatalítico de degradación, el<br />

fotocatalizador que presentó mayor eficiencia fue el correspondiente a nanohilos de<br />

óxido de titanio. Durante los procesos sono-Fenton y foto-Fenton, el catalizador más<br />

activo en la degradación de los compuestos estudiados fue el FeCl 2 .<br />

xxiv

Chapter One<br />

Introduction<br />

Water is an important resource in our society. Less than a 0.7% of the total of<br />

water in the Planet is fresh water and only 0.01% is accessible to be used (Garriga I<br />

Cabo 2007). This resource is essential for sustaining the basic human functions as<br />

health, agriculture and the integrity of the biomes (Garriga I Cabo 2007, UNEP et al.<br />

2002). One of the human basic rights, especially children, is access to safe water for<br />

drinking and other uses (UNEP et al. 2002) because biological and chemical<br />

contaminants compromise the water quality in the world. <strong>To</strong>day, some of the most<br />

discussed issues around the world are the sanitation, soil and water chemical pollution,<br />

air pollution, the degradation of water sources and natural resources (Garriga I Cabo<br />

2007, UNEP et al. 2002). Organic, inorganic, bionutrients and microorganisms are some<br />

of the most common contaminants in water (Garriga I Cabo 2007). One of the facts<br />

mentioned by UNEP et al. (2002) said:<br />

“at the dawn of the 21 st Century, about 18 per cent of the<br />

world’s population do not have access to safe drinking<br />

water, and nearly 40 per cent lack adequate sanitation”.<br />

In many regions of the world, water is a scarce resource, and in these places the reuse<br />

of the water is a relevant issue (Marin et al. 2007).<br />

The production and use of synthetic chemical products have experienced an<br />

important increase during the last century. These products imply a challenge to the<br />

environment (UNEP et al. 2002), due to the fact that the environment does not have the<br />

1

2<br />

required mechanisms to promote the degradation, and these contaminants can become<br />

highly toxic to many species including the human being. Humankind is responsible for<br />

the release of the pollutants to the environment in many of their normal activities like<br />

industrial processes, wastewater discharges, excessive use of pesticides, fertilizers, etc.<br />

Many contaminants could move through the trophic chains and be accumulated in the<br />

organisms (UNEP et al. 2002).<br />

This situation highlights the importance of more<br />

epidemiological studies to understand the effect (synergistic or antagonist) of the<br />

population exposure to environmental contaminants.<br />

According to the OAS (2010), one of the objectives of the “Sustainable<br />

development of the Americas” is the protection of the public health by keeping the<br />

drinking water free of microorganisms, heavy metals and hazardous pollutants and trying<br />

to strengthen the development and implementing laws, regulations and policies.<br />

Organizations in different countries as “Alianza para el Desarrollo Sostenible” (ALIDES),<br />

“Organización Panamericana de la Salud” (OPS), the “Comité Coordinador de<br />

Instituciones de Agua Potable y Saneamiento de Centroamerica”, the Environmental<br />

Protection Agency (EPA), etc. work together to establish laws and regulations to protect<br />

the environment (OAS 2010). Examples of countries that are working with to achieve a<br />

better quality of water and environment protection are Belize, Costa Rica, Guatemala,<br />

etc. (OAS 2010). Chile is another example of a Latin American country that presents a<br />

relevant interest in the protection of the water sources and the environment (UNEP<br />

[undated]). According to the report of the UNEP et al. (2002), in 2002 the 30% of the<br />

industrial effluents were discharged into sewage systems without the appropriate<br />

discharge treatments.<br />

Another example of the strong interest of the countries for the conservation and<br />

management of the water resources was the UNEP Conference entitled “Greening<br />

Water Law in Africa: Managing Freshwater Resources for People and the Environment”

3<br />

held in Kampala, Uganda. The main objective of this meeting was the analysis of the<br />

socio-economic infrastructure with the environmental protection and conservation of the<br />

resources in the African continent (UNEP 2010).<br />

The Clean Water Act (CWA) of 1977 described in the 33 USC §1251 et seq.<br />

establishes all the basis and regulations to avoid the pollution of the waters of the United<br />

States of America regulating the discharges. The CWA enables the Environmental<br />

Protection Agency to implement the regulatory standards for water quality and<br />

discharges through the National Pollutant Discharge Elimination System (NPDES).<br />

However, the NPDES only regulates specific discharges, including industrial and<br />

treatment plant effluents. Non specific discharges, as for instance the septic systems,<br />

are not regulated by NPDES.<br />

In Puerto Rico, Environmental Quality Board (EQB)<br />

establishes some discharge regulations to protect the quality of the waters according<br />

with the uses.<br />

The EPA has proposed a “Strategic Plan” for the fiscal years of 2011 to 2012 to<br />

protect and restore the waters in the USA, and specifically to protect the human and<br />

aquatic ecosystem health (USEPA [undated]). In the “Notice of Final 2010 Effluent<br />

Gui<strong>del</strong>ines Program Plan”, the effluents gui<strong>del</strong>ines and pretreatment standards are<br />

evaluated to maintain the integrity of the water sources (FR 2010). Meanwhile, Best<br />

Available Technology Economically Achievable (BAT) are promulgates for reach the<br />

EPAs goal as suggest in the Federal Register as a form to increase the effectivity of the<br />

treatments processes.<br />

The United States Geological Survey (USGS) as part of the US Department of<br />

the Interior is developing different studies to determine the level of contamination of<br />

different streams in the US. A survey from 1999 to 2000 of the USGS (Barnes et al.<br />

2002a, 2002b) has demonstrated the presence of 82 of the 95 organic wastewater<br />

contaminants analyzed. A total of 80% of the samples taken from 30 of the states were

4<br />

positive for the presence of at least 1 of the contaminants including antibiotics,<br />

hormones, detergents, plasticizers, disinfectants, insecticides, fire retarded (using during<br />

fibers synthesis), and antioxidants. Most commonly detected products are steroids, nonprescript<br />

drugs and insect repellents.<br />

Emerging Contaminants Project of the USGS (USGS 2011a) has the goal of<br />

provide information (analytical methods, environmental occurrence, pathways and<br />

ecological effects) of the contaminants that are not monitored due to the lack of<br />

regulation but have the potential to reach the environment in significant amounts, having<br />

adverse effects on the biosphere and specifically in humans.<br />

Different studies<br />

developed in New York and New Jersey were undertaken to determine the occurrence<br />

and concentration of emerging contaminants after treatment processes (USGS 2008).<br />

The coordinator of the USGS <strong>To</strong>xic Substances Hydrology Program, Herb Buxton,<br />

declared that:<br />

“The wastewater treatments are not really designed to remove<br />

those trace-organic chemicals”<br />

and these contaminants are normally released to the environment (USGS 2011b).<br />

Among the emerging contaminants found in the environment, the group of<br />

cosmetic and personal care products (PPCs) deserves special attention. The UV filters<br />

is one of the products commonly used and several studies demonstrate the presence in<br />

different water samples. The UV filters also possess potential risks derived from the<br />

presence of single or multiple aromatic groups in their structures and these substances<br />

are normally used in sunscreen lotions and many cosmetics. Comparison studies in<br />

Switzerland, between river and lake fish as Salmo trutta fario, Coregonus spp and R<br />

rutilus demonstrated the presence of UV-filters in muscle tissue of the fishes (Buser et<br />

al. 2006).<br />

Another study of Schlumpf et al. (2008) demonstrated the presence of<br />

sunscreen compounds from analyses of human milk.

5<br />

These results demonstrate the need for efficient water treatment technologies<br />

able to remove or degrade hazardous contaminants present in the effluents, making the<br />

water resources both safe and potable to human consumption. For example, to maintain<br />

the aesthetic and diminish the environmental impact of industrial effluents is necessary<br />

the discoloration of the wastewaters (Hussein et al. 2008). Currently, the most used<br />

treatment methods for the removal of contaminants from water are the reverse osmosis,<br />

ion-exchange technology, precipitation of materials and adsorption of the contaminants,<br />

especially using activated carbon (charcoal) and biological degradation (Gupta et al.<br />

2004; Mezohegyi et al. 2007). Other processes as Fenton, photochemistry, radiolysis or<br />

sonolysis generate highly reactive hydroxyl radicals for bleaching; finally arising to the<br />

mineralization of recalcitrant compounds (Ozen et al. 2005). In the boom of the ecoconservation<br />

and the eco-friendly techniques to degrade the pollutants in water and<br />

wastewater, the Advance Oxidation Processes or AOPs are seen as alternative<br />

techniques (Gupta et al. 2004) to the traditional processes.<br />

Techniques as hydrogen peroxide oxidation, ozonation, photolysis, Fenton<br />

process, photocatalytic oxidation, wet-air oxidation and ultrasonic sonication are<br />

considered as part of the AOPs used for the degradation of contaminants (Gupta et al.<br />

2004; Garriga I Cabo 2007). The AOPs use chemical procedures based on the use of<br />

catalysts or photochemical compounds which generate highly reactive transient species<br />

as the hydroxyl radical which possesses high affectivity for the oxidation of organic<br />

compounds (Marin et al. 2007). The AOPs are defined as “processes that involve in situ<br />

generation of free radicals” (Priyas and Madras 2006) with a highly potential oxidant<br />

such as the hydroxyl radicals (•OH) (Priyas and Madras 2006; Ai et al. 2007a; Garriga I<br />

Cabo 2007; Marin et al. 2007; Mosteo et al. 2008) being non-selective chemical oxidant<br />

processes (Ai et al. 2007a; Mosteo et al. 2008). These radicals are produced by the<br />

combination of the hydrogen peroxide, UV radiation, ozone and a semiconductor as

6<br />

titanium oxide or the combination of hydrogen peroxide with iron ions (Fenton reaction)<br />

(Marin et al. 2007). The radicals (OH • ) produced during the AOPs are powerful oxidants<br />

because they have high oxidative potential (E 0 OH/H2O=2.8 V) when compared with the<br />

normal hydrogen electrode (Ab<strong>del</strong>malek et al. 2006).<br />

AOPs have many advantages as: the complete mineralization of the pollutant,<br />

are non-selective process, can be used in low concentration of contaminants and can be<br />

combined with other methods (Garriga I Cabo 2007). The use and development of<br />

photocatalytic processes for the removal of harmful contaminants, as a treatment for<br />

wastewater and air pollutants is becoming increasingly popular (Yin et al. 2009).<br />

<strong>Heterogeneous</strong> photocatalysis is one of the AOP’s and is based on the direct or indirect<br />

absorption of photons from ultraviolet (UV) or visible light by a semiconductor that<br />

possesses the appropriate energy gap. According with Ruan and Zhang (2009) the “UV<br />

–driven photocatalytic activity of the sample is much higher than the visible light –driven<br />

photocatalytic activity” because the shorter the wavelength the higher quantum yield.<br />

Velegraki and Mantvinos (2008) describe the importance of the heterogeneous<br />

photocatalytic degradation as<br />

“organic compounds can then undergo both oxidative degradation<br />

through their reactions with valence band holes, hydroxyl and<br />

peroxide radicals and reductive cleavage through their reactions<br />

with electrons yielding various by-products and eventually mineral<br />

end-products.”<br />

The excitation of the semiconductor can take place by two different ways: i) the direct<br />

excitation of the semiconductor (direct absorption of the photons by the surface of the<br />

semiconductor) or ii) the excitation of molecules previously adsorbed on the surface of<br />

the semiconductor which transfer the electrons to the semiconductor (Marin et al. 2007).<br />

The direct absorption process of the photon causes the excitation of the surface or

7<br />

interface region between the solid and the liquid avoiding any chemical change in the<br />

catalyst (Marin et al. 2007). A distinctive characteristic of the interface is the charge<br />

redistribution to both sides of the interface (Marin et al. 2007). Vinu and Madras (2010)<br />

define photocatalysis as<br />

“the acceleration of the rate of chemical reactions<br />

(oxidation/reduction) brought about by the activation of a catalyst,<br />

usually a semiconductor oxide, by UV or visible radiation”.<br />

Other authors (Aarthi and Madras 2007) argue that<br />

“in aqueous environment, the holes created under the UV<br />

irradiation are scavenged by the hydroxyl groups present on the<br />

surface, generating OH• radicals, which promote the oxidation of<br />

the organics”.<br />

The semiconductor for the photocatalyst should be chemical and biological inert,<br />

stable, inexpensive, of easy synthesis and production, and without human and<br />

environmental risks (Garriga I Cabo 2007). When a dye is used, the mechanism of<br />

photodegradation involves the excitation of the dye and the transference of the electrons<br />

to the conduction band of the photocatalyst (i.e. TiO 2 ) to generate the dye radicals.<br />

These radicals react with the oxygen on the surface of the catalyst generating oxygen<br />

radical species as O •- 2 , H 2 O 2 and •O 2 remaining the valence band unaffected (Yin et al.<br />

2009).<br />

Another form to simplify this complex process is considering that the<br />

photocatalyst (i.e. titanium oxide) absorbs a photon having energy greater than or equal<br />

to the band gap (hv≥ E BG ); This energy absorption implies the promotion of an electron<br />

from the valence band to the conduction band of the photocatalyst. This promotion<br />

leaves a “hole” (positive charge) in the valence band giving place to the formation of

8<br />

“electron-hole” pairs. If the pairs migrate to the surface of the metal they can react with<br />

the solution (Prakash et al. 2009; Vinu and Madras 2010).<br />

Figure 1.01 shows a<br />

schematic view of the photoexcitation process experienced by a semiconductor.<br />

Figure 1.01. Schematic diagram for the photoexcitation process<br />

in a semiconductor via photon irradiation (Adapted from: Hu et al.<br />

2010; Vinu and Madras 2010).<br />

Considering this photocatalytic mechanism, the photodegradation process should<br />

be affected by the light source (irradiation energy), dye concentration, catalyst<br />

concentration and the presence of other organic substances or ions in the solution<br />

(Aarthi and Madras 2007, Yin et al. 2009). Some of the most common photocatalysts<br />

include TiO 2 , ZnO, ZnS, CdS, WO 3 , SrTiO 3 , and SnO 2 (Sokmen et al. 2000; Priya and<br />

Madra 2006). Additionally, catalysts with perovskite structure (Yu et al. 2009; <strong>To</strong>rres<br />

Martínez et al. 2010) are also used for photochemical reactions. For degradation on wet<br />

oxidation, different types of catalysts are used including heterogeneous catalysts of<br />

metal oxides (ZnO, CuO, MnO 2 , SeO 2 , TiO 2 , ZrO 2 , etc.), noble metals on alumina

9<br />

support and metal impregnation on activated carbon (Cu, Co, Bi, Fe, Mn) (Ma et al.<br />

2007).<br />

The photocatalysis is an AOP commonly used because is able to mineralize<br />

organic pollutants at low cost (Yu et al. 2009). Other important AOP is the ultrasonic<br />

irradiation. At the beginning of the 20 th century, Richards and Loomis described the use<br />

of the ultrasound irradiation technique as driving force for a chemical transformation<br />

(Priya and Madras 2006).<br />

Degradation process using ultrasound irradiation in<br />

heterogeneous catalysis can be increased due the formation of radicals as •OH during<br />

the cavitation process (Shimizu et al. 2007). Cavitation phenomenon in liquids includes<br />

the nucleation, growth and collapse of small bubbles (Shimizu et al. 2007). According to<br />

the authors (Shimizu et al. 2007), cavitation is fundamental for the chemical and<br />

mechanical process occurring during the ultrasound irradiation. This process can induce<br />

the increase of temperature in hot spots of thousands of Kelvin (T=4000 K) in an<br />

adiabatic heating, and pressures in the scale of hundreds of atmospheres (313 atm)<br />

leading the dissociation of the water molecules producing hydrogen atoms and hydroxyl<br />

radicals (•OH) (Priyas and Madras 2006; Shimizu et al. 2007). These radicals can<br />

produce many chemical reactions (sonochemical reactions) (Shimizu et al. 2007;<br />

Kavitha and Palanisamy 2011).<br />

The use of the sonochemical reactions could be<br />

potentially used in environmental processes as wastewater treatments (Shimizu et al.<br />

2007). Semiconductor catalysts commonly used in ultrasonic degradation are Fe 2 O 3 ,<br />

TiO 2 , ZnO and CuO (Priya and Madra 2006).<br />

Priya and Madra (2006) point out that one of the main advantages of the<br />

ultrasonic irradiation with respect to the photocatalytic process is the elimination of the<br />

“spatial limitation” over the catalyst, because cavitation process increases the generation<br />

of radicals and is extended along the solution and it is not exclusively limited to the

10<br />

catalyst surface. This process increases the surface area, avoiding the occlusion of the<br />

active sites on the surface, reducing the mass-transfer limitations. Authors describe the<br />

“spatial limitation” as a problem caused by light screening effects produced during the<br />

photocatalytic reaction that reduces the excitation area on the surface of the catalyst<br />

(Priya and Madra 2006). Use of the ultrasonic irradiation for the degradation process of<br />

a dye could be affected by many factors as the concentration of the catalyst and the dye,<br />

the presence of anions, the pH and presence of scavenger agents in the solution<br />

(Shimizu et al. 2007). Some authors (Shimizu et al. 2007) studied the synergistic effect<br />

of the photochemical process on the sonochemical process (ie. degradation of salicylic<br />

acid).<br />

The Fenton reaction as part of the AOPs generates hydroxyl radicals. This<br />

process is clearly non selective (Ai et al. 2007b) and represents a viable technique to<br />

degrade hazardous organic compounds. Horstman-Fenton and Jackson (1899)<br />

demonstrated the importance of iron and hydrogen peroxide during the oxidation of<br />

some substances. A characteristic of the Fenton process is that the reaction requires<br />

acid conditions to work more efficiently (pH ranging from 2 to 3) (Ai et al. 2007b). The<br />

development of a Fenton process working efficiently in a neutral pH should be an<br />

advance, because it is unnecessary the decrease of the pH before the reaction takes<br />

place, decreasing the generation of sludges during the process and increasing the<br />

possibility to recuperate the Fenton reagent (iron) from the media (Ai et al. 2007b).<br />

<strong>To</strong>xicological studies with L gibba demonstrated the degradation of substances as<br />

sulfonamides (antibiotics) using anodic Fenton treatment (AFT) in solutions with<br />

concentration of 100 μM (Neafsey et al. 2010).<br />

In a biological process, Hotta et al. (2010) demonstrated that the addition of Fe 2+<br />

ion stimulated the cell growth of Sphingomonas spp increasing the biodegradation<br />

activity of the alkylphenol polyethoxylates or APEO n (used as detergents, emulsifiers and

11<br />

pesticides) increasing the production of endocrine active metabolites. According with<br />

the authors (Hotta et al. 2010) three possible classifications of the microbial degradation<br />

of man-made compounds in the environment are possible; biodegradation rate increases<br />

by stimulation of the cell growth by a chemical substance, by minerals presents in the<br />

media and by enzyme induced and/or stimulation of the minerals.<br />

It is relevant to define some important terms concerning these reactions (i.e.<br />

Fenton and Fenton-like reagents). According to Ai et al. (2007a), the Fenton reagent<br />

can be defined as the combination of hydrogen peroxide and iron (II) (Fe 2+ /H 2 O 2 ).<br />

Fenton-like reagent does not include iron (II) species and normally this term is used for<br />

the combination of Fe 3+ /H 2 O 2 although both reagents (Fenton and Fenton-like) are<br />

present during the reaction because both iron species are in equilibrium during the<br />

reaction. The Fenton-like reagent is capable of oxidizing organic substrates, but it is<br />

somewhat less reactive than Fenton reagent. Similarly to Fenton reactions produced by<br />

Fe 2+ /Fe 3+ in presence of hydrogen peroxide, Randorn et al. (2004) demonstrated that<br />

analogous processes are also observed with other transition metals as titanium. The<br />

reactive titanium species involved in the Fenton reaction are Ti 3+ /Ti 4+ .<br />

Use of the Fenton and Fenton-like reactions has two principal disadvantages for<br />

the use in large scale; the first one is the high cost of the reagents required (H 2 O 2 ) and<br />

their instability in solution, and the second one is the concerns involved in the use of<br />

acidic pH (pH < 4) and with a narrow range of pH values during the process (Ai et al.<br />

2007b). As Fenton reagents (Ai et al. 2007b) different compounds including hematite,<br />

goethite, clays, iron hydroxide and iron supported on different materials have been<br />

evaluated.<br />

An alternative to the typical Fenton reactions based on the use of soluble<br />

Fe 2+ /Fe 3+ species is the use of Fe 0 phase as a supported or immobilized catalyst and<br />

hydrogen peroxide as oxidizer (Ai et al. 2007a). Examples of possible reagents for

12<br />

environmental remediation include Fe 0 , Fe 3 O 4 (magnetite) and Fe 2 O 3 (maghemite) (Ai et<br />

al. 2007a). The Fe 0 is used to remove organic compounds from the soil and Fe 3 O 4 and<br />

Fe 2 O 3 are normally used for the degradation of organic compounds in solution. Ai et al.<br />

(2007a) demonstrated the efficiency of the Fe@Fe 2 O 3 core-shell nanowires for the<br />

degradation of RhB.<br />

These materials have been synthesized by using different<br />

procedures as chemical vapor deposition, different metal oxidation processes and wet<br />

chemistry (Huh et al. 2010). Some authors point out the disadvantage of using zinc<br />

compounds because they are easily oxidized and the zinc oxide is weak and instable<br />

forming zinc hydroxide in some solutions (Randorn et al. 2004).<br />

Magnetites and related materials attracted a great deal of attention when a<br />

Martian meteorite was analyzed and these materials where found as one of their main<br />

components (Nyiro-Kosa et al. 2009). The magnetite is a versatile material due to their<br />

interesting applications in different fields such as catalysis, information storage,<br />

optoelectronics and biomedical applications that include magnetic bioseparation,<br />

magnetic resonance imaging contrast enhancement and targeted drug (Marquez et al.<br />

2011, 2012). For these applications, the particle size of the magnetites should range<br />

from 30 to 120 nm (Nyiro-Kosa et al. 2009). Proteins of magnetotactic bacteria can be<br />

used to biomimetic the natural process in the lab (Nyiro-Kosa et al. 2009. The magnetite<br />

size is influenced by different parameters, including the concentration of the reagents,<br />

temperature, pH of the solution and the reaction time (Nyiro-Kosa et al. 2009). Among<br />

the possible methods for the synthesis of magnetites the co-precipitation, pyrolysis,<br />

ultrasound irradiation, hydrothermal or electrochemical approach can be considered as<br />

the most useful and with higher yields than other processes (Nyiro-Kosa et al. 2009).<br />

The use of the nanomaterials for environmental and energy applications has<br />

experienced an important increase due to the development of new synthesis processes<br />

to manufacture these new materials at atomic and molecular scale.<br />

As a result,

13<br />

materials can be designed to have different chemical and/or physical properties<br />

according to the interest of the investigator (Hu et al. 2010).<br />

The electronic band<br />

structures finally determine the properties of the inorganic catalyst (Osterloh 2008). The<br />

use of transition metals is relevant due to the presence of d orbitals in their electronic<br />

configuration (Randorn et al. 2004). Many synthesis techniques as co-precipitation, solgel,<br />

microemulsions, freeze drying (or lyophilization), hydrothermal processes, chemical<br />

vapor deposition, etc. are commonly used to control the morphology, size and the<br />

uniformity of the structured nanoparticles so grown (Hu et al. 2010). Cao (2004) studied<br />

the electrophoretic deposition for the synthesis of titanium oxide nanorods synthesis.<br />

The use of heterogeneous catalysis, by using nanosized catalysts as TiO 2 ,<br />

demonstrated the complete mineralization of the hazardous substances to CO 2 and<br />

water by means of •OH radicals generated during the photochemical process (Shimizu<br />

et al. 2007). The TiO 2 has important applications in green chemistry because it is<br />

commonly used as a catalyst for the synthesis of pharmaceutical products, reducing the<br />

traditional large amount of waste because can be recoverable, increasing the yield of<br />

products (Prakash et al. 2009). An example of this improvement in the pharmaceutical<br />

production is the modification in the Biginelli’s reaction on the synthesis of<br />

dihydropyrimidin-2 (1H)-ones (Prakash et al. 2009). The titanium oxide is inexpensive,<br />

non-toxic in nature, stable under ambient conditions, environmental friendly, able to use<br />

the solar radiation (Randorn et al. 2004, Marin et al. 2007, Yin et al. 2009, Velegraki and<br />

Mantvinos 2008), antibacterial activity (Parthasarathi and Thilagavathi 2009), interesting<br />

optical and electronic properties, low cost, abundance (Velegraki and Mantvinos 2008)<br />

and it is appropriate for some oxidation or reduction reactions in aqueous solutions<br />

(Prakash et al. 2009). Titanium oxide nanowires are other interesting structures of the<br />

oxide and have been used, among other applications, for the degradation of pollutants<br />

by photocatalysis and for the production of hydrogen by a photocatalytic water splitting

14<br />

process (Huh et al. 2010). The TiO 2 has a band gap of 3.2 eV (Marin et al. 2007;<br />

Prakash et al. 2009) which is relevant for the photocatalytic activity. Other advantages<br />

of the titanium nanowires include the high specific surface area and an easy recovery<br />

process by filtration, centrifugation, etc. (Huh et al. 2010). The titanium oxide is wi<strong>del</strong>y<br />

studied because it possesses photocatalytic and photoconductor characteristics; is used<br />

for the degradation of azo dyes, volatile organic compounds and others (Hernandez<br />

Enriquez et al. 2008) and could be recoverable after the process (Rahmani et al. 2008).<br />

Another pollutant studied was phenol by titanium oxide (anatase) (Rahmani et al. 2008).<br />

Titanium oxide nanostructured films have also been used for the degradation of stearic<br />

acid (Takahashi et al. 2011).<br />

In the recombination process between the valence band and conduction band a<br />

low quantum yield should be observed; to resolve this situation some authors<br />

recommend the use of the transition metal and their oxide to create an electron trap to<br />

increase the efficiency (Li and Shang 2010; Zhou et al. 2010).<br />

The use of PdO<br />

nanoparticles on titanium oxide nanotubes is an alternative to create an electron trap to<br />

increase the lifetime of charge carriers and subsequently improve the photoactivity (Li<br />

and Shang 2010). Several materials as the Pt@TiO 2 NWs synthesized by hydrothermal<br />

process are an example of materials in which the Schottky effect for the degradation<br />

process is relevant (Wang et al. 2010). Synthesis in gas phase of titanium oxide doped<br />

with SiO 2 and the synthesis of Ag 2 O/TiO 2 are also known (Remnev et al. 2009, Zhou et<br />

al. 2010).<br />

Other types of oxide catalysts with catalytic applications are the<br />

nanostructured Mn 2 O 3 (Su et al. 2010) and CuO-MoO 3 -P 2 O 5 materials (Ma et al. 2007).<br />

According to Marin et al. (2007), the use of a sol-gel approach for the synthesis<br />

of TiO 2 over different supports (i.e. glass) is a good method because the synthesized<br />

product is obtained as a stable and homogeneous sheet of titanium oxide, catalytically<br />

active and resistant. Randorn et al. (2004) mentioned the importance of some thermal

15<br />

treatments in this catalyst (i.e. calcination in presence of oxygen) to increase the<br />

interactions between OH - from water to the surface of the catalyst.<br />

The carbon nanotubes (CNTs) are another important group of materials in the<br />

development of nano-optical and electronic devices as quantum memory elements,<br />

magnetic storage media and semiconducting devices due to their internal structures,<br />

high surface area, low density and chemical stability (Hussein Sharif Zein and<br />

Boccaccini 2008).<br />

These materials can be modified adding other materials to the<br />

surface of the CNTs (Hussein Sharif Zein and Boccaccini 2008). The carbon nanotubes<br />

are “cylindrical molecules formed by one or more sheets of carbon atoms rolled one over<br />

one” (Anson Casaos 2005) with a diverse range of diameters and lengths. This material<br />

has been extensively studied during the last years due to its special geometry and<br />

amazing properties (Anson Casaos 2005).<br />

The carbon nanotubes are classified in two main groups: multiple concentric<br />

nanotubes precisely nested within one another namely multi walled carbon nanotubes<br />

(MWCNTs) and nanotubes with a single wall (SWCNTs) (Lopez-Fernandez 2009). The<br />

nanotubes are composed by sheets of graphene. The graphene structure is composed<br />

by carbon atoms having a hexagonal arrangement of carbons with sp 2<br />

hybridization<br />

(Anson Casaos 2005). In the SWCNTs the graphene sheet is rolled to form the tube,<br />

meanwhile in the case of MWCNTs the structure is formed by concentric cylinders<br />

(Lopez-Fernandez 2009, Hernández Rueda 2010). A secondary classification of the<br />

nanotubes is based on the chirality (as “zig-zag”, “armchair” and chiral), diameter and<br />

quantity of walls (Anson Casaos 2005; Hernandez Rueda 2010). The chirality defines<br />

the possible behavior of the nanotube; i.e. metallic behavior defines electrical properties<br />

of the material (Lopez-Fernandez 2009). The surface of carbon nanotubes can be<br />

related to the possible uses in some applications (Anson-Casaos 2005) including<br />

hydrogen storage and fuel cells (Anson Casaos 2005).

16<br />

The nanotubes are commonly as aggregates. <strong>To</strong> disperse these materials is<br />

necessary to use mechanical dispersion, ultrasound and functionalization techniques<br />

(Hernandez Rueda 2010). These materials can be functionalized by two principal<br />

approaches; the covalent and supramolecular functionalization.<br />

These methods<br />

preserve the structural and electronic integrity of the materials (Lopez-Fernandez 2009).<br />

Treatments as purification with acids (acid reflux), thermal oxidations (in air and high<br />

temperature) or chemical activations can partially modify the structure of the nanotubes<br />

(Anson Casaos 2005). The most relevant structural modification consists in opening the<br />

ends of the nanotubes because the original structure is closed as a capsule (Anson<br />

Casaos 2005).<br />

The use of mo<strong>del</strong> contaminants is relevant for the study of many processes. The<br />

most common substances used as mo<strong>del</strong> contaminants are the organic dyes. Until the<br />

XIX century, synthetic dyes were used as inks (Confortin et al. [unknown date]). The<br />

dyes have different applications in paper industries, leather, cosmetics, drugs,<br />

electronics, plastics and printing (Vinu and Madras 2009). According to the authors<br />

(Vinu and Madras 2009) 80% of the synthetic dyes are consumed by the textile industry.<br />

Some authors have determined that the annual discharge of waters containing dyes<br />

ranges from 30 000-150 000 tons (Vanhulle et al. 2008). These wastewaters also<br />

contain other chemicals used during the processes (Vinus and Madras 2009). <strong>To</strong>rres<br />

Martinez et al. (2010) point out that according to some statistical results approximately<br />

12% of the synthetic textile dyes used during a year are “lost” during the manufacturing<br />

and operational procedures and from that 12%, the 20% will be finally released to the<br />

ecosystem through the industrial water discharges.<br />

In the textile industry, more than 10 000 different dyes and pigments are<br />

available in the market and 20-30% of them are reactive dyes (Karadag et al. 2006;<br />

Dafnopatidou et al. 2007). These dyes are characterized by their brilliant colors, high

17<br />

wet fastness, easy application and a minimum of energy applied during the process.<br />

These dyes have, as part of the structure, azo, anthraquinone, phthalocyanine, formazin<br />

or oxazine functional groups (Karadag et al. 2006). Approximately 60% of the reactive<br />

dyes used contain an azo group (Karadag et al. 2006).<br />

Dyes are nonbiodegradable compounds (Mahanta et al. 2008).<br />

Industrial<br />

wastewaters that contain biorefractory compounds are normally limited to the use of<br />

chemical treatments because the chemicals are toxic to the microorganisms used in the<br />

conventional biological treatments (Barrera-Diaz et al. 2009). Potential human exposure<br />

to wastewater which contains dyes is a concern because are carcinogenic compounds,<br />

showing high resistance against biological, physical and chemical reactions (Vanhulle et<br />

al. 2008). Different processes are employed to remove color from wastewaters including<br />

the use of activated carbon, membrane filtration, ultrafiltration, coagulation-flocculation,<br />

electrocoagulation, UV light and ozone (Barrera-Diaz et al. 2009).<br />

The effluents of the textile industry have high concentrations of organic and<br />

inorganic dyes which are strongly colored, have high chemical oxygen demand (COD),<br />

present important fluctuations in the pH, and are toxic to the organism (Ab<strong>del</strong>malek et al.<br />

2006). The common techniques used to remove the dyes include chemical, physical<br />

and biological processes (Dafnopatidou et al. 2007). Nevertheless, these conventional<br />

processes for the treatment of sewage waters including the degradation of residual<br />

dyestuffs are inefficient because these compounds have high molecular weight and<br />

biochemical stability (aromatic rings) (Panizza et al. 2006; Ma et al. 2007).<br />

The<br />

adsorption process using activated carbon to eliminate the contaminants has the<br />

advantage that is very easy to use but this method is expensive (Gupta et al. 2004) and<br />

produces another problem during the disposition of the contaminated material. Another<br />

method is the adsorption of the dye by polymers and other materials (Karadag et al.<br />

2006; Mahanta et al. 2008). The conventional treatments do not reduce the toxicity of

18<br />

the dyes (Barrera-Diaz et al. 2009). One of the principal disadvantages of the physical<br />

methods as coagulation, precipitation and adsorption is the sludge formation, possible<br />

toxic by-products and the chemical processes are expensive (Panizza et al. 2006; Ma et<br />

al. 2007; Hernandez Enriquez et al. 2008; Mahanta et al. 2008).<br />

Most of the dyes are organic or organometallic compounds characterized by<br />

having aromatic rings. This characteristic necessarily implies the use of treatments by<br />

unconventional methods (<strong>To</strong>rres Martinez et al. 2010). The decomposition of many<br />

organic compounds as pesticides, dyes, aromatics, halogenated aliphatic compounds,<br />

metallurgical residuals, oil and chemical compounds derived from steel processes are<br />

based on photocatalytic degradation processes (Sokmen et al. 2000). Meanwhile, to<br />

maintain the aesthetic and reduce the environmental impacts of the industrial effluents is<br />

necessary the discoloration of wastewaters (Hussein Sharif Zein et al. 2008).<br />

The degradation process of the organic dyes could be defined in two different<br />

ways: one is the discoloration and the other one is the mineralization (Vinu and Madras<br />

2010). The authors (Vinu and Madras 2010) also clarify the difference between<br />

discoloration process (reduction of the parent dye) and mineralization (complete removal<br />

of the organic components and their transformation in CO 2 ). Intermediates that are<br />

generated during the degradation process could be colored (Vinu and Madras 2010).<br />

The total organic carbon (TOC) analysis helps to determine the carbon content and its<br />

variation during the degradation process.<br />

Different dyes exposed to photochemical<br />

degradation under visible light show the following degradation order: indigo<br />

≈phenanthrene > triphenylmethane > azo ≈ quinoline > xanthenes ≈ thiazine ><br />

anthraquinone. The order of the light sources is: natural sunlight >> 90 W halogen flood<br />

light > 150 W spotlight (Vinu and Madras 2010).

19<br />

The organic dyes are classified according to their functional groups as: azoic,<br />

anthraquinonic, heteropolyaromatic, aryl methanes, xanthenes, indigo, acridine, nitro,<br />

nitroso, cyanine and stilbene (Vinu and Madras 2010).<br />

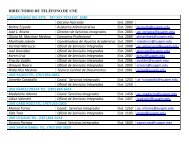

Table 1.1 Characteristics of the most important dyes classes (Adapted from: Parshetti et<br />

al. 2006; Vanhulle et al. 2008).<br />

Classes of<br />

Dyes<br />

Type of Fiber<br />

Chemical Class<br />

Acid Polyamide, wool<br />

and nylon<br />